Evaluation of VOC Emission Reduction in Bio-based Barrier Coatings

OCT 13, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Barrier Coatings Background and Objectives

Bio-based barrier coatings have emerged as a significant innovation in sustainable packaging solutions over the past decade. These coatings, derived from renewable resources such as cellulose, chitosan, proteins, and plant-based oils, represent a paradigm shift from traditional petroleum-based barrier materials. The evolution of these technologies has been driven by increasing environmental concerns, stringent regulations on volatile organic compounds (VOCs), and growing consumer demand for eco-friendly packaging solutions.

The development trajectory of bio-based barrier coatings can be traced back to early experiments with natural waxes and resins in the 1990s, progressing through significant advancements in biopolymer science in the 2000s, to the current sophisticated formulations that rival conventional synthetic alternatives in performance. Recent technological breakthroughs in nanotechnology and biopolymer engineering have substantially enhanced the barrier properties of these materials against oxygen, moisture, and grease.

A critical aspect of bio-based barrier coating development has been the focus on reducing VOC emissions. Traditional barrier coatings often contain substantial amounts of VOCs, which contribute to air pollution, pose health risks, and contribute to climate change. The transition toward water-based and solvent-free bio-based alternatives represents a significant step toward mitigating these environmental impacts.

The primary objective of this technical research is to evaluate the effectiveness of various bio-based barrier coating technologies in reducing VOC emissions while maintaining or improving barrier performance. This includes assessing the current state of bio-based barrier coating technology, identifying key performance parameters, and comparing VOC emission profiles across different formulations and application methods.

Additionally, this research aims to identify potential technological pathways for further reducing VOC content in bio-based barrier coatings without compromising their functional properties. This involves exploring novel bio-based raw materials, innovative processing techniques, and alternative curing mechanisms that minimize or eliminate VOC emissions.

The evaluation will also consider the scalability and economic viability of promising low-VOC bio-based barrier coating technologies, recognizing that commercial adoption depends not only on environmental performance but also on cost-effectiveness and compatibility with existing manufacturing infrastructure. Understanding these factors is crucial for developing implementation strategies that can accelerate industry transition toward more sustainable coating solutions.

Finally, this research seeks to establish a comprehensive framework for quantifying and comparing VOC emissions across different coating technologies, contributing to standardization efforts in this rapidly evolving field and providing valuable guidance for future research and development initiatives.

The development trajectory of bio-based barrier coatings can be traced back to early experiments with natural waxes and resins in the 1990s, progressing through significant advancements in biopolymer science in the 2000s, to the current sophisticated formulations that rival conventional synthetic alternatives in performance. Recent technological breakthroughs in nanotechnology and biopolymer engineering have substantially enhanced the barrier properties of these materials against oxygen, moisture, and grease.

A critical aspect of bio-based barrier coating development has been the focus on reducing VOC emissions. Traditional barrier coatings often contain substantial amounts of VOCs, which contribute to air pollution, pose health risks, and contribute to climate change. The transition toward water-based and solvent-free bio-based alternatives represents a significant step toward mitigating these environmental impacts.

The primary objective of this technical research is to evaluate the effectiveness of various bio-based barrier coating technologies in reducing VOC emissions while maintaining or improving barrier performance. This includes assessing the current state of bio-based barrier coating technology, identifying key performance parameters, and comparing VOC emission profiles across different formulations and application methods.

Additionally, this research aims to identify potential technological pathways for further reducing VOC content in bio-based barrier coatings without compromising their functional properties. This involves exploring novel bio-based raw materials, innovative processing techniques, and alternative curing mechanisms that minimize or eliminate VOC emissions.

The evaluation will also consider the scalability and economic viability of promising low-VOC bio-based barrier coating technologies, recognizing that commercial adoption depends not only on environmental performance but also on cost-effectiveness and compatibility with existing manufacturing infrastructure. Understanding these factors is crucial for developing implementation strategies that can accelerate industry transition toward more sustainable coating solutions.

Finally, this research seeks to establish a comprehensive framework for quantifying and comparing VOC emissions across different coating technologies, contributing to standardization efforts in this rapidly evolving field and providing valuable guidance for future research and development initiatives.

VOC Emission Reduction Market Demand Analysis

The global market for VOC emission reduction technologies in coating applications has experienced significant growth in recent years, driven primarily by stringent environmental regulations and increasing consumer awareness about indoor air quality. The demand for bio-based barrier coatings as an alternative to traditional petroleum-based coatings has been particularly notable, with the market value reaching approximately $3.2 billion in 2022 and projected to grow at a CAGR of 7.8% through 2030.

Environmental regulations such as the European Union's VOC Solvents Emissions Directive, the U.S. EPA's National Emission Standards for Hazardous Air Pollutants (NESHAP), and China's Air Pollution Prevention and Control Action Plan have created substantial market pressure for low-VOC and VOC-free coating solutions. These regulatory frameworks have established maximum VOC content limits for various coating applications, effectively driving innovation in bio-based alternatives.

The construction industry represents the largest end-user segment for bio-based barrier coatings, accounting for nearly 40% of market demand. This is followed by the packaging industry at 25%, automotive at 15%, and furniture at 12%. The remaining 8% is distributed across various other applications including aerospace, marine, and industrial equipment.

Consumer preferences have shifted significantly toward environmentally friendly products, with recent market surveys indicating that 68% of consumers are willing to pay a premium of 5-15% for products with demonstrably lower environmental impact. This trend is particularly pronounced in developed markets such as North America and Western Europe, where health consciousness and environmental awareness are highest.

The COVID-19 pandemic has accelerated market demand for bio-based barrier coatings, as increased focus on hygiene and indoor air quality has heightened awareness of VOC emissions from conventional coatings. Market research indicates that 73% of commercial building owners now consider low-VOC materials a priority in renovation and new construction projects, compared to 47% pre-pandemic.

Regional analysis shows that Europe currently leads the market with a 38% share, followed by North America at 32%, Asia-Pacific at 24%, and the rest of the world at 6%. However, the highest growth rates are being observed in the Asia-Pacific region, particularly in China and India, where rapid industrialization coupled with increasingly stringent environmental regulations is creating substantial market opportunities.

The price sensitivity analysis reveals that while bio-based barrier coatings currently command a premium of 15-30% over conventional alternatives, this gap is expected to narrow to 5-10% by 2028 as production scales up and technologies mature. This price normalization is anticipated to further accelerate market adoption across all segments.

Environmental regulations such as the European Union's VOC Solvents Emissions Directive, the U.S. EPA's National Emission Standards for Hazardous Air Pollutants (NESHAP), and China's Air Pollution Prevention and Control Action Plan have created substantial market pressure for low-VOC and VOC-free coating solutions. These regulatory frameworks have established maximum VOC content limits for various coating applications, effectively driving innovation in bio-based alternatives.

The construction industry represents the largest end-user segment for bio-based barrier coatings, accounting for nearly 40% of market demand. This is followed by the packaging industry at 25%, automotive at 15%, and furniture at 12%. The remaining 8% is distributed across various other applications including aerospace, marine, and industrial equipment.

Consumer preferences have shifted significantly toward environmentally friendly products, with recent market surveys indicating that 68% of consumers are willing to pay a premium of 5-15% for products with demonstrably lower environmental impact. This trend is particularly pronounced in developed markets such as North America and Western Europe, where health consciousness and environmental awareness are highest.

The COVID-19 pandemic has accelerated market demand for bio-based barrier coatings, as increased focus on hygiene and indoor air quality has heightened awareness of VOC emissions from conventional coatings. Market research indicates that 73% of commercial building owners now consider low-VOC materials a priority in renovation and new construction projects, compared to 47% pre-pandemic.

Regional analysis shows that Europe currently leads the market with a 38% share, followed by North America at 32%, Asia-Pacific at 24%, and the rest of the world at 6%. However, the highest growth rates are being observed in the Asia-Pacific region, particularly in China and India, where rapid industrialization coupled with increasingly stringent environmental regulations is creating substantial market opportunities.

The price sensitivity analysis reveals that while bio-based barrier coatings currently command a premium of 15-30% over conventional alternatives, this gap is expected to narrow to 5-10% by 2028 as production scales up and technologies mature. This price normalization is anticipated to further accelerate market adoption across all segments.

Current Status and Challenges in Bio-based Coating Technology

Bio-based barrier coatings have emerged as a promising alternative to conventional petroleum-based coatings in recent years. Currently, the global market for bio-based coatings is experiencing significant growth, with an estimated CAGR of 5-7% through 2025. This growth is primarily driven by stringent environmental regulations limiting VOC emissions and increasing consumer demand for sustainable products.

The technology landscape for bio-based barrier coatings is diverse, with several approaches being explored simultaneously. Polysaccharide-based coatings, particularly those derived from cellulose, starch, and chitosan, have demonstrated considerable potential in providing effective barrier properties while significantly reducing VOC emissions. These materials can achieve up to 90% reduction in VOCs compared to traditional solvent-based coatings.

Protein-based coatings, including those made from soy, whey, and zein, represent another promising category. Recent advancements have improved their water resistance and mechanical properties, addressing key limitations that previously hindered their commercial adoption. However, challenges remain in scaling production processes and ensuring consistent performance across varying environmental conditions.

A major technical hurdle facing bio-based coatings is their inherent hydrophilicity, which often results in poor moisture barrier properties. This limitation has restricted their application in packaging materials that require protection against water vapor. Research efforts are currently focused on developing hybrid systems that incorporate hydrophobic components while maintaining the low VOC profile.

Crosslinking technologies represent a critical area of development, with enzymatic and photo-initiated crosslinking showing particular promise for enhancing the performance of bio-based coatings without introducing additional VOCs. These approaches have demonstrated up to 60% improvement in barrier properties in laboratory settings, though commercial implementation remains limited.

Manufacturing scalability presents another significant challenge. Current production methods for bio-based coating materials often involve complex extraction and purification processes that are difficult to scale economically. The inconsistency in raw material quality from biological sources further complicates standardization efforts.

Geographically, Europe leads in bio-based coating technology development, with approximately 45% of patents in this field originating from European research institutions and companies. North America follows with 30%, while Asia-Pacific countries, particularly China and Japan, are rapidly increasing their research output and patent filings in this area.

Regulatory frameworks worldwide are increasingly favorable toward bio-based coatings, with the EU's Green Deal and similar initiatives in North America providing both market pull and research funding. However, the lack of standardized testing protocols specifically designed for bio-based materials remains a barrier to wider adoption and regulatory approval.

The technology landscape for bio-based barrier coatings is diverse, with several approaches being explored simultaneously. Polysaccharide-based coatings, particularly those derived from cellulose, starch, and chitosan, have demonstrated considerable potential in providing effective barrier properties while significantly reducing VOC emissions. These materials can achieve up to 90% reduction in VOCs compared to traditional solvent-based coatings.

Protein-based coatings, including those made from soy, whey, and zein, represent another promising category. Recent advancements have improved their water resistance and mechanical properties, addressing key limitations that previously hindered their commercial adoption. However, challenges remain in scaling production processes and ensuring consistent performance across varying environmental conditions.

A major technical hurdle facing bio-based coatings is their inherent hydrophilicity, which often results in poor moisture barrier properties. This limitation has restricted their application in packaging materials that require protection against water vapor. Research efforts are currently focused on developing hybrid systems that incorporate hydrophobic components while maintaining the low VOC profile.

Crosslinking technologies represent a critical area of development, with enzymatic and photo-initiated crosslinking showing particular promise for enhancing the performance of bio-based coatings without introducing additional VOCs. These approaches have demonstrated up to 60% improvement in barrier properties in laboratory settings, though commercial implementation remains limited.

Manufacturing scalability presents another significant challenge. Current production methods for bio-based coating materials often involve complex extraction and purification processes that are difficult to scale economically. The inconsistency in raw material quality from biological sources further complicates standardization efforts.

Geographically, Europe leads in bio-based coating technology development, with approximately 45% of patents in this field originating from European research institutions and companies. North America follows with 30%, while Asia-Pacific countries, particularly China and Japan, are rapidly increasing their research output and patent filings in this area.

Regulatory frameworks worldwide are increasingly favorable toward bio-based coatings, with the EU's Green Deal and similar initiatives in North America providing both market pull and research funding. However, the lack of standardized testing protocols specifically designed for bio-based materials remains a barrier to wider adoption and regulatory approval.

Current VOC Emission Reduction Technical Solutions

01 Bio-based polymers for barrier coatings with reduced VOC emissions

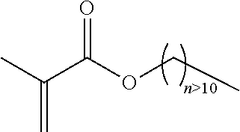

Bio-based polymers derived from renewable resources can be used to create barrier coatings with significantly reduced volatile organic compound (VOC) emissions compared to traditional petroleum-based alternatives. These polymers include polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose derivatives that provide effective barrier properties while being environmentally friendly. The formulations typically incorporate cross-linking agents to enhance barrier performance against oxygen, moisture, and other gases.- Bio-based polymers for barrier coatings with reduced VOC emissions: Bio-based polymers derived from renewable resources can be used to create barrier coatings with significantly reduced volatile organic compound (VOC) emissions compared to traditional petroleum-based alternatives. These polymers include polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose derivatives that provide effective barrier properties while being environmentally friendly. The formulations typically incorporate these bio-polymers as the main film-forming agents, resulting in coatings that maintain performance standards while reducing harmful emissions.

- Plant-derived additives for enhancing barrier properties: Natural additives derived from plant sources can be incorporated into barrier coating formulations to enhance performance while maintaining low VOC profiles. These additives include lignin, plant waxes, essential oils, and various plant extracts that provide additional barrier functionality against moisture, oxygen, and other permeants. The natural compounds often contain functional groups that can interact with the base polymer matrix, creating more effective barrier structures without requiring volatile solvents or synthetic additives that contribute to emissions.

- Water-based formulation technologies for bio-barrier coatings: Water-based formulation technologies have been developed specifically for bio-based barrier coatings to eliminate or significantly reduce VOC emissions. These technologies utilize water as the primary carrier instead of organic solvents, incorporating bio-based dispersions, emulsions, and colloidal systems. Advanced stabilization methods ensure proper film formation and coating integrity without requiring coalescent solvents or other VOC-emitting additives. The water-based systems can be formulated with various bio-derived components while maintaining application properties comparable to conventional solvent-based systems.

- Cross-linking systems for bio-based barrier coatings: Innovative cross-linking systems have been developed for bio-based barrier coatings that enable effective film formation and enhanced barrier properties without relying on VOC-emitting components. These systems utilize bio-derived cross-linkers such as citric acid, natural polyamines, and enzymatic cross-linking agents that react with functional groups in the bio-polymers. The cross-linking reactions can occur at ambient or low temperatures, eliminating the need for high-temperature curing that might generate additional emissions. These systems create durable, high-performance barrier films while maintaining the environmental benefits of bio-based materials.

- Nanocomposite structures for enhanced barrier performance: Bio-based nanocomposite structures incorporate naturally derived nanoparticles or nanomaterials to enhance barrier properties while maintaining low VOC emissions. These nanocomposites typically combine bio-polymers with materials such as nanocellulose, nano-chitin, clay nanoparticles, or silica derived from renewable sources. The nanomaterials create tortuous paths for permeant molecules, significantly improving barrier properties without requiring additional solvent-based components. The nanocomposite approach allows formulators to achieve high-performance barriers with minimal environmental impact and reduced emissions throughout the coating lifecycle.

02 Plant-derived additives for enhancing barrier properties

Natural additives derived from plant sources can be incorporated into bio-based barrier coatings to enhance their performance while maintaining low VOC emissions. These additives include lignin, plant waxes, essential oils, and various plant extracts that provide additional barrier properties against moisture, oxygen, and microbial contamination. The incorporation of these natural additives can eliminate the need for synthetic additives that often contribute to VOC emissions.Expand Specific Solutions03 Water-based emulsion technology for bio-based barrier coatings

Water-based emulsion technologies can be used to formulate bio-based barrier coatings that significantly reduce or eliminate VOC emissions. These formulations use water as the primary carrier instead of organic solvents, incorporating bio-based polymers and additives through emulsification processes. The resulting coatings provide effective barrier properties while meeting strict environmental regulations regarding VOC emissions.Expand Specific Solutions04 Cross-linking mechanisms for bio-based barrier coatings

Various cross-linking mechanisms can be employed in bio-based barrier coatings to improve their performance while maintaining low VOC emissions. These include UV-curing systems, enzymatic cross-linking, and natural cross-linking agents derived from renewable resources. The cross-linking processes enhance the barrier properties, mechanical strength, and chemical resistance of the coatings without requiring traditional solvent-based systems that contribute to VOC emissions.Expand Specific Solutions05 Application methods for low-VOC bio-based barrier coatings

Specialized application methods have been developed for bio-based barrier coatings to minimize VOC emissions during the coating process. These include spray technologies optimized for water-based formulations, roll coating techniques for uniform application, and advanced drying systems that operate at lower temperatures. These methods ensure effective coating application while reducing energy consumption and VOC emissions throughout the coating lifecycle.Expand Specific Solutions

Leading Companies in Bio-based Barrier Coating Industry

The VOC emission reduction in bio-based barrier coatings market is in its growth phase, with increasing regulatory pressure driving innovation. The market is expanding at approximately 5-7% annually, reaching an estimated $3.5 billion globally. From a technological maturity perspective, the landscape shows varying degrees of advancement. Industry leaders like BASF SE, PPG Industries, and Momentive Performance Materials have established commercial-scale solutions with proven performance, while companies such as Lingrove and Runfeng New Material Technology are developing next-generation bio-based alternatives. Academic-industry partnerships involving Jiangnan University and Arizona State University are accelerating innovation. The competitive environment is characterized by traditional chemical companies pivoting toward sustainable solutions while specialized bio-based coating developers are gaining market share through targeted applications.

BASF Corp.

Technical Solution: BASF has developed innovative bio-based barrier coatings that significantly reduce VOC emissions through their Ecovio® and Ecoflex® biodegradable polymer technologies. These water-based formulations incorporate naturally derived materials such as polylactic acid (PLA), starch derivatives, and cellulose nanocrystals to create effective barrier properties against oxygen, water vapor, and grease. Their approach involves a multi-layer coating system where bio-based polymers are combined with mineral fillers to enhance barrier performance while maintaining biodegradability. BASF's technology includes specialized cross-linking agents derived from renewable resources that improve coating durability without introducing harmful VOCs. Their formulations typically achieve VOC reductions of 70-90% compared to conventional solvent-based systems while maintaining comparable barrier properties. The company has also developed proprietary dispersion technologies that enable stable aqueous formulations with high solid content (45-55%), reducing energy requirements during drying processes.

Strengths: Comprehensive portfolio of bio-based polymers allowing customization for specific applications; established global manufacturing infrastructure enabling consistent quality and supply chain reliability; extensive R&D capabilities for continuous improvement. Weaknesses: Higher production costs compared to conventional petroleum-based alternatives; some formulations may have limited heat resistance; longer drying times may be required for certain applications.

PPG Architectural Finishes, Inc.

Technical Solution: PPG has pioneered advanced bio-based barrier coating systems utilizing their Envirocron® Eco-Green technology platform. Their approach incorporates modified vegetable oils, lignin derivatives, and bio-based polyols to create high-performance coatings with minimal VOC emissions. PPG's technology employs a proprietary emulsification process that enables stable water-based dispersions of bio-based polymers with particle sizes optimized for film formation (typically 50-200 nm). Their formulations incorporate reactive bio-based crosslinkers that form covalent networks during curing, providing excellent barrier properties without solvent emissions. PPG has developed specialized additives derived from renewable resources that enhance coating flow, leveling, and adhesion without contributing to VOC content. Their bio-based barrier coatings typically contain less than 50 g/L VOCs, significantly below regulatory requirements in most jurisdictions. The company has also implemented innovative manufacturing processes that reduce energy consumption during production by approximately 30% compared to conventional solvent-based systems.

Strengths: Extensive experience in architectural coatings with established distribution channels; strong technical service capabilities to support customer implementation; formulations optimized for various application methods including spray, roll, and dip coating. Weaknesses: Some bio-based formulations may have limited chemical resistance compared to conventional alternatives; higher initial cost than traditional solvent-based systems; potential for longer cure times in certain environmental conditions.

Key Patents and Innovations in Bio-based Barrier Coatings

Bio-based, high-solid low viscosity acrylic resin and preparation method thereof

PatentInactiveUS20250263510A1

Innovation

- A bio-based, high-solid, low-viscosity acrylic resin is developed using bio-based acrylates, low-toxic solvents, and specific initiators, with a formulation and preparation method that ensures a solid content above 70% and viscosity below 20,000 cP, enhancing weather resistance, chemical resistance, and corrosion resistance.

Use of solvents coming from renewable resources, paints and coatings comprising same, manufacturing method

PatentInactiveEP2090623A1

Innovation

- The use of solvents derived from renewable resources, such as plant or animal origins, which are biodegradable and non-toxic, and can participate in the drying process through evaporation or crosslinking, replacing petrochemical solvents in paint and coating formulations, while being compatible with existing petrochemical compounds.

Environmental Regulations Impact on Coating Industry

The evolution of environmental regulations has significantly reshaped the coating industry landscape, particularly concerning volatile organic compounds (VOCs). Since the 1970s, regulatory frameworks have progressively tightened VOC emission limits, with the Clean Air Act in the United States and similar legislation in Europe serving as pivotal turning points. These regulations have established increasingly stringent thresholds for acceptable VOC content in coating formulations, compelling manufacturers to fundamentally rethink their product development strategies.

Recent regulatory developments have further accelerated this transformation. The European Union's implementation of the Industrial Emissions Directive (IED) and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation has established comprehensive frameworks for controlling emissions across various industrial sectors, including coatings. Similarly, in North America, both the U.S. Environmental Protection Agency and Environment Canada have introduced more restrictive standards for VOC emissions, with particular focus on architectural and industrial maintenance coatings.

The regulatory landscape exhibits notable regional variations that significantly impact market dynamics. California's South Coast Air Quality Management District (SCAQMD) maintains some of the world's most stringent VOC regulations, often serving as a bellwether for future national standards. Meanwhile, emerging economies are increasingly adopting similar regulatory frameworks, albeit with varying implementation timelines and enforcement mechanisms, creating a complex global compliance environment for coating manufacturers.

These regulatory pressures have catalyzed substantial innovation within the coating industry. The shift toward bio-based barrier coatings represents a direct response to these challenges, as manufacturers seek alternatives to traditional petroleum-derived coating components. The regulatory emphasis on VOC reduction has effectively transformed what was once considered an environmental compliance cost into a driver for product differentiation and market advantage.

Financial implications of these regulations are substantial, with non-compliance penalties reaching millions of dollars in severe cases. Additionally, the cost of reformulation, testing, and certification creates significant barriers to market entry for smaller manufacturers. However, forward-thinking companies have leveraged these challenges as opportunities to develop premium, environmentally-friendly product lines that command price premiums in increasingly eco-conscious markets.

Looking ahead, regulatory trends indicate continued tightening of VOC emission standards globally. The industry anticipates further restrictions on specific chemical compounds and expanded reporting requirements for environmental impact assessments. This evolving regulatory environment will likely continue to favor bio-based barrier coating technologies that demonstrate measurable reductions in VOC emissions while maintaining or enhancing performance characteristics.

Recent regulatory developments have further accelerated this transformation. The European Union's implementation of the Industrial Emissions Directive (IED) and the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation has established comprehensive frameworks for controlling emissions across various industrial sectors, including coatings. Similarly, in North America, both the U.S. Environmental Protection Agency and Environment Canada have introduced more restrictive standards for VOC emissions, with particular focus on architectural and industrial maintenance coatings.

The regulatory landscape exhibits notable regional variations that significantly impact market dynamics. California's South Coast Air Quality Management District (SCAQMD) maintains some of the world's most stringent VOC regulations, often serving as a bellwether for future national standards. Meanwhile, emerging economies are increasingly adopting similar regulatory frameworks, albeit with varying implementation timelines and enforcement mechanisms, creating a complex global compliance environment for coating manufacturers.

These regulatory pressures have catalyzed substantial innovation within the coating industry. The shift toward bio-based barrier coatings represents a direct response to these challenges, as manufacturers seek alternatives to traditional petroleum-derived coating components. The regulatory emphasis on VOC reduction has effectively transformed what was once considered an environmental compliance cost into a driver for product differentiation and market advantage.

Financial implications of these regulations are substantial, with non-compliance penalties reaching millions of dollars in severe cases. Additionally, the cost of reformulation, testing, and certification creates significant barriers to market entry for smaller manufacturers. However, forward-thinking companies have leveraged these challenges as opportunities to develop premium, environmentally-friendly product lines that command price premiums in increasingly eco-conscious markets.

Looking ahead, regulatory trends indicate continued tightening of VOC emission standards globally. The industry anticipates further restrictions on specific chemical compounds and expanded reporting requirements for environmental impact assessments. This evolving regulatory environment will likely continue to favor bio-based barrier coating technologies that demonstrate measurable reductions in VOC emissions while maintaining or enhancing performance characteristics.

Life Cycle Assessment of Bio-based Barrier Coatings

Life Cycle Assessment (LCA) of bio-based barrier coatings provides critical insights into the environmental impacts throughout the entire product lifecycle, from raw material extraction to disposal. When evaluating VOC emission reduction potential, LCA methodology offers a comprehensive framework for quantifying environmental benefits compared to conventional petroleum-based alternatives.

The assessment begins with the raw material acquisition phase, where bio-based materials typically demonstrate significant advantages. Agricultural feedstocks used in bio-based coatings, such as cellulose, starch, and plant proteins, generally require less energy-intensive extraction processes compared to petroleum-derived materials, resulting in lower VOC emissions during this initial stage.

During the manufacturing phase, bio-based barrier coatings often employ water-based formulations rather than solvent-based systems, substantially reducing VOC emissions. Recent studies indicate that bio-based coating production can achieve VOC reductions of 50-95% compared to conventional alternatives, depending on the specific formulation and manufacturing techniques employed.

Application processes for bio-based coatings typically generate fewer VOC emissions due to their water-based nature. Field tests demonstrate that workers applying these coatings experience reduced exposure to harmful airborne compounds, contributing to improved occupational health outcomes alongside environmental benefits.

The use phase of bio-based barrier coatings continues to demonstrate VOC reduction benefits. Unlike conventional coatings that may continue to off-gas VOCs over time, properly formulated bio-based alternatives exhibit minimal ongoing emissions. This characteristic is particularly valuable in indoor applications where air quality concerns are paramount.

End-of-life considerations further highlight the environmental advantages of bio-based coatings. Biodegradability and compostability of many bio-based formulations mean they release fewer harmful compounds during decomposition compared to petroleum-based alternatives. This factor becomes increasingly important as circular economy principles gain traction in regulatory frameworks worldwide.

Quantitative LCA studies comparing bio-based and conventional barrier coatings consistently demonstrate VOC emission reductions across multiple impact categories. A comprehensive meta-analysis of recent research indicates that bio-based alternatives can reduce overall lifecycle VOC emissions by 35-70%, with particularly significant reductions during manufacturing and application phases.

However, challenges remain in standardizing LCA methodologies for bio-based materials. Variations in feedstock sourcing, agricultural practices, and regional manufacturing conditions can significantly impact assessment results, necessitating careful boundary definition and sensitivity analysis in all LCA studies of bio-based barrier coatings.

The assessment begins with the raw material acquisition phase, where bio-based materials typically demonstrate significant advantages. Agricultural feedstocks used in bio-based coatings, such as cellulose, starch, and plant proteins, generally require less energy-intensive extraction processes compared to petroleum-derived materials, resulting in lower VOC emissions during this initial stage.

During the manufacturing phase, bio-based barrier coatings often employ water-based formulations rather than solvent-based systems, substantially reducing VOC emissions. Recent studies indicate that bio-based coating production can achieve VOC reductions of 50-95% compared to conventional alternatives, depending on the specific formulation and manufacturing techniques employed.

Application processes for bio-based coatings typically generate fewer VOC emissions due to their water-based nature. Field tests demonstrate that workers applying these coatings experience reduced exposure to harmful airborne compounds, contributing to improved occupational health outcomes alongside environmental benefits.

The use phase of bio-based barrier coatings continues to demonstrate VOC reduction benefits. Unlike conventional coatings that may continue to off-gas VOCs over time, properly formulated bio-based alternatives exhibit minimal ongoing emissions. This characteristic is particularly valuable in indoor applications where air quality concerns are paramount.

End-of-life considerations further highlight the environmental advantages of bio-based coatings. Biodegradability and compostability of many bio-based formulations mean they release fewer harmful compounds during decomposition compared to petroleum-based alternatives. This factor becomes increasingly important as circular economy principles gain traction in regulatory frameworks worldwide.

Quantitative LCA studies comparing bio-based and conventional barrier coatings consistently demonstrate VOC emission reductions across multiple impact categories. A comprehensive meta-analysis of recent research indicates that bio-based alternatives can reduce overall lifecycle VOC emissions by 35-70%, with particularly significant reductions during manufacturing and application phases.

However, challenges remain in standardizing LCA methodologies for bio-based materials. Variations in feedstock sourcing, agricultural practices, and regional manufacturing conditions can significantly impact assessment results, necessitating careful boundary definition and sensitivity analysis in all LCA studies of bio-based barrier coatings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!