Bio-based Barrier Coatings for Food Contact Safety and Performance

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Barrier Coatings Background and Objectives

Bio-based barrier coatings have emerged as a significant innovation in sustainable packaging solutions over the past decade. These coatings, derived from renewable biological resources such as cellulose, chitosan, proteins, and plant-based waxes, represent a paradigm shift from conventional petroleum-based materials that have dominated the food packaging industry since the mid-20th century. The evolution of these bio-based alternatives has been accelerated by increasing environmental concerns, stringent regulations on plastic waste, and growing consumer demand for sustainable packaging options.

The technical trajectory of barrier coatings has evolved from simple wax applications in the early 20th century to sophisticated multi-layer petroleum-based polymers in recent decades. However, the environmental implications of these non-biodegradable materials have prompted intensive research into bio-based alternatives since the early 2000s, with significant breakthroughs occurring in the last five years regarding performance capabilities and commercial viability.

Current bio-based barrier coating technologies aim to provide comparable or superior protection against oxygen, moisture, grease, and microbial contamination while maintaining food safety standards. The technical challenge lies in achieving these functional properties using renewable materials without compromising on performance, processability, or cost-effectiveness. Recent advancements in nanotechnology and biopolymer engineering have significantly narrowed the performance gap between conventional and bio-based solutions.

The primary objective of this research is to comprehensively evaluate the current state of bio-based barrier coating technologies specifically designed for food contact applications. This includes assessing their barrier properties against oxygen, moisture, and grease; analyzing their mechanical stability during processing and use; and examining their compliance with food safety regulations across major global markets.

Additionally, this research aims to identify emerging trends and innovations in the field, particularly focusing on novel bio-based materials and composite systems that demonstrate enhanced barrier properties while maintaining biodegradability and compostability. The investigation will also address scalability challenges and economic feasibility of transitioning from conventional petroleum-based coatings to bio-based alternatives in commercial food packaging applications.

Furthermore, this technical assessment seeks to establish a roadmap for future development by identifying critical technological gaps and research priorities that could accelerate the adoption of bio-based barrier coatings in mainstream food packaging. This includes exploring potential synergies between different bio-based materials and investigating innovative processing technologies that could enhance coating performance while reducing production costs.

The technical trajectory of barrier coatings has evolved from simple wax applications in the early 20th century to sophisticated multi-layer petroleum-based polymers in recent decades. However, the environmental implications of these non-biodegradable materials have prompted intensive research into bio-based alternatives since the early 2000s, with significant breakthroughs occurring in the last five years regarding performance capabilities and commercial viability.

Current bio-based barrier coating technologies aim to provide comparable or superior protection against oxygen, moisture, grease, and microbial contamination while maintaining food safety standards. The technical challenge lies in achieving these functional properties using renewable materials without compromising on performance, processability, or cost-effectiveness. Recent advancements in nanotechnology and biopolymer engineering have significantly narrowed the performance gap between conventional and bio-based solutions.

The primary objective of this research is to comprehensively evaluate the current state of bio-based barrier coating technologies specifically designed for food contact applications. This includes assessing their barrier properties against oxygen, moisture, and grease; analyzing their mechanical stability during processing and use; and examining their compliance with food safety regulations across major global markets.

Additionally, this research aims to identify emerging trends and innovations in the field, particularly focusing on novel bio-based materials and composite systems that demonstrate enhanced barrier properties while maintaining biodegradability and compostability. The investigation will also address scalability challenges and economic feasibility of transitioning from conventional petroleum-based coatings to bio-based alternatives in commercial food packaging applications.

Furthermore, this technical assessment seeks to establish a roadmap for future development by identifying critical technological gaps and research priorities that could accelerate the adoption of bio-based barrier coatings in mainstream food packaging. This includes exploring potential synergies between different bio-based materials and investigating innovative processing technologies that could enhance coating performance while reducing production costs.

Food Packaging Market Demand Analysis

The global food packaging market has witnessed substantial growth in recent years, driven by changing consumer lifestyles, increasing urbanization, and growing awareness about food safety and sustainability. The market was valued at approximately 338 billion USD in 2021 and is projected to reach 478 billion USD by 2028, growing at a CAGR of around 5.1% during the forecast period. This growth trajectory underscores the significant demand for innovative packaging solutions, particularly those incorporating bio-based barrier coatings.

Consumer preferences have shifted dramatically toward environmentally friendly packaging options. Recent surveys indicate that over 70% of consumers globally express willingness to pay premium prices for sustainable packaging alternatives. This trend is particularly pronounced among millennials and Gen Z consumers, who prioritize brands demonstrating environmental responsibility. The demand for plastic-free and biodegradable packaging has increased by nearly 40% since 2018, creating substantial market opportunities for bio-based barrier coating technologies.

Food safety concerns represent another critical driver in the packaging market. Regulatory bodies worldwide have implemented increasingly stringent standards regarding food contact materials, with particular emphasis on reducing harmful chemicals like PFAS, BPA, and phthalates. The European Food Safety Authority and FDA have both issued updated guidelines restricting various synthetic compounds in food packaging, accelerating the transition toward bio-based alternatives that can demonstrate safety compliance while maintaining performance standards.

The ready-to-eat and convenience food sectors have expanded significantly, with global sales increasing by 8.2% annually. These products require advanced barrier properties to ensure extended shelf life without compromising food quality or safety. Traditional petroleum-based barrier coatings face mounting challenges from both regulatory pressure and consumer rejection, creating an urgent market need for bio-based alternatives that can deliver comparable or superior performance metrics.

Regional analysis reveals varying adoption rates for sustainable packaging solutions. European markets lead in bio-based packaging implementation, driven by progressive regulations like the European Green Deal and Single-Use Plastics Directive. North American markets show strong growth potential, particularly in premium food categories, while Asia-Pacific represents the fastest-growing region for sustainable packaging adoption, with annual growth rates exceeding 7.5% in countries like China, Japan, and South Korea.

The COVID-19 pandemic has further accelerated certain packaging trends, including heightened consumer awareness of hygiene and safety aspects of food packaging. This has created additional demand for antimicrobial properties in packaging solutions, an area where certain bio-based coatings show promising potential through naturally derived compounds with inherent antimicrobial characteristics.

Consumer preferences have shifted dramatically toward environmentally friendly packaging options. Recent surveys indicate that over 70% of consumers globally express willingness to pay premium prices for sustainable packaging alternatives. This trend is particularly pronounced among millennials and Gen Z consumers, who prioritize brands demonstrating environmental responsibility. The demand for plastic-free and biodegradable packaging has increased by nearly 40% since 2018, creating substantial market opportunities for bio-based barrier coating technologies.

Food safety concerns represent another critical driver in the packaging market. Regulatory bodies worldwide have implemented increasingly stringent standards regarding food contact materials, with particular emphasis on reducing harmful chemicals like PFAS, BPA, and phthalates. The European Food Safety Authority and FDA have both issued updated guidelines restricting various synthetic compounds in food packaging, accelerating the transition toward bio-based alternatives that can demonstrate safety compliance while maintaining performance standards.

The ready-to-eat and convenience food sectors have expanded significantly, with global sales increasing by 8.2% annually. These products require advanced barrier properties to ensure extended shelf life without compromising food quality or safety. Traditional petroleum-based barrier coatings face mounting challenges from both regulatory pressure and consumer rejection, creating an urgent market need for bio-based alternatives that can deliver comparable or superior performance metrics.

Regional analysis reveals varying adoption rates for sustainable packaging solutions. European markets lead in bio-based packaging implementation, driven by progressive regulations like the European Green Deal and Single-Use Plastics Directive. North American markets show strong growth potential, particularly in premium food categories, while Asia-Pacific represents the fastest-growing region for sustainable packaging adoption, with annual growth rates exceeding 7.5% in countries like China, Japan, and South Korea.

The COVID-19 pandemic has further accelerated certain packaging trends, including heightened consumer awareness of hygiene and safety aspects of food packaging. This has created additional demand for antimicrobial properties in packaging solutions, an area where certain bio-based coatings show promising potential through naturally derived compounds with inherent antimicrobial characteristics.

Current Status and Challenges in Bio-based Barrier Technologies

Bio-based barrier coatings represent a significant advancement in sustainable food packaging, yet their current development status reveals both promising achievements and substantial challenges. Globally, research institutions and companies have made considerable progress in developing bio-based alternatives to conventional petroleum-based barrier materials, with cellulose, chitosan, protein-based coatings, and polylactic acid (PLA) emerging as leading solutions.

In North America and Europe, regulatory frameworks supporting sustainable packaging have accelerated research and commercialization efforts. Several companies have successfully launched bio-based barrier products with comparable oxygen and moisture barrier properties to traditional materials. However, these solutions often come at premium costs, limiting widespread market adoption.

Asia-Pacific region, particularly Japan and China, has shown remarkable growth in bio-based barrier technology research, focusing on utilizing regional agricultural byproducts as raw materials. This geographical distribution of research efforts has created diverse approaches to similar technical challenges.

The primary technical challenges facing bio-based barrier coatings include inconsistent barrier performance under varying environmental conditions. Many bio-based materials exhibit excellent oxygen barrier properties but struggle with moisture resistance—a critical limitation for food packaging applications. This hydrophilic nature of many bio-polymers remains a fundamental obstacle to overcome.

Scalability presents another significant challenge. Laboratory-scale successes often encounter difficulties in industrial-scale production, with issues in process consistency, coating uniformity, and production efficiency. The complex rheological properties of bio-based formulations frequently cause application problems in high-speed coating operations.

Cost competitiveness remains a persistent constraint. Current bio-based barrier solutions typically cost 20-40% more than conventional alternatives, making market penetration difficult despite growing consumer interest in sustainable packaging. The economic viability of these technologies depends heavily on achieving production efficiencies and securing reliable raw material supply chains.

Regulatory compliance and food safety verification represent additional hurdles. While many bio-based materials are generally recognized as safe, comprehensive migration studies and long-term safety assessments are still developing. The interaction between bio-based coatings and various food types requires extensive testing to ensure compliance with increasingly stringent food contact regulations worldwide.

Durability and shelf-life limitations also constrain current bio-based solutions. Many exhibit degradation in barrier properties over time, particularly when exposed to varying humidity and temperature conditions typical in food distribution chains. This performance gap compared to synthetic alternatives remains a critical area requiring innovation.

In North America and Europe, regulatory frameworks supporting sustainable packaging have accelerated research and commercialization efforts. Several companies have successfully launched bio-based barrier products with comparable oxygen and moisture barrier properties to traditional materials. However, these solutions often come at premium costs, limiting widespread market adoption.

Asia-Pacific region, particularly Japan and China, has shown remarkable growth in bio-based barrier technology research, focusing on utilizing regional agricultural byproducts as raw materials. This geographical distribution of research efforts has created diverse approaches to similar technical challenges.

The primary technical challenges facing bio-based barrier coatings include inconsistent barrier performance under varying environmental conditions. Many bio-based materials exhibit excellent oxygen barrier properties but struggle with moisture resistance—a critical limitation for food packaging applications. This hydrophilic nature of many bio-polymers remains a fundamental obstacle to overcome.

Scalability presents another significant challenge. Laboratory-scale successes often encounter difficulties in industrial-scale production, with issues in process consistency, coating uniformity, and production efficiency. The complex rheological properties of bio-based formulations frequently cause application problems in high-speed coating operations.

Cost competitiveness remains a persistent constraint. Current bio-based barrier solutions typically cost 20-40% more than conventional alternatives, making market penetration difficult despite growing consumer interest in sustainable packaging. The economic viability of these technologies depends heavily on achieving production efficiencies and securing reliable raw material supply chains.

Regulatory compliance and food safety verification represent additional hurdles. While many bio-based materials are generally recognized as safe, comprehensive migration studies and long-term safety assessments are still developing. The interaction between bio-based coatings and various food types requires extensive testing to ensure compliance with increasingly stringent food contact regulations worldwide.

Durability and shelf-life limitations also constrain current bio-based solutions. Many exhibit degradation in barrier properties over time, particularly when exposed to varying humidity and temperature conditions typical in food distribution chains. This performance gap compared to synthetic alternatives remains a critical area requiring innovation.

Current Bio-based Barrier Coating Solutions

01 Bio-based barrier coating materials and compositions

Various bio-based materials can be used to create effective barrier coatings with improved environmental profiles. These include plant-derived polymers, cellulosic materials, proteins, and other renewable resources that can be formulated into functional barrier coatings. These compositions often combine multiple bio-based components to achieve desired barrier properties against moisture, oxygen, and other substances while maintaining biodegradability and sustainability advantages.- Bio-based barrier coatings for food packaging: Bio-based barrier coatings derived from renewable resources can be applied to food packaging materials to enhance their barrier properties against oxygen, moisture, and grease. These coatings are formulated using natural polymers such as cellulose derivatives, proteins, and polysaccharides, providing an environmentally friendly alternative to conventional petroleum-based barriers while maintaining food safety standards and extending shelf life.

- Safety assessment methods for bio-based coatings: Various testing methodologies have been developed to evaluate the safety of bio-based barrier coatings, including migration studies, toxicological assessments, and biodegradability tests. These methods ensure that the coatings meet regulatory requirements for food contact materials and do not release harmful substances during use. The safety assessment includes evaluation of raw materials, processing aids, and potential breakdown products under different environmental conditions.

- Performance enhancement of bio-based barrier coatings: The performance of bio-based barrier coatings can be enhanced through various formulation strategies and processing techniques. These include the incorporation of nanoparticles, crosslinking agents, and plasticizers to improve mechanical properties, barrier efficiency, and durability. Advanced processing methods such as layer-by-layer deposition and surface modification techniques can further optimize coating performance while maintaining the renewable nature of the materials.

- Biodegradability and environmental impact: Bio-based barrier coatings offer significant environmental advantages through their biodegradability and reduced carbon footprint. These coatings are designed to break down naturally at the end of their life cycle, minimizing waste accumulation and environmental pollution. Life cycle assessments demonstrate that bio-based coatings generally have lower environmental impacts compared to conventional petroleum-based alternatives, contributing to sustainable packaging solutions.

- Industrial applications and scalability: Bio-based barrier coatings have been successfully implemented in various industrial applications beyond food packaging, including pharmaceuticals, cosmetics, and consumer goods. Scalable production methods have been developed to enable commercial viability, addressing challenges related to consistency, cost-effectiveness, and integration with existing manufacturing processes. These developments have facilitated the broader adoption of bio-based coatings across multiple industries.

02 Safety assessments and toxicity profiles of bio-based coatings

Bio-based barrier coatings undergo rigorous safety evaluations to ensure they meet regulatory requirements for various applications, particularly in food packaging and medical devices. These assessments examine potential migration of components, biocompatibility, absence of harmful substances, and overall toxicological profiles. Many bio-based coatings demonstrate favorable safety characteristics compared to conventional petroleum-based alternatives, with reduced environmental and health impacts throughout their lifecycle.Expand Specific Solutions03 Barrier performance enhancement techniques

Various methods can improve the barrier properties of bio-based coatings, including crosslinking mechanisms, nanocomposite incorporation, multilayer structures, and surface modifications. These techniques help overcome inherent limitations of some bio-based materials, such as moisture sensitivity or insufficient oxygen barrier properties. Advanced processing methods like plasma treatment or specialized application techniques can further optimize barrier performance while maintaining the renewable nature of the coating materials.Expand Specific Solutions04 Durability and shelf-life considerations

Bio-based barrier coatings must maintain their protective properties throughout the intended product lifecycle. Research focuses on improving resistance to environmental factors like humidity, temperature fluctuations, UV exposure, and mechanical stress. Stabilizers, antioxidants, and specialized formulations help extend coating durability while preserving biodegradability. Testing protocols evaluate long-term performance under various conditions to ensure these coatings provide reliable protection comparable to conventional alternatives.Expand Specific Solutions05 Application methods and processing compatibility

Effective application of bio-based barrier coatings requires compatibility with existing manufacturing equipment and processes. Innovations in coating technologies address challenges related to viscosity, drying requirements, adhesion to various substrates, and integration into high-speed production lines. Water-based formulations, specialized application techniques, and optimized curing methods help ensure uniform coverage and consistent barrier performance while minimizing energy consumption and environmental impact during processing.Expand Specific Solutions

Key Industry Players in Bio-based Packaging Materials

The bio-based barrier coatings market for food contact applications is in a growth phase, driven by increasing demand for sustainable packaging solutions. The market size is expanding rapidly as consumer preferences shift towards eco-friendly alternatives, with projections indicating significant growth over the next decade. Technologically, the field shows varying maturity levels, with established players like DuPont, International Paper, and Eastman Chemical offering commercial solutions, while innovative startups like traceless materials GmbH are introducing disruptive technologies. Research institutions including Delft University of Technology and Leibniz-Institut für Neue Materialien are advancing fundamental science in this area. Companies like Kemira, Solenis, and Metsä Board are developing specialized coatings for paper-based packaging, focusing on both performance and sustainability to meet stringent food safety regulations while reducing environmental impact.

Kemira Oyj

Technical Solution: Kemira has developed FennoGuard™, an advanced bio-based barrier coating platform specifically engineered for food packaging applications. Their technology utilizes modified biopolymers derived from side streams of the forest industry, primarily hemicellulose and lignin fractions that are typically underutilized. Kemira's innovation lies in their proprietary cross-linking chemistry that creates a three-dimensional network structure, significantly enhancing barrier properties against oxygen, water vapor, and mineral oils. The coating achieves oxygen transmission rates below 20 cc/m²/day and water vapor transmission rates under 10 g/m²/day, making it suitable for medium to high barrier applications. A distinctive feature of Kemira's approach is their water-based application system that eliminates the need for organic solvents, reducing VOC emissions during manufacturing. The company has also incorporated natural antimicrobial compounds derived from plant extracts to enhance food preservation capabilities. Their coatings demonstrate excellent heat-sealing properties, enabling the creation of fully bio-based packaging solutions that maintain integrity throughout the supply chain. Kemira's technology has been successfully implemented in commercial applications for bakery products, dry foods, and confectionery items.

Strengths: Utilizes industrial side streams, enhancing sustainability credentials; excellent printability and converting characteristics; strong performance in varying humidity conditions. Weaknesses: Higher production costs compared to conventional petroleum-based alternatives; limited resistance to certain fatty foods; requires specific application parameters to achieve optimal barrier formation.

Solenis Technologies LP

Technical Solution: Solenis has developed TopScreen™, a comprehensive bio-based barrier coating platform designed specifically for food packaging applications. Their technology utilizes a combination of modified starches, cellulose derivatives, and proprietary bio-based additives to create effective barriers against water, oil, and oxygen. The innovation centers on their patented polymer architecture that creates a tortuous path for permeants, significantly reducing transmission rates while maintaining flexibility and printability. Solenis' coatings achieve grease resistance values of Kit 12 (the highest industry standard) and oxygen transmission rates below 25 cc/m²/day, positioning them as effective alternatives to traditional fluorochemical treatments and plastic laminates. Their water-based formulations are applied using conventional equipment, requiring minimal modification to existing production lines. A key advantage of Solenis' approach is their tailored barrier performance, allowing customization based on specific food requirements and shelf-life targets. The company has successfully commercialized these solutions for applications including quick-service restaurant packaging, bakery products, and frozen food containers, demonstrating performance comparable to conventional materials while offering improved sustainability profiles.

Strengths: Exceptional grease and oil resistance without fluorochemicals; customizable barrier properties for specific applications; compatible with existing converting equipment and processes. Weaknesses: Oxygen barrier properties less effective than some synthetic alternatives; performance can be affected by high humidity environments; higher cost structure compared to conventional treatments.

Critical Patents and Innovations in Food Contact Materials

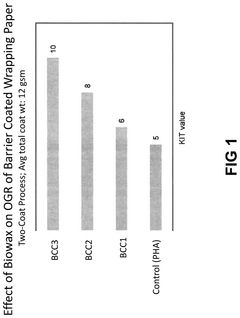

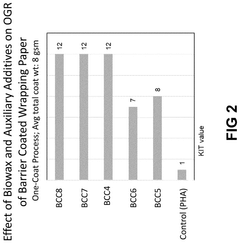

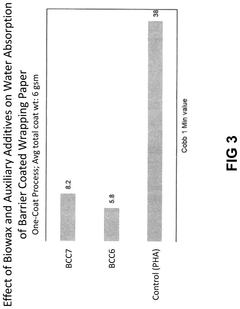

Biowax polyhydroxyalkanoate dispersions as bio-based barrier coatings

PatentPendingUS20240344272A1

Innovation

- The development of biowax emulsions combined with polyhydroxyalkanoate (PHA) dispersions and auxiliary additives, such as clay and microcrystalline cellulose, to form barrier coatings that can be applied at room temperature, achieving enhanced oil and water resistance with a high bio-based content.

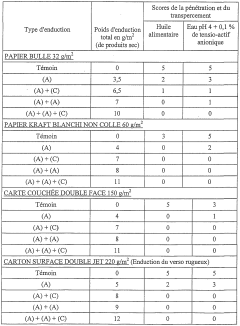

Composition, kits and method for providing a substrate with barrier properties and uses thereof

PatentWO2002002705A1

Innovation

- A composition is developed by dispersing a film-forming resin or gum of natural or biotechnological origin in an aqueous solution with a film-forming, water-soluble compound, creating a barrier coating that is biodegradable, heat-sealable, and suitable for food contact, using components like gelatin, polysaccharides, and shellac, which can be applied to various substrates to confer barrier properties against oils, greases, and water.

Regulatory Framework for Food Contact Materials

The regulatory landscape governing food contact materials (FCMs) is complex and varies significantly across different regions, creating a challenging environment for manufacturers of bio-based barrier coatings. In the United States, the Food and Drug Administration (FDA) regulates FCMs under the Federal Food, Drug, and Cosmetic Act, requiring manufacturers to ensure that materials are "generally recognized as safe" (GRAS) or approved through Food Contact Notifications (FCNs). The FDA's approach focuses on the safety of individual substances rather than the final material, which presents unique challenges for novel bio-based coatings composed of multiple natural components.

The European Union employs a more comprehensive framework through Regulation (EC) No 1935/2004, which establishes that materials must not transfer constituents to food in quantities that could endanger human health or change food composition unacceptably. For plastic materials specifically, Regulation (EU) No 10/2011 sets migration limits and includes a positive list of authorized substances. Bio-based coatings often face regulatory hurdles as many natural components are not yet included in these positive lists, requiring extensive testing and authorization processes.

In Asia, regulatory approaches vary widely. Japan implements a positive list system similar to the EU but with different specific requirements, while China has been rapidly developing its national standards for food contact materials through GB standards. These regional differences create significant compliance challenges for global manufacturers of bio-based barrier coatings.

Migration testing represents a critical aspect of regulatory compliance for bio-based coatings. These tests measure the transfer of substances from packaging materials to food under standardized conditions. The complexity of bio-based materials, which may contain numerous naturally occurring compounds, makes comprehensive migration testing particularly challenging. Current analytical methods may not adequately detect all potential migrants from these complex natural matrices.

Certification systems have emerged to help navigate these regulatory frameworks. Programs like FDA's Food Contact Substance Notification program and the EU's Declaration of Compliance provide pathways for new materials to gain market access. Additionally, third-party certifications such as ISEGA in Europe offer manufacturers ways to demonstrate compliance with relevant regulations.

Recent regulatory trends indicate a growing acceptance of bio-based materials, with some authorities developing specific guidelines for these sustainable alternatives. However, the pace of regulatory adaptation often lags behind innovation in this rapidly evolving field, creating a significant barrier to market entry for novel bio-based barrier coatings.

The European Union employs a more comprehensive framework through Regulation (EC) No 1935/2004, which establishes that materials must not transfer constituents to food in quantities that could endanger human health or change food composition unacceptably. For plastic materials specifically, Regulation (EU) No 10/2011 sets migration limits and includes a positive list of authorized substances. Bio-based coatings often face regulatory hurdles as many natural components are not yet included in these positive lists, requiring extensive testing and authorization processes.

In Asia, regulatory approaches vary widely. Japan implements a positive list system similar to the EU but with different specific requirements, while China has been rapidly developing its national standards for food contact materials through GB standards. These regional differences create significant compliance challenges for global manufacturers of bio-based barrier coatings.

Migration testing represents a critical aspect of regulatory compliance for bio-based coatings. These tests measure the transfer of substances from packaging materials to food under standardized conditions. The complexity of bio-based materials, which may contain numerous naturally occurring compounds, makes comprehensive migration testing particularly challenging. Current analytical methods may not adequately detect all potential migrants from these complex natural matrices.

Certification systems have emerged to help navigate these regulatory frameworks. Programs like FDA's Food Contact Substance Notification program and the EU's Declaration of Compliance provide pathways for new materials to gain market access. Additionally, third-party certifications such as ISEGA in Europe offer manufacturers ways to demonstrate compliance with relevant regulations.

Recent regulatory trends indicate a growing acceptance of bio-based materials, with some authorities developing specific guidelines for these sustainable alternatives. However, the pace of regulatory adaptation often lags behind innovation in this rapidly evolving field, creating a significant barrier to market entry for novel bio-based barrier coatings.

Sustainability Impact and Life Cycle Assessment

The sustainability impact of bio-based barrier coatings represents a critical dimension in evaluating their overall viability as alternatives to conventional petroleum-based materials. Life cycle assessment (LCA) studies indicate that bio-based coatings can reduce carbon footprint by 30-45% compared to traditional plastic coatings, primarily due to the renewable nature of their feedstock and potentially lower energy requirements during production.

When examining the environmental benefits, bio-based barrier coatings demonstrate significant advantages in terms of biodegradability and compostability. Materials derived from cellulose, chitosan, and plant proteins typically degrade within 3-6 months under industrial composting conditions, compared to centuries for conventional plastics. This characteristic substantially reduces end-of-life environmental burden and aligns with circular economy principles increasingly adopted by regulatory frameworks worldwide.

Resource efficiency metrics reveal that bio-based coatings generally require less non-renewable energy during manufacturing. For instance, polylactic acid (PLA) and cellulose-based coatings consume approximately 25-40% less fossil fuel energy throughout their production cycle compared to polyethylene terephthalate (PET) coatings. However, water usage presents a complex trade-off, as agricultural feedstock production can be water-intensive depending on crop selection and cultivation practices.

Land use considerations remain a significant challenge in scaling bio-based solutions. Current analyses suggest that widespread adoption would require careful agricultural planning to avoid competition with food production. Innovative approaches utilizing agricultural waste streams and by-products from food processing industries offer promising pathways to mitigate these concerns while simultaneously addressing waste management challenges.

Toxicity profiles of bio-based barrier coatings generally show reduced environmental and human health impacts compared to petroleum-based alternatives. The absence of bisphenol A, phthalates, and other endocrine-disrupting chemicals commonly found in conventional packaging materials represents a substantial advantage for both environmental and food safety considerations.

Economic sustainability assessments indicate that while production costs for bio-based coatings currently exceed those of conventional materials by 15-30%, this gap is narrowing as technologies mature and economies of scale develop. Market projections suggest price parity could be achieved within 5-7 years for certain applications, particularly as carbon pricing mechanisms and extended producer responsibility regulations evolve globally.

When examining the environmental benefits, bio-based barrier coatings demonstrate significant advantages in terms of biodegradability and compostability. Materials derived from cellulose, chitosan, and plant proteins typically degrade within 3-6 months under industrial composting conditions, compared to centuries for conventional plastics. This characteristic substantially reduces end-of-life environmental burden and aligns with circular economy principles increasingly adopted by regulatory frameworks worldwide.

Resource efficiency metrics reveal that bio-based coatings generally require less non-renewable energy during manufacturing. For instance, polylactic acid (PLA) and cellulose-based coatings consume approximately 25-40% less fossil fuel energy throughout their production cycle compared to polyethylene terephthalate (PET) coatings. However, water usage presents a complex trade-off, as agricultural feedstock production can be water-intensive depending on crop selection and cultivation practices.

Land use considerations remain a significant challenge in scaling bio-based solutions. Current analyses suggest that widespread adoption would require careful agricultural planning to avoid competition with food production. Innovative approaches utilizing agricultural waste streams and by-products from food processing industries offer promising pathways to mitigate these concerns while simultaneously addressing waste management challenges.

Toxicity profiles of bio-based barrier coatings generally show reduced environmental and human health impacts compared to petroleum-based alternatives. The absence of bisphenol A, phthalates, and other endocrine-disrupting chemicals commonly found in conventional packaging materials represents a substantial advantage for both environmental and food safety considerations.

Economic sustainability assessments indicate that while production costs for bio-based coatings currently exceed those of conventional materials by 15-30%, this gap is narrowing as technologies mature and economies of scale develop. Market projections suggest price parity could be achieved within 5-7 years for certain applications, particularly as carbon pricing mechanisms and extended producer responsibility regulations evolve globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!