Rheological Behavior of Bio-based Barrier Coating Formulations

OCT 13, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Barrier Coating Evolution and Objectives

The evolution of bio-based barrier coatings represents a significant shift in packaging technology, moving from petroleum-based materials toward sustainable alternatives derived from renewable resources. This transition began in the early 2000s when environmental concerns and regulatory pressures prompted research into bio-based alternatives. Initially, these coatings faced considerable challenges in matching the performance characteristics of conventional petroleum-based products, particularly in moisture resistance and oxygen barrier properties.

The rheological behavior of these formulations has emerged as a critical factor in their development and application. Rheology—the study of flow and deformation of matter—directly impacts coating processability, film formation, and ultimate barrier performance. Early bio-based formulations exhibited inconsistent rheological profiles, leading to application difficulties and variable barrier effectiveness.

Significant advancements occurred between 2010-2015 when researchers began incorporating modified starches, cellulose derivatives, and protein-based components with improved flow characteristics. These developments enabled better control over viscosity, thixotropy, and shear-thinning properties—essential parameters for industrial coating processes.

The integration of nanotechnology marked another pivotal moment in this evolution. Nano-cellulose, nano-chitin, and other bio-based nanoparticles introduced after 2015 dramatically improved both rheological control and barrier performance. These materials created tortuous paths for gas molecules, enhancing barrier properties while maintaining appropriate flow characteristics for various application methods.

Current objectives in this field focus on several key areas. First, achieving rheological stability across varying temperature and humidity conditions remains crucial for consistent industrial application. Second, developing formulations with tunable rheological properties to accommodate diverse substrate materials and application techniques represents an ongoing challenge. Third, maintaining optimal flow characteristics while maximizing barrier performance continues to drive innovation.

Another significant objective involves reducing the sensitivity of bio-based formulations to processing conditions. Unlike conventional coatings, many bio-based alternatives exhibit complex rheological responses to shear rates, temperature fluctuations, and dwell times, necessitating precise process control.

The ultimate goal remains developing bio-based barrier coating formulations with rheological behaviors that enable seamless integration into existing manufacturing infrastructure while delivering equivalent or superior barrier properties compared to conventional alternatives. This would facilitate broader industrial adoption without requiring significant capital investment in new application equipment or processing lines.

The rheological behavior of these formulations has emerged as a critical factor in their development and application. Rheology—the study of flow and deformation of matter—directly impacts coating processability, film formation, and ultimate barrier performance. Early bio-based formulations exhibited inconsistent rheological profiles, leading to application difficulties and variable barrier effectiveness.

Significant advancements occurred between 2010-2015 when researchers began incorporating modified starches, cellulose derivatives, and protein-based components with improved flow characteristics. These developments enabled better control over viscosity, thixotropy, and shear-thinning properties—essential parameters for industrial coating processes.

The integration of nanotechnology marked another pivotal moment in this evolution. Nano-cellulose, nano-chitin, and other bio-based nanoparticles introduced after 2015 dramatically improved both rheological control and barrier performance. These materials created tortuous paths for gas molecules, enhancing barrier properties while maintaining appropriate flow characteristics for various application methods.

Current objectives in this field focus on several key areas. First, achieving rheological stability across varying temperature and humidity conditions remains crucial for consistent industrial application. Second, developing formulations with tunable rheological properties to accommodate diverse substrate materials and application techniques represents an ongoing challenge. Third, maintaining optimal flow characteristics while maximizing barrier performance continues to drive innovation.

Another significant objective involves reducing the sensitivity of bio-based formulations to processing conditions. Unlike conventional coatings, many bio-based alternatives exhibit complex rheological responses to shear rates, temperature fluctuations, and dwell times, necessitating precise process control.

The ultimate goal remains developing bio-based barrier coating formulations with rheological behaviors that enable seamless integration into existing manufacturing infrastructure while delivering equivalent or superior barrier properties compared to conventional alternatives. This would facilitate broader industrial adoption without requiring significant capital investment in new application equipment or processing lines.

Market Analysis for Sustainable Packaging Solutions

The sustainable packaging market is experiencing unprecedented growth, driven by increasing environmental awareness and regulatory pressures worldwide. The global sustainable packaging market was valued at approximately $274 billion in 2020 and is projected to reach $470 billion by 2027, growing at a CAGR of around 7.9% during the forecast period. Bio-based barrier coatings represent a significant segment within this market, addressing the critical need for environmentally friendly alternatives to traditional petroleum-based packaging solutions.

Consumer demand for sustainable packaging has become a major market driver, with recent surveys indicating that over 70% of consumers are willing to pay premium prices for products with environmentally responsible packaging. This shift in consumer preference has prompted major brands across food and beverage, personal care, and retail sectors to commit to sustainable packaging goals, creating substantial market opportunities for bio-based barrier coating technologies.

The food packaging segment dominates the sustainable packaging market, accounting for approximately 40% of the total market share. This is particularly relevant for bio-based barrier coating formulations, as food products require packaging with excellent barrier properties against oxygen, moisture, and grease. The rheological behavior of these formulations directly impacts their applicability and performance in food packaging applications.

Regionally, Europe leads the sustainable packaging market with the most stringent regulations and highest adoption rates, followed by North America. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming years due to rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India.

Key market challenges include cost competitiveness with conventional packaging solutions and technical performance limitations. While consumers express willingness to pay more for sustainable options, price sensitivity remains a significant factor, especially in emerging markets. The rheological properties of bio-based barrier coatings must be optimized to ensure they can be processed using existing manufacturing equipment without compromising production efficiency.

Market segmentation analysis reveals growing demand across various industries beyond food and beverage, including pharmaceuticals, cosmetics, and electronics. Each segment presents unique requirements for barrier properties and coating performance, necessitating tailored rheological profiles for specific applications.

The competitive landscape features both established packaging giants investing heavily in sustainable solutions and innovative startups developing novel bio-based formulations. Strategic partnerships between raw material suppliers, coating manufacturers, and end-users are becoming increasingly common to accelerate commercialization and market penetration of these sustainable technologies.

Consumer demand for sustainable packaging has become a major market driver, with recent surveys indicating that over 70% of consumers are willing to pay premium prices for products with environmentally responsible packaging. This shift in consumer preference has prompted major brands across food and beverage, personal care, and retail sectors to commit to sustainable packaging goals, creating substantial market opportunities for bio-based barrier coating technologies.

The food packaging segment dominates the sustainable packaging market, accounting for approximately 40% of the total market share. This is particularly relevant for bio-based barrier coating formulations, as food products require packaging with excellent barrier properties against oxygen, moisture, and grease. The rheological behavior of these formulations directly impacts their applicability and performance in food packaging applications.

Regionally, Europe leads the sustainable packaging market with the most stringent regulations and highest adoption rates, followed by North America. However, the Asia-Pacific region is expected to witness the fastest growth rate in the coming years due to rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India.

Key market challenges include cost competitiveness with conventional packaging solutions and technical performance limitations. While consumers express willingness to pay more for sustainable options, price sensitivity remains a significant factor, especially in emerging markets. The rheological properties of bio-based barrier coatings must be optimized to ensure they can be processed using existing manufacturing equipment without compromising production efficiency.

Market segmentation analysis reveals growing demand across various industries beyond food and beverage, including pharmaceuticals, cosmetics, and electronics. Each segment presents unique requirements for barrier properties and coating performance, necessitating tailored rheological profiles for specific applications.

The competitive landscape features both established packaging giants investing heavily in sustainable solutions and innovative startups developing novel bio-based formulations. Strategic partnerships between raw material suppliers, coating manufacturers, and end-users are becoming increasingly common to accelerate commercialization and market penetration of these sustainable technologies.

Rheological Challenges in Bio-based Formulations

Bio-based barrier coating formulations present unique rheological challenges that significantly impact their performance and applicability. These formulations typically consist of complex mixtures of biopolymers, nanoparticles, plasticizers, and other additives, creating multiphase systems with intricate flow behaviors. The primary rheological challenge lies in achieving optimal viscosity profiles that enable efficient processing while maintaining the desired barrier properties.

The non-Newtonian behavior of bio-based formulations presents a significant obstacle, as these materials often exhibit shear-thinning or shear-thickening characteristics that vary dramatically under different processing conditions. This variability makes it difficult to predict and control flow behavior during coating application, particularly at the high shear rates encountered in industrial coating processes.

Thixotropy and yield stress phenomena further complicate the rheological landscape. Many bio-based formulations display time-dependent viscosity changes, requiring precise control of rest periods and application timing. The presence of yield stress—a minimum force required to initiate flow—affects coating uniformity and penetration into substrate irregularities, directly impacting barrier performance.

Temperature sensitivity represents another critical challenge, as bio-based materials often demonstrate dramatic viscosity changes across relatively narrow temperature ranges. This sensitivity necessitates tight temperature control during processing and can limit the operational window for coating application, increasing production complexity and costs.

The interaction between formulation components creates additional rheological complexities. Biopolymers may undergo conformational changes or form physical networks that significantly alter flow properties. When combined with nanoparticles or other functional additives, these interactions can produce unexpected rheological behaviors that are difficult to predict from individual component properties alone.

Stability issues also plague bio-based coating formulations. Many exhibit phase separation, sedimentation, or aggregation over time, leading to inconsistent rheological properties during storage. These instabilities can compromise coating quality and barrier performance, necessitating careful formulation design and stabilization strategies.

Water sensitivity presents a particular challenge for aqueous bio-based formulations. Humidity fluctuations during processing and storage can dramatically alter rheological properties, affecting coating thickness, uniformity, and ultimately barrier performance. This sensitivity requires careful environmental control throughout the production process and may limit application in certain climates or seasons.

Addressing these rheological challenges requires sophisticated characterization techniques and modeling approaches that can capture the complex, multifaceted nature of bio-based formulation flow behaviors. Advanced rheometers capable of measuring properties under various shear rates, temperatures, and time scales are essential for developing robust formulations with predictable processing characteristics.

The non-Newtonian behavior of bio-based formulations presents a significant obstacle, as these materials often exhibit shear-thinning or shear-thickening characteristics that vary dramatically under different processing conditions. This variability makes it difficult to predict and control flow behavior during coating application, particularly at the high shear rates encountered in industrial coating processes.

Thixotropy and yield stress phenomena further complicate the rheological landscape. Many bio-based formulations display time-dependent viscosity changes, requiring precise control of rest periods and application timing. The presence of yield stress—a minimum force required to initiate flow—affects coating uniformity and penetration into substrate irregularities, directly impacting barrier performance.

Temperature sensitivity represents another critical challenge, as bio-based materials often demonstrate dramatic viscosity changes across relatively narrow temperature ranges. This sensitivity necessitates tight temperature control during processing and can limit the operational window for coating application, increasing production complexity and costs.

The interaction between formulation components creates additional rheological complexities. Biopolymers may undergo conformational changes or form physical networks that significantly alter flow properties. When combined with nanoparticles or other functional additives, these interactions can produce unexpected rheological behaviors that are difficult to predict from individual component properties alone.

Stability issues also plague bio-based coating formulations. Many exhibit phase separation, sedimentation, or aggregation over time, leading to inconsistent rheological properties during storage. These instabilities can compromise coating quality and barrier performance, necessitating careful formulation design and stabilization strategies.

Water sensitivity presents a particular challenge for aqueous bio-based formulations. Humidity fluctuations during processing and storage can dramatically alter rheological properties, affecting coating thickness, uniformity, and ultimately barrier performance. This sensitivity requires careful environmental control throughout the production process and may limit application in certain climates or seasons.

Addressing these rheological challenges requires sophisticated characterization techniques and modeling approaches that can capture the complex, multifaceted nature of bio-based formulation flow behaviors. Advanced rheometers capable of measuring properties under various shear rates, temperatures, and time scales are essential for developing robust formulations with predictable processing characteristics.

Current Rheological Control Methodologies

01 Bio-based polymers for barrier coatings

Bio-based polymers derived from renewable resources can be formulated into barrier coatings with effective rheological properties. These polymers, which may include cellulose derivatives, starch, chitosan, and plant-based proteins, provide sustainable alternatives to petroleum-based materials while maintaining barrier performance against moisture, oxygen, and other permeants. The rheological behavior of these bio-based formulations can be tailored to achieve optimal coating application properties such as flow, leveling, and film formation.- Bio-based polymers for barrier coatings: Bio-based polymers derived from renewable resources can be used to formulate environmentally friendly barrier coatings. These polymers, such as cellulose derivatives, starch, and plant-based proteins, provide effective barrier properties against oxygen, moisture, and other substances. The rheological behavior of these bio-based polymers can be optimized to ensure proper application characteristics and film formation, resulting in coatings with good adhesion and durability.

- Rheological modifiers for bio-based coating formulations: Rheological modifiers play a crucial role in controlling the flow behavior of bio-based barrier coating formulations. These additives, which can include natural thickeners, cellulose derivatives, and bio-based associative thickeners, help adjust viscosity, prevent sagging, and improve application properties. The selection and concentration of rheological modifiers significantly impact coating performance, including barrier properties, film formation, and surface appearance.

- Processing techniques affecting rheological behavior: Various processing techniques can be employed to optimize the rheological behavior of bio-based barrier coating formulations. These include high-shear mixing, temperature control during processing, and specific dispersion methods. The processing conditions significantly influence the microstructure of the coating formulation, which in turn affects its flow properties, stability, and barrier performance. Proper processing techniques ensure consistent rheological properties and coating performance.

- Composite bio-based barrier systems: Composite systems combining multiple bio-based materials can enhance barrier properties while maintaining desirable rheological characteristics. These systems may incorporate nanoparticles, layered structures, or blends of different bio-based polymers to achieve synergistic effects. The interaction between components affects the rheological behavior of the coating formulation, requiring careful formulation to balance processability and barrier performance. These composite systems offer improved moisture resistance, oxygen barrier properties, and mechanical strength.

- Characterization and testing of rheological properties: Various methods and techniques are used to characterize and test the rheological properties of bio-based barrier coating formulations. These include viscometry, oscillatory rheology, extensional rheology, and flow visualization techniques. Understanding the relationship between formulation composition, processing conditions, and rheological behavior is essential for developing effective bio-based barrier coatings. Rheological characterization helps predict coating performance, application behavior, and stability during storage.

02 Rheology modifiers for bio-based coating systems

Specific rheology modifiers can be incorporated into bio-based barrier coating formulations to control viscosity, thixotropy, and shear-thinning behavior. These modifiers, which may include natural gums, modified celluloses, silicas, and clay minerals, help optimize the application properties and stability of the coating systems. By carefully selecting and combining rheology modifiers, formulators can achieve desired flow characteristics during application while maintaining good barrier properties in the final dried film.Expand Specific Solutions03 Processing techniques affecting rheological behavior

Various processing techniques significantly influence the rheological behavior of bio-based barrier coating formulations. Methods such as high-shear mixing, ultrasonication, homogenization, and temperature-controlled processing can modify the molecular structure and interactions within the coating system. These processing parameters directly affect properties like viscosity stability, thixotropy recovery, and application performance. Optimizing processing conditions is essential for achieving consistent rheological properties in bio-based barrier coatings.Expand Specific Solutions04 Nanocomposite additives for rheology control

Incorporating nanoparticles and nanostructured materials into bio-based barrier coating formulations can provide enhanced rheological control while simultaneously improving barrier properties. Materials such as nanoclays, cellulose nanocrystals, nanofibrillated cellulose, and bio-based nanoparticles create complex network structures within the coating matrix. These nanocomposite systems exhibit unique rheological behaviors including yield stress, shear-thinning, and thixotropic recovery that can be advantageous for coating application and performance.Expand Specific Solutions05 Temperature and humidity effects on rheological stability

The rheological behavior of bio-based barrier coating formulations is significantly influenced by environmental factors such as temperature and humidity. These formulations often show greater sensitivity to environmental conditions compared to conventional petroleum-based systems. Understanding and controlling these effects is crucial for maintaining consistent application properties and ensuring coating performance across varying conditions. Formulation strategies may include incorporating stabilizers, crosslinkers, or phase-transition modifiers to mitigate environmental sensitivity.Expand Specific Solutions

Leading Companies in Bio-based Coating Industry

The rheological behavior of bio-based barrier coating formulations represents an emerging field at the intersection of sustainability and advanced materials science. The market is currently in its growth phase, with an estimated global value of $3.5-4 billion and projected annual growth of 8-10% as industries shift toward eco-friendly alternatives. Technical maturity varies significantly among key players: established chemical giants like BASF, DuPont, and Dow Global Technologies lead with comprehensive R&D infrastructures, while specialty companies such as BYK Chemie and Lubrizol focus on performance additives. Academic-industry partnerships, notably with South China University of Technology, are accelerating innovation. The competitive landscape is diversifying as coating specialists like Sherwin-Williams and PPG Coatings develop bio-based alternatives to traditional petroleum-derived formulations, responding to increasing regulatory pressure and consumer demand for sustainable packaging solutions.

BASF Corp.

Technical Solution: BASF has developed advanced bio-based barrier coating formulations utilizing renewable raw materials like modified starches, cellulose derivatives, and plant-based proteins. Their technology focuses on controlling rheological behavior through precise polymer chain engineering and crosslinking mechanisms. BASF's formulations incorporate specialized bio-based rheology modifiers that create shear-thinning behavior for optimal application properties while maintaining high barrier performance against oxygen, moisture, and grease. Their research has demonstrated that controlling the molecular weight distribution and branching structure of bio-polymers significantly impacts coating viscosity profiles during application and drying processes[1]. BASF has also pioneered the use of nanocellulose fibrils as rheological modifiers, which create three-dimensional networks in coating formulations, providing excellent suspension stability and controlled flow properties[3].

Strengths: Superior control over rheological properties through advanced polymer engineering; excellent sustainability profile with high renewable content; strong technical expertise in formulation optimization. Weaknesses: Higher production costs compared to conventional petroleum-based alternatives; potential challenges with long-term stability in varying environmental conditions; may require specialized application equipment for optimal performance.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered innovative bio-based barrier coating formulations with advanced rheological control systems. Their technology utilizes a combination of modified plant oils, cellulose derivatives, and proprietary bio-based polymers to create coatings with precisely engineered flow properties. 3M's approach focuses on controlling the viscoelastic behavior through careful selection of polymer molecular weight distributions and the incorporation of specialized bio-based thickeners. Their formulations exhibit controlled pseudoplastic behavior with defined yield points, allowing for excellent application characteristics while preventing sagging on vertical surfaces. 3M has developed proprietary techniques for measuring and predicting rheological behavior under various application conditions, enabling formulation optimization for specific coating methods[5]. Their research has demonstrated that controlling the interaction between bio-based polymers and inorganic barrier components creates synergistic effects that enhance both rheological properties and barrier performance[6].

Strengths: Exceptional control over rheological properties across a wide temperature range; excellent compatibility with various substrates; superior barrier properties against oxygen, moisture, and grease. Weaknesses: Complex manufacturing process requiring specialized equipment; higher cost compared to conventional petroleum-based alternatives; potential challenges with scale-up for mass production.

Key Patents in Bio-based Barrier Rheology

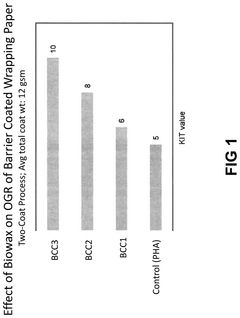

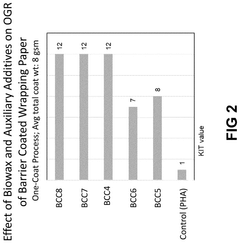

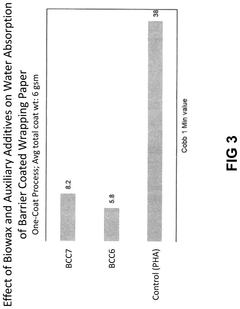

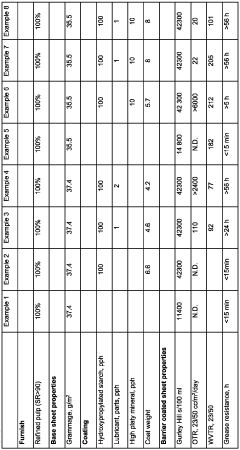

Biowax polyhydroxyalkanoate dispersions as bio-based barrier coatings

PatentPendingUS20240344272A1

Innovation

- The development of biowax emulsions combined with polyhydroxyalkanoate (PHA) dispersions and auxiliary additives, such as clay and microcrystalline cellulose, to form barrier coatings that can be applied at room temperature, achieving enhanced oil and water resistance with a high bio-based content.

Biobased barrier film for packaging material

PatentWO2022259105A1

Innovation

- A biobased barrier film comprising a substrate layer of highly refined cellulose pulp and a coating layer of film-forming modified starch with a biobased lubricant, which provides improved resistance to oxygen, water vapor, and grease while facilitating recycling and high-speed production without affecting barrier performance.

Environmental Impact Assessment

The environmental impact of bio-based barrier coating formulations represents a critical dimension in evaluating their overall sustainability and market viability. These formulations, derived primarily from renewable resources such as cellulose, starch, proteins, and plant-based oils, offer significant environmental advantages compared to conventional petroleum-based alternatives. Life cycle assessments (LCAs) indicate that bio-based coatings generally demonstrate reduced carbon footprints, with greenhouse gas emissions typically 30-45% lower than their synthetic counterparts when considering the entire production chain.

Water consumption patterns for bio-based barrier coatings vary considerably depending on feedstock selection and processing methods. Agricultural feedstocks may require substantial water inputs during cultivation, though this can be mitigated through responsible farming practices and selection of drought-resistant crop varieties. The processing phase of bio-based formulations often demonstrates reduced water requirements compared to conventional coating production, with some studies reporting water savings of up to 25%.

Biodegradability and end-of-life considerations represent perhaps the most significant environmental advantage of these formulations. While petroleum-based coatings can persist in the environment for decades or centuries, properly formulated bio-based alternatives can decompose within months under industrial composting conditions. This characteristic substantially reduces waste accumulation and microplastic pollution, addressing growing regulatory and consumer concerns regarding packaging waste.

The rheological properties of bio-based formulations directly influence their environmental performance through application efficiency. Formulations with optimized flow behavior require less material to achieve equivalent barrier properties, reducing resource consumption. Additionally, rheology-optimized coatings typically require lower drying temperatures, translating to energy savings during the application process. Research indicates energy reductions of 15-30% are achievable through rheological optimization.

Chemical safety profiles of bio-based barrier coatings generally show reduced ecotoxicity compared to conventional alternatives. The absence of potentially harmful substances such as bisphenols, phthalates, and certain solvents minimizes environmental contamination risks. However, certain bio-based additives used to modify rheological properties may present their own environmental challenges, necessitating careful formulation design and thorough ecotoxicological assessment.

Regulatory frameworks increasingly favor environmentally advantageous materials, with policies like the European Single-Use Plastics Directive and various Extended Producer Responsibility schemes creating market incentives for bio-based alternatives. Companies adopting these formulations may benefit from reduced compliance costs and improved market positioning as environmental regulations continue to strengthen globally.

Water consumption patterns for bio-based barrier coatings vary considerably depending on feedstock selection and processing methods. Agricultural feedstocks may require substantial water inputs during cultivation, though this can be mitigated through responsible farming practices and selection of drought-resistant crop varieties. The processing phase of bio-based formulations often demonstrates reduced water requirements compared to conventional coating production, with some studies reporting water savings of up to 25%.

Biodegradability and end-of-life considerations represent perhaps the most significant environmental advantage of these formulations. While petroleum-based coatings can persist in the environment for decades or centuries, properly formulated bio-based alternatives can decompose within months under industrial composting conditions. This characteristic substantially reduces waste accumulation and microplastic pollution, addressing growing regulatory and consumer concerns regarding packaging waste.

The rheological properties of bio-based formulations directly influence their environmental performance through application efficiency. Formulations with optimized flow behavior require less material to achieve equivalent barrier properties, reducing resource consumption. Additionally, rheology-optimized coatings typically require lower drying temperatures, translating to energy savings during the application process. Research indicates energy reductions of 15-30% are achievable through rheological optimization.

Chemical safety profiles of bio-based barrier coatings generally show reduced ecotoxicity compared to conventional alternatives. The absence of potentially harmful substances such as bisphenols, phthalates, and certain solvents minimizes environmental contamination risks. However, certain bio-based additives used to modify rheological properties may present their own environmental challenges, necessitating careful formulation design and thorough ecotoxicological assessment.

Regulatory frameworks increasingly favor environmentally advantageous materials, with policies like the European Single-Use Plastics Directive and various Extended Producer Responsibility schemes creating market incentives for bio-based alternatives. Companies adopting these formulations may benefit from reduced compliance costs and improved market positioning as environmental regulations continue to strengthen globally.

Scalability and Manufacturing Considerations

The scalability of bio-based barrier coating formulations from laboratory to industrial scale presents significant challenges that must be addressed for commercial viability. Current manufacturing processes require adaptation to accommodate the unique rheological properties of these sustainable formulations. Viscosity stability during scale-up remains a critical concern, as bio-based materials often exhibit non-Newtonian behavior that changes under different processing conditions and equipment configurations.

Equipment compatibility represents another major consideration, as existing coating machinery may require modifications to handle the specific flow characteristics of bio-based formulations. The shear sensitivity of many bio-polymers necessitates careful control of pumping systems, pipe geometries, and application methods to maintain consistent coating performance. Manufacturers must evaluate whether their current infrastructure can accommodate these requirements or if capital investments in specialized equipment are necessary.

Process parameters require precise optimization during scale-up to maintain the desired rheological profile. Temperature control becomes increasingly critical at industrial scales, as bio-based formulations often demonstrate temperature-dependent viscosity changes that are more pronounced than their synthetic counterparts. Similarly, mixing protocols must be standardized to ensure homogeneity without degrading sensitive bio-components through excessive shear forces.

Quality control systems need enhancement to monitor rheological properties throughout the manufacturing process. In-line viscosity measurements, coupled with rapid feedback mechanisms, can help maintain consistency across production batches. The development of standardized testing protocols specific to bio-based coatings will facilitate quality assurance and regulatory compliance.

Cost considerations cannot be overlooked when scaling bio-based barrier coating production. While raw material costs remain higher than conventional alternatives, optimizing rheological properties can improve application efficiency and reduce waste. Process efficiency improvements, such as reducing drying energy requirements through rheology modification, can help offset initial cost disadvantages and improve the overall economic viability.

Supply chain resilience presents unique challenges for bio-based formulations. Seasonal variations in agricultural feedstocks can affect the consistency of raw materials, potentially altering rheological properties between batches. Developing robust formulations that can accommodate these variations without compromising performance is essential for reliable large-scale manufacturing. Strategic partnerships with biomaterial suppliers and investment in preprocessing technologies may help mitigate these supply chain risks.

Equipment compatibility represents another major consideration, as existing coating machinery may require modifications to handle the specific flow characteristics of bio-based formulations. The shear sensitivity of many bio-polymers necessitates careful control of pumping systems, pipe geometries, and application methods to maintain consistent coating performance. Manufacturers must evaluate whether their current infrastructure can accommodate these requirements or if capital investments in specialized equipment are necessary.

Process parameters require precise optimization during scale-up to maintain the desired rheological profile. Temperature control becomes increasingly critical at industrial scales, as bio-based formulations often demonstrate temperature-dependent viscosity changes that are more pronounced than their synthetic counterparts. Similarly, mixing protocols must be standardized to ensure homogeneity without degrading sensitive bio-components through excessive shear forces.

Quality control systems need enhancement to monitor rheological properties throughout the manufacturing process. In-line viscosity measurements, coupled with rapid feedback mechanisms, can help maintain consistency across production batches. The development of standardized testing protocols specific to bio-based coatings will facilitate quality assurance and regulatory compliance.

Cost considerations cannot be overlooked when scaling bio-based barrier coating production. While raw material costs remain higher than conventional alternatives, optimizing rheological properties can improve application efficiency and reduce waste. Process efficiency improvements, such as reducing drying energy requirements through rheology modification, can help offset initial cost disadvantages and improve the overall economic viability.

Supply chain resilience presents unique challenges for bio-based formulations. Seasonal variations in agricultural feedstocks can affect the consistency of raw materials, potentially altering rheological properties between batches. Developing robust formulations that can accommodate these variations without compromising performance is essential for reliable large-scale manufacturing. Strategic partnerships with biomaterial suppliers and investment in preprocessing technologies may help mitigate these supply chain risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!