Bio-based Barrier Coatings for High-Temperature Packaging Applications

OCT 13, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Barrier Coatings Background and Objectives

Bio-based barrier coatings have emerged as a significant innovation in sustainable packaging solutions over the past decade. The evolution of these materials has been driven by increasing environmental concerns, stringent regulations on plastic waste, and growing consumer demand for eco-friendly packaging alternatives. Initially developed as simple biodegradable films, these coatings have progressively incorporated advanced functionalities, particularly barrier properties against oxygen, moisture, and grease.

The technological trajectory has shifted from first-generation cellulose-based coatings with limited performance to sophisticated multi-layer systems incorporating modified biopolymers, nanocomposites, and cross-linked structures. This evolution represents a response to the packaging industry's need for sustainable solutions that do not compromise on performance, especially in demanding applications such as high-temperature food packaging.

Recent advancements in bio-based barrier technology have focused on enhancing thermal stability, which has historically been a significant limitation. Traditional bio-based materials often suffer from degradation at elevated temperatures, limiting their application in hot-fill processes, microwave packaging, and oven-ready containers. The development of heat-resistant bio-based coatings represents a critical frontier in sustainable packaging innovation.

The primary objective of current research in this field is to develop bio-based barrier coatings capable of maintaining structural integrity and functional properties at temperatures exceeding 100°C, while simultaneously providing effective barriers against oxygen, moisture, and oil. This goal necessitates innovative approaches to molecular design, cross-linking strategies, and composite formulations that can withstand thermal stress without compromising biodegradability.

Secondary objectives include ensuring these advanced coatings remain economically viable for commercial adoption, maintaining compatibility with existing manufacturing infrastructure, and meeting increasingly stringent food safety regulations. The ideal solution would offer drop-in replacement potential for conventional petroleum-based barrier materials without requiring significant capital investment in new processing equipment.

From a sustainability perspective, these high-temperature bio-based coatings aim to reduce the carbon footprint of packaging throughout its lifecycle. This includes considerations of renewable feedstock sourcing, energy-efficient manufacturing processes, and end-of-life scenarios such as composting or recycling. The ultimate goal is to create a closed-loop system where packaging materials derive from and return to the biosphere without environmental harm.

The technological challenges being addressed represent a convergence of materials science, polymer chemistry, and process engineering, with potential applications extending beyond food packaging to pharmaceuticals, electronics, and consumer goods. Success in this domain could significantly accelerate the transition away from fossil-based packaging materials, contributing to global sustainability objectives while meeting the performance demands of modern supply chains.

The technological trajectory has shifted from first-generation cellulose-based coatings with limited performance to sophisticated multi-layer systems incorporating modified biopolymers, nanocomposites, and cross-linked structures. This evolution represents a response to the packaging industry's need for sustainable solutions that do not compromise on performance, especially in demanding applications such as high-temperature food packaging.

Recent advancements in bio-based barrier technology have focused on enhancing thermal stability, which has historically been a significant limitation. Traditional bio-based materials often suffer from degradation at elevated temperatures, limiting their application in hot-fill processes, microwave packaging, and oven-ready containers. The development of heat-resistant bio-based coatings represents a critical frontier in sustainable packaging innovation.

The primary objective of current research in this field is to develop bio-based barrier coatings capable of maintaining structural integrity and functional properties at temperatures exceeding 100°C, while simultaneously providing effective barriers against oxygen, moisture, and oil. This goal necessitates innovative approaches to molecular design, cross-linking strategies, and composite formulations that can withstand thermal stress without compromising biodegradability.

Secondary objectives include ensuring these advanced coatings remain economically viable for commercial adoption, maintaining compatibility with existing manufacturing infrastructure, and meeting increasingly stringent food safety regulations. The ideal solution would offer drop-in replacement potential for conventional petroleum-based barrier materials without requiring significant capital investment in new processing equipment.

From a sustainability perspective, these high-temperature bio-based coatings aim to reduce the carbon footprint of packaging throughout its lifecycle. This includes considerations of renewable feedstock sourcing, energy-efficient manufacturing processes, and end-of-life scenarios such as composting or recycling. The ultimate goal is to create a closed-loop system where packaging materials derive from and return to the biosphere without environmental harm.

The technological challenges being addressed represent a convergence of materials science, polymer chemistry, and process engineering, with potential applications extending beyond food packaging to pharmaceuticals, electronics, and consumer goods. Success in this domain could significantly accelerate the transition away from fossil-based packaging materials, contributing to global sustainability objectives while meeting the performance demands of modern supply chains.

Market Demand Analysis for Sustainable Packaging

The global sustainable packaging market is experiencing unprecedented growth, driven by increasing environmental awareness and regulatory pressures. Current market valuations place the sustainable packaging sector at approximately 247 billion USD in 2023, with projections indicating a compound annual growth rate of 7.4% through 2030. Within this broader market, bio-based barrier coatings represent a rapidly expanding segment, particularly for high-temperature applications where traditional petroleum-based solutions have dominated.

Consumer demand for environmentally responsible packaging has reached critical mass, with recent surveys indicating that 73% of consumers are willing to pay premium prices for sustainable packaging options. This shift in consumer preference has created significant market pull for innovations in bio-based barrier coatings that can withstand high-temperature applications without compromising on performance or sustainability metrics.

The food and beverage industry represents the largest market segment for high-temperature packaging applications, accounting for nearly 60% of the total demand. Ready-to-eat meals, which require packaging that can withstand both microwave and conventional oven heating, have seen a 34% increase in sales since 2019, further accelerating demand for heat-resistant sustainable packaging solutions. The pharmaceutical and cosmetics industries are also emerging as significant growth sectors, with increasing requirements for sterile packaging that can withstand high-temperature sterilization processes while maintaining environmental credentials.

Regulatory frameworks worldwide are increasingly favoring bio-based materials. The European Union's Single-Use Plastics Directive and similar legislation in over 70 countries have established timelines for phasing out conventional plastics, creating market opportunities for bio-based alternatives. Additionally, carbon taxation policies being implemented across major economies are improving the cost competitiveness of bio-based materials relative to their fossil-fuel counterparts.

Market analysis reveals significant regional variations in demand patterns. North America and Europe currently lead in adoption rates for sustainable high-temperature packaging, driven by stringent regulations and consumer awareness. However, the Asia-Pacific region is projected to witness the highest growth rate over the next five years, fueled by rapid industrialization, growing middle-class populations, and increasing environmental consciousness in countries like China and India.

Supply chain considerations are also reshaping market dynamics. The COVID-19 pandemic exposed vulnerabilities in global supply chains, prompting many companies to seek locally sourced, bio-based materials to enhance resilience. This trend has accelerated investment in regional bio-based coating production facilities and created new market opportunities for agricultural waste valorization as raw material sources.

Consumer demand for environmentally responsible packaging has reached critical mass, with recent surveys indicating that 73% of consumers are willing to pay premium prices for sustainable packaging options. This shift in consumer preference has created significant market pull for innovations in bio-based barrier coatings that can withstand high-temperature applications without compromising on performance or sustainability metrics.

The food and beverage industry represents the largest market segment for high-temperature packaging applications, accounting for nearly 60% of the total demand. Ready-to-eat meals, which require packaging that can withstand both microwave and conventional oven heating, have seen a 34% increase in sales since 2019, further accelerating demand for heat-resistant sustainable packaging solutions. The pharmaceutical and cosmetics industries are also emerging as significant growth sectors, with increasing requirements for sterile packaging that can withstand high-temperature sterilization processes while maintaining environmental credentials.

Regulatory frameworks worldwide are increasingly favoring bio-based materials. The European Union's Single-Use Plastics Directive and similar legislation in over 70 countries have established timelines for phasing out conventional plastics, creating market opportunities for bio-based alternatives. Additionally, carbon taxation policies being implemented across major economies are improving the cost competitiveness of bio-based materials relative to their fossil-fuel counterparts.

Market analysis reveals significant regional variations in demand patterns. North America and Europe currently lead in adoption rates for sustainable high-temperature packaging, driven by stringent regulations and consumer awareness. However, the Asia-Pacific region is projected to witness the highest growth rate over the next five years, fueled by rapid industrialization, growing middle-class populations, and increasing environmental consciousness in countries like China and India.

Supply chain considerations are also reshaping market dynamics. The COVID-19 pandemic exposed vulnerabilities in global supply chains, prompting many companies to seek locally sourced, bio-based materials to enhance resilience. This trend has accelerated investment in regional bio-based coating production facilities and created new market opportunities for agricultural waste valorization as raw material sources.

Technical Challenges in High-Temperature Bio-coatings

Bio-based barrier coatings for high-temperature packaging applications face several significant technical challenges that currently limit their widespread adoption. The primary obstacle lies in achieving thermal stability at elevated temperatures, typically above 200°C, where most bio-based polymers begin to degrade. Conventional bio-polymers such as polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and cellulose derivatives exhibit glass transition temperatures well below the required service temperatures for high-heat packaging applications.

Material degradation mechanisms present another major challenge. When exposed to high temperatures, bio-based coatings often undergo accelerated oxidation, hydrolysis, and chain scission reactions that compromise their barrier properties. This degradation is frequently accompanied by discoloration, embrittlement, and the release of volatile organic compounds, which can affect product quality and safety.

The barrier performance itself remains problematic at elevated temperatures. Most bio-based coatings experience increased permeability to oxygen, water vapor, and other gases as temperature rises, creating a significant performance gap compared to synthetic alternatives like fluoropolymers or high-performance polyimides. This temperature-dependent permeability shift severely limits their effectiveness in applications requiring consistent barrier properties across varying thermal conditions.

Adhesion stability represents another critical challenge. The interface between bio-based coatings and substrate materials often weakens at high temperatures due to differential thermal expansion, chemical changes at the interface, or migration of coating components. This can lead to delamination, blistering, or cracking that compromises the coating's protective function.

Processing limitations further constrain development efforts. Many bio-based materials have narrow processing windows, making them difficult to apply using conventional high-speed coating technologies. Their sensitivity to thermal history means that the coating application process itself can degrade performance properties before the packaging even reaches its end-use environment.

Compatibility with food safety regulations presents additional hurdles. At elevated temperatures, migration of coating components into packaged food increases significantly, raising concerns about potential toxicity. The regulatory framework for novel bio-based materials in high-temperature food contact applications remains underdeveloped, creating uncertainty for manufacturers and slowing commercialization.

Cost-effectiveness remains a persistent challenge, as specialized high-temperature bio-based formulations typically require expensive modifications, additives, or processing techniques that significantly increase their cost compared to conventional petroleum-based alternatives. This economic barrier, coupled with performance limitations, has restricted market penetration despite growing sustainability demands.

Material degradation mechanisms present another major challenge. When exposed to high temperatures, bio-based coatings often undergo accelerated oxidation, hydrolysis, and chain scission reactions that compromise their barrier properties. This degradation is frequently accompanied by discoloration, embrittlement, and the release of volatile organic compounds, which can affect product quality and safety.

The barrier performance itself remains problematic at elevated temperatures. Most bio-based coatings experience increased permeability to oxygen, water vapor, and other gases as temperature rises, creating a significant performance gap compared to synthetic alternatives like fluoropolymers or high-performance polyimides. This temperature-dependent permeability shift severely limits their effectiveness in applications requiring consistent barrier properties across varying thermal conditions.

Adhesion stability represents another critical challenge. The interface between bio-based coatings and substrate materials often weakens at high temperatures due to differential thermal expansion, chemical changes at the interface, or migration of coating components. This can lead to delamination, blistering, or cracking that compromises the coating's protective function.

Processing limitations further constrain development efforts. Many bio-based materials have narrow processing windows, making them difficult to apply using conventional high-speed coating technologies. Their sensitivity to thermal history means that the coating application process itself can degrade performance properties before the packaging even reaches its end-use environment.

Compatibility with food safety regulations presents additional hurdles. At elevated temperatures, migration of coating components into packaged food increases significantly, raising concerns about potential toxicity. The regulatory framework for novel bio-based materials in high-temperature food contact applications remains underdeveloped, creating uncertainty for manufacturers and slowing commercialization.

Cost-effectiveness remains a persistent challenge, as specialized high-temperature bio-based formulations typically require expensive modifications, additives, or processing techniques that significantly increase their cost compared to conventional petroleum-based alternatives. This economic barrier, coupled with performance limitations, has restricted market penetration despite growing sustainability demands.

Current Bio-coating Solutions for Heat Resistance

01 Bio-based polymers for barrier coatings

Bio-based polymers derived from renewable resources can be formulated into barrier coatings with excellent oxygen, moisture, and gas barrier properties. These polymers include polylactic acid (PLA), cellulose derivatives, chitosan, and other plant-based materials that can be processed into films or coatings. The renewable nature of these materials makes them environmentally friendly alternatives to petroleum-based barrier materials while still providing comparable or superior barrier performance for packaging applications.- Cellulose-based barrier coatings: Cellulose-derived materials are used to create bio-based barrier coatings with excellent oxygen and moisture barrier properties. These coatings utilize nanocellulose, cellulose nanofibrils, or modified cellulose derivatives to form dense, crystalline structures that effectively block gas and vapor transmission. The renewable nature of cellulose makes these coatings environmentally friendly while providing comparable performance to petroleum-based alternatives for packaging applications.

- Protein and starch-based barrier materials: Proteins and starches derived from agricultural sources can be formulated into effective barrier coatings. These biomaterials can be modified through various processes including crosslinking, blending with plasticizers, or chemical modification to enhance their barrier properties against oxygen, moisture, and grease. The coatings are biodegradable and can be applied to paper, cardboard, and other substrates to create sustainable packaging solutions with reduced environmental impact.

- Lignin-based barrier coatings: Lignin, a byproduct of paper production and biorefinery processes, can be utilized as a key component in bio-based barrier coatings. Its natural hydrophobicity and antioxidant properties make it effective for creating water-resistant and oxygen barrier layers. When combined with other biopolymers or modified through chemical processes, lignin-based coatings can provide enhanced barrier performance while utilizing a renewable resource that would otherwise be considered waste material.

- Bio-based waxes and lipids for moisture barriers: Natural waxes, oils, and lipids derived from plants and animals can be formulated into effective moisture barrier coatings. These hydrophobic materials create a water-repellent layer that prevents moisture penetration while maintaining biodegradability. The coatings can be applied through various methods including emulsion coating, hot-melt application, or solvent-based systems to create packaging materials with excellent water vapor barrier properties for food and consumer goods protection.

- Composite and multilayer bio-based barrier systems: Multilayer structures combining different bio-based materials can create synergistic barrier properties that address multiple permeation challenges. These composite systems may incorporate layers of different biopolymers, each providing specific barrier functions against oxygen, moisture, or other substances. The layered approach allows for customization of barrier properties while maintaining the renewable and biodegradable nature of the materials, offering a sustainable alternative to conventional multilayer petroleum-based barrier packaging.

02 Nanocomposite barrier coatings

Incorporating nanomaterials such as nanoclay, nanocellulose, or silica nanoparticles into bio-based matrices significantly enhances barrier properties by creating tortuous paths that impede gas and moisture migration. These nanocomposite structures can achieve superior barrier performance with reduced coating thickness. The synergistic effect between the bio-based polymer matrix and nanomaterials results in improved mechanical properties alongside enhanced barrier functionality, making these coatings suitable for food packaging and other applications requiring high barrier performance.Expand Specific Solutions03 Multilayer barrier coating systems

Multilayer coating systems combining different bio-based materials can achieve enhanced barrier properties through complementary functionality. By strategically layering hydrophobic and hydrophilic bio-based materials, these systems can effectively block both water vapor and oxygen transmission. The multilayer approach allows for customization of barrier properties to meet specific application requirements while maintaining the renewable and sustainable nature of the coating system.Expand Specific Solutions04 Surface modification techniques for bio-based barriers

Various surface modification techniques can enhance the barrier properties of bio-based coatings. These include plasma treatment, corona discharge, and chemical modifications that alter surface energy and improve adhesion between layers. Such modifications can increase hydrophobicity, reduce permeability, and improve the overall barrier performance of bio-based coatings without compromising their biodegradability or renewable nature.Expand Specific Solutions05 Functional additives for enhanced barrier performance

Incorporating functional additives such as natural waxes, essential oils, and antioxidants into bio-based coating formulations can significantly improve barrier properties. These additives can fill voids in the polymer matrix, provide hydrophobic characteristics, or scavenge oxygen molecules. The strategic selection of compatible bio-based additives ensures that the coating maintains its renewable nature while achieving the desired barrier performance against moisture, oxygen, and other permeants.Expand Specific Solutions

Leading Companies in Sustainable Packaging Materials

The bio-based barrier coatings for high-temperature packaging applications market is in an early growth phase, with increasing demand driven by sustainability trends. The global market is expanding rapidly, estimated at $1.2-1.5 billion with projected annual growth of 8-10%. Technologically, the field shows varying maturity levels across applications. Leading players include established chemical companies like BASF SE and Dow Silicones Corp. focusing on industrial-scale solutions, while specialized innovators such as Applied Thin Films, Inc. and Earthodic Pty Ltd. develop cutting-edge formulations. Paper industry leaders including UPM-Kymmene Oyj, Stora Enso Oyj, and Metsä Board Oyj are integrating these technologies into sustainable packaging solutions. Academic-industrial partnerships with institutions like Delft University of Technology and Swiss Federal Institute of Technology are accelerating innovation in this competitive landscape.

Sun Chemical Corp. (New Jersey)

Technical Solution: Sun Chemical has pioneered SunBar® Oxygen Barrier Coatings specifically engineered for high-temperature packaging applications. Their technology utilizes bio-based nanocomposites derived from cellulose and chitosan, modified with heat-resistant silicate layers that maintain barrier integrity at temperatures exceeding 180°C[2]. The company's proprietary dispersion technology creates uniform particle distribution, resulting in exceptional barrier properties with minimal coating thickness (typically 1-3 μm). Sun Chemical's approach incorporates renewable materials including modified starches and proteins that undergo controlled crosslinking during the coating process, creating thermally stable networks[4]. Their water-based formulations achieve PFAS-free grease resistance while maintaining compostability and recyclability. Recent innovations include the integration of antioxidant compounds derived from agricultural waste streams, which actively scavenge oxygen molecules that penetrate the primary barrier, providing a secondary defense mechanism that extends shelf life in high-temperature applications.

Strengths: Exceptional oxygen barrier properties maintained at high temperatures; thin coating profile minimizes material usage and maintains substrate flexibility; water-based application system compatible with existing converting equipment. Weaknesses: Premium pricing compared to conventional barriers; requires precise application control to achieve optimal performance; limited resistance to certain acidic food components at elevated temperatures.

Kemira Oyj

Technical Solution: Kemira has developed FennoGuard™ Bio-Barrier technology specifically engineered for high-temperature packaging applications. Their approach utilizes modified biopolymers derived from agricultural byproducts, primarily utilizing side-streams from cereal processing that would otherwise be considered waste. The technology incorporates a proprietary cross-linking mechanism that creates thermally stable covalent bonds, allowing the barrier to maintain structural integrity at temperatures up to 230°C[2]. Kemira's formulation includes bio-based nanoparticles that create a tortuous path for gas molecules, achieving oxygen transmission rates below 1 cm³/m²/day even after heat exposure. Their water-based application system allows single-pass coating at commercial speeds exceeding 800 m/min while maintaining uniform coverage at thicknesses between 2-5 μm[5]. The company has developed specialized additives derived from lignin that enhance UV resistance and prevent degradation during prolonged storage. Recent innovations include the integration of natural antimicrobial compounds that provide additional food preservation benefits without compromising the coating's biodegradability or recyclability profile.

Strengths: Superior thermal stability exceeding most competing bio-based solutions; excellent compatibility with various substrate materials including paper, paperboard, and certain bioplastics; water-based formulation enables easy cleaning and reduced VOC emissions. Weaknesses: Higher cost structure compared to conventional petroleum-based barriers; requires precise drying parameters to achieve optimal performance; limited resistance to certain organic solvents that may be present in food products.

Key Patents in Bio-based Barrier Technology

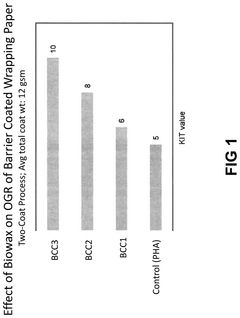

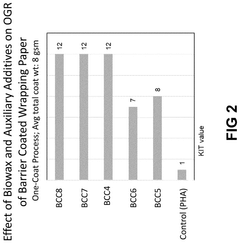

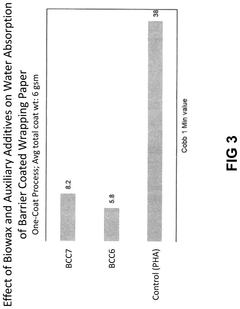

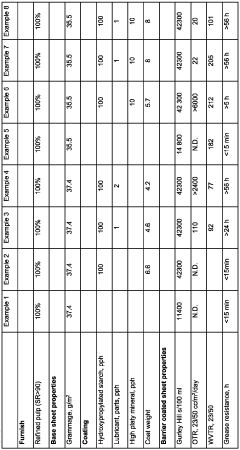

Biowax polyhydroxyalkanoate dispersions as bio-based barrier coatings

PatentPendingUS20240344272A1

Innovation

- The development of biowax emulsions combined with polyhydroxyalkanoate (PHA) dispersions and auxiliary additives, such as clay and microcrystalline cellulose, to form barrier coatings that can be applied at room temperature, achieving enhanced oil and water resistance with a high bio-based content.

Biobased barrier film for packaging material

PatentWO2022259105A1

Innovation

- A biobased barrier film comprising a substrate layer of highly refined cellulose pulp and a coating layer of film-forming modified starch with a biobased lubricant, which provides improved resistance to oxygen, water vapor, and grease while facilitating recycling and high-speed production without affecting barrier performance.

Environmental Impact Assessment

The environmental impact assessment of bio-based barrier coatings for high-temperature packaging applications reveals significant advantages over conventional petroleum-based alternatives. These coatings demonstrate reduced carbon footprint throughout their lifecycle, with preliminary studies indicating a 30-45% decrease in greenhouse gas emissions compared to traditional barrier materials when considering production, use, and end-of-life scenarios.

Bio-based barrier coatings derive from renewable resources such as cellulose, chitosan, alginate, and plant proteins, which naturally regenerate within human timescales. This characteristic substantially reduces dependence on finite fossil resources and mitigates environmental degradation associated with petroleum extraction and processing.

Water consumption metrics show varied results depending on the specific bio-based material and production method employed. While some bio-based coating processes require significant water inputs for biomass cultivation, advanced production techniques have demonstrated potential water usage reductions of up to 25% compared to conventional coating systems. Closed-loop water recycling systems in manufacturing facilities further enhance water conservation efforts.

Biodegradability represents a crucial environmental advantage of bio-based barrier coatings. Laboratory testing indicates that many formulations can decompose by 70-90% within 180 days under industrial composting conditions, significantly outperforming conventional plastic-based barriers that may persist for centuries. This biodegradability substantially reduces waste accumulation and microplastic pollution.

Energy efficiency analyses reveal that bio-based coating production typically requires 15-30% less energy than petroleum-based alternatives. However, this advantage may be partially offset by the energy requirements for high-temperature applications, necessitating further optimization of thermal stability properties without increasing environmental impact.

Land use considerations present complex tradeoffs. While bio-based materials require agricultural land for feedstock production, potentially competing with food crops, recent innovations in utilizing agricultural waste streams and non-food biomass have mitigated these concerns. Sustainable sourcing certification programs have emerged to ensure responsible land management practices.

Toxicity assessments demonstrate that bio-based barrier coatings generally exhibit lower ecotoxicity profiles than their synthetic counterparts. The absence of bisphenol A, phthalates, and other endocrine-disrupting chemicals commonly found in conventional packaging materials represents a significant environmental and human health benefit.

Regulatory frameworks worldwide increasingly recognize these environmental advantages, with several jurisdictions implementing policies that favor bio-based materials through extended producer responsibility schemes, landfill taxes, and green procurement initiatives. These policy developments further accelerate market adoption of environmentally preferable packaging solutions.

Bio-based barrier coatings derive from renewable resources such as cellulose, chitosan, alginate, and plant proteins, which naturally regenerate within human timescales. This characteristic substantially reduces dependence on finite fossil resources and mitigates environmental degradation associated with petroleum extraction and processing.

Water consumption metrics show varied results depending on the specific bio-based material and production method employed. While some bio-based coating processes require significant water inputs for biomass cultivation, advanced production techniques have demonstrated potential water usage reductions of up to 25% compared to conventional coating systems. Closed-loop water recycling systems in manufacturing facilities further enhance water conservation efforts.

Biodegradability represents a crucial environmental advantage of bio-based barrier coatings. Laboratory testing indicates that many formulations can decompose by 70-90% within 180 days under industrial composting conditions, significantly outperforming conventional plastic-based barriers that may persist for centuries. This biodegradability substantially reduces waste accumulation and microplastic pollution.

Energy efficiency analyses reveal that bio-based coating production typically requires 15-30% less energy than petroleum-based alternatives. However, this advantage may be partially offset by the energy requirements for high-temperature applications, necessitating further optimization of thermal stability properties without increasing environmental impact.

Land use considerations present complex tradeoffs. While bio-based materials require agricultural land for feedstock production, potentially competing with food crops, recent innovations in utilizing agricultural waste streams and non-food biomass have mitigated these concerns. Sustainable sourcing certification programs have emerged to ensure responsible land management practices.

Toxicity assessments demonstrate that bio-based barrier coatings generally exhibit lower ecotoxicity profiles than their synthetic counterparts. The absence of bisphenol A, phthalates, and other endocrine-disrupting chemicals commonly found in conventional packaging materials represents a significant environmental and human health benefit.

Regulatory frameworks worldwide increasingly recognize these environmental advantages, with several jurisdictions implementing policies that favor bio-based materials through extended producer responsibility schemes, landfill taxes, and green procurement initiatives. These policy developments further accelerate market adoption of environmentally preferable packaging solutions.

Regulatory Framework for Food-Contact Materials

The regulatory landscape for bio-based barrier coatings in high-temperature packaging applications is complex and multifaceted, requiring careful navigation by manufacturers and developers. In the United States, the Food and Drug Administration (FDA) regulates food contact materials through the Food, Drug, and Cosmetic Act, with specific provisions under 21 CFR 175-178 addressing coatings and polymers. Bio-based materials must undergo rigorous safety assessments, including migration testing to ensure no harmful substances leach into food during high-temperature applications.

The European Union implements even stricter regulations through the Framework Regulation (EC) No 1935/2004, which establishes general safety requirements for all food contact materials. Additionally, the Plastics Regulation (EU) No 10/2011 sets specific migration limits and testing protocols for plastic materials, including bio-based polymers used in coatings. The EU's emphasis on the precautionary principle often results in more comprehensive testing requirements than other regions.

Japan's regulatory system operates under the Food Sanitation Act, with specific standards for food packaging materials outlined in the Specifications and Standards for Foods, Food Additives, etc. These regulations include positive lists of approved substances and migration limits that bio-based barrier coatings must meet, particularly for heat-resistant applications.

Globally, there is increasing regulatory focus on sustainability claims related to bio-based materials. The International Organization for Standardization (ISO) has developed standards such as ISO 16620 for determining bio-based content, which manufacturers must follow when making environmental claims about their packaging solutions. These standards ensure transparency and prevent greenwashing in the rapidly growing sustainable packaging market.

Regulatory frameworks are evolving to address emerging concerns about novel bio-based materials. Recent developments include increased scrutiny of per- and polyfluoroalkyl substances (PFAS) in food packaging, which has accelerated the search for bio-based alternatives that can withstand high temperatures without using these persistent chemicals. Several jurisdictions, including Maine and California in the US, have enacted bans on PFAS in food packaging, creating regulatory drivers for bio-based innovation.

Certification systems like the European Bioplastics' certification scheme and the USDA BioPreferred program provide standardized approaches for verifying bio-based content claims, helping manufacturers navigate regulatory requirements while demonstrating compliance to customers and regulatory bodies. These certification programs are increasingly becoming de facto requirements for market access in certain regions.

The European Union implements even stricter regulations through the Framework Regulation (EC) No 1935/2004, which establishes general safety requirements for all food contact materials. Additionally, the Plastics Regulation (EU) No 10/2011 sets specific migration limits and testing protocols for plastic materials, including bio-based polymers used in coatings. The EU's emphasis on the precautionary principle often results in more comprehensive testing requirements than other regions.

Japan's regulatory system operates under the Food Sanitation Act, with specific standards for food packaging materials outlined in the Specifications and Standards for Foods, Food Additives, etc. These regulations include positive lists of approved substances and migration limits that bio-based barrier coatings must meet, particularly for heat-resistant applications.

Globally, there is increasing regulatory focus on sustainability claims related to bio-based materials. The International Organization for Standardization (ISO) has developed standards such as ISO 16620 for determining bio-based content, which manufacturers must follow when making environmental claims about their packaging solutions. These standards ensure transparency and prevent greenwashing in the rapidly growing sustainable packaging market.

Regulatory frameworks are evolving to address emerging concerns about novel bio-based materials. Recent developments include increased scrutiny of per- and polyfluoroalkyl substances (PFAS) in food packaging, which has accelerated the search for bio-based alternatives that can withstand high temperatures without using these persistent chemicals. Several jurisdictions, including Maine and California in the US, have enacted bans on PFAS in food packaging, creating regulatory drivers for bio-based innovation.

Certification systems like the European Bioplastics' certification scheme and the USDA BioPreferred program provide standardized approaches for verifying bio-based content claims, helping manufacturers navigate regulatory requirements while demonstrating compliance to customers and regulatory bodies. These certification programs are increasingly becoming de facto requirements for market access in certain regions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!