Thermal Stability and Mechanical Integrity of Bio-based Barrier Coatings

OCT 13, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Barrier Coatings Background and Objectives

Bio-based barrier coatings have emerged as a significant area of research and development over the past two decades, driven by increasing environmental concerns and regulatory pressures to reduce petroleum-based plastic usage. These coatings, derived from renewable resources such as cellulose, chitosan, proteins, and plant-based oils, represent a sustainable alternative to conventional synthetic polymer barriers used in packaging, construction, and consumer goods industries.

The evolution of bio-based barrier technologies can be traced back to early experiments with natural waxes and resins in the 1980s, which provided limited functionality. Significant advancements occurred in the early 2000s with the development of more sophisticated biopolymer formulations that began to approach the performance of synthetic alternatives. Recent years have witnessed accelerated innovation in this field, particularly in enhancing the thermal stability and mechanical integrity of these materials.

Current technological trends indicate a shift toward multi-functional bio-based coatings that not only provide excellent barrier properties against oxygen, water vapor, and grease but also demonstrate improved thermal resistance and mechanical durability. This evolution is critical as traditional bio-based materials often suffer from performance degradation at elevated temperatures and lack the structural integrity required for many commercial applications.

The primary objective of research in this domain is to develop bio-based barrier coatings that maintain their functional properties under varying thermal conditions while providing mechanical robustness comparable to petroleum-based alternatives. Specifically, researchers aim to achieve thermal stability at processing temperatures of 80-200°C and mechanical integrity that allows for less than 5% performance degradation after standard flexing and abrasion tests.

Additional technical goals include enhancing the compatibility of these coatings with various substrate materials, improving their processability in existing manufacturing equipment, and extending their shelf life under diverse environmental conditions. The ultimate aim is to create drop-in replacements for conventional barrier materials that offer equivalent or superior performance while reducing environmental impact.

Understanding the fundamental structure-property relationships that govern thermal stability and mechanical integrity in bio-based systems represents a critical knowledge gap that must be addressed to achieve these objectives. This includes investigating the molecular interactions between different biopolymers, exploring novel cross-linking mechanisms, and developing effective stabilization strategies against thermal degradation.

The successful development of thermally stable and mechanically robust bio-based barrier coatings would significantly advance sustainable packaging solutions and contribute to circular economy initiatives across multiple industries.

The evolution of bio-based barrier technologies can be traced back to early experiments with natural waxes and resins in the 1980s, which provided limited functionality. Significant advancements occurred in the early 2000s with the development of more sophisticated biopolymer formulations that began to approach the performance of synthetic alternatives. Recent years have witnessed accelerated innovation in this field, particularly in enhancing the thermal stability and mechanical integrity of these materials.

Current technological trends indicate a shift toward multi-functional bio-based coatings that not only provide excellent barrier properties against oxygen, water vapor, and grease but also demonstrate improved thermal resistance and mechanical durability. This evolution is critical as traditional bio-based materials often suffer from performance degradation at elevated temperatures and lack the structural integrity required for many commercial applications.

The primary objective of research in this domain is to develop bio-based barrier coatings that maintain their functional properties under varying thermal conditions while providing mechanical robustness comparable to petroleum-based alternatives. Specifically, researchers aim to achieve thermal stability at processing temperatures of 80-200°C and mechanical integrity that allows for less than 5% performance degradation after standard flexing and abrasion tests.

Additional technical goals include enhancing the compatibility of these coatings with various substrate materials, improving their processability in existing manufacturing equipment, and extending their shelf life under diverse environmental conditions. The ultimate aim is to create drop-in replacements for conventional barrier materials that offer equivalent or superior performance while reducing environmental impact.

Understanding the fundamental structure-property relationships that govern thermal stability and mechanical integrity in bio-based systems represents a critical knowledge gap that must be addressed to achieve these objectives. This includes investigating the molecular interactions between different biopolymers, exploring novel cross-linking mechanisms, and developing effective stabilization strategies against thermal degradation.

The successful development of thermally stable and mechanically robust bio-based barrier coatings would significantly advance sustainable packaging solutions and contribute to circular economy initiatives across multiple industries.

Market Demand Analysis for Sustainable Packaging Solutions

The global sustainable packaging market is experiencing unprecedented growth, driven by increasing environmental awareness and regulatory pressures. Current market valuations place the sustainable packaging sector at approximately 300 billion USD in 2023, with projections indicating a compound annual growth rate of 7-8% through 2030. Bio-based barrier coatings represent a rapidly expanding segment within this market, with particular demand coming from food and beverage industries seeking alternatives to traditional petroleum-based packaging solutions.

Consumer preferences have shifted dramatically toward environmentally responsible products, with recent surveys indicating that over 70% of consumers across North America, Europe, and Asia-Pacific regions express willingness to pay premium prices for sustainable packaging options. This trend is particularly pronounced among millennial and Gen Z demographics, who demonstrate higher environmental consciousness in purchasing decisions.

Regulatory frameworks worldwide are increasingly stringent regarding single-use plastics and non-biodegradable packaging materials. The European Union's Single-Use Plastics Directive, China's plastic waste import ban, and similar legislation in various countries have created urgent market demand for viable alternatives that maintain necessary barrier properties while offering improved environmental profiles.

The food packaging industry represents the largest application segment for bio-based barrier coatings, accounting for approximately 45% of market demand. This sector requires solutions that provide effective barriers against oxygen, moisture, and grease while maintaining food safety standards. The cosmetics and personal care industry follows as the second-largest application segment, with pharmaceutical packaging showing the fastest growth rate due to increasing regulations on medical waste.

Major consumer packaged goods (CPG) companies have established ambitious sustainability targets, with many pledging to achieve 100% recyclable, reusable, or compostable packaging by 2025-2030. These corporate commitments have accelerated research and development investments in bio-based barrier technologies that can match the performance of conventional materials.

Market challenges primarily revolve around performance limitations of current bio-based solutions, particularly regarding thermal stability and mechanical integrity under various environmental conditions. End-users report concerns about shelf-life reduction, processing compatibility with existing manufacturing equipment, and cost premiums compared to conventional alternatives. The price differential between bio-based and petroleum-based packaging solutions remains a significant market barrier, though this gap has narrowed in recent years due to economies of scale and technological advancements.

Regional analysis reveals that Europe leads in adoption of bio-based barrier coatings, followed by North America, while Asia-Pacific represents the fastest-growing market due to rapid industrialization, expanding middle-class populations, and increasing environmental regulations in countries like China, Japan, and South Korea.

Consumer preferences have shifted dramatically toward environmentally responsible products, with recent surveys indicating that over 70% of consumers across North America, Europe, and Asia-Pacific regions express willingness to pay premium prices for sustainable packaging options. This trend is particularly pronounced among millennial and Gen Z demographics, who demonstrate higher environmental consciousness in purchasing decisions.

Regulatory frameworks worldwide are increasingly stringent regarding single-use plastics and non-biodegradable packaging materials. The European Union's Single-Use Plastics Directive, China's plastic waste import ban, and similar legislation in various countries have created urgent market demand for viable alternatives that maintain necessary barrier properties while offering improved environmental profiles.

The food packaging industry represents the largest application segment for bio-based barrier coatings, accounting for approximately 45% of market demand. This sector requires solutions that provide effective barriers against oxygen, moisture, and grease while maintaining food safety standards. The cosmetics and personal care industry follows as the second-largest application segment, with pharmaceutical packaging showing the fastest growth rate due to increasing regulations on medical waste.

Major consumer packaged goods (CPG) companies have established ambitious sustainability targets, with many pledging to achieve 100% recyclable, reusable, or compostable packaging by 2025-2030. These corporate commitments have accelerated research and development investments in bio-based barrier technologies that can match the performance of conventional materials.

Market challenges primarily revolve around performance limitations of current bio-based solutions, particularly regarding thermal stability and mechanical integrity under various environmental conditions. End-users report concerns about shelf-life reduction, processing compatibility with existing manufacturing equipment, and cost premiums compared to conventional alternatives. The price differential between bio-based and petroleum-based packaging solutions remains a significant market barrier, though this gap has narrowed in recent years due to economies of scale and technological advancements.

Regional analysis reveals that Europe leads in adoption of bio-based barrier coatings, followed by North America, while Asia-Pacific represents the fastest-growing market due to rapid industrialization, expanding middle-class populations, and increasing environmental regulations in countries like China, Japan, and South Korea.

Technical Challenges in Bio-based Coating Stability

Bio-based barrier coatings face significant thermal stability challenges that limit their widespread industrial adoption. When exposed to elevated temperatures during processing or end-use applications, these coatings often undergo structural degradation, resulting in compromised barrier properties. The primary issue stems from the inherent thermal sensitivity of bio-based polymers, which typically begin to degrade at temperatures between 150-250°C, substantially lower than their petroleum-based counterparts.

The mechanical integrity of bio-based coatings presents another critical challenge. These coatings frequently exhibit brittleness and poor adhesion to substrates, particularly under fluctuating environmental conditions. The dimensional stability is compromised during thermal cycling, leading to micro-crack formation that creates pathways for moisture and gas permeation, ultimately defeating the barrier purpose.

Cross-linking deficiencies represent a significant technical hurdle. Unlike conventional synthetic coatings with well-established cross-linking mechanisms, bio-based alternatives often rely on natural cross-linking agents that provide insufficient bond density and strength. This results in reduced cohesive strength and diminished resistance to thermal stress, particularly at the coating-substrate interface.

Water sensitivity compounds these challenges, as many bio-based materials are inherently hydrophilic. When exposed to moisture at elevated temperatures, these coatings can undergo hydrolytic degradation, swelling, and plasticization effects that permanently alter their barrier properties. This hygroscopic nature creates a complex technical challenge requiring innovative solutions to maintain coating integrity in humid environments.

Phase separation during thermal processing presents another obstacle. Bio-based coating formulations often contain multiple components with varying thermal properties, leading to phase incompatibility at elevated temperatures. This results in non-uniform films with localized weak points that compromise overall barrier performance.

The processing window for bio-based coatings is notably narrow compared to conventional alternatives. The temperature range between achieving proper flow characteristics and the onset of thermal degradation is often just 20-30°C, making manufacturing control extremely challenging. This narrow processing window limits production speeds and increases manufacturing complexity.

Antioxidant depletion occurs rapidly in bio-based systems exposed to heat, as natural antioxidants present in bio-based materials are typically less thermally stable than synthetic alternatives. This accelerated depletion leaves the coating vulnerable to oxidative degradation, particularly during extended exposure to elevated temperatures, resulting in chain scission and deterioration of mechanical properties.

The mechanical integrity of bio-based coatings presents another critical challenge. These coatings frequently exhibit brittleness and poor adhesion to substrates, particularly under fluctuating environmental conditions. The dimensional stability is compromised during thermal cycling, leading to micro-crack formation that creates pathways for moisture and gas permeation, ultimately defeating the barrier purpose.

Cross-linking deficiencies represent a significant technical hurdle. Unlike conventional synthetic coatings with well-established cross-linking mechanisms, bio-based alternatives often rely on natural cross-linking agents that provide insufficient bond density and strength. This results in reduced cohesive strength and diminished resistance to thermal stress, particularly at the coating-substrate interface.

Water sensitivity compounds these challenges, as many bio-based materials are inherently hydrophilic. When exposed to moisture at elevated temperatures, these coatings can undergo hydrolytic degradation, swelling, and plasticization effects that permanently alter their barrier properties. This hygroscopic nature creates a complex technical challenge requiring innovative solutions to maintain coating integrity in humid environments.

Phase separation during thermal processing presents another obstacle. Bio-based coating formulations often contain multiple components with varying thermal properties, leading to phase incompatibility at elevated temperatures. This results in non-uniform films with localized weak points that compromise overall barrier performance.

The processing window for bio-based coatings is notably narrow compared to conventional alternatives. The temperature range between achieving proper flow characteristics and the onset of thermal degradation is often just 20-30°C, making manufacturing control extremely challenging. This narrow processing window limits production speeds and increases manufacturing complexity.

Antioxidant depletion occurs rapidly in bio-based systems exposed to heat, as natural antioxidants present in bio-based materials are typically less thermally stable than synthetic alternatives. This accelerated depletion leaves the coating vulnerable to oxidative degradation, particularly during extended exposure to elevated temperatures, resulting in chain scission and deterioration of mechanical properties.

Current Thermal Stabilization Approaches for Bio-coatings

01 Bio-based polymers for barrier coatings

Bio-based polymers derived from renewable resources can be used to create effective barrier coatings with enhanced thermal stability and mechanical integrity. These polymers, such as polylactic acid (PLA), cellulose derivatives, and starch-based materials, provide sustainable alternatives to petroleum-based coatings while maintaining essential barrier properties against moisture, oxygen, and other environmental factors. The incorporation of these bio-based materials can result in coatings that exhibit good thermal resistance and mechanical strength suitable for various packaging and construction applications.- Bio-based polymers for barrier coatings: Bio-based polymers derived from renewable resources can be used to create effective barrier coatings with enhanced thermal stability and mechanical integrity. These polymers include polylactic acid (PLA), cellulose derivatives, and other plant-based materials that can be formulated into coatings that provide protection against moisture, oxygen, and other environmental factors. The renewable nature of these materials makes them environmentally friendly alternatives to petroleum-based polymers while still maintaining necessary performance characteristics.

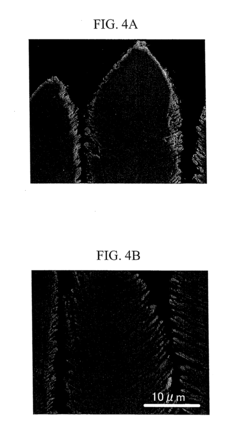

- Nanocomposite reinforcement for thermal stability: Incorporating nanoparticles such as nanoclay, nanocellulose, or silica into bio-based barrier coatings significantly enhances their thermal stability and mechanical properties. These nanocomposites create a tortuous path for gas molecules, improving barrier properties while simultaneously increasing heat resistance. The nanoparticles act as reinforcing agents that can withstand high temperatures without degradation, making these coatings suitable for applications requiring exposure to elevated temperatures while maintaining structural integrity.

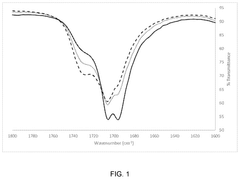

- Crosslinking techniques for improved mechanical integrity: Various crosslinking methods can be applied to bio-based barrier coatings to enhance their mechanical integrity and thermal stability. These techniques include chemical crosslinking with natural or synthetic agents, UV-initiated crosslinking, and thermal curing processes. Crosslinking creates a three-dimensional network structure within the coating, resulting in improved tensile strength, flexibility, and resistance to environmental stressors while maintaining the bio-based nature of the material.

- Multi-layer barrier systems with bio-based components: Multi-layer coating systems that incorporate bio-based materials in strategic layers can achieve superior barrier properties along with enhanced thermal stability and mechanical integrity. These systems typically combine different bio-based polymers with complementary properties or integrate bio-based layers with conventional materials to create synergistic effects. The layered structure allows for optimization of specific properties in each layer while maintaining overall sustainability and performance requirements.

- Additives for enhanced thermal and mechanical performance: Specific additives can be incorporated into bio-based barrier coatings to enhance their thermal stability and mechanical integrity. These include natural fibers, bio-based plasticizers, antioxidants, and flame retardants derived from renewable sources. The additives modify the polymer matrix to improve heat resistance, flexibility, and strength without compromising the environmentally friendly aspects of the coating. Careful selection and optimization of these additives can result in bio-based coatings that meet or exceed the performance of conventional petroleum-based alternatives.

02 Nanocomposite reinforcement for improved thermal stability

The addition of nanoparticles to bio-based barrier coatings significantly enhances their thermal stability and mechanical properties. Nanomaterials such as nanoclay, nanocellulose, and silica nanoparticles create a tortuous path for gas molecules, improving barrier properties while simultaneously reinforcing the coating matrix. These nanocomposites demonstrate increased heat resistance, reduced thermal expansion, and improved structural integrity at elevated temperatures, making them suitable for applications requiring exposure to thermal stress while maintaining barrier functionality.Expand Specific Solutions03 Crosslinking techniques for enhanced mechanical integrity

Various crosslinking methods can be employed to improve the mechanical integrity and thermal stability of bio-based barrier coatings. Chemical crosslinking agents, UV-initiated crosslinking, and enzymatic approaches create stronger intermolecular bonds within the coating structure. These techniques result in coatings with improved tensile strength, abrasion resistance, and dimensional stability under thermal stress. Crosslinked bio-based coatings maintain their barrier properties even after exposure to elevated temperatures, making them suitable for demanding applications where conventional bio-based materials might fail.Expand Specific Solutions04 Multi-layer barrier systems with bio-based components

Multi-layer coating systems that incorporate bio-based materials in strategic layers can achieve superior thermal stability and mechanical integrity. These systems typically combine bio-based layers with complementary conventional materials to optimize performance. The layered structure allows for tailored properties, with some layers providing excellent barrier properties while others contribute mechanical strength or thermal resistance. This approach enables the development of coatings that maintain their integrity across a wide temperature range while reducing the overall environmental impact compared to fully synthetic systems.Expand Specific Solutions05 Additives for improving thermal and mechanical properties

Specific additives can be incorporated into bio-based barrier coatings to enhance their thermal stability and mechanical integrity. These include natural antioxidants, flame retardants, plasticizers, and compatibilizers that improve the performance of the base bio-polymer. The additives work by preventing thermal degradation, improving flexibility without sacrificing strength, or enhancing the compatibility between different components in the coating formulation. Properly selected additives can significantly extend the temperature range in which bio-based coatings maintain their barrier properties and structural integrity.Expand Specific Solutions

Leading Companies and Research Institutions in Bio-coatings

The bio-based barrier coatings market is in a growth phase, characterized by increasing demand for sustainable packaging solutions. The market size is expanding rapidly due to environmental regulations and consumer preferences, with projections indicating significant growth over the next decade. Technologically, the field is advancing from early commercial applications toward maturity, with companies at different development stages. Leading players like Mitsubishi Heavy Industries and Toshiba are focusing on thermal stability improvements, while academic institutions such as Tsinghua University and South China Agricultural University are conducting fundamental research. Kemira Oyj and Sun Chemical are developing commercial applications, while specialized firms like Shanghai Sanyin Paint and Guangdong Carbon and New Material Technology are creating innovative bio-based formulations that address mechanical integrity challenges in diverse environmental conditions.

ROLLS ROYCE PLC

Technical Solution: Rolls Royce has pioneered a bio-mimetic approach to thermal barrier coatings using renewable materials derived from agricultural waste. Their proprietary "BioShield" technology incorporates modified lignin and cellulose nanocrystals extracted from sustainable sources to create multi-functional barrier coatings. The company's innovation lies in their cross-linking technology that bonds these bio-based components with conventional ceramic materials, creating a hybrid structure with enhanced thermal stability. Laboratory testing demonstrates these coatings can withstand temperatures up to 900°C while maintaining mechanical integrity. Rolls Royce has developed a specialized application process that allows for controlled thickness deposition (15-200 μm) depending on the specific thermal requirements. The coatings exhibit self-healing properties when minor damage occurs, as the bio-based components undergo controlled transformation under heat exposure, effectively sealing microcracks before they propagate through the coating structure.

Strengths: Innovative self-healing capabilities reduce maintenance requirements, excellent adhesion to various substrate materials, and significant weight reduction compared to traditional ceramic coatings. Weaknesses: Currently limited to applications below 1000°C, which restricts use in the hottest sections of jet engines, and higher manufacturing complexity requiring specialized application equipment.

Kemira Oyj

Technical Solution: Kemira has developed an innovative bio-based barrier coating technology called "CellGuard" that leverages their expertise in pulp and paper chemistry. Their approach utilizes modified cellulose derivatives and bio-based polymers derived from side streams of the forest industry to create environmentally friendly thermal barrier coatings. Kemira's technology incorporates a unique layering system with nanocellulose as the primary component, modified with silica precursors and cross-linked with bio-based polyols to enhance thermal stability. The company has developed a water-based application process that significantly reduces VOC emissions during manufacturing and application. Laboratory testing demonstrates these coatings can withstand temperatures up to 400°C while maintaining structural integrity, with excellent resistance to thermal cycling. Kemira has successfully implemented these coatings in packaging applications requiring heat resistance and moisture barriers, showing a 50% reduction in carbon footprint compared to conventional petroleum-based barrier coatings while achieving comparable or superior barrier properties against oxygen, water vapor, and grease.

Strengths: Excellent biodegradability at end-of-life, superior moisture barrier properties combined with thermal resistance, and compatibility with existing coating application equipment. Weaknesses: Lower maximum temperature threshold compared to inorganic systems limits applications to moderate temperature environments, and potential for higher water absorption in extremely humid conditions requiring additional protective measures.

Key Patents and Innovations in Bio-based Barrier Materials

Thermal barrier coating system and method of manufacturing the same

PatentInactiveUS20080075879A1

Innovation

- A thermal barrier coating system with a ceramics thermal barrier layer formed via electron beam physical vapor deposition (EB-PVD) method, incorporating 0.1 to 10 mol % of lanthanum oxide (La2O3) in a columnar structure of stabilized zirconia (ZrO2) or zirconia-hafnia (ZrO2-HfO2) solid solution, which reduces thermal conductivity and enhances durability and heat resistance.

Method of applying a wood bark derived substance on a surface

PatentPendingUS20240392506A1

Innovation

- A method involving the application and polymerization of wood bark-derived substances, such as suberin, on fibrous substrates using condensation or esterification reactions, with optional heat treatment, to create a bio-based barrier coating that enhances moisture resistance and mechanical properties.

Environmental Impact and Life Cycle Assessment

The environmental impact of bio-based barrier coatings represents a critical dimension in their overall assessment and market viability. Compared to conventional petroleum-derived coatings, bio-based alternatives generally demonstrate significantly lower carbon footprints throughout their life cycles. Recent life cycle assessment (LCA) studies indicate that bio-based barrier coatings can reduce greenhouse gas emissions by 30-45% compared to their synthetic counterparts, primarily due to the renewable nature of their raw materials.

Water consumption patterns vary considerably depending on the specific biomass feedstock utilized. While some plant-based materials require substantial irrigation during cultivation, others like agricultural residues offer environmental advantages by repurposing waste streams. The water footprint analysis of various bio-based coating formulations reveals that those derived from agricultural by-products typically consume 25-40% less water across their life cycle compared to first-generation biomass sources.

Land use considerations present both challenges and opportunities. The cultivation of dedicated crops for bio-based coatings raises concerns about potential competition with food production and biodiversity impacts. However, innovations in utilizing non-food biomass sources and industrial side-streams have emerged as promising approaches to mitigate these concerns while maintaining the thermal stability and mechanical integrity required for effective barrier properties.

End-of-life scenarios for bio-based barrier coatings offer substantial environmental benefits. Many formulations demonstrate enhanced biodegradability compared to conventional alternatives, with laboratory testing showing complete decomposition within 3-6 months under industrial composting conditions. This characteristic significantly reduces waste accumulation and microplastic pollution potential, addressing growing regulatory and consumer concerns regarding persistent packaging materials.

Chemical safety profiles of bio-based barrier coatings generally show reduced toxicity and ecotoxicity compared to petroleum-based alternatives. The absence of bisphenol A, phthalates, and certain volatile organic compounds in many bio-based formulations translates to lower environmental hazards during production, use, and disposal phases. However, certain bio-based additives used to enhance thermal stability may introduce their own environmental considerations that require careful assessment.

Regulatory frameworks increasingly recognize the environmental advantages of bio-based materials through preferential treatment in extended producer responsibility schemes and waste management regulations. The EU's Circular Economy Action Plan and similar initiatives worldwide are creating policy environments that favor materials with demonstrable environmental benefits across their complete life cycles, potentially accelerating market adoption of thermally stable bio-based barrier coatings despite their current cost premiums.

Water consumption patterns vary considerably depending on the specific biomass feedstock utilized. While some plant-based materials require substantial irrigation during cultivation, others like agricultural residues offer environmental advantages by repurposing waste streams. The water footprint analysis of various bio-based coating formulations reveals that those derived from agricultural by-products typically consume 25-40% less water across their life cycle compared to first-generation biomass sources.

Land use considerations present both challenges and opportunities. The cultivation of dedicated crops for bio-based coatings raises concerns about potential competition with food production and biodiversity impacts. However, innovations in utilizing non-food biomass sources and industrial side-streams have emerged as promising approaches to mitigate these concerns while maintaining the thermal stability and mechanical integrity required for effective barrier properties.

End-of-life scenarios for bio-based barrier coatings offer substantial environmental benefits. Many formulations demonstrate enhanced biodegradability compared to conventional alternatives, with laboratory testing showing complete decomposition within 3-6 months under industrial composting conditions. This characteristic significantly reduces waste accumulation and microplastic pollution potential, addressing growing regulatory and consumer concerns regarding persistent packaging materials.

Chemical safety profiles of bio-based barrier coatings generally show reduced toxicity and ecotoxicity compared to petroleum-based alternatives. The absence of bisphenol A, phthalates, and certain volatile organic compounds in many bio-based formulations translates to lower environmental hazards during production, use, and disposal phases. However, certain bio-based additives used to enhance thermal stability may introduce their own environmental considerations that require careful assessment.

Regulatory frameworks increasingly recognize the environmental advantages of bio-based materials through preferential treatment in extended producer responsibility schemes and waste management regulations. The EU's Circular Economy Action Plan and similar initiatives worldwide are creating policy environments that favor materials with demonstrable environmental benefits across their complete life cycles, potentially accelerating market adoption of thermally stable bio-based barrier coatings despite their current cost premiums.

Regulatory Framework for Food-Contact Bio-based Materials

The regulatory landscape governing bio-based barrier coatings for food packaging is complex and continuously evolving. In the United States, the FDA regulates food-contact materials through the Food, Drug, and Cosmetic Act, requiring manufacturers to demonstrate that their bio-based coatings are safe for intended use. The FDA's Food Contact Notification (FCN) program provides a streamlined pathway for approval, though novel bio-based materials often face additional scrutiny regarding migration potential and toxicological profiles.

In the European Union, Regulation (EC) No 1935/2004 establishes the framework for food-contact materials, complemented by specific measures for certain material types. The EU has implemented a positive list approach through Regulation (EU) No 10/2011 for plastic materials, which impacts bio-based coatings when they contain plastic components. Additionally, the Novel Food Regulation (EU) 2015/2283 may apply to certain bio-based materials derived from unconventional sources.

The thermal stability requirements for food-contact materials are particularly stringent, with regulations specifying temperature ranges for various applications. Bio-based barrier coatings must maintain their integrity without releasing harmful substances when exposed to temperatures ranging from freezing to cooking conditions, depending on the intended use.

Migration limits represent a critical regulatory parameter, with both the EU and FDA establishing specific migration limits (SMLs) for substances that might transfer from packaging to food. For bio-based coatings, demonstrating compliance with these migration limits can be challenging due to the complex nature of natural polymers and their degradation products under thermal stress.

Certification systems have emerged to validate the environmental claims of bio-based materials. The USDA BioPreferred program in the US and the European CEN standards (EN 16785) for bio-based content determination provide frameworks for verifying the renewable content of packaging materials. These certifications are increasingly important for market access as consumers demand transparent sustainability credentials.

Emerging regulations are focusing on the end-of-life considerations for bio-based materials. The EU's Single-Use Plastics Directive and various national composting standards (such as EN 13432) are shaping requirements for biodegradability and compostability claims, which many bio-based coating manufacturers promote as a key advantage of their products.

Global harmonization efforts, led by organizations like the International Organization for Standardization (ISO), are working to standardize testing methodologies and safety assessments for bio-based materials, though significant regional differences in regulatory approaches persist, creating compliance challenges for global manufacturers of thermally stable bio-based barrier coatings.

In the European Union, Regulation (EC) No 1935/2004 establishes the framework for food-contact materials, complemented by specific measures for certain material types. The EU has implemented a positive list approach through Regulation (EU) No 10/2011 for plastic materials, which impacts bio-based coatings when they contain plastic components. Additionally, the Novel Food Regulation (EU) 2015/2283 may apply to certain bio-based materials derived from unconventional sources.

The thermal stability requirements for food-contact materials are particularly stringent, with regulations specifying temperature ranges for various applications. Bio-based barrier coatings must maintain their integrity without releasing harmful substances when exposed to temperatures ranging from freezing to cooking conditions, depending on the intended use.

Migration limits represent a critical regulatory parameter, with both the EU and FDA establishing specific migration limits (SMLs) for substances that might transfer from packaging to food. For bio-based coatings, demonstrating compliance with these migration limits can be challenging due to the complex nature of natural polymers and their degradation products under thermal stress.

Certification systems have emerged to validate the environmental claims of bio-based materials. The USDA BioPreferred program in the US and the European CEN standards (EN 16785) for bio-based content determination provide frameworks for verifying the renewable content of packaging materials. These certifications are increasingly important for market access as consumers demand transparent sustainability credentials.

Emerging regulations are focusing on the end-of-life considerations for bio-based materials. The EU's Single-Use Plastics Directive and various national composting standards (such as EN 13432) are shaping requirements for biodegradability and compostability claims, which many bio-based coating manufacturers promote as a key advantage of their products.

Global harmonization efforts, led by organizations like the International Organization for Standardization (ISO), are working to standardize testing methodologies and safety assessments for bio-based materials, though significant regional differences in regulatory approaches persist, creating compliance challenges for global manufacturers of thermally stable bio-based barrier coatings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!