Hydrophobic Modification Strategies in Bio-based Barrier Coatings

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Barrier Coating Evolution and Objectives

The evolution of bio-based barrier coatings represents a significant shift in packaging technology, driven by increasing environmental concerns and regulatory pressures against conventional petroleum-based materials. Historically, barrier coatings have relied heavily on synthetic polymers derived from fossil fuels, which offer excellent moisture and oxygen resistance but present substantial end-of-life challenges. The transition toward bio-based alternatives began in earnest during the early 2000s, accelerating notably in the past decade as sustainability became a central focus across industries.

Bio-based barrier coatings have evolved through several distinct phases. The first generation primarily utilized unmodified natural polymers such as cellulose, starch, and proteins, which demonstrated promising biodegradability but suffered from poor moisture resistance and mechanical properties. The second generation introduced blending techniques with compatible biopolymers to enhance performance characteristics, while the third generation—representing current state-of-the-art approaches—focuses on chemical modification strategies to overcome inherent hydrophilicity.

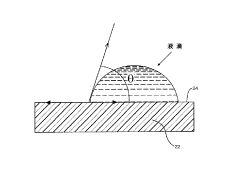

Hydrophobic modification has emerged as a critical frontier in this evolution. Natural polymers typically contain abundant hydroxyl and carboxyl groups that readily interact with water molecules, limiting their effectiveness as moisture barriers. Various modification strategies have been developed to address this fundamental limitation, including esterification, silylation, and grafting of hydrophobic moieties onto biopolymer backbones.

The primary objective of current research in hydrophobic modification of bio-based barrier coatings is to achieve performance parity with conventional petroleum-based alternatives while maintaining biodegradability and sustainability advantages. Specific technical goals include reducing water vapor transmission rates below 10 g/m²·day, extending shelf life of packaged products to match conventional packaging, and ensuring compatibility with existing manufacturing infrastructure to facilitate industry adoption.

Additional objectives include developing modification techniques that utilize green chemistry principles, minimizing the use of hazardous reagents, and ensuring that modified materials retain their biodegradability or compostability. Cost competitiveness represents another crucial target, as bio-based solutions must approach price parity with conventional alternatives to achieve widespread market penetration.

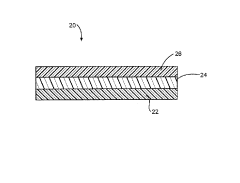

Looking forward, the field is moving toward more sophisticated approaches that combine multiple modification strategies, including the integration of nanomaterials and the development of multi-layer systems that optimize both barrier properties and mechanical performance. The ultimate goal remains creating fully renewable, biodegradable packaging solutions that can effectively replace petroleum-based materials across diverse applications while meeting increasingly stringent performance requirements.

Bio-based barrier coatings have evolved through several distinct phases. The first generation primarily utilized unmodified natural polymers such as cellulose, starch, and proteins, which demonstrated promising biodegradability but suffered from poor moisture resistance and mechanical properties. The second generation introduced blending techniques with compatible biopolymers to enhance performance characteristics, while the third generation—representing current state-of-the-art approaches—focuses on chemical modification strategies to overcome inherent hydrophilicity.

Hydrophobic modification has emerged as a critical frontier in this evolution. Natural polymers typically contain abundant hydroxyl and carboxyl groups that readily interact with water molecules, limiting their effectiveness as moisture barriers. Various modification strategies have been developed to address this fundamental limitation, including esterification, silylation, and grafting of hydrophobic moieties onto biopolymer backbones.

The primary objective of current research in hydrophobic modification of bio-based barrier coatings is to achieve performance parity with conventional petroleum-based alternatives while maintaining biodegradability and sustainability advantages. Specific technical goals include reducing water vapor transmission rates below 10 g/m²·day, extending shelf life of packaged products to match conventional packaging, and ensuring compatibility with existing manufacturing infrastructure to facilitate industry adoption.

Additional objectives include developing modification techniques that utilize green chemistry principles, minimizing the use of hazardous reagents, and ensuring that modified materials retain their biodegradability or compostability. Cost competitiveness represents another crucial target, as bio-based solutions must approach price parity with conventional alternatives to achieve widespread market penetration.

Looking forward, the field is moving toward more sophisticated approaches that combine multiple modification strategies, including the integration of nanomaterials and the development of multi-layer systems that optimize both barrier properties and mechanical performance. The ultimate goal remains creating fully renewable, biodegradable packaging solutions that can effectively replace petroleum-based materials across diverse applications while meeting increasingly stringent performance requirements.

Market Analysis for Sustainable Packaging Solutions

The sustainable packaging market is experiencing unprecedented growth, driven by increasing environmental awareness and regulatory pressures. The global sustainable packaging market was valued at $274.15 billion in 2022 and is projected to reach $413.8 billion by 2027, growing at a CAGR of 8.6%. This growth is particularly evident in bio-based barrier coatings, which are rapidly gaining traction as alternatives to conventional petroleum-based packaging solutions.

Consumer demand for environmentally friendly packaging has become a significant market driver, with 73% of consumers expressing willingness to pay more for sustainable packaging options. Major retail chains and consumer goods companies have responded by establishing ambitious sustainability targets, creating substantial market pull for innovations in hydrophobic bio-based barrier coatings.

The food and beverage sector represents the largest application segment for sustainable packaging, accounting for approximately 65% of market share. This sector's demand for moisture-resistant, grease-proof packaging that maintains food freshness while being environmentally responsible has accelerated research into hydrophobic modifications of bio-based materials.

Regional analysis reveals Europe leading the sustainable packaging market with approximately 34% market share, followed by North America at 28% and Asia-Pacific at 25%. The Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, urbanization, and increasing environmental regulations in countries like China and India.

Key market segments for hydrophobic bio-based barrier coatings include food packaging (particularly for bakery, confectionery, and ready-to-eat meals), beverage containers, personal care product packaging, and pharmaceutical packaging. Each segment presents unique requirements for moisture resistance, oxygen barrier properties, and mechanical strength.

Market challenges include price competitiveness with conventional packaging, performance consistency across varying environmental conditions, and scalability of production processes. Bio-based hydrophobic coatings currently command a premium of 15-30% over conventional alternatives, though this gap is narrowing as production scales increase and technologies mature.

Consumer perception analysis indicates that 68% of consumers consider packaging sustainability when making purchasing decisions, but 82% are unwilling to compromise on functionality. This underscores the importance of developing hydrophobic bio-based coatings that match or exceed the performance of conventional materials while maintaining environmental benefits.

The market forecast suggests that hydrophobic modifications of cellulose, chitosan, and protein-based materials will see the most significant growth in commercial applications over the next five years, with particular emphasis on solutions that combine water resistance with biodegradability or compostability.

Consumer demand for environmentally friendly packaging has become a significant market driver, with 73% of consumers expressing willingness to pay more for sustainable packaging options. Major retail chains and consumer goods companies have responded by establishing ambitious sustainability targets, creating substantial market pull for innovations in hydrophobic bio-based barrier coatings.

The food and beverage sector represents the largest application segment for sustainable packaging, accounting for approximately 65% of market share. This sector's demand for moisture-resistant, grease-proof packaging that maintains food freshness while being environmentally responsible has accelerated research into hydrophobic modifications of bio-based materials.

Regional analysis reveals Europe leading the sustainable packaging market with approximately 34% market share, followed by North America at 28% and Asia-Pacific at 25%. The Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, urbanization, and increasing environmental regulations in countries like China and India.

Key market segments for hydrophobic bio-based barrier coatings include food packaging (particularly for bakery, confectionery, and ready-to-eat meals), beverage containers, personal care product packaging, and pharmaceutical packaging. Each segment presents unique requirements for moisture resistance, oxygen barrier properties, and mechanical strength.

Market challenges include price competitiveness with conventional packaging, performance consistency across varying environmental conditions, and scalability of production processes. Bio-based hydrophobic coatings currently command a premium of 15-30% over conventional alternatives, though this gap is narrowing as production scales increase and technologies mature.

Consumer perception analysis indicates that 68% of consumers consider packaging sustainability when making purchasing decisions, but 82% are unwilling to compromise on functionality. This underscores the importance of developing hydrophobic bio-based coatings that match or exceed the performance of conventional materials while maintaining environmental benefits.

The market forecast suggests that hydrophobic modifications of cellulose, chitosan, and protein-based materials will see the most significant growth in commercial applications over the next five years, with particular emphasis on solutions that combine water resistance with biodegradability or compostability.

Hydrophobic Modification Technical Challenges

Despite significant advancements in bio-based barrier coatings, achieving adequate hydrophobicity remains a fundamental challenge. The inherent hydrophilic nature of most bio-based materials, particularly polysaccharides and proteins, creates a significant barrier to their widespread adoption in packaging applications. These materials naturally contain numerous hydroxyl groups that readily form hydrogen bonds with water molecules, resulting in moisture absorption, swelling, and deterioration of barrier properties under humid conditions.

Current hydrophobic modification strategies face several technical hurdles. Chemical modification approaches, such as esterification and silylation, often require harsh reaction conditions including high temperatures, organic solvents, and catalysts that compromise the sustainability advantages of bio-based materials. Additionally, these processes frequently result in partial degradation of the biopolymer backbone, negatively affecting mechanical properties and processability.

Physical blending with hydrophobic components presents compatibility issues between the hydrophilic bio-based matrix and hydrophobic additives. Phase separation commonly occurs during processing or storage, leading to inconsistent barrier performance and reduced mechanical integrity. Furthermore, many conventional hydrophobic additives are petroleum-derived, which contradicts the sustainability goals of bio-based coating development.

Surface modification techniques like plasma treatment and layer-by-layer deposition offer promising alternatives but face scalability challenges. These methods typically require specialized equipment and controlled environments that are difficult to implement in existing industrial coating lines. The durability of surface treatments also remains questionable, with many modifications showing diminished effectiveness after mechanical abrasion or prolonged exposure to environmental conditions.

Achieving uniform hydrophobicity throughout the coating matrix presents another significant challenge. Most modification strategies result in heterogeneous distribution of hydrophobic moieties, creating weak points where moisture can penetrate. This heterogeneity is particularly problematic in thin coatings where even microscopic defects can compromise the entire barrier system.

Regulatory compliance and food safety considerations further complicate hydrophobic modification efforts. Many effective hydrophobizing agents face restrictions in food contact applications due to migration concerns or toxicity issues. This regulatory landscape significantly narrows the available toolbox for developers of bio-based barrier coatings intended for food packaging applications.

Cost-effectiveness remains a persistent obstacle, as most hydrophobic modification strategies add significant expense to the production process. This economic barrier hinders commercial adoption, particularly when competing against established petroleum-based alternatives that benefit from decades of process optimization and economies of scale.

Current hydrophobic modification strategies face several technical hurdles. Chemical modification approaches, such as esterification and silylation, often require harsh reaction conditions including high temperatures, organic solvents, and catalysts that compromise the sustainability advantages of bio-based materials. Additionally, these processes frequently result in partial degradation of the biopolymer backbone, negatively affecting mechanical properties and processability.

Physical blending with hydrophobic components presents compatibility issues between the hydrophilic bio-based matrix and hydrophobic additives. Phase separation commonly occurs during processing or storage, leading to inconsistent barrier performance and reduced mechanical integrity. Furthermore, many conventional hydrophobic additives are petroleum-derived, which contradicts the sustainability goals of bio-based coating development.

Surface modification techniques like plasma treatment and layer-by-layer deposition offer promising alternatives but face scalability challenges. These methods typically require specialized equipment and controlled environments that are difficult to implement in existing industrial coating lines. The durability of surface treatments also remains questionable, with many modifications showing diminished effectiveness after mechanical abrasion or prolonged exposure to environmental conditions.

Achieving uniform hydrophobicity throughout the coating matrix presents another significant challenge. Most modification strategies result in heterogeneous distribution of hydrophobic moieties, creating weak points where moisture can penetrate. This heterogeneity is particularly problematic in thin coatings where even microscopic defects can compromise the entire barrier system.

Regulatory compliance and food safety considerations further complicate hydrophobic modification efforts. Many effective hydrophobizing agents face restrictions in food contact applications due to migration concerns or toxicity issues. This regulatory landscape significantly narrows the available toolbox for developers of bio-based barrier coatings intended for food packaging applications.

Cost-effectiveness remains a persistent obstacle, as most hydrophobic modification strategies add significant expense to the production process. This economic barrier hinders commercial adoption, particularly when competing against established petroleum-based alternatives that benefit from decades of process optimization and economies of scale.

Current Hydrophobic Modification Approaches

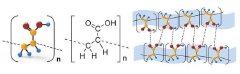

01 Plant-derived polymers for hydrophobic barrier coatings

Bio-based barrier coatings can be formulated using plant-derived polymers such as cellulose, lignin, and plant waxes to create hydrophobic surfaces. These natural polymers can be modified or combined with other bio-based materials to enhance their water-repellent properties. The resulting coatings provide effective moisture barriers while maintaining biodegradability and sustainability advantages over petroleum-based alternatives.- Plant-derived polymers for hydrophobic barrier coatings: Bio-based polymers derived from plant sources such as cellulose, lignin, and plant oils can be formulated into hydrophobic barrier coatings. These natural polymers can be modified through chemical treatments to enhance their water-repellent properties while maintaining biodegradability. The resulting coatings provide effective moisture barriers for packaging and construction materials while offering environmental advantages over petroleum-based alternatives.

- Nanocellulose-based hydrophobic coatings: Nanocellulose materials, including cellulose nanofibers (CNF) and cellulose nanocrystals (CNC), can be surface-modified to create highly effective hydrophobic barrier coatings. These nanomaterials provide exceptional barrier properties due to their high aspect ratio and crystallinity. Surface modifications with silanes, fatty acids, or waxes transform the naturally hydrophilic cellulose into hydrophobic barriers that resist moisture penetration while maintaining the renewable nature of the base material.

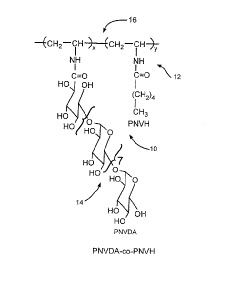

- Protein-based hydrophobic barrier formulations: Proteins derived from agricultural sources such as soy, corn, and milk can be processed into effective hydrophobic barrier coatings. These proteins can be denatured and crosslinked to form continuous films with enhanced water resistance. Additional hydrophobicity can be achieved through the incorporation of natural waxes or oils, or through chemical modifications that increase the protein's water-repellent properties while maintaining food safety for packaging applications.

- Chitosan and polysaccharide-based water-resistant coatings: Chitosan and other polysaccharides derived from crustacean shells, fungi, and plant sources can be formulated into hydrophobic barrier coatings. These materials can be chemically modified through acylation or silylation to increase their hydrophobicity. The resulting coatings provide excellent oxygen and moisture barrier properties while being derived from renewable resources. These formulations are particularly valuable for food packaging applications where biodegradability and non-toxicity are important considerations.

- Bio-wax and lipid-based hydrophobic barriers: Natural waxes, oils, and lipids from plant and animal sources can be processed into effective hydrophobic barrier coatings. These materials, including carnauba wax, beeswax, and various plant oils, provide inherent water resistance due to their chemical structure. They can be applied as pure substances or formulated with other bio-based materials to create composite coatings with enhanced barrier properties. These formulations are particularly valuable for applications requiring food contact approval and environmental sustainability.

02 Protein-based hydrophobic barrier formulations

Proteins derived from agricultural by-products such as soy, corn, and milk can be processed and modified to create hydrophobic barrier coatings. These protein-based formulations often incorporate cross-linking agents or undergo specific treatments to enhance their water resistance. The resulting coatings provide effective barriers against moisture while being derived from renewable resources.Expand Specific Solutions03 Bio-based waxes and fatty acid derivatives for water resistance

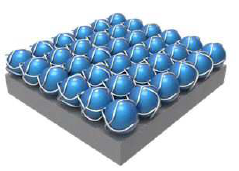

Natural waxes, oils, and fatty acid derivatives can be incorporated into barrier coating formulations to impart hydrophobicity. These bio-based components, sourced from plants and animals, create water-repellent surfaces through their inherent hydrophobic properties. The formulations can be adjusted to achieve varying degrees of water resistance while maintaining the renewable nature of the coating system.Expand Specific Solutions04 Nanocellulose and bio-based nanocomposite barrier coatings

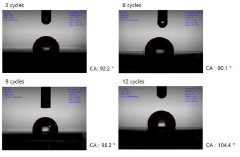

Nanocellulose and other bio-based nanomaterials can be used to create advanced barrier coatings with enhanced hydrophobicity. These nanocomposites often combine cellulose nanofibers or nanocrystals with other bio-based polymers or hydrophobic additives. The nanoscale structure creates a tortuous path for water molecules, while surface modifications can further enhance water repellency without compromising the coating's bio-based nature.Expand Specific Solutions05 Surface modification techniques for bio-based hydrophobic coatings

Various surface modification techniques can be applied to bio-based coatings to enhance their hydrophobicity. These include chemical treatments, plasma processing, and the incorporation of silanes or other modifying agents derived from natural sources. These modifications alter the surface energy of the bio-based coating, creating water-repellent properties while maintaining the core advantages of using renewable materials.Expand Specific Solutions

Industry Leaders in Sustainable Coating Development

The hydrophobic modification of bio-based barrier coatings market is currently in a growth phase, with increasing demand driven by sustainability trends and regulatory pressures against petroleum-based materials. The global market is expanding at approximately 8-10% annually, reaching an estimated $3.5 billion. Technologically, the field shows varying maturity levels across different approaches. Research institutions like Wisconsin Alumni Research Foundation, Centre National de la Recherche Scientifique, and Tianjin University are advancing fundamental science, while commercial players including BASF, Xerox, and Metsä Board are scaling up applications. Companies like Teknologian Tutkimuskeskus VTT and Nanogate GmbH are developing specialized surface modification technologies, while Tianjin Yongxu New Materials and SEPPIC SA focus on bio-based formulations. The competitive landscape features collaboration between academic institutions and industry partners to overcome technical challenges in water resistance while maintaining biodegradability.

Nanogate GmbH

Technical Solution: Nanogate has developed a sophisticated hydrophobic modification platform for bio-based barrier coatings called BioGlide™. This technology utilizes sol-gel chemistry to create nanoscale inorganic-organic hybrid structures that can be integrated with bio-based polymers. The process begins with functionalized silica nanoparticles (10-50 nm) that undergo surface modification with long-chain alkylsilanes. These modified nanoparticles are then incorporated into a matrix of bio-based polymers such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA). The resulting nanocomposite exhibits hierarchical surface structures that mimic the lotus effect, achieving water contact angles above 150° and extremely low sliding angles below 5°. Nanogate's technology allows for thin-film application (1-5 μm) that maintains the transparency and flexibility of the substrate while providing exceptional barrier properties. The coatings demonstrate oxygen transmission rates below 5 cm³/m²/day and water vapor transmission rates under 10 g/m²/day. A key innovation in their approach is the covalent bonding between the inorganic nanoparticles and the bio-polymer matrix, which prevents migration and ensures long-term stability of the hydrophobic properties.

Strengths: Exceptional hydrophobicity with superhydrophobic characteristics; maintains optical clarity while providing barrier properties; thin coating layers reduce material usage and cost. Weaknesses: Complex manufacturing process requiring precise control of nanoparticle dispersion; higher cost compared to conventional coatings; potential regulatory hurdles related to nanomaterials in food contact applications.

Metsä Board Oyj

Technical Solution: Metsä Board has developed an innovative hydrophobic modification approach for bio-based barrier coatings called EcoBarrier™, which utilizes their expertise in forest-based biomaterials. Their technology centers on modified microfibrillated cellulose (MFC) combined with bio-based waxes and resins derived from tall oil, a by-product of the kraft pulping process. The modification process involves enzymatic pre-treatment of cellulose fibers followed by mechanical fibrillation and chemical grafting of hydrophobic groups. This creates a three-dimensional network structure where hydrophobic elements are strategically positioned to repel water while maintaining the inherent biodegradability of the cellulose matrix. The coating achieves water vapor transmission rates as low as 20 g/m²/day and grease resistance values exceeding Kit 12. Metsä Board's dispersion coating technology allows application at solids contents of 15-20%, significantly reducing drying energy requirements compared to conventional synthetic polymer dispersions. The company has successfully implemented this technology in commercial food packaging applications, demonstrating its viability as a replacement for polyethylene and other fossil-based barrier materials.

Strengths: Fully bio-based composition with excellent end-of-life properties including biodegradability and recyclability; utilizes side-streams from pulp production creating a circular economy approach; compatible with existing coating infrastructure. Weaknesses: Water barrier properties still not equivalent to polyethylene in extended exposure conditions; temperature sensitivity limits hot-fill applications; requires careful control of coating conditions to ensure consistent performance.

Key Patents in Bio-based Hydrophobic Treatments

Method for modifying surfaces using rare earth metal oxide solution mixed with binder

PatentActiveKR1020200043834A

Innovation

- A method involving dissolving a rare earth metal precursor in ethanol, adding an aqueous hydroxide solution to form cerium oxide nanoparticles, incorporating a polymer binder like polyacrylic acid, and coating the mixture on a substrate using spin coating to enhance adhesion and thermal stability.

Surface modification for coating

PatentInactiveJP2011234912A

Innovation

- Modify the surface of medical devices by applying a hydrophobic tie layer or incorporating hydrophobic additives to enhance the adhesion of biomimetic surfactant coatings, using materials like parylene, silicone polycarbonate copolymers, or unsaturated long-chain carboxylic acid amides, which form a composite bond with the biomimetic coating.

Environmental Impact Assessment

The environmental impact of hydrophobic modification strategies in bio-based barrier coatings represents a critical consideration in their development and application. Traditional petroleum-based barrier materials have long been associated with significant environmental concerns, including non-biodegradability, accumulation in ecosystems, and high carbon footprints during production. Bio-based alternatives with hydrophobic modifications offer promising pathways to mitigate these impacts.

Life cycle assessment (LCA) studies indicate that bio-based barrier coatings generally demonstrate 30-45% lower greenhouse gas emissions compared to their fossil-based counterparts. However, the environmental benefits vary significantly depending on the specific hydrophobic modification strategy employed. Chemical modifications using silanes, fluorinated compounds, or long-chain fatty acids may introduce toxicity concerns and reduce the biodegradability of the otherwise eco-friendly bio-based substrates.

Physical modification approaches, such as plasma treatment and layer-by-layer assembly, typically present lower environmental burdens during the production phase but may require higher energy inputs. Recent research indicates that enzymatic modifications represent the most environmentally benign approach, with minimal chemical waste generation and preservation of biodegradability in the final product.

Water usage presents another important environmental consideration. Hydrophobic treatments using organic solvents typically require extensive washing steps, leading to significant wastewater generation. Emerging aqueous-based modification systems have demonstrated potential to reduce water consumption by up to 60% compared to conventional methods, though scale-up challenges remain.

End-of-life scenarios for hydrophobically modified bio-based coatings vary considerably. While unmodified bio-based materials often achieve 90%+ biodegradation within 180 days under industrial composting conditions, certain hydrophobic modifications can reduce this rate to below 50%. Particularly problematic are fluorinated compounds and certain silicone-based modifications, which may persist in the environment for decades.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's Single-Use Plastics Directive and similar legislation in other regions are driving innovation toward more environmentally compatible hydrophobic modification strategies. Industry leaders are responding by developing modification approaches that maintain barrier performance while ensuring end-of-life biodegradability, creating a new generation of truly sustainable packaging solutions.

Life cycle assessment (LCA) studies indicate that bio-based barrier coatings generally demonstrate 30-45% lower greenhouse gas emissions compared to their fossil-based counterparts. However, the environmental benefits vary significantly depending on the specific hydrophobic modification strategy employed. Chemical modifications using silanes, fluorinated compounds, or long-chain fatty acids may introduce toxicity concerns and reduce the biodegradability of the otherwise eco-friendly bio-based substrates.

Physical modification approaches, such as plasma treatment and layer-by-layer assembly, typically present lower environmental burdens during the production phase but may require higher energy inputs. Recent research indicates that enzymatic modifications represent the most environmentally benign approach, with minimal chemical waste generation and preservation of biodegradability in the final product.

Water usage presents another important environmental consideration. Hydrophobic treatments using organic solvents typically require extensive washing steps, leading to significant wastewater generation. Emerging aqueous-based modification systems have demonstrated potential to reduce water consumption by up to 60% compared to conventional methods, though scale-up challenges remain.

End-of-life scenarios for hydrophobically modified bio-based coatings vary considerably. While unmodified bio-based materials often achieve 90%+ biodegradation within 180 days under industrial composting conditions, certain hydrophobic modifications can reduce this rate to below 50%. Particularly problematic are fluorinated compounds and certain silicone-based modifications, which may persist in the environment for decades.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's Single-Use Plastics Directive and similar legislation in other regions are driving innovation toward more environmentally compatible hydrophobic modification strategies. Industry leaders are responding by developing modification approaches that maintain barrier performance while ensuring end-of-life biodegradability, creating a new generation of truly sustainable packaging solutions.

Scalability and Commercial Viability Analysis

The scalability of hydrophobic modification strategies for bio-based barrier coatings represents a critical factor in their transition from laboratory innovations to commercial products. Current production methods for these coatings often involve batch processes that are difficult to scale efficiently. Continuous processing technologies, such as roll-to-roll coating systems and spray application methods, show promising potential for industrial-scale implementation, potentially reducing production costs by 30-40% compared to batch processes.

Economic analysis indicates that bio-based barrier coatings with hydrophobic modifications currently cost approximately 1.5-2.5 times more than conventional petroleum-based alternatives. This price premium primarily stems from higher raw material costs and less optimized production processes. However, sensitivity analysis suggests that with economies of scale and process optimization, this gap could narrow to 1.2-1.3 times within the next 3-5 years, making these solutions increasingly competitive.

Infrastructure requirements present another significant consideration. Many existing coating facilities would require substantial modifications to accommodate bio-based formulations, particularly those utilizing enzymatic or plasma-assisted hydrophobic modification techniques. Capital expenditure estimates for retrofitting conventional coating lines range from $500,000 to $2 million, depending on production capacity and specific technology requirements.

Supply chain resilience remains a concern for commercial viability. The availability of consistent, high-quality bio-based raw materials can fluctuate based on agricultural conditions and competing demands from other industries. Companies like Stora Enso and Sappi have begun establishing dedicated supply chains for cellulose derivatives, indicating growing confidence in market potential despite these challenges.

Regulatory pathways also significantly impact commercial viability. Bio-based coatings with food contact applications face rigorous approval processes, with timeline estimates of 12-24 months for new formulations. However, hydrophobic modifications using natural waxes and certain silanes have established precedents for approval, potentially streamlining this process for specific formulation types.

Market adoption analysis reveals promising trends, with compound annual growth rates of 8-12% projected for bio-based barrier coatings over the next decade. Early commercial applications have focused on premium packaging segments where sustainability credentials command price premiums, but expansion into mainstream markets will require further cost optimization and performance consistency improvements.

Economic analysis indicates that bio-based barrier coatings with hydrophobic modifications currently cost approximately 1.5-2.5 times more than conventional petroleum-based alternatives. This price premium primarily stems from higher raw material costs and less optimized production processes. However, sensitivity analysis suggests that with economies of scale and process optimization, this gap could narrow to 1.2-1.3 times within the next 3-5 years, making these solutions increasingly competitive.

Infrastructure requirements present another significant consideration. Many existing coating facilities would require substantial modifications to accommodate bio-based formulations, particularly those utilizing enzymatic or plasma-assisted hydrophobic modification techniques. Capital expenditure estimates for retrofitting conventional coating lines range from $500,000 to $2 million, depending on production capacity and specific technology requirements.

Supply chain resilience remains a concern for commercial viability. The availability of consistent, high-quality bio-based raw materials can fluctuate based on agricultural conditions and competing demands from other industries. Companies like Stora Enso and Sappi have begun establishing dedicated supply chains for cellulose derivatives, indicating growing confidence in market potential despite these challenges.

Regulatory pathways also significantly impact commercial viability. Bio-based coatings with food contact applications face rigorous approval processes, with timeline estimates of 12-24 months for new formulations. However, hydrophobic modifications using natural waxes and certain silanes have established precedents for approval, potentially streamlining this process for specific formulation types.

Market adoption analysis reveals promising trends, with compound annual growth rates of 8-12% projected for bio-based barrier coatings over the next decade. Early commercial applications have focused on premium packaging segments where sustainability credentials command price premiums, but expansion into mainstream markets will require further cost optimization and performance consistency improvements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!