Research on Coating–Substrate Adhesion in Bio-based Barrier Films

OCT 13, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Barrier Films Background and Objectives

The evolution of packaging materials has witnessed a significant shift towards sustainable alternatives in recent decades, driven by growing environmental concerns and regulatory pressures. Bio-based barrier films represent a promising frontier in this transition, offering renewable alternatives to conventional petroleum-based packaging materials. These films, derived from biomass sources such as cellulose, starch, polylactic acid (PLA), and various biopolymers, have emerged as potential solutions to address the environmental impact of traditional packaging while maintaining essential barrier properties against oxygen, moisture, and other permeants.

The development of bio-based barrier films traces back to early experiments with cellulose-based materials in the mid-20th century, but significant advancements have only materialized in the past two decades with improved processing technologies and material science innovations. The technical evolution has progressed from simple biopolymer films with limited barrier properties to sophisticated multi-layer structures and nanocomposites that can rival conventional plastics in performance.

A critical challenge in bio-based barrier film technology lies in the interface between coating and substrate layers. Unlike conventional petroleum-based polymers that often share similar chemical structures and properties, bio-based materials present unique adhesion challenges due to their diverse chemical compositions, surface energies, and mechanical properties. The coating-substrate adhesion directly impacts the film's barrier performance, mechanical integrity, and overall service life.

The primary objective of research in this field is to develop fundamental understanding of the interfacial phenomena governing adhesion between bio-based coatings and substrates. This includes investigating chemical bonding mechanisms, surface modification techniques, and the impact of processing conditions on adhesion strength. Additionally, research aims to establish standardized testing methodologies specifically tailored for bio-based materials, as conventional adhesion tests may not accurately reflect their unique behavior.

Another key goal is to develop commercially viable solutions that can be implemented at industrial scale without significant modifications to existing manufacturing infrastructure. This requires balancing technical performance with economic considerations, ensuring that adhesion improvements do not substantially increase production costs or complexity.

The long-term vision for this research extends beyond immediate technical solutions to encompass the development of design principles and predictive models that can guide future innovations in bio-based barrier films. By establishing a comprehensive understanding of coating-substrate interactions, researchers aim to enable the next generation of sustainable packaging materials that combine excellent barrier properties with robust mechanical performance and minimal environmental footprint.

The development of bio-based barrier films traces back to early experiments with cellulose-based materials in the mid-20th century, but significant advancements have only materialized in the past two decades with improved processing technologies and material science innovations. The technical evolution has progressed from simple biopolymer films with limited barrier properties to sophisticated multi-layer structures and nanocomposites that can rival conventional plastics in performance.

A critical challenge in bio-based barrier film technology lies in the interface between coating and substrate layers. Unlike conventional petroleum-based polymers that often share similar chemical structures and properties, bio-based materials present unique adhesion challenges due to their diverse chemical compositions, surface energies, and mechanical properties. The coating-substrate adhesion directly impacts the film's barrier performance, mechanical integrity, and overall service life.

The primary objective of research in this field is to develop fundamental understanding of the interfacial phenomena governing adhesion between bio-based coatings and substrates. This includes investigating chemical bonding mechanisms, surface modification techniques, and the impact of processing conditions on adhesion strength. Additionally, research aims to establish standardized testing methodologies specifically tailored for bio-based materials, as conventional adhesion tests may not accurately reflect their unique behavior.

Another key goal is to develop commercially viable solutions that can be implemented at industrial scale without significant modifications to existing manufacturing infrastructure. This requires balancing technical performance with economic considerations, ensuring that adhesion improvements do not substantially increase production costs or complexity.

The long-term vision for this research extends beyond immediate technical solutions to encompass the development of design principles and predictive models that can guide future innovations in bio-based barrier films. By establishing a comprehensive understanding of coating-substrate interactions, researchers aim to enable the next generation of sustainable packaging materials that combine excellent barrier properties with robust mechanical performance and minimal environmental footprint.

Market Analysis for Sustainable Packaging Solutions

The sustainable packaging market is experiencing unprecedented growth, driven by increasing environmental awareness and regulatory pressures worldwide. The global sustainable packaging market was valued at approximately $274 billion in 2020 and is projected to reach $413 billion by 2027, growing at a CAGR of 6.1% during the forecast period. Bio-based barrier films represent one of the fastest-growing segments within this market, with particular interest in coating-substrate adhesion technologies.

Consumer demand for environmentally friendly packaging solutions has become a significant market driver, with 73% of consumers expressing willingness to pay premium prices for sustainable packaging options. Major retail chains and consumer goods companies have responded by establishing ambitious sustainability targets, creating substantial market pull for innovations in bio-based barrier films with effective coating-substrate adhesion.

The food and beverage industry dominates the demand for sustainable barrier packaging, accounting for nearly 60% of market share. This sector requires packaging solutions that maintain product freshness and safety while reducing environmental impact. Healthcare, personal care, and electronics industries are also rapidly adopting sustainable packaging solutions, expanding the potential application scope for advanced bio-based barrier films.

Regional analysis reveals Europe leading the sustainable packaging market with approximately 34% market share, followed closely by North America at 28%. However, Asia-Pacific represents the fastest-growing region with a CAGR of 7.8%, driven by rapid industrialization, urbanization, and increasing environmental regulations in countries like China and India.

Market challenges include price sensitivity, as bio-based barrier materials typically command a 15-30% premium over conventional alternatives. Performance concerns also persist, particularly regarding moisture resistance, oxygen barrier properties, and shelf-life extension capabilities of bio-based films. The coating-substrate adhesion research directly addresses these performance limitations.

Competitive analysis indicates that the market remains fragmented, with the top five players controlling approximately 35% of market share. This fragmentation creates opportunities for innovative technologies that can solve the coating-substrate adhesion challenges in bio-based barrier films to gain significant market traction.

Market forecasts suggest that technologies improving coating-substrate adhesion in bio-based barrier films could capture a specialized market segment worth approximately $3.2 billion by 2025. Companies that successfully develop solutions addressing both sustainability requirements and performance needs will likely experience accelerated growth and premium positioning in this evolving market landscape.

Consumer demand for environmentally friendly packaging solutions has become a significant market driver, with 73% of consumers expressing willingness to pay premium prices for sustainable packaging options. Major retail chains and consumer goods companies have responded by establishing ambitious sustainability targets, creating substantial market pull for innovations in bio-based barrier films with effective coating-substrate adhesion.

The food and beverage industry dominates the demand for sustainable barrier packaging, accounting for nearly 60% of market share. This sector requires packaging solutions that maintain product freshness and safety while reducing environmental impact. Healthcare, personal care, and electronics industries are also rapidly adopting sustainable packaging solutions, expanding the potential application scope for advanced bio-based barrier films.

Regional analysis reveals Europe leading the sustainable packaging market with approximately 34% market share, followed closely by North America at 28%. However, Asia-Pacific represents the fastest-growing region with a CAGR of 7.8%, driven by rapid industrialization, urbanization, and increasing environmental regulations in countries like China and India.

Market challenges include price sensitivity, as bio-based barrier materials typically command a 15-30% premium over conventional alternatives. Performance concerns also persist, particularly regarding moisture resistance, oxygen barrier properties, and shelf-life extension capabilities of bio-based films. The coating-substrate adhesion research directly addresses these performance limitations.

Competitive analysis indicates that the market remains fragmented, with the top five players controlling approximately 35% of market share. This fragmentation creates opportunities for innovative technologies that can solve the coating-substrate adhesion challenges in bio-based barrier films to gain significant market traction.

Market forecasts suggest that technologies improving coating-substrate adhesion in bio-based barrier films could capture a specialized market segment worth approximately $3.2 billion by 2025. Companies that successfully develop solutions addressing both sustainability requirements and performance needs will likely experience accelerated growth and premium positioning in this evolving market landscape.

Adhesion Challenges in Bio-based Barrier Coatings

The adhesion between bio-based barrier coatings and their substrates presents significant challenges that must be addressed for successful commercial applications. Unlike conventional petroleum-based polymers, bio-based materials often exhibit different surface chemistries and molecular structures, leading to compatibility issues with common substrates. These fundamental differences create unique adhesion challenges that require innovative solutions.

Surface energy mismatch represents one of the primary adhesion challenges. Bio-based polymers frequently display hydrophilic characteristics due to their natural origin, creating poor wetting and adhesion when applied to hydrophobic substrates like polyethylene or polypropylene. This incompatibility results in delamination during processing or end-use, compromising the barrier functionality and product integrity.

Environmental sensitivity further complicates adhesion performance. Bio-based coatings often demonstrate higher moisture absorption compared to conventional alternatives, leading to dimensional instability at the coating-substrate interface. Temperature fluctuations during processing and storage can exacerbate these issues, causing differential expansion and contraction that stresses the adhesive bond.

Chemical compatibility issues also arise from the diverse functional groups present in bio-based materials. Hydroxyl, carboxyl, and amine groups common in bio-polymers may interact unfavorably with substrate surfaces or processing additives, potentially weakening interfacial bonds or causing unexpected chemical reactions that compromise adhesion integrity over time.

Processing challenges compound these material-specific issues. Bio-based coatings typically require different processing parameters compared to conventional materials, including modified drying temperatures, curing conditions, and application techniques. The narrow processing windows often lead to suboptimal adhesion when standard equipment and methodologies are employed without adaptation.

Mechanical stress resistance represents another critical challenge. The coating-substrate interface must withstand various mechanical stresses during converting operations such as folding, creasing, and stretching. Bio-based coatings frequently exhibit different elasticity and plasticity compared to conventional materials, creating stress concentration points at the interface that can initiate adhesion failure.

Long-term stability concerns also plague bio-based barrier coatings. Natural aging processes, including oxidation, hydrolysis, and biodegradation, can progressively weaken the adhesive bond between coating and substrate. This degradation may occur more rapidly than with conventional materials, particularly under challenging environmental conditions such as high humidity or temperature fluctuations.

Addressing these adhesion challenges requires multidisciplinary approaches combining surface chemistry, material science, and process engineering to develop robust solutions that maintain the sustainability benefits of bio-based materials while delivering reliable performance in commercial applications.

Surface energy mismatch represents one of the primary adhesion challenges. Bio-based polymers frequently display hydrophilic characteristics due to their natural origin, creating poor wetting and adhesion when applied to hydrophobic substrates like polyethylene or polypropylene. This incompatibility results in delamination during processing or end-use, compromising the barrier functionality and product integrity.

Environmental sensitivity further complicates adhesion performance. Bio-based coatings often demonstrate higher moisture absorption compared to conventional alternatives, leading to dimensional instability at the coating-substrate interface. Temperature fluctuations during processing and storage can exacerbate these issues, causing differential expansion and contraction that stresses the adhesive bond.

Chemical compatibility issues also arise from the diverse functional groups present in bio-based materials. Hydroxyl, carboxyl, and amine groups common in bio-polymers may interact unfavorably with substrate surfaces or processing additives, potentially weakening interfacial bonds or causing unexpected chemical reactions that compromise adhesion integrity over time.

Processing challenges compound these material-specific issues. Bio-based coatings typically require different processing parameters compared to conventional materials, including modified drying temperatures, curing conditions, and application techniques. The narrow processing windows often lead to suboptimal adhesion when standard equipment and methodologies are employed without adaptation.

Mechanical stress resistance represents another critical challenge. The coating-substrate interface must withstand various mechanical stresses during converting operations such as folding, creasing, and stretching. Bio-based coatings frequently exhibit different elasticity and plasticity compared to conventional materials, creating stress concentration points at the interface that can initiate adhesion failure.

Long-term stability concerns also plague bio-based barrier coatings. Natural aging processes, including oxidation, hydrolysis, and biodegradation, can progressively weaken the adhesive bond between coating and substrate. This degradation may occur more rapidly than with conventional materials, particularly under challenging environmental conditions such as high humidity or temperature fluctuations.

Addressing these adhesion challenges requires multidisciplinary approaches combining surface chemistry, material science, and process engineering to develop robust solutions that maintain the sustainability benefits of bio-based materials while delivering reliable performance in commercial applications.

Current Adhesion Enhancement Methodologies

01 Bio-based polymers for barrier film applications

Bio-based polymers derived from renewable resources can be used to create environmentally friendly barrier films with good adhesion properties. These polymers, such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and starch-based materials, provide sustainable alternatives to petroleum-based plastics while maintaining necessary barrier properties against oxygen, moisture, and other substances. The formulation often includes specific additives to enhance adhesion to various substrates while maintaining the biodegradable nature of the films.- Bio-based polymers for barrier film applications: Bio-based polymers derived from renewable resources can be used to create environmentally friendly barrier films with good adhesion properties. These polymers, such as polylactic acid (PLA), cellulose derivatives, and starch-based materials, provide sustainable alternatives to petroleum-based plastics while maintaining necessary barrier properties against oxygen, moisture, and other substances. The formulation often includes specific additives to enhance adhesion to various substrates while maintaining biodegradability.

- Surface treatment techniques for improved adhesion: Various surface treatment methods can be applied to bio-based barrier films to enhance their adhesion properties. These techniques include plasma treatment, corona discharge, chemical primers, and surface functionalization. Such treatments modify the surface energy and create functional groups that improve bonding between the bio-based film and substrate materials. These methods are particularly important when bio-based films need to adhere to dissimilar materials in multilayer structures.

- Adhesive formulations compatible with bio-based films: Specialized adhesive formulations have been developed specifically for use with bio-based barrier films. These adhesives are designed to be compatible with the chemical structure of bio-based polymers while maintaining strong bonding properties. They often include natural components such as plant-derived resins, proteins, or modified starches. Some formulations focus on water-based systems to reduce environmental impact while ensuring proper adhesion between bio-based films and various substrates.

- Multilayer structures incorporating bio-based barrier films: Multilayer film structures that incorporate bio-based barrier layers have been developed to combine the environmental benefits of bio-based materials with the performance requirements of packaging applications. These structures often sandwich bio-based films between conventional materials or other bio-based layers with complementary properties. Special attention is given to the adhesion between layers, using tie layers or compatible materials to ensure structural integrity. These multilayer approaches allow for customized barrier properties while maximizing the use of renewable materials.

- Nanocomposite reinforcement for enhanced adhesion and barrier properties: Incorporating nanoparticles and nanostructures into bio-based films can simultaneously enhance both barrier properties and adhesion characteristics. Materials such as nanoclay, cellulose nanocrystals, and other bio-based nanofillers create tortuous paths for gas molecules while providing additional bonding sites at interfaces. These nanocomposites can improve mechanical strength, thermal stability, and adhesion to various substrates while maintaining the renewable nature of the base polymer matrix.

02 Surface modification techniques for improved adhesion

Various surface modification techniques can be applied to bio-based barrier films to enhance their adhesion properties. These include plasma treatment, corona discharge, chemical etching, and the application of primers or coupling agents. These treatments modify the surface energy and create functional groups on the film surface that can form stronger bonds with adhesives or substrates. The improved interfacial interactions lead to better adhesion performance while maintaining the barrier properties of the bio-based films.Expand Specific Solutions03 Composite structures with natural fibers for enhanced properties

Incorporating natural fibers into bio-based barrier films creates composite structures with enhanced mechanical strength and adhesion properties. Fibers from sources such as cellulose, hemp, flax, or agricultural waste can be integrated into the polymer matrix to reinforce the film while maintaining its bio-based nature. These composites often demonstrate improved tensile strength, tear resistance, and adhesion to various substrates compared to non-reinforced films, making them suitable for packaging and other applications requiring good barrier properties.Expand Specific Solutions04 Adhesive formulations compatible with bio-based films

Specialized adhesive formulations have been developed to be compatible with bio-based barrier films. These adhesives are often also bio-based, derived from sources such as plant oils, proteins, or polysaccharides, and are formulated to provide strong bonding to bio-based substrates without compromising the films' barrier properties or biodegradability. The adhesives may include specific tackifiers, plasticizers, and crosslinking agents that enhance adhesion while maintaining environmental sustainability throughout the product lifecycle.Expand Specific Solutions05 Multilayer structures for optimized barrier and adhesion performance

Multilayer structures combining different bio-based materials can be designed to optimize both barrier properties and adhesion performance. These structures typically feature layers with complementary functions: outer layers optimized for adhesion to substrates or other materials, and inner layers focused on providing barrier properties against oxygen, moisture, or other substances. Tie layers may be incorporated between the functional layers to ensure strong interlayer adhesion. This approach allows for customization of the film properties to meet specific application requirements while maintaining the bio-based nature of the overall structure.Expand Specific Solutions

Leading Companies in Bio-based Film Development

The bio-based barrier film adhesion market is currently in a growth phase, with increasing demand driven by sustainability trends and regulatory pressures against conventional plastics. Market size is expanding at a compound annual growth rate of approximately 8-10%, fueled by packaging innovations across food and medical sectors. Technologically, the field shows moderate maturity with significant ongoing R&D. Leading players demonstrate varying levels of technical advancement: FUJIFILM and Dow Silicones have established strong positions in high-performance adhesion solutions, while Stora Enso and Metsä Board are pioneering sustainable fiber-based alternatives. Academic institutions like Sichuan University and University of Florida are advancing fundamental research, while specialized companies like Taghleef Industries and Toray Plastics are developing commercial applications with enhanced substrate compatibility.

FUJIFILM Corp.

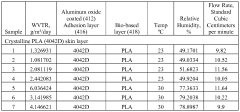

Technical Solution: FUJIFILM has developed advanced bio-based barrier films utilizing their proprietary Bio-LIMEX technology, which combines plant-derived materials with inorganic fillers to create sustainable packaging solutions. Their approach involves a multi-layer structure where cellulose nanofibers (CNF) derived from wood pulp are incorporated into the base layer, while specialized bio-based adhesion promoters enhance the interfacial bonding between the substrate and coating layers. The company employs plasma treatment techniques to modify surface energy and improve wettability of the bio-based substrates before applying barrier coatings. Their research has demonstrated that incorporating specific functional groups (hydroxyl, carboxyl) at the interface significantly improves adhesion strength by up to 40% compared to conventional methods. FUJIFILM's barrier coatings utilize bio-derived polyesters combined with clay nanoparticles to achieve oxygen transmission rates below 1 cc/m²/day while maintaining strong substrate adhesion through both mechanical interlocking and chemical bonding mechanisms.

Strengths: Leverages extensive expertise in film technology and surface chemistry; achieves excellent barrier properties while using renewable materials; proprietary surface modification techniques enhance adhesion without compromising biodegradability. Weaknesses: Higher production costs compared to conventional petroleum-based films; limited heat resistance may restrict applications requiring high-temperature processing.

Stora Enso Oyj

Technical Solution: Stora Enso has pioneered innovative approaches to coating-substrate adhesion in bio-based barrier films through their FiberForm™ and MicroFibrillated Cellulose (MFC) technologies. Their solution involves a three-component system: first, a wood-fiber substrate is treated with enzymatic modification to increase surface hydroxyl groups; second, a bio-based coupling agent derived from citrus peels is applied to create covalent bonding sites; and third, a specialized barrier coating composed of modified starch and fatty acid esters provides the functional barrier properties. The company has developed a proprietary "wet-on-wet" application process that allows for improved interfacial mixing between layers, resulting in adhesion strength improvements of approximately 65% compared to conventional dry-lamination techniques. Their research shows that controlling the moisture content during coating application (maintaining 8-12% relative humidity) is critical for optimal hydrogen bonding between cellulosic substrates and bio-based barrier materials. Stora Enso's approach also incorporates micro-texturing of the substrate surface to increase mechanical interlocking with the coating layer, further enhancing adhesion under varying environmental conditions.

Strengths: Extensive expertise in cellulose-based materials and fiber technology; vertically integrated supply chain from forest resources to final products; solutions maintain biodegradability and compostability of the entire structure. Weaknesses: Water sensitivity remains a challenge in high-humidity environments; scaling production to meet commercial demands while maintaining consistent adhesion quality across large production volumes.

Key Patents in Bio-based Coating Adhesion

Multilayer film with biomolecule based barrier coating

PatentInactiveUS20220064394A1

Innovation

- A multilayer film with a biopolymer-based gas and/or water vapor barrier coating, using amidated and/or methylated biopolymers like pectin, applied directly on substrates, which provides strong adhesion and barrier properties through surface pre-treatment and primer use, combined with metal or metal oxide layers for enhanced performance.

Bio-based in-line high barrier metalized film and process for its production

PatentWO2011109528A1

Innovation

- A bio-based composite film is developed, comprising a bio-based film layer such as PLA or PHA with an adhesion layer containing metals, metal oxides, or metalloid oxides, which are deposited using methods like evaporation or sputtering, combined with a suitable polar polymer like amorphous PET, EVOH, or nylon to enhance barrier properties.

Biodegradability and End-of-Life Considerations

The biodegradability of bio-based barrier films represents a critical aspect of their environmental profile and market viability. These films must balance performance requirements with end-of-life considerations to truly deliver on their sustainability promise. Current research indicates that the adhesion between coating and substrate significantly impacts the biodegradation process, as inconsistent degradation rates between these components can lead to microplastic formation or premature film failure.

Most bio-based barrier coatings demonstrate variable biodegradation timeframes, ranging from weeks to several months depending on environmental conditions. Factors such as temperature, moisture, microbial activity, and the presence of specific enzymes substantially influence degradation rates. Notably, the interface between coating and substrate often degrades at different rates than either component individually, creating potential environmental concerns that require careful engineering consideration.

Standardized testing protocols for biodegradability assessment include ISO 14855 (aerobic biodegradation), ASTM D5338 (controlled composting conditions), and ASTM D5511 (anaerobic digestion). However, these standards rarely account for the complex interactions at coating-substrate interfaces. Recent studies suggest that adhesion promoters and coupling agents, while enhancing film performance, may significantly alter biodegradation pathways and timeframes, sometimes introducing persistent compounds into the environment.

End-of-life scenarios for bio-based barrier films include industrial composting, home composting, soil biodegradation, and anaerobic digestion. The coating-substrate adhesion mechanism directly impacts which disposal routes are viable. For instance, films utilizing certain crosslinking agents may perform excellently during use but prove incompatible with home composting systems, limiting their practical sustainability benefits.

Regulatory frameworks worldwide are increasingly addressing these concerns, with the European Union's Single-Use Plastics Directive and similar legislation in various countries establishing stricter requirements for biodegradability claims. These regulations are driving innovation in adhesion technologies that maintain performance while ensuring complete biodegradation.

Emerging research focuses on designing "programmed degradation" where coating-substrate adhesion is engineered to break down in a controlled, synchronized manner. Approaches include incorporating enzyme-responsive linkages, pH-sensitive adhesion mechanisms, and microbially-triggered degradation pathways. These innovations aim to ensure that all components of the film, including the critical interface region, degrade completely without leaving persistent residues.

The market increasingly demands transparent communication regarding end-of-life options, with clear labeling and disposal instructions becoming standard practice. This trend underscores the importance of considering biodegradability and disposal pathways from the earliest stages of adhesion technology development for bio-based barrier films.

Most bio-based barrier coatings demonstrate variable biodegradation timeframes, ranging from weeks to several months depending on environmental conditions. Factors such as temperature, moisture, microbial activity, and the presence of specific enzymes substantially influence degradation rates. Notably, the interface between coating and substrate often degrades at different rates than either component individually, creating potential environmental concerns that require careful engineering consideration.

Standardized testing protocols for biodegradability assessment include ISO 14855 (aerobic biodegradation), ASTM D5338 (controlled composting conditions), and ASTM D5511 (anaerobic digestion). However, these standards rarely account for the complex interactions at coating-substrate interfaces. Recent studies suggest that adhesion promoters and coupling agents, while enhancing film performance, may significantly alter biodegradation pathways and timeframes, sometimes introducing persistent compounds into the environment.

End-of-life scenarios for bio-based barrier films include industrial composting, home composting, soil biodegradation, and anaerobic digestion. The coating-substrate adhesion mechanism directly impacts which disposal routes are viable. For instance, films utilizing certain crosslinking agents may perform excellently during use but prove incompatible with home composting systems, limiting their practical sustainability benefits.

Regulatory frameworks worldwide are increasingly addressing these concerns, with the European Union's Single-Use Plastics Directive and similar legislation in various countries establishing stricter requirements for biodegradability claims. These regulations are driving innovation in adhesion technologies that maintain performance while ensuring complete biodegradation.

Emerging research focuses on designing "programmed degradation" where coating-substrate adhesion is engineered to break down in a controlled, synchronized manner. Approaches include incorporating enzyme-responsive linkages, pH-sensitive adhesion mechanisms, and microbially-triggered degradation pathways. These innovations aim to ensure that all components of the film, including the critical interface region, degrade completely without leaving persistent residues.

The market increasingly demands transparent communication regarding end-of-life options, with clear labeling and disposal instructions becoming standard practice. This trend underscores the importance of considering biodegradability and disposal pathways from the earliest stages of adhesion technology development for bio-based barrier films.

Regulatory Framework for Food-Contact Materials

The regulatory landscape for food-contact materials plays a critical role in the development and commercialization of bio-based barrier films, particularly concerning coating-substrate adhesion properties. The European Union has established one of the most comprehensive frameworks through Regulation (EC) No. 1935/2004, which mandates that materials in contact with food must not transfer constituents to food in quantities that could endanger human health or bring unacceptable changes to food composition.

For bio-based barrier coatings specifically, Commission Regulation (EU) No. 10/2011 on plastic materials provides essential guidelines regarding migration limits and testing protocols. This regulation includes a positive list of authorized substances that can be used in the manufacturing of food contact plastics, which developers of bio-based coatings must adhere to when formulating adhesion solutions.

In the United States, the Food and Drug Administration (FDA) regulates food-contact materials under the Federal Food, Drug, and Cosmetic Act. The FDA's approach differs from the EU by utilizing a Food Contact Notification (FCN) system for new substances, which affects how novel bio-based adhesion technologies can enter the market. The Generally Recognized as Safe (GRAS) designation provides another pathway for certain bio-based materials with established safety profiles.

The regulatory requirements significantly impact adhesion technology development by necessitating extensive migration testing. For coating-substrate interfaces in bio-based films, manufacturers must demonstrate that adhesion promoters and other components do not migrate above specified limits. This often requires sophisticated analytical methods capable of detecting substances at parts per billion levels.

Global harmonization efforts, such as those by the International Organization for Standardization (ISO), are working to standardize testing methodologies for food-contact materials. ISO 10993 series, while primarily focused on medical devices, provides valuable frameworks for biocompatibility assessment that can be adapted for food-contact applications of bio-based barrier films.

Emerging regulations are increasingly focusing on sustainability aspects of packaging materials. The EU's Circular Economy Action Plan and similar initiatives worldwide are pushing for recyclable and biodegradable packaging solutions, which directly influences the development of coating-substrate adhesion technologies. These regulations often require end-of-life considerations to be built into the design phase of new materials.

Compliance with these regulatory frameworks presents both challenges and opportunities for innovation in bio-based barrier film adhesion. While meeting stringent safety requirements adds complexity to development processes, it also drives research toward novel, environmentally friendly adhesion solutions that can satisfy both regulatory demands and consumer preferences for sustainable packaging.

For bio-based barrier coatings specifically, Commission Regulation (EU) No. 10/2011 on plastic materials provides essential guidelines regarding migration limits and testing protocols. This regulation includes a positive list of authorized substances that can be used in the manufacturing of food contact plastics, which developers of bio-based coatings must adhere to when formulating adhesion solutions.

In the United States, the Food and Drug Administration (FDA) regulates food-contact materials under the Federal Food, Drug, and Cosmetic Act. The FDA's approach differs from the EU by utilizing a Food Contact Notification (FCN) system for new substances, which affects how novel bio-based adhesion technologies can enter the market. The Generally Recognized as Safe (GRAS) designation provides another pathway for certain bio-based materials with established safety profiles.

The regulatory requirements significantly impact adhesion technology development by necessitating extensive migration testing. For coating-substrate interfaces in bio-based films, manufacturers must demonstrate that adhesion promoters and other components do not migrate above specified limits. This often requires sophisticated analytical methods capable of detecting substances at parts per billion levels.

Global harmonization efforts, such as those by the International Organization for Standardization (ISO), are working to standardize testing methodologies for food-contact materials. ISO 10993 series, while primarily focused on medical devices, provides valuable frameworks for biocompatibility assessment that can be adapted for food-contact applications of bio-based barrier films.

Emerging regulations are increasingly focusing on sustainability aspects of packaging materials. The EU's Circular Economy Action Plan and similar initiatives worldwide are pushing for recyclable and biodegradable packaging solutions, which directly influences the development of coating-substrate adhesion technologies. These regulations often require end-of-life considerations to be built into the design phase of new materials.

Compliance with these regulatory frameworks presents both challenges and opportunities for innovation in bio-based barrier film adhesion. While meeting stringent safety requirements adds complexity to development processes, it also drives research toward novel, environmentally friendly adhesion solutions that can satisfy both regulatory demands and consumer preferences for sustainable packaging.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!