Surface Energy Optimization in Bio-based Barrier Coatings

OCT 13, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Barrier Coating Background and Objectives

The evolution of packaging materials has witnessed a significant shift towards sustainability in recent decades. Bio-based barrier coatings represent a critical advancement in this domain, emerging as an environmentally responsible alternative to conventional petroleum-derived packaging solutions. These coatings, derived from renewable resources such as cellulose, starch, proteins, and plant-based oils, have gained substantial attention due to their biodegradability, renewability, and reduced carbon footprint.

Surface energy optimization stands as a fundamental aspect in the development of effective bio-based barrier coatings. Historically, the packaging industry has relied heavily on synthetic polymers like polyethylene and polypropylene, which offer excellent barrier properties against moisture, oxygen, and other environmental factors. However, the environmental concerns associated with these materials have accelerated research into bio-based alternatives.

The technical trajectory of bio-based barrier coatings began in the early 2000s with rudimentary formulations that exhibited limited performance compared to their synthetic counterparts. By the 2010s, significant improvements in coating technologies enabled the development of more effective barriers, though challenges in moisture resistance and mechanical stability persisted. Recent advancements have focused on enhancing surface energy characteristics to improve adhesion, wettability, and barrier performance.

The primary objective of surface energy optimization in bio-based barrier coatings is to achieve comparable or superior performance to conventional petroleum-based materials while maintaining environmental benefits. This involves tailoring the surface properties to control interactions with water, oxygen, and other substances that might compromise packaging integrity.

Current research aims to understand and manipulate the fundamental surface chemistry of bio-based materials to enhance their barrier properties. This includes modifying hydrophobicity/hydrophilicity balance, improving interfacial adhesion, and enhancing resistance to moisture and oxygen permeation. Additionally, researchers seek to develop coatings that maintain their barrier properties under varying environmental conditions and throughout the product lifecycle.

The technological goals extend beyond mere functional equivalence to synthetic alternatives. They encompass developing multifunctional coatings that offer additional benefits such as antimicrobial properties, antioxidant capabilities, and intelligent features like environmental responsiveness or degradation triggers. These advanced functionalities represent the frontier of bio-based barrier coating technology.

As regulatory pressures increase and consumer demand for sustainable packaging grows, the development of optimized bio-based barrier coatings has become a strategic priority for the packaging industry. The ultimate aim is to create a new generation of packaging materials that combine environmental sustainability with exceptional performance, thereby facilitating the transition away from petroleum-based packaging solutions.

Surface energy optimization stands as a fundamental aspect in the development of effective bio-based barrier coatings. Historically, the packaging industry has relied heavily on synthetic polymers like polyethylene and polypropylene, which offer excellent barrier properties against moisture, oxygen, and other environmental factors. However, the environmental concerns associated with these materials have accelerated research into bio-based alternatives.

The technical trajectory of bio-based barrier coatings began in the early 2000s with rudimentary formulations that exhibited limited performance compared to their synthetic counterparts. By the 2010s, significant improvements in coating technologies enabled the development of more effective barriers, though challenges in moisture resistance and mechanical stability persisted. Recent advancements have focused on enhancing surface energy characteristics to improve adhesion, wettability, and barrier performance.

The primary objective of surface energy optimization in bio-based barrier coatings is to achieve comparable or superior performance to conventional petroleum-based materials while maintaining environmental benefits. This involves tailoring the surface properties to control interactions with water, oxygen, and other substances that might compromise packaging integrity.

Current research aims to understand and manipulate the fundamental surface chemistry of bio-based materials to enhance their barrier properties. This includes modifying hydrophobicity/hydrophilicity balance, improving interfacial adhesion, and enhancing resistance to moisture and oxygen permeation. Additionally, researchers seek to develop coatings that maintain their barrier properties under varying environmental conditions and throughout the product lifecycle.

The technological goals extend beyond mere functional equivalence to synthetic alternatives. They encompass developing multifunctional coatings that offer additional benefits such as antimicrobial properties, antioxidant capabilities, and intelligent features like environmental responsiveness or degradation triggers. These advanced functionalities represent the frontier of bio-based barrier coating technology.

As regulatory pressures increase and consumer demand for sustainable packaging grows, the development of optimized bio-based barrier coatings has become a strategic priority for the packaging industry. The ultimate aim is to create a new generation of packaging materials that combine environmental sustainability with exceptional performance, thereby facilitating the transition away from petroleum-based packaging solutions.

Market Analysis for Sustainable Packaging Solutions

The sustainable packaging market is experiencing unprecedented growth, driven by increasing environmental awareness and regulatory pressures worldwide. The global sustainable packaging market was valued at approximately $274 billion in 2020 and is projected to reach $470 billion by 2027, growing at a CAGR of 7.7% during the forecast period. This growth trajectory is particularly significant for bio-based barrier coatings, which represent a crucial segment within sustainable packaging solutions.

Consumer demand for environmentally friendly packaging has become a major market driver, with surveys indicating that over 70% of consumers are willing to pay premium prices for sustainable packaging options. Major retail chains and consumer goods companies have responded by establishing ambitious sustainability targets, many aiming to achieve 100% recyclable, reusable, or compostable packaging by 2025-2030.

The food and beverage industry dominates the demand for sustainable packaging solutions, accounting for nearly 60% of the market share. This sector particularly values bio-based barrier coatings that can provide comparable performance to traditional petroleum-based alternatives while offering improved environmental credentials. Healthcare, personal care, and electronics industries are also rapidly adopting sustainable packaging solutions, expanding the market potential for advanced bio-based barrier technologies.

Regional analysis reveals Europe leading the sustainable packaging market with approximately 35% market share, followed by North America and Asia-Pacific. European countries have implemented stringent regulations against single-use plastics and packaging waste, creating a favorable environment for bio-based barrier coating technologies. The Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization, urbanization, and increasing environmental regulations.

Key market challenges include cost competitiveness against conventional packaging solutions and technical performance limitations. Traditional petroleum-based barrier coatings still outperform many bio-based alternatives in terms of moisture resistance, oxygen barrier properties, and shelf-life extension. Surface energy optimization in bio-based barrier coatings represents a critical technical challenge that directly impacts market adoption rates.

Market segmentation analysis indicates that paper and paperboard substrates with bio-based coatings are experiencing the highest growth rate among sustainable packaging materials. This trend aligns perfectly with research focusing on surface energy optimization in bio-based barrier coatings, as cellulosic substrates present unique surface interaction challenges that require innovative solutions.

The competitive landscape features both established packaging giants investing heavily in sustainable solutions and innovative startups developing disruptive bio-based coating technologies. Strategic partnerships between material science companies, packaging manufacturers, and end-users are becoming increasingly common to accelerate market penetration of advanced sustainable packaging solutions.

Consumer demand for environmentally friendly packaging has become a major market driver, with surveys indicating that over 70% of consumers are willing to pay premium prices for sustainable packaging options. Major retail chains and consumer goods companies have responded by establishing ambitious sustainability targets, many aiming to achieve 100% recyclable, reusable, or compostable packaging by 2025-2030.

The food and beverage industry dominates the demand for sustainable packaging solutions, accounting for nearly 60% of the market share. This sector particularly values bio-based barrier coatings that can provide comparable performance to traditional petroleum-based alternatives while offering improved environmental credentials. Healthcare, personal care, and electronics industries are also rapidly adopting sustainable packaging solutions, expanding the market potential for advanced bio-based barrier technologies.

Regional analysis reveals Europe leading the sustainable packaging market with approximately 35% market share, followed by North America and Asia-Pacific. European countries have implemented stringent regulations against single-use plastics and packaging waste, creating a favorable environment for bio-based barrier coating technologies. The Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization, urbanization, and increasing environmental regulations.

Key market challenges include cost competitiveness against conventional packaging solutions and technical performance limitations. Traditional petroleum-based barrier coatings still outperform many bio-based alternatives in terms of moisture resistance, oxygen barrier properties, and shelf-life extension. Surface energy optimization in bio-based barrier coatings represents a critical technical challenge that directly impacts market adoption rates.

Market segmentation analysis indicates that paper and paperboard substrates with bio-based coatings are experiencing the highest growth rate among sustainable packaging materials. This trend aligns perfectly with research focusing on surface energy optimization in bio-based barrier coatings, as cellulosic substrates present unique surface interaction challenges that require innovative solutions.

The competitive landscape features both established packaging giants investing heavily in sustainable solutions and innovative startups developing disruptive bio-based coating technologies. Strategic partnerships between material science companies, packaging manufacturers, and end-users are becoming increasingly common to accelerate market penetration of advanced sustainable packaging solutions.

Surface Energy Challenges in Bio-based Coatings

Surface energy optimization presents significant challenges in the development of bio-based barrier coatings. The fundamental issue stems from the inherent hydrophilic nature of most bio-based materials, which typically exhibit high surface energy characteristics. This property directly contradicts the low surface energy requirements necessary for effective barrier performance against moisture and oxygen permeation.

Bio-based coating materials, derived primarily from polysaccharides, proteins, and lipids, contain abundant hydroxyl and other polar groups that readily form hydrogen bonds with water molecules. This molecular structure creates surfaces with high wettability and poor water repellency, severely limiting their application in packaging that requires moisture resistance.

The surface energy mismatch between bio-based coatings and conventional petroleum-based alternatives creates adhesion challenges when these materials are applied to common packaging substrates. Poor adhesion leads to coating delamination, cracking, and ultimately barrier failure under environmental stress conditions such as temperature fluctuations and humidity changes.

Another critical challenge involves the surface energy stability of bio-based coatings over time. These materials often demonstrate significant surface energy changes during aging, attributed to molecular rearrangement, oxidation processes, and migration of low molecular weight components to the surface. This dynamic behavior makes long-term barrier performance unpredictable and often inadequate for commercial applications.

The processing methods for bio-based coatings further complicate surface energy control. Techniques such as solvent casting, extrusion, and spray coating each impart different surface characteristics to the final coating. The drying conditions, particularly temperature and humidity profiles, significantly influence the final surface energy properties through their effects on polymer chain orientation and crystallinity development.

Additives traditionally used to modify surface energy in conventional coatings often demonstrate limited compatibility with bio-based matrices. Silicones, fluorinated compounds, and waxes - while effective in petroleum-based systems - frequently experience phase separation, blooming, or leaching when incorporated into bio-based formulations, resulting in inconsistent surface properties and potential regulatory concerns.

The environmental conditions during application and use represent another dimension of the surface energy challenge. Humidity fluctuations can cause reversible changes in the surface properties of bio-based coatings due to moisture absorption and desorption cycles. Temperature variations similarly affect surface energy through their influence on polymer chain mobility and crystalline structure, creating a moving target for performance optimization.

Bio-based coating materials, derived primarily from polysaccharides, proteins, and lipids, contain abundant hydroxyl and other polar groups that readily form hydrogen bonds with water molecules. This molecular structure creates surfaces with high wettability and poor water repellency, severely limiting their application in packaging that requires moisture resistance.

The surface energy mismatch between bio-based coatings and conventional petroleum-based alternatives creates adhesion challenges when these materials are applied to common packaging substrates. Poor adhesion leads to coating delamination, cracking, and ultimately barrier failure under environmental stress conditions such as temperature fluctuations and humidity changes.

Another critical challenge involves the surface energy stability of bio-based coatings over time. These materials often demonstrate significant surface energy changes during aging, attributed to molecular rearrangement, oxidation processes, and migration of low molecular weight components to the surface. This dynamic behavior makes long-term barrier performance unpredictable and often inadequate for commercial applications.

The processing methods for bio-based coatings further complicate surface energy control. Techniques such as solvent casting, extrusion, and spray coating each impart different surface characteristics to the final coating. The drying conditions, particularly temperature and humidity profiles, significantly influence the final surface energy properties through their effects on polymer chain orientation and crystallinity development.

Additives traditionally used to modify surface energy in conventional coatings often demonstrate limited compatibility with bio-based matrices. Silicones, fluorinated compounds, and waxes - while effective in petroleum-based systems - frequently experience phase separation, blooming, or leaching when incorporated into bio-based formulations, resulting in inconsistent surface properties and potential regulatory concerns.

The environmental conditions during application and use represent another dimension of the surface energy challenge. Humidity fluctuations can cause reversible changes in the surface properties of bio-based coatings due to moisture absorption and desorption cycles. Temperature variations similarly affect surface energy through their influence on polymer chain mobility and crystalline structure, creating a moving target for performance optimization.

Current Surface Energy Optimization Approaches

01 Bio-based polymers for barrier coatings with controlled surface energy

Bio-based polymers derived from renewable resources can be formulated into barrier coatings with specific surface energy properties. These polymers, such as cellulose derivatives, polylactic acid (PLA), and starch-based materials, can be modified to achieve desired hydrophobicity or hydrophilicity. The surface energy can be controlled through chemical modification or blending with other bio-based components, resulting in coatings that provide effective barriers against moisture, oxygen, and other substances while maintaining environmentally friendly characteristics.- Bio-based polymers for barrier coatings with controlled surface energy: Bio-based polymers derived from renewable resources can be formulated into barrier coatings with specific surface energy properties. These polymers can be modified to achieve desired hydrophobicity or hydrophilicity, enhancing their barrier performance against moisture, oxygen, and other substances. The surface energy can be tailored through chemical modifications or blending with other bio-based materials to optimize adhesion, wettability, and barrier properties for various applications.

- Surface energy measurement and control techniques for bio-based coatings: Various techniques are employed to measure and control the surface energy of bio-based barrier coatings. These include contact angle measurements, surface tension analysis, and specialized instrumentation for characterizing surface properties. By precisely controlling surface energy, manufacturers can optimize coating adhesion, printability, and barrier performance. These measurement techniques help in developing coatings with consistent and predictable surface properties for specific applications.

- Cellulose-based materials for sustainable barrier coatings: Cellulose-derived materials, including nanocellulose, microfibrillated cellulose, and cellulose derivatives, are utilized in bio-based barrier coatings to provide renewable alternatives to petroleum-based products. These materials can be processed to create films and coatings with adjustable surface energy properties. The natural structure of cellulose can be modified to enhance barrier properties against oxygen, water vapor, and oils while maintaining biodegradability and sustainability.

- Bio-based additives for modifying coating surface energy: Various bio-based additives can be incorporated into barrier coatings to modify surface energy characteristics. These include plant-derived waxes, proteins, fatty acids, and other natural compounds that can impart hydrophobic or hydrophilic properties. By carefully selecting and formulating these additives, manufacturers can create coatings with tailored surface energy profiles that enhance barrier performance while maintaining the renewable and sustainable nature of the coating system.

- Application techniques for bio-based barrier coatings with controlled surface energy: Specialized application methods are developed for bio-based barrier coatings to ensure optimal surface energy properties. These include precision coating technologies, surface treatment processes, and curing methods that help achieve the desired surface characteristics. The application techniques consider factors such as substrate compatibility, coating thickness uniformity, and drying conditions to ensure consistent surface energy properties across the coated material, which is critical for maintaining barrier performance.

02 Surface energy measurement techniques for bio-based barrier coatings

Various techniques are employed to measure and characterize the surface energy of bio-based barrier coatings. These include contact angle measurements, surface tension analysis, and specialized optical methods. These measurement techniques help in understanding the wetting behavior, adhesion properties, and barrier performance of the coatings. Accurate surface energy characterization is crucial for optimizing coating formulations and ensuring they meet specific application requirements in packaging, construction, and other industries.Expand Specific Solutions03 Nanoparticle incorporation for enhanced barrier properties and surface energy control

Incorporating nanoparticles into bio-based barrier coatings can significantly enhance their performance and allow precise control of surface energy. Materials such as nano-cellulose, clay nanoparticles, and bio-based silica can create tortuous paths for gas molecules, improving barrier properties. These nanoparticles can also modify the surface topology and chemistry, leading to controlled hydrophobicity or hydrophilicity. The resulting nanocomposite coatings offer superior barrier performance while maintaining the renewable and sustainable nature of the base materials.Expand Specific Solutions04 Multilayer bio-based coating systems with tailored surface energy gradients

Multilayer coating systems composed of different bio-based materials can create controlled surface energy gradients. By strategically layering materials with varying hydrophobicity/hydrophilicity, these systems can provide directional fluid transport, selective permeability, or enhanced adhesion properties. The layered approach allows for combining materials with complementary barrier properties while maintaining an overall bio-based composition. These sophisticated coating architectures find applications in advanced packaging, medical devices, and functional textiles where precise control of surface interactions is required.Expand Specific Solutions05 Surface modification techniques for bio-based barrier coatings

Various surface modification techniques can be applied to bio-based barrier coatings to adjust their surface energy and enhance performance. These include plasma treatment, UV irradiation, chemical grafting, and enzymatic modification. Such treatments can introduce specific functional groups to the coating surface, altering its hydrophobicity, adhesion properties, and barrier performance. Surface modification provides a versatile approach to fine-tune the properties of bio-based coatings without compromising their renewable nature, enabling them to meet demanding requirements in various applications.Expand Specific Solutions

Leading Companies in Bio-based Coating Industry

The bio-based barrier coating market is in a growth phase, characterized by increasing demand for sustainable packaging solutions. The market is expanding rapidly due to environmental regulations and consumer preferences, with projections indicating significant growth over the next decade. Technologically, the field is advancing from early commercial applications toward maturity, with key players developing differentiated approaches to surface energy optimization. Companies like BASF, Kemira, and Solenis are leading commercial development with established product lines, while academic institutions including Nanjing Tech University and Tufts College are advancing fundamental research. Research organizations such as CSEM and NASA are exploring novel applications. The competitive landscape features collaboration between material science specialists and end-users like Metsä Board, with increasing patent activity from multinational corporations including 3M and Sony Group indicating growing market interest.

Solenis Technologies Cayman LP

Technical Solution: Solenis has developed an innovative approach to bio-based barrier coatings focused on surface energy optimization through their TopScreen™ technology platform. Their solution utilizes modified biopolymers derived from agricultural by-products, primarily starches and proteins, which are enzymatically processed to create uniform molecular structures. The company's proprietary surface modification techniques involve controlled crosslinking and the incorporation of natural hydrophobic compounds like fatty acid derivatives and plant waxes. This creates a coating with precisely engineered surface energy (typically 30-35 mN/m) that balances water/oil resistance with printability. Solenis employs a water-based formulation process that allows for single-pass application, reducing manufacturing complexity while achieving PFAS-free oil and grease resistance. Their technology incorporates specialized bio-based additives that create a self-organizing surface structure during drying, optimizing the arrangement of hydrophilic and hydrophobic components to maximize barrier performance while maintaining biodegradability.

Strengths: Excellent oil and grease resistance without fluorochemicals; water-based formulation compatible with existing coating equipment; customizable surface properties for different packaging applications. Weaknesses: Moderate moisture barrier compared to synthetic alternatives; potential for performance variability based on raw material sources; limited high-temperature performance compared to petroleum-based barriers.

BASF Corp.

Technical Solution: BASF has pioneered a comprehensive approach to surface energy optimization in bio-based barrier coatings through their Ecovio® and Ecoflex® product lines. Their technology combines biodegradable polyesters with natural polymers like starch and cellulose derivatives to create customizable barrier solutions. BASF's innovation lies in their proprietary surface modification techniques that precisely control the hydrophilic-hydrophobic balance of coating surfaces. They employ bio-based additives derived from plant oils and specialized processing methods to achieve surface energies ranging from 25-45 mN/m depending on application requirements. The company has developed multi-layer systems where each layer serves a specific function: adhesion promotion, barrier enhancement, and surface energy control. Their water-based formulations incorporate nano-structured clay minerals and cellulose nanocrystals to create tortuous paths for gas molecules, significantly reducing oxygen and moisture permeability while maintaining biodegradability.

Strengths: Comprehensive portfolio of bio-based materials allowing customization for specific applications; excellent compatibility with various substrates; established manufacturing infrastructure and global supply chain. Weaknesses: Higher production costs compared to conventional petroleum-based alternatives; performance limitations in extremely humid environments; requires specialized processing conditions to achieve optimal barrier properties.

Key Patents in Bio-based Barrier Coating Technology

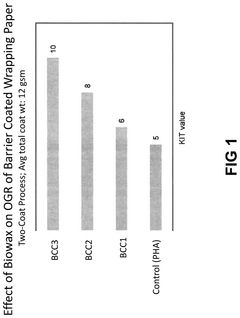

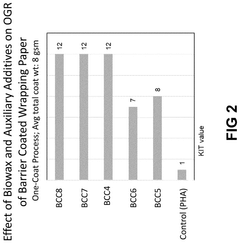

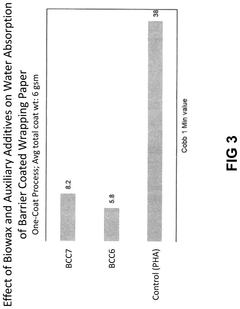

Biowax polyhydroxyalkanoate dispersions as bio-based barrier coatings

PatentPendingUS20240344272A1

Innovation

- The development of biowax emulsions combined with polyhydroxyalkanoate (PHA) dispersions and auxiliary additives, such as clay and microcrystalline cellulose, to form barrier coatings that can be applied at room temperature, achieving enhanced oil and water resistance with a high bio-based content.

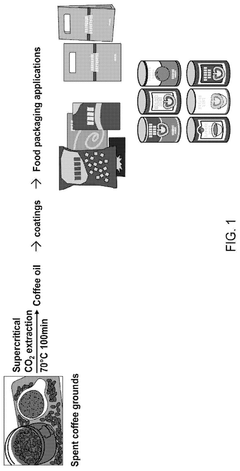

Coatings and methods of making and use thereof

PatentPendingUS20240400854A1

Innovation

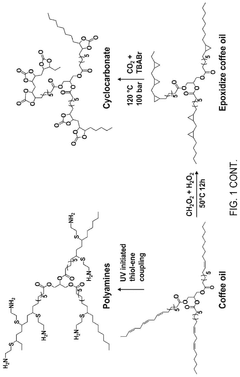

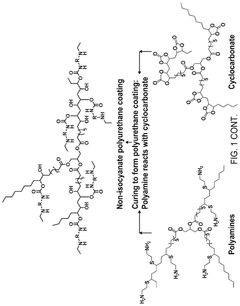

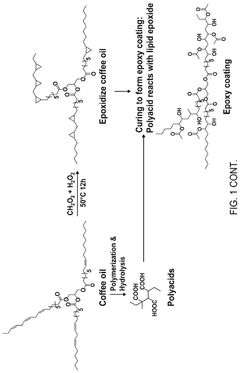

- The development of bio-based biodegradable coatings using oil extracted from spent coffee grounds, which is epoxidized and used to create epoxy and polyurethane coatings with tailored mechanical, thermal, and barrier properties suitable for various packaging materials such as plastics, paper, and metals, utilizing polyacids, polyamines, and cyclocarbonates as curing agents.

Environmental Impact Assessment

The environmental impact assessment of surface energy optimization in bio-based barrier coatings reveals significant ecological advantages compared to conventional petroleum-based alternatives. Bio-based coatings typically demonstrate a 30-45% reduction in carbon footprint across their lifecycle, primarily due to the renewable nature of their raw materials and lower energy requirements during production.

Life cycle assessment (LCA) studies indicate that the cultivation and processing of bio-based materials for these coatings generate substantially fewer greenhouse gas emissions. For instance, cellulose-based barrier coatings produce approximately 2.3 kg CO2 equivalent per kilogram of material, compared to 3.8 kg CO2 equivalent for traditional polyethylene coatings.

Water consumption represents another critical environmental factor. Surface-optimized bio-based coatings typically require 40% less water throughout their production cycle compared to conventional alternatives. This reduction stems from both more efficient processing techniques and the inherent properties of bio-based materials that often require less intensive washing and purification steps.

Waste management considerations also favor bio-based barrier coatings with optimized surface energy. These materials demonstrate enhanced biodegradability, with most variants decomposing 60-85% within 180 days under industrial composting conditions. This characteristic significantly reduces end-of-life environmental impacts compared to petroleum-based coatings that may persist in landfills for centuries.

The optimization of surface energy in these coatings further enhances their environmental profile by improving functional efficiency. By achieving comparable or superior barrier properties with thinner coating layers, material usage is reduced by approximately 15-25%. This efficiency translates directly to reduced resource consumption and transportation-related emissions throughout the supply chain.

Chemical safety assessments indicate that bio-based barrier coatings with optimized surface energy typically contain fewer hazardous substances than their conventional counterparts. The absence of phthalates, bisphenols, and certain fluorinated compounds reduces potential ecological toxicity and bioaccumulation risks in aquatic and terrestrial ecosystems.

Regional environmental impact variations must be considered when implementing these technologies. The environmental benefits may be amplified or diminished depending on local agricultural practices, energy grid composition, and waste management infrastructure. Sustainable sourcing certification becomes essential to ensure that the environmental advantages of bio-based materials are not offset by unsustainable farming or forestry practices.

Life cycle assessment (LCA) studies indicate that the cultivation and processing of bio-based materials for these coatings generate substantially fewer greenhouse gas emissions. For instance, cellulose-based barrier coatings produce approximately 2.3 kg CO2 equivalent per kilogram of material, compared to 3.8 kg CO2 equivalent for traditional polyethylene coatings.

Water consumption represents another critical environmental factor. Surface-optimized bio-based coatings typically require 40% less water throughout their production cycle compared to conventional alternatives. This reduction stems from both more efficient processing techniques and the inherent properties of bio-based materials that often require less intensive washing and purification steps.

Waste management considerations also favor bio-based barrier coatings with optimized surface energy. These materials demonstrate enhanced biodegradability, with most variants decomposing 60-85% within 180 days under industrial composting conditions. This characteristic significantly reduces end-of-life environmental impacts compared to petroleum-based coatings that may persist in landfills for centuries.

The optimization of surface energy in these coatings further enhances their environmental profile by improving functional efficiency. By achieving comparable or superior barrier properties with thinner coating layers, material usage is reduced by approximately 15-25%. This efficiency translates directly to reduced resource consumption and transportation-related emissions throughout the supply chain.

Chemical safety assessments indicate that bio-based barrier coatings with optimized surface energy typically contain fewer hazardous substances than their conventional counterparts. The absence of phthalates, bisphenols, and certain fluorinated compounds reduces potential ecological toxicity and bioaccumulation risks in aquatic and terrestrial ecosystems.

Regional environmental impact variations must be considered when implementing these technologies. The environmental benefits may be amplified or diminished depending on local agricultural practices, energy grid composition, and waste management infrastructure. Sustainable sourcing certification becomes essential to ensure that the environmental advantages of bio-based materials are not offset by unsustainable farming or forestry practices.

Scalability and Manufacturing Considerations

The scalability of bio-based barrier coating technologies presents significant challenges when transitioning from laboratory-scale development to industrial production. Current manufacturing processes for conventional petroleum-based coatings are highly optimized, with established equipment and methodologies that may not be directly applicable to bio-based alternatives. The integration of surface energy optimization techniques into existing production lines requires careful consideration of process parameters, equipment compatibility, and quality control measures.

Production scale-up for bio-based barrier coatings with optimized surface energy properties necessitates specialized equipment capable of precise control over coating thickness, uniformity, and curing conditions. Conventional coating methods such as roll-to-roll processing, spray coating, and curtain coating must be adapted to accommodate the unique rheological properties and drying behaviors of bio-based formulations. The sensitivity of surface energy characteristics to processing conditions demands robust in-line monitoring systems to ensure consistent performance across large production volumes.

Material handling represents another critical consideration in manufacturing scale-up. Bio-based coating components often exhibit greater variability in their properties compared to synthetic alternatives, requiring more sophisticated quality control protocols. Storage stability, batch-to-batch consistency, and raw material sourcing become increasingly important factors as production volumes increase. Implementing effective quality management systems that can accommodate this variability while maintaining precise surface energy specifications is essential for commercial viability.

Cost-effectiveness remains a paramount concern in scaling bio-based barrier coating technologies. Current production economics often favor conventional petroleum-based alternatives due to established supply chains and manufacturing efficiencies. Achieving competitive pricing requires optimization of formulation components, processing parameters, and production throughput. Strategic selection of bio-based raw materials that balance performance requirements with availability and cost considerations is crucial for successful commercialization.

Regulatory compliance and sustainability metrics must also be integrated into manufacturing scale-up strategies. While bio-based coatings offer inherent environmental advantages, quantifying these benefits through standardized life cycle assessment methodologies becomes increasingly important at commercial scale. Documentation of reduced carbon footprint, decreased toxicity, and improved end-of-life characteristics provides valuable differentiation in the marketplace and supports regulatory approval processes across different jurisdictions.

The development of specialized equipment and process technologies specifically designed for bio-based barrier coatings represents a significant opportunity for innovation. Custom-designed application systems that can precisely control surface energy parameters while accommodating the unique characteristics of bio-based formulations could dramatically improve manufacturing efficiency and product performance. Collaborative efforts between coating formulators, equipment manufacturers, and end-users will be essential in addressing these manufacturing challenges and realizing the full potential of surface energy-optimized bio-based barrier coatings.

Production scale-up for bio-based barrier coatings with optimized surface energy properties necessitates specialized equipment capable of precise control over coating thickness, uniformity, and curing conditions. Conventional coating methods such as roll-to-roll processing, spray coating, and curtain coating must be adapted to accommodate the unique rheological properties and drying behaviors of bio-based formulations. The sensitivity of surface energy characteristics to processing conditions demands robust in-line monitoring systems to ensure consistent performance across large production volumes.

Material handling represents another critical consideration in manufacturing scale-up. Bio-based coating components often exhibit greater variability in their properties compared to synthetic alternatives, requiring more sophisticated quality control protocols. Storage stability, batch-to-batch consistency, and raw material sourcing become increasingly important factors as production volumes increase. Implementing effective quality management systems that can accommodate this variability while maintaining precise surface energy specifications is essential for commercial viability.

Cost-effectiveness remains a paramount concern in scaling bio-based barrier coating technologies. Current production economics often favor conventional petroleum-based alternatives due to established supply chains and manufacturing efficiencies. Achieving competitive pricing requires optimization of formulation components, processing parameters, and production throughput. Strategic selection of bio-based raw materials that balance performance requirements with availability and cost considerations is crucial for successful commercialization.

Regulatory compliance and sustainability metrics must also be integrated into manufacturing scale-up strategies. While bio-based coatings offer inherent environmental advantages, quantifying these benefits through standardized life cycle assessment methodologies becomes increasingly important at commercial scale. Documentation of reduced carbon footprint, decreased toxicity, and improved end-of-life characteristics provides valuable differentiation in the marketplace and supports regulatory approval processes across different jurisdictions.

The development of specialized equipment and process technologies specifically designed for bio-based barrier coatings represents a significant opportunity for innovation. Custom-designed application systems that can precisely control surface energy parameters while accommodating the unique characteristics of bio-based formulations could dramatically improve manufacturing efficiency and product performance. Collaborative efforts between coating formulators, equipment manufacturers, and end-users will be essential in addressing these manufacturing challenges and realizing the full potential of surface energy-optimized bio-based barrier coatings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!