Moisture Absorption Control via Bio-based Coating Design

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Coating Technology Background and Objectives

Bio-based coatings represent a significant advancement in sustainable material science, emerging from the growing need to replace petroleum-based products with renewable alternatives. The evolution of these coatings can be traced back to early experiments with natural oils and resins in the mid-20th century, but substantial progress has accelerated in the past two decades due to increasing environmental concerns and regulatory pressures on volatile organic compounds (VOCs).

The technological trajectory has shifted from simple plant oil modifications to sophisticated bio-based polymer systems with enhanced functionality. Recent innovations have focused on developing coatings that not only provide traditional protection but also offer advanced properties such as moisture regulation, antimicrobial activity, and self-healing capabilities. This progression aligns with the global push toward circular economy principles and reduced carbon footprints in manufacturing processes.

Moisture absorption control represents a critical challenge in coating technology, particularly for applications in humid environments or materials susceptible to water damage. Traditional synthetic coatings often create impermeable barriers that trap moisture, leading to substrate deterioration. Bio-based alternatives offer the potential for "intelligent" moisture management through hydrophilic-hydrophobic balance optimization and biomimetic approaches inspired by natural systems like plant cuticles.

The primary objective of research in this field is to develop bio-based coating formulations that can actively regulate moisture absorption and desorption processes while maintaining structural integrity and adhesion properties. This involves understanding the complex interactions between coating components, substrate materials, and environmental conditions to create systems that respond dynamically to changing humidity levels.

Secondary goals include achieving comparable or superior performance to conventional petroleum-based products, ensuring cost-effectiveness for commercial viability, and maintaining sustainability throughout the product lifecycle. Researchers aim to develop coatings with controlled biodegradability that maintain functionality during their service life but decompose harmlessly after disposal.

Technical targets encompass developing formulations with tunable moisture vapor transmission rates, hydrophobicity gradients, and responsive behavior to environmental triggers. The ideal bio-based moisture-controlling coating would combine renewable raw materials with minimal processing requirements, low environmental impact, and enhanced functional properties that extend substrate lifespans through effective moisture management.

The technological trajectory has shifted from simple plant oil modifications to sophisticated bio-based polymer systems with enhanced functionality. Recent innovations have focused on developing coatings that not only provide traditional protection but also offer advanced properties such as moisture regulation, antimicrobial activity, and self-healing capabilities. This progression aligns with the global push toward circular economy principles and reduced carbon footprints in manufacturing processes.

Moisture absorption control represents a critical challenge in coating technology, particularly for applications in humid environments or materials susceptible to water damage. Traditional synthetic coatings often create impermeable barriers that trap moisture, leading to substrate deterioration. Bio-based alternatives offer the potential for "intelligent" moisture management through hydrophilic-hydrophobic balance optimization and biomimetic approaches inspired by natural systems like plant cuticles.

The primary objective of research in this field is to develop bio-based coating formulations that can actively regulate moisture absorption and desorption processes while maintaining structural integrity and adhesion properties. This involves understanding the complex interactions between coating components, substrate materials, and environmental conditions to create systems that respond dynamically to changing humidity levels.

Secondary goals include achieving comparable or superior performance to conventional petroleum-based products, ensuring cost-effectiveness for commercial viability, and maintaining sustainability throughout the product lifecycle. Researchers aim to develop coatings with controlled biodegradability that maintain functionality during their service life but decompose harmlessly after disposal.

Technical targets encompass developing formulations with tunable moisture vapor transmission rates, hydrophobicity gradients, and responsive behavior to environmental triggers. The ideal bio-based moisture-controlling coating would combine renewable raw materials with minimal processing requirements, low environmental impact, and enhanced functional properties that extend substrate lifespans through effective moisture management.

Market Analysis for Moisture-Resistant Bio-based Coatings

The global market for moisture-resistant bio-based coatings is experiencing significant growth, driven by increasing environmental regulations and consumer demand for sustainable products. Currently valued at approximately 4.2 billion USD in 2023, this market segment is projected to reach 7.8 billion USD by 2030, representing a compound annual growth rate of 9.3% during the forecast period.

The construction industry remains the largest end-user of moisture-resistant bio-based coatings, accounting for nearly 38% of the total market share. This dominance is attributed to the growing emphasis on green building practices and the need for durable, environmentally friendly materials that can withstand varying climate conditions while maintaining structural integrity.

Packaging represents the fastest-growing application segment, with a growth rate exceeding 12% annually. This surge is primarily due to stringent regulations on food packaging materials and increasing consumer preference for sustainable packaging solutions. Bio-based moisture barriers are increasingly replacing petroleum-based alternatives in food packaging, cosmetics containers, and pharmaceutical packaging.

Regionally, Europe leads the market with approximately 35% share, supported by stringent environmental regulations and well-established sustainability goals. The European Green Deal has further accelerated adoption rates across various industries. North America follows closely at 28%, with significant growth potential in the residential construction and automotive sectors.

Asia-Pacific represents the most promising growth region, with countries like China, Japan, and India investing heavily in sustainable technologies. The region is expected to witness the highest CAGR of 11.2% through 2030, driven by rapid industrialization, urbanization, and increasing environmental awareness among consumers and manufacturers alike.

Consumer preferences are shifting decisively toward eco-friendly products, with 73% of global consumers expressing willingness to pay premium prices for sustainable coatings. This trend is particularly pronounced among millennials and Gen Z consumers, who prioritize environmental impact in their purchasing decisions.

Key market challenges include price sensitivity compared to conventional petroleum-based alternatives, with bio-based solutions typically commanding a 15-30% premium. However, this gap is narrowing as production scales increase and technological advancements improve cost efficiency. Performance consistency across varying environmental conditions remains another significant challenge, particularly for applications requiring long-term exposure to extreme weather conditions.

Emerging opportunities include the development of hybrid systems combining bio-based materials with conventional technologies to optimize performance while maintaining sustainability credentials. Additionally, the circular economy approach is gaining traction, with manufacturers exploring coating systems that facilitate recycling and biodegradability at end-of-life.

The construction industry remains the largest end-user of moisture-resistant bio-based coatings, accounting for nearly 38% of the total market share. This dominance is attributed to the growing emphasis on green building practices and the need for durable, environmentally friendly materials that can withstand varying climate conditions while maintaining structural integrity.

Packaging represents the fastest-growing application segment, with a growth rate exceeding 12% annually. This surge is primarily due to stringent regulations on food packaging materials and increasing consumer preference for sustainable packaging solutions. Bio-based moisture barriers are increasingly replacing petroleum-based alternatives in food packaging, cosmetics containers, and pharmaceutical packaging.

Regionally, Europe leads the market with approximately 35% share, supported by stringent environmental regulations and well-established sustainability goals. The European Green Deal has further accelerated adoption rates across various industries. North America follows closely at 28%, with significant growth potential in the residential construction and automotive sectors.

Asia-Pacific represents the most promising growth region, with countries like China, Japan, and India investing heavily in sustainable technologies. The region is expected to witness the highest CAGR of 11.2% through 2030, driven by rapid industrialization, urbanization, and increasing environmental awareness among consumers and manufacturers alike.

Consumer preferences are shifting decisively toward eco-friendly products, with 73% of global consumers expressing willingness to pay premium prices for sustainable coatings. This trend is particularly pronounced among millennials and Gen Z consumers, who prioritize environmental impact in their purchasing decisions.

Key market challenges include price sensitivity compared to conventional petroleum-based alternatives, with bio-based solutions typically commanding a 15-30% premium. However, this gap is narrowing as production scales increase and technological advancements improve cost efficiency. Performance consistency across varying environmental conditions remains another significant challenge, particularly for applications requiring long-term exposure to extreme weather conditions.

Emerging opportunities include the development of hybrid systems combining bio-based materials with conventional technologies to optimize performance while maintaining sustainability credentials. Additionally, the circular economy approach is gaining traction, with manufacturers exploring coating systems that facilitate recycling and biodegradability at end-of-life.

Current Challenges in Bio-based Moisture Control Technologies

Despite significant advancements in bio-based coating technologies for moisture control, several critical challenges continue to impede widespread commercial adoption and optimal performance. The primary technical obstacle remains achieving consistent moisture barrier properties comparable to synthetic petroleum-based alternatives. Bio-based coatings often exhibit higher water vapor transmission rates due to their inherent hydrophilic nature, limiting their effectiveness in high-humidity environments.

Durability presents another significant challenge, as many bio-based formulations demonstrate accelerated degradation when exposed to fluctuating environmental conditions. The molecular structure of bio-polymers typically contains numerous hydroxyl groups that facilitate hydrogen bonding with water molecules, resulting in dimensional instability and reduced mechanical strength over time. This hygroscopic behavior compromises long-term performance, particularly in outdoor or high-moisture applications.

Scalability and processing difficulties further complicate commercial implementation. Bio-based raw materials often display batch-to-batch variability in composition and properties, making standardized manufacturing processes difficult to establish. Additionally, many promising bio-based coating formulations require specialized processing equipment or techniques that are not readily compatible with existing industrial coating lines.

Cost competitiveness remains a substantial barrier, with bio-based alternatives typically commanding a 20-40% price premium over conventional moisture barrier solutions. This economic disadvantage stems from relatively immature supply chains, smaller production volumes, and more complex processing requirements for bio-based raw materials.

Regulatory uncertainty and inconsistent performance testing methodologies create additional challenges. The lack of standardized evaluation protocols specifically designed for bio-based moisture control coatings makes performance comparisons difficult and hinders market acceptance. Current testing methods often fail to account for the unique behavior of bio-based materials under varying environmental conditions.

Compatibility issues with substrate materials represent another technical hurdle. Many bio-based coatings exhibit poor adhesion to certain substrates or may interact unfavorably with underlying materials, limiting their application range. Additionally, some formulations demonstrate inadequate resistance to microbial growth due to their biological origin, potentially compromising both performance and safety in certain applications.

Finally, achieving multifunctional performance remains challenging. While conventional synthetic coatings can be engineered to provide moisture barrier properties alongside other functionalities like UV resistance or antimicrobial activity, bio-based alternatives often struggle to deliver this comprehensive performance profile without significant compromises in their primary moisture control function.

Durability presents another significant challenge, as many bio-based formulations demonstrate accelerated degradation when exposed to fluctuating environmental conditions. The molecular structure of bio-polymers typically contains numerous hydroxyl groups that facilitate hydrogen bonding with water molecules, resulting in dimensional instability and reduced mechanical strength over time. This hygroscopic behavior compromises long-term performance, particularly in outdoor or high-moisture applications.

Scalability and processing difficulties further complicate commercial implementation. Bio-based raw materials often display batch-to-batch variability in composition and properties, making standardized manufacturing processes difficult to establish. Additionally, many promising bio-based coating formulations require specialized processing equipment or techniques that are not readily compatible with existing industrial coating lines.

Cost competitiveness remains a substantial barrier, with bio-based alternatives typically commanding a 20-40% price premium over conventional moisture barrier solutions. This economic disadvantage stems from relatively immature supply chains, smaller production volumes, and more complex processing requirements for bio-based raw materials.

Regulatory uncertainty and inconsistent performance testing methodologies create additional challenges. The lack of standardized evaluation protocols specifically designed for bio-based moisture control coatings makes performance comparisons difficult and hinders market acceptance. Current testing methods often fail to account for the unique behavior of bio-based materials under varying environmental conditions.

Compatibility issues with substrate materials represent another technical hurdle. Many bio-based coatings exhibit poor adhesion to certain substrates or may interact unfavorably with underlying materials, limiting their application range. Additionally, some formulations demonstrate inadequate resistance to microbial growth due to their biological origin, potentially compromising both performance and safety in certain applications.

Finally, achieving multifunctional performance remains challenging. While conventional synthetic coatings can be engineered to provide moisture barrier properties alongside other functionalities like UV resistance or antimicrobial activity, bio-based alternatives often struggle to deliver this comprehensive performance profile without significant compromises in their primary moisture control function.

Current Bio-based Coating Solutions for Moisture Control

01 Bio-based polymers for moisture-absorbing coatings

Bio-based polymers derived from renewable resources can be formulated into coatings with excellent moisture absorption properties. These polymers, such as modified cellulose, starch derivatives, and plant-based proteins, create a network structure that effectively absorbs and retains moisture from the environment. The natural hygroscopic properties of these bio-polymers make them ideal for applications requiring humidity control and moisture management.- Bio-based moisture-absorbing coating materials: Various bio-based materials can be incorporated into coatings to enhance moisture absorption properties. These materials include natural fibers, plant extracts, and biodegradable polymers that have inherent hygroscopic properties. The bio-based components can effectively absorb and regulate moisture, making them suitable for applications requiring humidity control while maintaining environmental sustainability.

- Cellulose-derived coating formulations: Cellulose and its derivatives serve as excellent bio-based components in moisture-absorbing coatings. Modified cellulose materials, including microcrystalline cellulose, cellulose nanofibers, and cellulose ethers, can be formulated into coatings that provide superior moisture management properties. These formulations offer renewable alternatives to synthetic moisture-absorbing materials while maintaining comparable or superior performance characteristics.

- Starch and protein-based moisture control systems: Starch and protein-based materials derived from agricultural sources can be engineered into effective moisture-absorbing coating systems. These bio-polymers can be modified through various processes to enhance their moisture absorption capacity, stability, and adhesion properties. The resulting coatings provide sustainable solutions for applications requiring controlled humidity environments while utilizing renewable resources.

- Composite bio-based coatings with enhanced moisture properties: Composite systems combining multiple bio-based components can create synergistic effects for moisture absorption. These formulations typically incorporate combinations of natural fibers, biopolymers, and functional additives to optimize moisture management capabilities. The composite approach allows for customization of absorption rates, capacity, and moisture retention properties while maintaining the environmental benefits of bio-based materials.

- Application techniques for bio-based moisture-absorbing coatings: Specialized application methods and processing techniques can significantly enhance the performance of bio-based moisture-absorbing coatings. These include multi-layer systems, controlled porosity development, surface modification treatments, and curing processes optimized for bio-based materials. The appropriate application technique ensures optimal distribution and functionality of the moisture-absorbing components while maintaining coating integrity and durability.

02 Natural fiber reinforcement in moisture-absorbing coatings

Incorporating natural fibers into bio-based coating formulations enhances moisture absorption capacity while improving mechanical properties. Fibers from sources like flax, hemp, jute, and agricultural waste create a capillary network within the coating that facilitates moisture uptake and distribution. These reinforced coatings demonstrate superior dimensional stability under varying humidity conditions while maintaining their eco-friendly characteristics.Expand Specific Solutions03 Superabsorbent bio-composites for enhanced moisture control

Advanced bio-based superabsorbent composites can be formulated by combining natural polymers with specific additives to dramatically increase moisture absorption capacity. These formulations typically incorporate modified polysaccharides, hydrogels derived from natural sources, and porous bio-fillers to create coatings that can absorb many times their weight in water. The controlled release properties of these materials make them suitable for applications in agriculture, construction, and packaging where moisture regulation is critical.Expand Specific Solutions04 Functional additives for bio-based moisture-absorbing coatings

Various functional additives can be incorporated into bio-based coating formulations to enhance moisture absorption performance and durability. These include natural clay minerals, silica derivatives, and plant extracts with hygroscopic properties. The addition of crosslinking agents derived from renewable resources improves the coating's structural integrity while maintaining its moisture absorption capabilities. These additives also contribute to preventing microbial growth in high-humidity environments.Expand Specific Solutions05 Application techniques for bio-based moisture-absorbing coatings

Specialized application methods have been developed for bio-based moisture-absorbing coatings to optimize their performance across different substrates. These techniques include multi-layer application systems, controlled drying processes, and surface preparation methods that enhance adhesion and moisture absorption properties. The coating thickness, curing conditions, and application temperature significantly impact the final moisture absorption capacity and longevity of the coating system.Expand Specific Solutions

Leading Companies and Research Institutions in Bio-based Coatings

The bio-based coating market for moisture absorption control is in a growth phase, characterized by increasing demand for sustainable packaging solutions. The market size is expanding rapidly, driven by environmental regulations and consumer preferences for eco-friendly materials. Technologically, the field shows varying maturity levels across different applications. Academic institutions like University of Florida, Sichuan University, and Sorbonne Université are leading fundamental research, while companies demonstrate different specialization levels. BASF Corp. and Dow Global Technologies possess advanced commercial capabilities, while JSR Corp. and DSM IP Assets BV show strong innovation in specialized applications. Emerging players like Zhangjiagang Duplus Chemical and Henan Tuoren are developing niche solutions. The collaboration between research institutions and industry partners is accelerating technology transfer, with companies like Metsä Board implementing bio-based coatings in commercial packaging applications.

DSM IP Assets BV

Technical Solution: DSM has developed advanced bio-based coating systems utilizing their Decovery® platform, which incorporates plant-based materials to replace fossil-fuel derived components. Their moisture control technology employs bio-based polyesters and modified plant oils that create highly cross-linked networks with exceptional water repellency. DSM's coatings incorporate specialized bio-based additives that actively respond to environmental humidity changes, adjusting their molecular configuration to maintain optimal moisture barrier properties. Their research has demonstrated moisture vapor transmission rates reduced by up to 75% compared to conventional coatings while maintaining flexibility and adhesion. The company has also developed bio-based self-stratifying coatings where hydrophobic components naturally migrate to the surface during curing, creating enhanced moisture barriers without requiring multiple application steps.

Strengths: Strong expertise in sustainable materials science and established manufacturing capabilities for bio-based ingredients provide competitive advantages in scaling new technologies. Weaknesses: Higher initial development costs and potential limitations in extreme temperature applications compared to some petroleum-based alternatives.

Metsä Board Oyj

Technical Solution: Metsä Board has developed innovative bio-based barrier coatings derived primarily from wood pulp and forest industry by-products. Their technology utilizes microfibrillated cellulose (MFC) and specialized hemicellulose derivatives to create dense, interlocking networks that effectively control moisture transmission. The company's approach involves surface modification of natural fibers to enhance hydrophobicity while maintaining biodegradability. Their research has demonstrated that these coatings can reduce moisture absorption by up to 70% compared to uncoated substrates while remaining fully recyclable and biodegradable. Metsä's bio-based coatings also incorporate natural waxes and resins that provide additional moisture resistance through a multi-layer protection system. The company has successfully implemented these technologies in packaging applications where controlled moisture transmission is critical for product preservation.

Strengths: Vertical integration with sustainable forestry operations provides secure access to raw materials and supports consistent quality in bio-based coating production. Weaknesses: Limited application range primarily focused on paper and packaging industries rather than broader industrial applications.

Key Patents and Innovations in Bio-based Moisture Barriers

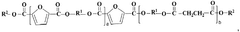

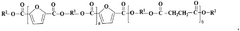

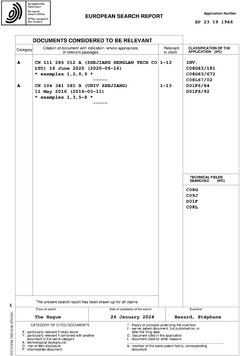

Bio-based moisture absorption and sweat discharging multifunctional finishing agent and preparation method and application thereof

PatentActiveEP4438650A1

Innovation

- A bio-based moisture absorption and sweat discharging multifunctional finishing agent is developed, comprising a specific molecular structure derived from bio-based polyethylene glycol, bio-based dibasic acids or esters with a furan structure, and bio-based diols, which undergo transesterification and polycondensation reactions to create a finishing agent with improved hydrophilicity, anti-static properties, and laundering durability.

A BIO-based coating for agricultural applications.

PatentWO2025136095A1

Innovation

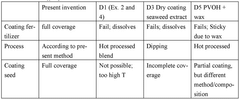

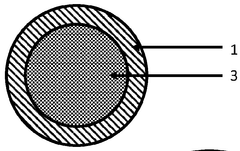

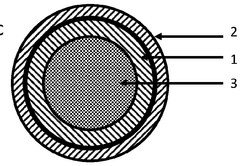

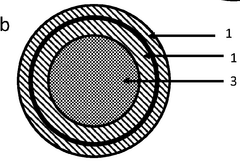

- A bio-based water-soluble coating comprising a protective layer made from 50-98 wt.% biopolymer, 0.1-35 wt.% non-polar binder, and optionally 0-49.9 wt.% plasticizer, applied to agricultural particles such as fertilizers and seeds, providing protection and controlled nutrient release.

Environmental Impact and Sustainability Assessment

Bio-based coatings represent a significant advancement in sustainable material science, offering an environmentally responsible alternative to conventional petroleum-based coating systems. The environmental impact assessment of these moisture-controlling bio-based coatings reveals substantial benefits across multiple ecological dimensions. Life cycle analyses demonstrate that bio-based coatings typically generate 40-60% lower carbon emissions compared to their synthetic counterparts, primarily due to the renewable nature of their feedstocks and less energy-intensive manufacturing processes.

Water consumption metrics also favor bio-based coating systems, with studies indicating a reduction of approximately 30% in water usage throughout the production chain. This advantage stems from the generally lower irrigation requirements of many bio-based raw materials compared to the extensive water needs in petrochemical processing. Additionally, these coatings significantly reduce the release of volatile organic compounds (VOCs), which are major contributors to air pollution and associated health concerns.

The biodegradability profile of bio-based moisture control coatings presents another environmental advantage. While conventional coatings may persist in ecosystems for decades, properly formulated bio-based alternatives can decompose within 2-5 years under appropriate conditions, minimizing long-term environmental accumulation. This characteristic is particularly valuable for applications with shorter service lifespans.

From a sustainability perspective, these coatings contribute to circular economy principles by utilizing agricultural by-products and waste streams as raw materials. For instance, cellulose derivatives from agricultural residues and lignin from paper production waste have demonstrated excellent moisture barrier properties when incorporated into coating formulations. This approach not only diverts waste from landfills but also creates additional value streams for agricultural and forestry sectors.

The renewable resource base for bio-based coatings offers significant sustainability advantages. Unlike petroleum-based alternatives that rely on finite fossil resources, bio-based systems can be continuously replenished through responsible agricultural and forestry practices. However, this benefit must be carefully balanced against potential land-use conflicts, particularly concerns regarding competition with food production or contribution to deforestation.

Regulatory frameworks increasingly favor bio-based coating technologies, with policies in Europe, North America, and parts of Asia providing incentives for their development and adoption. These include carbon taxation systems, extended producer responsibility regulations, and green procurement policies that collectively strengthen the market position of environmentally preferable coating solutions.

Water consumption metrics also favor bio-based coating systems, with studies indicating a reduction of approximately 30% in water usage throughout the production chain. This advantage stems from the generally lower irrigation requirements of many bio-based raw materials compared to the extensive water needs in petrochemical processing. Additionally, these coatings significantly reduce the release of volatile organic compounds (VOCs), which are major contributors to air pollution and associated health concerns.

The biodegradability profile of bio-based moisture control coatings presents another environmental advantage. While conventional coatings may persist in ecosystems for decades, properly formulated bio-based alternatives can decompose within 2-5 years under appropriate conditions, minimizing long-term environmental accumulation. This characteristic is particularly valuable for applications with shorter service lifespans.

From a sustainability perspective, these coatings contribute to circular economy principles by utilizing agricultural by-products and waste streams as raw materials. For instance, cellulose derivatives from agricultural residues and lignin from paper production waste have demonstrated excellent moisture barrier properties when incorporated into coating formulations. This approach not only diverts waste from landfills but also creates additional value streams for agricultural and forestry sectors.

The renewable resource base for bio-based coatings offers significant sustainability advantages. Unlike petroleum-based alternatives that rely on finite fossil resources, bio-based systems can be continuously replenished through responsible agricultural and forestry practices. However, this benefit must be carefully balanced against potential land-use conflicts, particularly concerns regarding competition with food production or contribution to deforestation.

Regulatory frameworks increasingly favor bio-based coating technologies, with policies in Europe, North America, and parts of Asia providing incentives for their development and adoption. These include carbon taxation systems, extended producer responsibility regulations, and green procurement policies that collectively strengthen the market position of environmentally preferable coating solutions.

Regulatory Framework for Bio-based Coating Materials

The regulatory landscape for bio-based coating materials is evolving rapidly as governments worldwide recognize the importance of sustainable alternatives to petroleum-based products. In the European Union, the Bio-based Products Directive (2009/28/EC) establishes a framework for promoting bio-based materials, including coatings, with specific requirements for carbon footprint reduction and biodegradability. This directive is complemented by the EU Ecolabel criteria for paints and varnishes, which sets stringent standards for volatile organic compound (VOC) content and overall environmental impact.

In the United States, the USDA BioPreferred Program provides certification for bio-based products, offering market advantages through federal procurement preferences. Additionally, the EPA's Significant New Use Rules under the Toxic Substances Control Act (TSCA) regulate the introduction of novel bio-based coating materials, requiring manufacturers to demonstrate safety before commercialization.

International standards such as ISO 16128 and ASTM D6866 provide methodologies for determining the bio-based content in materials, ensuring transparency and preventing greenwashing in the industry. These standards are increasingly referenced in regulatory frameworks and procurement policies globally, creating a unified approach to bio-based material verification.

Regulatory challenges specific to moisture absorption control coatings include performance validation protocols and durability testing requirements. The European Construction Products Regulation (CPR) mandates CE marking for construction materials, including moisture-resistant coatings, with specific requirements for hygroscopic behavior under EN 16755 standards.

Food contact applications represent a particularly stringent regulatory domain for bio-based coatings. The FDA's Food Contact Substance Notification program and the EU's Regulation (EC) No 1935/2004 establish comprehensive safety assessment requirements for materials intended to contact food, with additional considerations for bio-based alternatives regarding migration testing and toxicological evaluation.

Emerging regulatory trends include the development of life cycle assessment (LCA) requirements for bio-based materials, carbon footprint declarations, and extended producer responsibility schemes. Several countries, including France and the Netherlands, have introduced bio-based content quotas in public procurement, creating market drivers for innovation in this sector.

Compliance with these diverse regulatory frameworks presents both challenges and opportunities for researchers and manufacturers developing moisture absorption control coatings. Early engagement with regulatory bodies and certification organizations can facilitate smoother market entry and provide valuable guidance for research direction and product development strategies.

In the United States, the USDA BioPreferred Program provides certification for bio-based products, offering market advantages through federal procurement preferences. Additionally, the EPA's Significant New Use Rules under the Toxic Substances Control Act (TSCA) regulate the introduction of novel bio-based coating materials, requiring manufacturers to demonstrate safety before commercialization.

International standards such as ISO 16128 and ASTM D6866 provide methodologies for determining the bio-based content in materials, ensuring transparency and preventing greenwashing in the industry. These standards are increasingly referenced in regulatory frameworks and procurement policies globally, creating a unified approach to bio-based material verification.

Regulatory challenges specific to moisture absorption control coatings include performance validation protocols and durability testing requirements. The European Construction Products Regulation (CPR) mandates CE marking for construction materials, including moisture-resistant coatings, with specific requirements for hygroscopic behavior under EN 16755 standards.

Food contact applications represent a particularly stringent regulatory domain for bio-based coatings. The FDA's Food Contact Substance Notification program and the EU's Regulation (EC) No 1935/2004 establish comprehensive safety assessment requirements for materials intended to contact food, with additional considerations for bio-based alternatives regarding migration testing and toxicological evaluation.

Emerging regulatory trends include the development of life cycle assessment (LCA) requirements for bio-based materials, carbon footprint declarations, and extended producer responsibility schemes. Several countries, including France and the Netherlands, have introduced bio-based content quotas in public procurement, creating market drivers for innovation in this sector.

Compliance with these diverse regulatory frameworks presents both challenges and opportunities for researchers and manufacturers developing moisture absorption control coatings. Early engagement with regulatory bodies and certification organizations can facilitate smoother market entry and provide valuable guidance for research direction and product development strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!