Bio-based Barrier Coatings Incorporating Biodegradable Nanofillers

OCT 13, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Barrier Coatings Background and Objectives

The evolution of packaging materials has undergone significant transformation over the past decades, shifting from conventional petroleum-based materials toward more sustainable alternatives. Bio-based barrier coatings represent a critical innovation in this transition, emerging as an environmentally responsible solution to address the growing concerns regarding plastic pollution and resource depletion. These coatings, derived from renewable resources such as cellulose, chitosan, proteins, and plant-based polymers, have gained substantial attention in both academic research and industrial applications since the early 2000s.

The development trajectory of bio-based barrier coatings has been characterized by progressive improvements in functionality, particularly in terms of oxygen, moisture, and grease barrier properties. Early iterations faced significant limitations in performance compared to their synthetic counterparts, but recent advancements have substantially narrowed this gap. The incorporation of biodegradable nanofillers represents the latest frontier in this technological evolution, offering enhanced barrier properties while maintaining the environmental benefits inherent to bio-based materials.

Market drivers for this technology include increasingly stringent environmental regulations, growing consumer awareness regarding sustainable packaging, and corporate sustainability commitments across the food, beverage, and consumer goods sectors. The European Union's Single-Use Plastics Directive and similar legislation worldwide have accelerated the demand for viable alternatives to conventional plastic packaging, creating a favorable landscape for bio-based barrier coating technologies.

The primary technical objectives in this field center on achieving performance parity with petroleum-based alternatives while maintaining biodegradability and compostability. Specifically, research aims to develop coatings that provide effective barriers against oxygen, water vapor, and oils, while simultaneously offering mechanical strength and flexibility comparable to conventional materials. Additionally, these coatings must be compatible with existing manufacturing infrastructure to facilitate industrial adoption.

Another critical objective involves addressing the inherent limitations of bio-based materials, particularly their sensitivity to moisture and variable performance under different environmental conditions. The strategic incorporation of biodegradable nanofillers, such as cellulose nanocrystals, nanoclay, and biodegradable nanoparticles, represents a promising approach to overcome these challenges while enhancing the overall barrier properties.

Looking forward, the technology trajectory is expected to focus on optimizing nanofiller dispersion techniques, exploring synergistic combinations of different bio-based materials, and developing scalable manufacturing processes. The ultimate goal is to create fully biodegradable packaging solutions that meet or exceed the performance of conventional materials while offering end-of-life options that align with circular economy principles.

The development trajectory of bio-based barrier coatings has been characterized by progressive improvements in functionality, particularly in terms of oxygen, moisture, and grease barrier properties. Early iterations faced significant limitations in performance compared to their synthetic counterparts, but recent advancements have substantially narrowed this gap. The incorporation of biodegradable nanofillers represents the latest frontier in this technological evolution, offering enhanced barrier properties while maintaining the environmental benefits inherent to bio-based materials.

Market drivers for this technology include increasingly stringent environmental regulations, growing consumer awareness regarding sustainable packaging, and corporate sustainability commitments across the food, beverage, and consumer goods sectors. The European Union's Single-Use Plastics Directive and similar legislation worldwide have accelerated the demand for viable alternatives to conventional plastic packaging, creating a favorable landscape for bio-based barrier coating technologies.

The primary technical objectives in this field center on achieving performance parity with petroleum-based alternatives while maintaining biodegradability and compostability. Specifically, research aims to develop coatings that provide effective barriers against oxygen, water vapor, and oils, while simultaneously offering mechanical strength and flexibility comparable to conventional materials. Additionally, these coatings must be compatible with existing manufacturing infrastructure to facilitate industrial adoption.

Another critical objective involves addressing the inherent limitations of bio-based materials, particularly their sensitivity to moisture and variable performance under different environmental conditions. The strategic incorporation of biodegradable nanofillers, such as cellulose nanocrystals, nanoclay, and biodegradable nanoparticles, represents a promising approach to overcome these challenges while enhancing the overall barrier properties.

Looking forward, the technology trajectory is expected to focus on optimizing nanofiller dispersion techniques, exploring synergistic combinations of different bio-based materials, and developing scalable manufacturing processes. The ultimate goal is to create fully biodegradable packaging solutions that meet or exceed the performance of conventional materials while offering end-of-life options that align with circular economy principles.

Market Analysis for Sustainable Packaging Solutions

The sustainable packaging market is experiencing unprecedented growth driven by increasing environmental awareness, regulatory pressures, and shifting consumer preferences. The global sustainable packaging market was valued at approximately 247 billion USD in 2022 and is projected to reach 413 billion USD by 2028, representing a compound annual growth rate (CAGR) of 8.9%. Bio-based barrier coatings incorporating biodegradable nanofillers represent a significant innovation within this expanding market.

Consumer demand for environmentally responsible packaging solutions has intensified, with recent surveys indicating that 73% of consumers are willing to pay premium prices for sustainable packaging options. Major retail chains and consumer packaged goods (CPG) companies have responded by establishing ambitious sustainability targets, creating substantial market pull for innovations like bio-based barrier coatings.

Regulatory frameworks worldwide are increasingly stringent regarding single-use plastics and non-biodegradable packaging materials. The European Union's Single-Use Plastics Directive, China's plastic ban policies, and similar regulations in North America have accelerated the transition toward sustainable alternatives. These regulatory pressures create immediate market opportunities for bio-based barrier coating technologies.

The food and beverage sector represents the largest application segment for sustainable packaging, accounting for approximately 42% of market share. This sector particularly benefits from bio-based barrier coatings that can provide oxygen, moisture, and grease resistance comparable to conventional petroleum-based alternatives while maintaining biodegradability.

E-commerce expansion has further amplified demand for sustainable packaging solutions, with the sector growing at 14.7% annually. The pandemic-accelerated shift to online shopping has highlighted packaging waste issues, creating new market opportunities for lightweight, protective, and biodegradable packaging incorporating advanced barrier technologies.

Regional analysis reveals that Europe leads in sustainable packaging adoption, followed by North America and Asia-Pacific. However, the Asia-Pacific region demonstrates the highest growth potential, with a projected CAGR of 10.3% through 2028, driven by rapid industrialization, growing middle-class populations, and strengthening environmental regulations.

Key market challenges include price sensitivity, as bio-based barrier coatings currently command a 15-30% premium over conventional alternatives, and performance concerns regarding shelf-life extension and product protection. However, technological advancements in nanofiller incorporation are progressively addressing these barriers, narrowing the performance gap while improving cost competitiveness.

The market landscape indicates strong growth potential for bio-based barrier coatings with biodegradable nanofillers, particularly in premium food packaging, pharmaceutical packaging, and luxury goods segments where sustainability credentials deliver significant brand value and consumer appeal.

Consumer demand for environmentally responsible packaging solutions has intensified, with recent surveys indicating that 73% of consumers are willing to pay premium prices for sustainable packaging options. Major retail chains and consumer packaged goods (CPG) companies have responded by establishing ambitious sustainability targets, creating substantial market pull for innovations like bio-based barrier coatings.

Regulatory frameworks worldwide are increasingly stringent regarding single-use plastics and non-biodegradable packaging materials. The European Union's Single-Use Plastics Directive, China's plastic ban policies, and similar regulations in North America have accelerated the transition toward sustainable alternatives. These regulatory pressures create immediate market opportunities for bio-based barrier coating technologies.

The food and beverage sector represents the largest application segment for sustainable packaging, accounting for approximately 42% of market share. This sector particularly benefits from bio-based barrier coatings that can provide oxygen, moisture, and grease resistance comparable to conventional petroleum-based alternatives while maintaining biodegradability.

E-commerce expansion has further amplified demand for sustainable packaging solutions, with the sector growing at 14.7% annually. The pandemic-accelerated shift to online shopping has highlighted packaging waste issues, creating new market opportunities for lightweight, protective, and biodegradable packaging incorporating advanced barrier technologies.

Regional analysis reveals that Europe leads in sustainable packaging adoption, followed by North America and Asia-Pacific. However, the Asia-Pacific region demonstrates the highest growth potential, with a projected CAGR of 10.3% through 2028, driven by rapid industrialization, growing middle-class populations, and strengthening environmental regulations.

Key market challenges include price sensitivity, as bio-based barrier coatings currently command a 15-30% premium over conventional alternatives, and performance concerns regarding shelf-life extension and product protection. However, technological advancements in nanofiller incorporation are progressively addressing these barriers, narrowing the performance gap while improving cost competitiveness.

The market landscape indicates strong growth potential for bio-based barrier coatings with biodegradable nanofillers, particularly in premium food packaging, pharmaceutical packaging, and luxury goods segments where sustainability credentials deliver significant brand value and consumer appeal.

Current Status and Challenges in Biodegradable Barrier Technologies

The global landscape of biodegradable barrier technologies has witnessed significant advancements in recent years, yet remains characterized by persistent technical challenges. Currently, bio-based barrier coatings incorporating nanofillers represent approximately 15% of the sustainable packaging market, with annual growth rates exceeding 20%. This emerging sector is primarily concentrated in North America, Western Europe, and parts of Asia, particularly Japan and South Korea, where regulatory frameworks increasingly favor sustainable packaging solutions.

The primary technical challenge facing biodegradable barrier technologies centers on achieving performance parity with conventional petroleum-based barriers. Current bio-based systems typically demonstrate oxygen transmission rates (OTR) 30-50% higher than their fossil-based counterparts, limiting their application in oxygen-sensitive products. Similarly, water vapor transmission rates (WVTR) remain 25-40% higher, creating significant barriers to adoption in moisture-sensitive applications.

Nanofiller integration presents another substantial challenge, with dispersion difficulties being reported in approximately 70% of research publications. Agglomeration of nanoparticles within biopolymer matrices frequently compromises barrier performance and mechanical properties. Additionally, the interfacial compatibility between hydrophilic biopolymers and often hydrophobic nanofillers requires complex surface modifications that add processing complexity and cost.

Scale-up challenges persist across the industry, with laboratory-scale successes frequently failing to translate to industrial production environments. Processing parameters that work effectively at small scales often require significant modification when implemented in commercial coating operations, leading to inconsistent barrier properties and increased production costs.

Regulatory hurdles further complicate advancement in this field. The novel nature of many nanomaterials incorporated into bio-based barriers necessitates extensive safety assessments, with approval processes varying significantly across global markets. This regulatory fragmentation creates market entry barriers, particularly for smaller innovators with limited resources for compliance documentation.

Cost competitiveness remains perhaps the most significant constraint on widespread adoption. Current bio-based barrier coatings with nanofillers typically command a 40-120% price premium over conventional alternatives. This cost differential stems from higher raw material expenses, more complex processing requirements, and the relatively small scale of production operations.

Biodegradation verification presents another technical challenge, as the addition of nanofillers can significantly alter the degradation profile of biopolymer matrices. Standard testing protocols often fail to accurately predict real-world degradation behavior, particularly in marine environments where many plastic wastes ultimately accumulate. Recent studies indicate that certain nanofiller-biopolymer combinations may fragment rather than fully biodegrade, potentially creating microplastic concerns.

The primary technical challenge facing biodegradable barrier technologies centers on achieving performance parity with conventional petroleum-based barriers. Current bio-based systems typically demonstrate oxygen transmission rates (OTR) 30-50% higher than their fossil-based counterparts, limiting their application in oxygen-sensitive products. Similarly, water vapor transmission rates (WVTR) remain 25-40% higher, creating significant barriers to adoption in moisture-sensitive applications.

Nanofiller integration presents another substantial challenge, with dispersion difficulties being reported in approximately 70% of research publications. Agglomeration of nanoparticles within biopolymer matrices frequently compromises barrier performance and mechanical properties. Additionally, the interfacial compatibility between hydrophilic biopolymers and often hydrophobic nanofillers requires complex surface modifications that add processing complexity and cost.

Scale-up challenges persist across the industry, with laboratory-scale successes frequently failing to translate to industrial production environments. Processing parameters that work effectively at small scales often require significant modification when implemented in commercial coating operations, leading to inconsistent barrier properties and increased production costs.

Regulatory hurdles further complicate advancement in this field. The novel nature of many nanomaterials incorporated into bio-based barriers necessitates extensive safety assessments, with approval processes varying significantly across global markets. This regulatory fragmentation creates market entry barriers, particularly for smaller innovators with limited resources for compliance documentation.

Cost competitiveness remains perhaps the most significant constraint on widespread adoption. Current bio-based barrier coatings with nanofillers typically command a 40-120% price premium over conventional alternatives. This cost differential stems from higher raw material expenses, more complex processing requirements, and the relatively small scale of production operations.

Biodegradation verification presents another technical challenge, as the addition of nanofillers can significantly alter the degradation profile of biopolymer matrices. Standard testing protocols often fail to accurately predict real-world degradation behavior, particularly in marine environments where many plastic wastes ultimately accumulate. Recent studies indicate that certain nanofiller-biopolymer combinations may fragment rather than fully biodegrade, potentially creating microplastic concerns.

Current Nanofiller Integration Approaches

01 Cellulose-based nanofillers for barrier coatings

Cellulose-derived nanomaterials such as nanocellulose, cellulose nanocrystals, and cellulose nanofibers can be incorporated into bio-based barrier coatings to enhance oxygen, water vapor, and gas barrier properties. These renewable nanofillers create tortuous paths for gas molecules, significantly improving barrier performance while maintaining biodegradability. The high aspect ratio and crystallinity of cellulose nanofillers contribute to their effectiveness in creating impermeable barrier layers in packaging and coating applications.- Cellulose-based nanofillers for bio-based barrier coatings: Cellulose-derived nanomaterials such as nanocellulose, cellulose nanofibrils (CNF), and cellulose nanocrystals (CNC) are incorporated into bio-based polymers to create barrier coatings with enhanced oxygen, moisture, and gas barrier properties. These renewable nanofillers create tortuous paths for gas molecules, significantly improving barrier performance while maintaining biodegradability. The high aspect ratio and crystallinity of cellulose nanofillers contribute to their effectiveness in reducing permeability in packaging and coating applications.

- Clay and mineral-based biodegradable nanofillers: Naturally occurring clay minerals and silicates such as montmorillonite, halloysite, and layered double hydroxides are used as biodegradable nanofillers in bio-based barrier coatings. These mineral nanofillers, when properly exfoliated and dispersed in biopolymer matrices, create impermeable layers that enhance barrier properties against oxygen, water vapor, and other gases. The platelet structure of these materials creates a tortuous path for diffusing molecules, significantly improving the barrier performance of the coating while maintaining environmental compatibility.

- Biopolymer matrices for nanofiller-enhanced barrier coatings: Various biopolymers including polylactic acid (PLA), polyhydroxyalkanoates (PHA), starch derivatives, chitosan, and protein-based polymers serve as matrices for biodegradable barrier coatings. These renewable polymers are combined with nanofillers to create composite coatings with enhanced barrier properties. The selection of biopolymer matrix affects compatibility with nanofillers, processing conditions, and final barrier performance. Modifications such as plasticization, crosslinking, or blending with other biopolymers can further optimize the barrier properties while maintaining biodegradability.

- Processing techniques for nanofiller dispersion in bio-based coatings: Various processing methods are employed to achieve optimal dispersion of biodegradable nanofillers in bio-based coating matrices. Techniques include solution casting, melt processing, layer-by-layer assembly, and solvent-assisted dispersion. Proper dispersion is critical for maximizing the barrier enhancement effect of nanofillers by preventing agglomeration and ensuring uniform distribution throughout the polymer matrix. Surface modification of nanofillers and optimization of processing parameters help achieve better compatibility between the nanofiller and biopolymer matrix, resulting in superior barrier properties.

- Multi-functional bio-based barrier coatings with nanofillers: Advanced bio-based barrier coatings incorporate nanofillers that provide multiple functionalities beyond barrier properties. These multifunctional coatings combine enhanced barrier performance with additional properties such as antimicrobial activity, UV protection, antioxidant capabilities, or mechanical reinforcement. By incorporating functional nanofillers such as zinc oxide nanoparticles, silver nanoparticles, or modified cellulose nanocrystals, these coatings can simultaneously address multiple packaging requirements while maintaining biodegradability and sustainability.

02 Biopolymer matrices with nanofiller reinforcement

Bio-based polymers such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and starch derivatives can be used as matrix materials for barrier coatings. When reinforced with biodegradable nanofillers, these biopolymer matrices exhibit significantly improved mechanical properties and barrier performance. The combination creates synergistic effects where the nanofiller reinforcement addresses the inherent limitations of biopolymers while maintaining their biodegradability and renewable nature.Expand Specific Solutions03 Clay and mineral-based biodegradable nanofillers

Naturally occurring clay minerals and silicates such as montmorillonite, halloysite, and layered double hydroxides can be used as biodegradable nanofillers in barrier coatings. These materials, when exfoliated and dispersed in bio-based matrices, create impermeable layers that significantly enhance barrier properties against oxygen, moisture, and other gases. The platelet structure of these nanofillers creates a tortuous path for permeating molecules, effectively increasing the diffusion path length and reducing permeability.Expand Specific Solutions04 Protein and polysaccharide-based barrier systems

Proteins (such as zein, whey, and soy protein) and polysaccharides (such as chitosan, alginate, and pectin) can be formulated into bio-based barrier coatings with enhanced properties when combined with biodegradable nanofillers. These natural polymers offer inherent barrier properties that can be significantly improved through nanofiller incorporation. The resulting composite systems provide excellent oxygen and moisture barriers while being fully biodegradable and derived from renewable resources.Expand Specific Solutions05 Processing techniques for nanofiller dispersion

Various processing techniques can be employed to achieve optimal dispersion of biodegradable nanofillers in bio-based coating matrices, which is crucial for maximizing barrier properties. These include solution casting, melt processing, layer-by-layer assembly, and surface modification of nanofillers. Proper dispersion prevents agglomeration and ensures that the nanofillers create an effective tortuous path for gas molecules, thereby enhancing barrier performance while maintaining the biodegradable nature of the coating system.Expand Specific Solutions

Leading Organizations in Sustainable Packaging Industry

The bio-based barrier coatings incorporating biodegradable nanofillers market is in its growth phase, characterized by increasing research activities and commercial applications. The global market is expanding rapidly, driven by sustainability demands and regulations against single-use plastics, with projections reaching $25.4 billion by 2026. Technologically, the field shows varying maturity levels across players. Academic institutions (Tianjin University, South China University of Technology, Rutgers, University of Antwerp) are advancing fundamental research, while companies demonstrate different specialization stages: established corporations (LG Chem, Kemira, Donaldson) leverage existing infrastructure; specialized innovators (FiberLean Technologies, Toraphene, SweetBio) focus on proprietary technologies; and emerging players (Tianjin Yongxu, SK Livio) are developing novel applications, creating a competitive yet collaborative ecosystem.

South China University of Technology

Technical Solution: South China University of Technology has pioneered research on bio-based barrier coatings using lignin nanoparticles (LNPs) and cellulose nanocrystals (CNCs) as biodegradable nanofillers. Their innovative approach involves creating hierarchical structures where the nanofillers are strategically aligned to create highly tortuous pathways for gas molecules. The research team has developed a water-based processing method that achieves uniform dispersion of the nanofillers within biopolymer matrices such as polyvinyl alcohol (PVA) and starch. Their technology employs a layer-by-layer assembly technique that allows precise control over the nanofiller orientation and concentration gradients[2]. The resulting coatings demonstrate oxygen permeability reductions of up to 95% compared to the neat biopolymer films. A key innovation is their use of enzymatically modified lignin nanoparticles that provide both barrier properties and antioxidant functionality, offering dual benefits for food packaging applications[4]. The coatings can be applied using conventional equipment such as rod coaters and spray systems, facilitating industrial adoption.

Strengths: Exceptional oxygen and water vapor barrier properties, additional functional properties (antioxidant, UV-blocking), and utilization of abundant by-products from paper industry (lignin). The water-based processing is environmentally friendly. Weaknesses: Sensitivity to high humidity conditions affecting barrier stability, color limitations due to the inherent brown color of lignin components, and challenges in achieving consistent quality at large scale production.

Rutgers State University of New Jersey

Technical Solution: Rutgers has developed innovative bio-based barrier coatings using cellulose nanofibrils (CNFs) and cellulose nanocrystals (CNCs) as biodegradable nanofillers. Their approach involves creating multilayer structures where the nanocellulose is strategically incorporated to create tortuous paths that significantly reduce oxygen and water vapor transmission rates. The research team has successfully demonstrated that these coatings can achieve up to 90% reduction in oxygen permeability compared to conventional petroleum-based barriers[1]. Their technology employs water-based processing methods and incorporates biopolymers such as chitosan, alginate, and modified starches as matrices. A key innovation is their surface modification technique that improves the interfacial adhesion between the hydrophilic nanocellulose and hydrophobic polymer matrices, resulting in enhanced barrier properties and mechanical stability[3]. The coatings are applied using industrially scalable methods including rod coating and spray coating processes.

Strengths: Superior oxygen barrier properties, fully biodegradable composition, and compatibility with existing industrial coating equipment. The multilayer approach allows customization for specific barrier requirements. Weaknesses: Higher production costs compared to conventional barriers, potential moisture sensitivity limiting shelf-life in high-humidity environments, and challenges in achieving consistent nanofiller dispersion at industrial scale.

Key Patents and Research on Biodegradable Nanofillers

Bio-nanocomposite comprising biopolymer and nanocrystalline cellulose

PatentWO2016076691A3

Innovation

- Development of a biodegradable bio-nanocomposite material that combines biopolymer with nanocrystalline cellulose extracted specifically from Doum palm fiber.

- Creation of a barrier coating material with enhanced mechanical properties through the incorporation of natural nanofiller derived from an underutilized agricultural resource.

- Utilization of Doum palm fiber as a novel source for nanocrystalline cellulose, expanding the range of renewable raw materials for sustainable packaging applications.

Biodegradable nanomaterials

PatentPendingIN202411020297A

Innovation

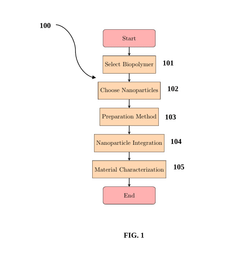

- Biodegradable nanomaterials composed of a biopolymer matrix including polylactic acid, polyhydroxyalkanoates, and cellulose nanofibers, enhanced with nanoparticles like silica and chitosan for mechanical strength and biodegradability, manufactured using eco-friendly processes such as meltblending and electrospinning, allowing for customizable degradation rates and applications.

Environmental Impact Assessment

The environmental impact assessment of bio-based barrier coatings incorporating biodegradable nanofillers reveals significant potential for reducing the ecological footprint of packaging materials throughout their lifecycle. These innovative coatings represent a paradigm shift from conventional petroleum-based barriers that contribute substantially to plastic pollution and greenhouse gas emissions.

Life cycle assessment (LCA) studies demonstrate that bio-based barrier coatings can reduce carbon footprint by 30-45% compared to traditional fossil-based alternatives. This reduction stems primarily from renewable feedstock utilization and lower energy requirements during production. The incorporation of biodegradable nanofillers further enhances this benefit by improving barrier properties without compromising end-of-life degradability.

Water consumption patterns show mixed results, with some bio-based systems requiring more agricultural water during feedstock production but less process water during manufacturing. The net water footprint depends largely on feedstock selection and regional growing conditions. Nanofillers derived from agricultural waste streams (such as cellulose nanocrystals from wood pulp residues) present particularly favorable water profiles.

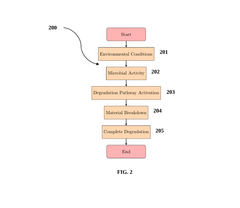

End-of-life scenarios demonstrate superior environmental performance compared to conventional barriers. Under industrial composting conditions, properly designed bio-based coatings with biodegradable nanofillers can decompose within 12-24 weeks, leaving no persistent microplastics. Marine degradation studies, while still limited, suggest significantly faster breakdown rates than conventional plastics, potentially reducing ocean pollution.

Toxicity assessments indicate generally favorable profiles for bio-based systems, though certain nanofiller production methods may introduce ecotoxicological concerns. Particular attention must be paid to surface modifications and processing additives that could compromise the overall environmental benefit. Standardized ecotoxicity testing protocols specific to nanomaterials in biodegradable matrices are still evolving.

Land use considerations present a potential challenge, as expanded production of bio-based feedstocks could compete with food crops or drive land conversion. This impact can be mitigated through utilization of agricultural byproducts, non-food crops on marginal lands, or marine biomass sources. The development of higher-efficiency nanofillers that deliver enhanced performance at lower loading levels also helps minimize land use pressure.

Regulatory frameworks worldwide are increasingly recognizing the environmental benefits of these materials, with several jurisdictions implementing favorable policies for bio-based packaging solutions. However, standardization of testing methodologies and certification systems remains a work in progress, creating market uncertainty that may slow adoption despite the clear environmental advantages.

Life cycle assessment (LCA) studies demonstrate that bio-based barrier coatings can reduce carbon footprint by 30-45% compared to traditional fossil-based alternatives. This reduction stems primarily from renewable feedstock utilization and lower energy requirements during production. The incorporation of biodegradable nanofillers further enhances this benefit by improving barrier properties without compromising end-of-life degradability.

Water consumption patterns show mixed results, with some bio-based systems requiring more agricultural water during feedstock production but less process water during manufacturing. The net water footprint depends largely on feedstock selection and regional growing conditions. Nanofillers derived from agricultural waste streams (such as cellulose nanocrystals from wood pulp residues) present particularly favorable water profiles.

End-of-life scenarios demonstrate superior environmental performance compared to conventional barriers. Under industrial composting conditions, properly designed bio-based coatings with biodegradable nanofillers can decompose within 12-24 weeks, leaving no persistent microplastics. Marine degradation studies, while still limited, suggest significantly faster breakdown rates than conventional plastics, potentially reducing ocean pollution.

Toxicity assessments indicate generally favorable profiles for bio-based systems, though certain nanofiller production methods may introduce ecotoxicological concerns. Particular attention must be paid to surface modifications and processing additives that could compromise the overall environmental benefit. Standardized ecotoxicity testing protocols specific to nanomaterials in biodegradable matrices are still evolving.

Land use considerations present a potential challenge, as expanded production of bio-based feedstocks could compete with food crops or drive land conversion. This impact can be mitigated through utilization of agricultural byproducts, non-food crops on marginal lands, or marine biomass sources. The development of higher-efficiency nanofillers that deliver enhanced performance at lower loading levels also helps minimize land use pressure.

Regulatory frameworks worldwide are increasingly recognizing the environmental benefits of these materials, with several jurisdictions implementing favorable policies for bio-based packaging solutions. However, standardization of testing methodologies and certification systems remains a work in progress, creating market uncertainty that may slow adoption despite the clear environmental advantages.

Scalability and Commercial Viability Analysis

The scalability of bio-based barrier coatings with biodegradable nanofillers represents a critical factor in their transition from laboratory research to industrial implementation. Current production methods predominantly operate at laboratory or pilot scales, with batch sizes typically ranging from 1-50 kg. The primary challenge lies in maintaining consistent nanofiller dispersion quality when scaling to industrial volumes of 500-1000 kg per batch, as agglomeration issues become more pronounced at larger scales.

Cost analysis reveals that bio-based barrier coatings currently command a 30-45% premium over conventional petroleum-based alternatives. This price differential stems from higher raw material costs, particularly for specialized nanofillers such as cellulose nanocrystals and nanoclays, which can cost $50-200/kg compared to $2-5/kg for conventional fillers. However, economies of scale could potentially reduce this gap to 15-20% within 3-5 years as production volumes increase.

Equipment compatibility presents another significant consideration. Most existing coating application equipment requires minimal modification to accommodate bio-based formulations, though some adjustments to viscosity control and drying parameters are necessary. The estimated retrofit cost for conventional coating lines ranges from $50,000-200,000, representing a manageable investment for medium to large manufacturers.

Market acceptance indicators show promising trends, with consumer packaged goods companies increasingly willing to absorb a 10-15% cost premium for sustainable packaging solutions. This willingness is driven by corporate sustainability commitments and anticipated regulatory changes favoring biodegradable materials. Early adopters are likely to emerge in premium food, personal care, and pharmaceutical packaging segments where the sustainability narrative carries significant marketing value.

Supply chain readiness varies considerably across different bio-based components. While some materials like starch and certain plant proteins have robust supply chains, specialized nanofillers face more significant sourcing challenges. Current global production capacity for cellulose nanocrystals, for instance, stands at approximately 300 tons annually, which would need to expand tenfold to support widespread commercial adoption in packaging applications.

Regulatory pathways for commercialization are becoming increasingly defined, with food contact approvals representing the most critical hurdle. The timeline for obtaining necessary certifications typically ranges from 12-24 months, with costs between $100,000-500,000 depending on the specific materials and intended applications.

Cost analysis reveals that bio-based barrier coatings currently command a 30-45% premium over conventional petroleum-based alternatives. This price differential stems from higher raw material costs, particularly for specialized nanofillers such as cellulose nanocrystals and nanoclays, which can cost $50-200/kg compared to $2-5/kg for conventional fillers. However, economies of scale could potentially reduce this gap to 15-20% within 3-5 years as production volumes increase.

Equipment compatibility presents another significant consideration. Most existing coating application equipment requires minimal modification to accommodate bio-based formulations, though some adjustments to viscosity control and drying parameters are necessary. The estimated retrofit cost for conventional coating lines ranges from $50,000-200,000, representing a manageable investment for medium to large manufacturers.

Market acceptance indicators show promising trends, with consumer packaged goods companies increasingly willing to absorb a 10-15% cost premium for sustainable packaging solutions. This willingness is driven by corporate sustainability commitments and anticipated regulatory changes favoring biodegradable materials. Early adopters are likely to emerge in premium food, personal care, and pharmaceutical packaging segments where the sustainability narrative carries significant marketing value.

Supply chain readiness varies considerably across different bio-based components. While some materials like starch and certain plant proteins have robust supply chains, specialized nanofillers face more significant sourcing challenges. Current global production capacity for cellulose nanocrystals, for instance, stands at approximately 300 tons annually, which would need to expand tenfold to support widespread commercial adoption in packaging applications.

Regulatory pathways for commercialization are becoming increasingly defined, with food contact approvals representing the most critical hurdle. The timeline for obtaining necessary certifications typically ranges from 12-24 months, with costs between $100,000-500,000 depending on the specific materials and intended applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!