Analysis of Polymer Crosslinking in Bio-based Barrier Coating Networks

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Barrier Coating Evolution and Objectives

Bio-based barrier coatings have emerged as a sustainable alternative to conventional petroleum-based packaging materials, evolving significantly over the past two decades. Initially developed as simple starch-based formulations in the early 2000s, these coatings have progressed through multiple generations of innovation, each addressing specific limitations of previous iterations. The evolution trajectory has been driven by increasing environmental concerns, stringent regulations on plastic waste, and growing consumer demand for sustainable packaging solutions.

The first generation of bio-based barrier coatings primarily focused on moisture resistance but lacked adequate oxygen barrier properties. By 2010, researchers had begun incorporating various biopolymers such as cellulose derivatives, chitosan, and protein-based materials to enhance functionality. The breakthrough came around 2015 with the development of composite systems that combined multiple biopolymers with natural reinforcing agents, significantly improving barrier performance.

Recent advancements have centered on polymer crosslinking mechanisms, which represent a critical frontier in bio-based coating technology. Crosslinking creates three-dimensional networks that substantially enhance barrier properties by reducing free volume and creating tortuous paths for permeant molecules. Various crosslinking approaches have been explored, including enzymatic, physical (UV, heat), and chemical methods, each offering distinct advantages for specific applications.

The current technological landscape is characterized by intensive research into novel crosslinking agents derived from renewable resources, optimization of crosslinking density, and development of stimuli-responsive crosslinked networks. These innovations aim to address the persistent challenges of moisture sensitivity and mechanical stability under varying environmental conditions.

The primary objectives of current research in polymer crosslinking for bio-based barrier coatings include: achieving oxygen transmission rates below 10 cc/m²/day and water vapor transmission rates under 10 g/m²/day; developing crosslinking systems that maintain food safety compliance; ensuring coating biodegradability is not compromised by crosslinking; and creating scalable processes suitable for industrial implementation.

Looking forward, the field is moving toward multifunctional crosslinked networks that not only provide excellent barrier properties but also incorporate active features such as antimicrobial activity, antioxidant properties, and intelligent response to environmental changes. The ultimate goal is to develop bio-based barrier coatings that match or exceed the performance of conventional plastics while maintaining complete biodegradability and competitive production costs.

The first generation of bio-based barrier coatings primarily focused on moisture resistance but lacked adequate oxygen barrier properties. By 2010, researchers had begun incorporating various biopolymers such as cellulose derivatives, chitosan, and protein-based materials to enhance functionality. The breakthrough came around 2015 with the development of composite systems that combined multiple biopolymers with natural reinforcing agents, significantly improving barrier performance.

Recent advancements have centered on polymer crosslinking mechanisms, which represent a critical frontier in bio-based coating technology. Crosslinking creates three-dimensional networks that substantially enhance barrier properties by reducing free volume and creating tortuous paths for permeant molecules. Various crosslinking approaches have been explored, including enzymatic, physical (UV, heat), and chemical methods, each offering distinct advantages for specific applications.

The current technological landscape is characterized by intensive research into novel crosslinking agents derived from renewable resources, optimization of crosslinking density, and development of stimuli-responsive crosslinked networks. These innovations aim to address the persistent challenges of moisture sensitivity and mechanical stability under varying environmental conditions.

The primary objectives of current research in polymer crosslinking for bio-based barrier coatings include: achieving oxygen transmission rates below 10 cc/m²/day and water vapor transmission rates under 10 g/m²/day; developing crosslinking systems that maintain food safety compliance; ensuring coating biodegradability is not compromised by crosslinking; and creating scalable processes suitable for industrial implementation.

Looking forward, the field is moving toward multifunctional crosslinked networks that not only provide excellent barrier properties but also incorporate active features such as antimicrobial activity, antioxidant properties, and intelligent response to environmental changes. The ultimate goal is to develop bio-based barrier coatings that match or exceed the performance of conventional plastics while maintaining complete biodegradability and competitive production costs.

Market Demand for Sustainable Packaging Solutions

The global packaging industry is experiencing a significant shift towards sustainable solutions, driven by increasing environmental concerns and regulatory pressures. The market for sustainable packaging is projected to grow at a compound annual growth rate of 7.7% from 2021 to 2028, reaching a value of $505.6 billion by 2028. This growth is particularly pronounced in the food and beverage sector, where consumers are increasingly demanding eco-friendly packaging alternatives that maintain product freshness and safety.

Bio-based barrier coatings represent a rapidly expanding segment within this market, as they offer a renewable alternative to traditional petroleum-based polymers. Consumer packaged goods companies are actively seeking solutions that can reduce their carbon footprint while maintaining or improving barrier properties against oxygen, moisture, and grease. A recent industry survey revealed that 73% of consumers are willing to pay a premium for products with sustainable packaging, highlighting the commercial viability of investments in this area.

Regulatory frameworks worldwide are accelerating this market transition. The European Union's Single-Use Plastics Directive and similar legislation in various countries are creating immediate demand for alternatives to conventional plastic packaging. Additionally, corporate sustainability commitments from major brands like Nestlé, Unilever, and PepsiCo to achieve 100% recyclable or compostable packaging by 2025 are driving innovation in bio-based barrier technologies.

The food service industry represents another significant market driver, with the global food service disposables market expected to reach $91.2 billion by 2026. Quick-service restaurants and food delivery services are actively seeking grease-resistant, water-resistant packaging solutions that are both functional and environmentally responsible. This sector's demand for bio-based barrier coatings is particularly strong due to consumer visibility and brand positioning considerations.

E-commerce expansion has further accelerated the need for sustainable packaging solutions with effective barrier properties. The pandemic-induced surge in online shopping has highlighted the importance of packaging that can withstand various distribution challenges while maintaining product integrity. This has created new opportunities for bio-based barrier coatings that can provide protection comparable to conventional materials.

Regional market analysis indicates that Europe currently leads in adoption of sustainable packaging solutions, followed by North America, while Asia-Pacific represents the fastest-growing market. This regional variation is influenced by differences in regulatory frameworks, consumer awareness, and industrial infrastructure. The most significant growth potential exists in emerging economies where rapid urbanization and rising middle-class consumption are creating new packaging demands that could be addressed through sustainable solutions from the outset.

Bio-based barrier coatings represent a rapidly expanding segment within this market, as they offer a renewable alternative to traditional petroleum-based polymers. Consumer packaged goods companies are actively seeking solutions that can reduce their carbon footprint while maintaining or improving barrier properties against oxygen, moisture, and grease. A recent industry survey revealed that 73% of consumers are willing to pay a premium for products with sustainable packaging, highlighting the commercial viability of investments in this area.

Regulatory frameworks worldwide are accelerating this market transition. The European Union's Single-Use Plastics Directive and similar legislation in various countries are creating immediate demand for alternatives to conventional plastic packaging. Additionally, corporate sustainability commitments from major brands like Nestlé, Unilever, and PepsiCo to achieve 100% recyclable or compostable packaging by 2025 are driving innovation in bio-based barrier technologies.

The food service industry represents another significant market driver, with the global food service disposables market expected to reach $91.2 billion by 2026. Quick-service restaurants and food delivery services are actively seeking grease-resistant, water-resistant packaging solutions that are both functional and environmentally responsible. This sector's demand for bio-based barrier coatings is particularly strong due to consumer visibility and brand positioning considerations.

E-commerce expansion has further accelerated the need for sustainable packaging solutions with effective barrier properties. The pandemic-induced surge in online shopping has highlighted the importance of packaging that can withstand various distribution challenges while maintaining product integrity. This has created new opportunities for bio-based barrier coatings that can provide protection comparable to conventional materials.

Regional market analysis indicates that Europe currently leads in adoption of sustainable packaging solutions, followed by North America, while Asia-Pacific represents the fastest-growing market. This regional variation is influenced by differences in regulatory frameworks, consumer awareness, and industrial infrastructure. The most significant growth potential exists in emerging economies where rapid urbanization and rising middle-class consumption are creating new packaging demands that could be addressed through sustainable solutions from the outset.

Polymer Crosslinking Challenges in Bio-based Materials

The development of bio-based barrier coatings represents a significant shift in packaging materials, driven by environmental concerns and sustainability goals. However, polymer crosslinking in these bio-based systems presents unique challenges that differ substantially from traditional petroleum-based polymers. The fundamental issue lies in achieving comparable barrier properties while maintaining the biodegradability and renewable nature of these materials.

Bio-based polymers often exhibit inherently different chemical structures compared to their synthetic counterparts, resulting in varied crosslinking mechanisms and efficiencies. Polysaccharides, proteins, and other bio-derived polymers contain numerous hydroxyl, carboxyl, and amine groups that can participate in crosslinking reactions, but controlling these reactions with precision remains difficult due to their heterogeneous nature.

Moisture sensitivity presents another significant challenge. Many bio-based polymers are hydrophilic, which compromises their barrier properties in humid conditions. Crosslinking strategies must therefore not only enhance mechanical properties but also effectively reduce water vapor transmission rates without sacrificing biodegradability.

Temperature stability during processing poses additional complications. Bio-based polymers typically have lower thermal degradation temperatures than petroleum-based alternatives, limiting the processing window for crosslinking reactions. This constraint necessitates the development of low-temperature crosslinking methods or the incorporation of heat-resistant modifications.

The kinetics of crosslinking reactions in bio-based systems often differ from conventional polymers, requiring precise control over reaction parameters. Achieving uniform crosslink density throughout the coating matrix is particularly challenging due to the variable molecular weight distribution and functional group accessibility in natural polymers.

Compatibility issues between different bio-based components further complicate crosslinking strategies. Creating effective blends that maintain phase compatibility while enabling controlled crosslinking requires sophisticated formulation approaches and often necessitates the use of compatibilizers or coupling agents.

Regulatory considerations add another layer of complexity. Crosslinking agents must comply with food contact regulations when used in packaging applications, limiting the selection of viable crosslinkers. Many traditional crosslinking agents contain formaldehyde or other potentially harmful compounds that are increasingly restricted in consumer products.

Scale-up challenges persist in translating laboratory-scale crosslinking techniques to industrial production. Maintaining consistent crosslink density, cure rates, and barrier properties at commercial scale requires robust process control strategies that are still being developed for many bio-based systems.

Bio-based polymers often exhibit inherently different chemical structures compared to their synthetic counterparts, resulting in varied crosslinking mechanisms and efficiencies. Polysaccharides, proteins, and other bio-derived polymers contain numerous hydroxyl, carboxyl, and amine groups that can participate in crosslinking reactions, but controlling these reactions with precision remains difficult due to their heterogeneous nature.

Moisture sensitivity presents another significant challenge. Many bio-based polymers are hydrophilic, which compromises their barrier properties in humid conditions. Crosslinking strategies must therefore not only enhance mechanical properties but also effectively reduce water vapor transmission rates without sacrificing biodegradability.

Temperature stability during processing poses additional complications. Bio-based polymers typically have lower thermal degradation temperatures than petroleum-based alternatives, limiting the processing window for crosslinking reactions. This constraint necessitates the development of low-temperature crosslinking methods or the incorporation of heat-resistant modifications.

The kinetics of crosslinking reactions in bio-based systems often differ from conventional polymers, requiring precise control over reaction parameters. Achieving uniform crosslink density throughout the coating matrix is particularly challenging due to the variable molecular weight distribution and functional group accessibility in natural polymers.

Compatibility issues between different bio-based components further complicate crosslinking strategies. Creating effective blends that maintain phase compatibility while enabling controlled crosslinking requires sophisticated formulation approaches and often necessitates the use of compatibilizers or coupling agents.

Regulatory considerations add another layer of complexity. Crosslinking agents must comply with food contact regulations when used in packaging applications, limiting the selection of viable crosslinkers. Many traditional crosslinking agents contain formaldehyde or other potentially harmful compounds that are increasingly restricted in consumer products.

Scale-up challenges persist in translating laboratory-scale crosslinking techniques to industrial production. Maintaining consistent crosslink density, cure rates, and barrier properties at commercial scale requires robust process control strategies that are still being developed for many bio-based systems.

Current Crosslinking Methodologies for Bio-polymers

01 Bio-based polymers for barrier coatings

Bio-based polymers derived from renewable resources can be used as environmentally friendly alternatives in barrier coating applications. These polymers, such as polylactic acid (PLA), cellulose derivatives, and starch-based materials, can be crosslinked to enhance their barrier properties against oxygen, moisture, and other substances. The crosslinking process improves the mechanical strength, thermal stability, and chemical resistance of these bio-based materials, making them suitable for packaging and protective coating applications.- Natural polymer crosslinking mechanisms for barrier properties: Bio-based polymers such as cellulose, starch, and chitosan can be crosslinked to enhance barrier properties against oxygen, moisture, and other substances. The crosslinking process creates a more dense and interconnected polymer network that reduces permeability. Various crosslinking agents including aldehydes, carboxylic acids, and enzymes can be used to form covalent bonds between polymer chains, resulting in improved mechanical strength and chemical resistance of the coating.

- UV-initiated crosslinking in bio-based coatings: UV radiation can be used to initiate crosslinking reactions in bio-based barrier coatings containing photosensitive functional groups. This method allows for rapid curing at ambient temperatures, reducing energy consumption during the coating process. UV-crosslinkable bio-based polymers often incorporate acrylate, methacrylate, or thiol-ene chemistry to enable the formation of a crosslinked network upon exposure to UV light. The resulting coatings exhibit enhanced barrier properties and durability while maintaining their bio-based nature.

- Polysaccharide-based crosslinked barrier films: Polysaccharides such as cellulose derivatives, alginate, and pectin can be modified and crosslinked to create effective barrier coatings. These materials can be crosslinked through various mechanisms including ionic crosslinking with multivalent cations, covalent crosslinking with specific reagents, or enzymatic crosslinking. The resulting films provide excellent oxygen and grease barrier properties while maintaining biodegradability. The degree of crosslinking can be controlled to balance barrier performance with other properties such as flexibility and water sensitivity.

- Protein-based crosslinked barrier coatings: Proteins from plant and animal sources can be formulated into barrier coatings and crosslinked to improve their performance. Common proteins used include soy protein, whey protein, zein, and gelatin. Crosslinking can be achieved through various methods including enzymatic treatment with transglutaminase, chemical crosslinking with aldehydes or carbodiimides, or physical crosslinking through heat treatment. The crosslinked protein networks provide excellent oxygen barrier properties and improved water resistance compared to non-crosslinked counterparts.

- Hybrid bio-synthetic crosslinked barrier systems: Combining bio-based polymers with synthetic components creates hybrid systems that can be crosslinked to achieve superior barrier properties. These formulations typically incorporate bio-based materials such as cellulose nanocrystals, lignin, or plant oils with synthetic polymers or crosslinkers. The hybrid approach allows for customization of barrier properties while maintaining a significant bio-based content. Various crosslinking chemistries including silane coupling, epoxy reactions, and click chemistry can be employed to create covalent bonds between the different components, resulting in durable and effective barrier coatings.

02 Crosslinking mechanisms for bio-based barrier coatings

Various crosslinking mechanisms can be employed to enhance the performance of bio-based barrier coatings. These include chemical crosslinking using agents such as aldehydes, carbodiimides, and isocyanates; enzymatic crosslinking; radiation-induced crosslinking through UV or electron beam exposure; and physical crosslinking through hydrogen bonding or ionic interactions. Each mechanism offers specific advantages in terms of processing conditions, environmental impact, and the resulting barrier properties of the coating.Expand Specific Solutions03 Novel crosslinking agents for improved barrier properties

Innovative crosslinking agents have been developed specifically for bio-based barrier coatings to enhance their performance. These include naturally derived crosslinkers such as citric acid, tannic acid, and genipin, as well as modified synthetic crosslinkers designed to be more environmentally friendly. These novel agents can create stronger molecular networks within the polymer matrix, resulting in improved oxygen and moisture barrier properties while maintaining the biodegradability and sustainability advantages of bio-based materials.Expand Specific Solutions04 Composite and hybrid barrier systems

Composite and hybrid barrier systems combine bio-based polymers with other materials to achieve enhanced barrier properties through strategic crosslinking. These systems may incorporate nanomaterials such as clay, silica, or cellulose nanocrystals, which can be crosslinked with the bio-based polymer matrix to create tortuous paths for gas molecules. Additionally, hybrid systems may combine bio-based polymers with synthetic polymers in crosslinked networks to leverage the advantages of both material types while minimizing environmental impact.Expand Specific Solutions05 Processing techniques for crosslinked bio-based coatings

Specialized processing techniques have been developed for applying and curing crosslinked bio-based barrier coatings. These include solution casting, extrusion coating, spray coating, and layer-by-layer deposition methods. The processing conditions, such as temperature, humidity, and curing time, significantly influence the crosslinking density and resulting barrier properties. Advanced techniques like atmospheric plasma treatment can also be used to initiate or enhance the crosslinking process on the surface of bio-based coatings, improving their adhesion and barrier performance.Expand Specific Solutions

Leading Organizations in Bio-based Coating Development

The polymer crosslinking bio-based barrier coating market is in a growth phase, with increasing demand driven by sustainability trends and packaging innovations. The market size is expanding rapidly as industries seek eco-friendly alternatives to traditional petroleum-based coatings. Technologically, the field shows moderate maturity with significant ongoing research and development. Key players include established chemical corporations like BASF, DuPont, and Dow, which leverage their extensive R&D capabilities, alongside specialized coating companies such as DuluxGroup and BASF Coatings. Academic institutions including Monash University, Ghent University, and ETH Zurich contribute fundamental research, while companies like 3M and Toshiba focus on innovative applications and commercialization pathways, creating a competitive landscape balanced between industrial giants and research-driven entities.

BASF Corp.

Technical Solution: BASF has developed innovative bio-based barrier coating networks utilizing their proprietary Ecovio® technology, which combines biodegradable polymers with crosslinking agents derived from renewable resources. Their approach focuses on controlled crosslinking density through multi-functional bio-based monomers that create three-dimensional networks with enhanced barrier properties. The company employs specialized catalysts to facilitate crosslinking reactions at lower temperatures, reducing energy consumption during manufacturing. BASF's technology incorporates modified polylactic acid (PLA) and polyhydroxyalkanoates (PHA) with reactive functional groups that form covalent bonds during processing, creating water-resistant barriers while maintaining biodegradability. Their research has demonstrated that optimized crosslinking parameters can achieve oxygen transmission rates below 10 cc/m²/day and water vapor transmission rates under 5 g/m²/day, comparable to conventional petroleum-based barriers.

Strengths: Extensive polymer chemistry expertise and global manufacturing capabilities allow for scalable production. Their bio-based solutions maintain excellent barrier properties while offering improved environmental profile. Weaknesses: Higher production costs compared to conventional petroleum-based alternatives, and potential limitations in high-temperature applications due to the thermal properties of bio-based polymers.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered a multi-layer crosslinked polymer system for bio-based barrier coatings utilizing their proprietary "Nexcare" technology platform. Their approach combines bio-derived polyesters with specialized crosslinking agents that create densely networked structures through UV-initiated reactions. The company has developed a unique process that enables precise control of crosslink density through modulated exposure to radiation, resulting in customizable barrier properties. 3M's technology incorporates modified cellulose nanocrystals as reinforcing elements within the polymer matrix, which significantly enhances oxygen barrier properties while maintaining flexibility. Their research has demonstrated that these bio-based coatings can achieve oxygen permeability values below 0.5 cc·mil/m²·day·atm and water vapor transmission rates under 3 g/m²/day when optimally crosslinked. The company has also developed bio-based coupling agents that improve adhesion between hydrophilic and hydrophobic components in the coating system.

Strengths: Advanced manufacturing capabilities and expertise in thin-film technology allow for production of ultra-thin barrier coatings with excellent performance. Their UV-curing approach enables rapid processing and energy efficiency. Weaknesses: Higher raw material costs compared to conventional systems, and potential limitations in applications requiring high chemical resistance.

Key Innovations in Bio-based Network Formation

Barrier coating composition with organic particles

PatentWO2012047246A1

Innovation

- A moisture vapor and oxygen transmission resistant film is created with a polymeric base layer and a barrier layer containing discrete particles of a water insoluble organic polymer dispersed in a continuous matrix of a water soluble organic polymer, using a coating composition of finely divided insoluble organic polymer particles suspended in an aqueous solution with a crosslinking agent and surfactant, which is heated to crosslink and evaporate the solvent.

Dynamic covalent hydrogels, precursors thereof and uses thereof

PatentWO2021180795A1

Innovation

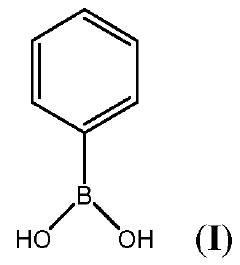

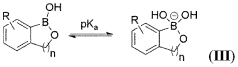

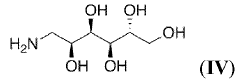

- Development of new boronic acid/diol couples for forming dynamic covalent hydrogels that are stable, self-healing, and minimally swellable, using phenylboronic acid derivatives and glucamine, allowing for instantaneous crosslinking at physiological pH and temperature, and can be varied for biodegradability and tissue mimicry.

Environmental Impact Assessment of Bio-based Coatings

The environmental impact assessment of bio-based coatings derived from polymer crosslinking networks reveals significant advantages over conventional petroleum-based alternatives. These bio-based barrier coatings demonstrate reduced carbon footprints throughout their lifecycle, with studies indicating up to 40-60% lower greenhouse gas emissions compared to traditional coating systems. The crosslinking mechanisms in these networks enable efficient material usage while maintaining or enhancing performance characteristics.

Life cycle assessments (LCA) of crosslinked bio-based polymers show notable reductions in environmental indicators including global warming potential, acidification, and resource depletion. The renewable feedstock sources—primarily agricultural byproducts and sustainably harvested biomass—contribute to circular economy principles by utilizing materials that would otherwise become waste streams. The crosslinking density optimization in these networks further enhances durability, potentially extending product lifespans and reducing replacement frequency.

Water-based formulations of these bio-based barrier coatings significantly reduce volatile organic compound (VOC) emissions during application and curing processes. Recent advancements in crosslinking technology have enabled VOC reductions of up to 85% compared to solvent-based systems while maintaining comparable barrier properties. This improvement addresses both environmental concerns and regulatory compliance requirements in various markets.

Biodegradability assessments of these coatings show promising results, with certain formulations achieving 70-90% degradation under controlled composting conditions within 180 days. The crosslinking density plays a crucial role in balancing performance requirements with end-of-life environmental considerations. Optimized networks can be designed to maintain integrity during product use while allowing for environmental breakdown after disposal.

Ecotoxicological studies indicate reduced aquatic toxicity from leachates of bio-based barrier coatings compared to conventional alternatives. The crosslinked polymer networks effectively encapsulate potentially harmful components, minimizing migration into environmental systems. This characteristic is particularly valuable for packaging applications where coating materials may eventually contact soil or water systems.

Resource efficiency metrics demonstrate that crosslinked bio-based coatings typically require 30-45% less energy during manufacturing processes compared to petroleum-based counterparts. The crosslinking reactions often occur under milder conditions, reducing energy inputs while creating robust barrier properties. Additionally, the utilization of agricultural and forestry byproducts as raw materials reduces pressure on virgin resource extraction and provides economic opportunities for agricultural communities.

Life cycle assessments (LCA) of crosslinked bio-based polymers show notable reductions in environmental indicators including global warming potential, acidification, and resource depletion. The renewable feedstock sources—primarily agricultural byproducts and sustainably harvested biomass—contribute to circular economy principles by utilizing materials that would otherwise become waste streams. The crosslinking density optimization in these networks further enhances durability, potentially extending product lifespans and reducing replacement frequency.

Water-based formulations of these bio-based barrier coatings significantly reduce volatile organic compound (VOC) emissions during application and curing processes. Recent advancements in crosslinking technology have enabled VOC reductions of up to 85% compared to solvent-based systems while maintaining comparable barrier properties. This improvement addresses both environmental concerns and regulatory compliance requirements in various markets.

Biodegradability assessments of these coatings show promising results, with certain formulations achieving 70-90% degradation under controlled composting conditions within 180 days. The crosslinking density plays a crucial role in balancing performance requirements with end-of-life environmental considerations. Optimized networks can be designed to maintain integrity during product use while allowing for environmental breakdown after disposal.

Ecotoxicological studies indicate reduced aquatic toxicity from leachates of bio-based barrier coatings compared to conventional alternatives. The crosslinked polymer networks effectively encapsulate potentially harmful components, minimizing migration into environmental systems. This characteristic is particularly valuable for packaging applications where coating materials may eventually contact soil or water systems.

Resource efficiency metrics demonstrate that crosslinked bio-based coatings typically require 30-45% less energy during manufacturing processes compared to petroleum-based counterparts. The crosslinking reactions often occur under milder conditions, reducing energy inputs while creating robust barrier properties. Additionally, the utilization of agricultural and forestry byproducts as raw materials reduces pressure on virgin resource extraction and provides economic opportunities for agricultural communities.

Scalability and Industrial Implementation Considerations

Scaling up polymer crosslinking processes for bio-based barrier coatings from laboratory to industrial scale presents significant challenges that require careful consideration. The transition demands optimization of reaction parameters, equipment design, and process controls to maintain consistent crosslinking density and barrier properties across large production volumes. Current industrial implementation typically employs continuous coating lines with integrated curing systems, which must be adapted to accommodate the specific reaction kinetics of bio-based polymers.

Material handling represents a critical factor in scalability, as bio-based polymers often exhibit different rheological behaviors compared to petroleum-based alternatives. Viscosity management during production becomes essential, particularly when incorporating natural crosslinking agents that may have variable reactivity based on their biological origin. Manufacturers must develop robust formulations that remain stable during storage and processing while maintaining consistent crosslinking performance.

Energy consumption during curing processes constitutes a significant consideration for industrial implementation. Traditional thermal curing methods may require substantial energy inputs, potentially offsetting the environmental benefits of bio-based materials. Alternative curing technologies such as UV, electron beam, or microwave-assisted processes offer potential energy savings but require specialized equipment and process validation. The selection of appropriate curing technology must balance crosslinking efficiency, production speed, and energy consumption.

Quality control systems for industrial-scale production must be adapted to monitor crosslinking reactions in real-time. Spectroscopic methods, rheological measurements, and barrier property testing need integration into production lines to ensure consistent performance. The development of rapid, non-destructive testing protocols becomes essential for maintaining quality without compromising production efficiency.

Supply chain considerations significantly impact the industrial feasibility of bio-based barrier coatings. The availability, consistency, and cost of bio-based raw materials may fluctuate seasonally or regionally, affecting production planning and economics. Establishing reliable sourcing networks and potentially developing secondary supplier relationships becomes crucial for maintaining consistent production. Additionally, manufacturers must consider storage stability of bio-based components, which may require modified handling protocols compared to conventional materials.

Regulatory compliance presents another dimension of industrial implementation. As bio-based barrier coatings often target food packaging and similar sensitive applications, manufacturers must navigate complex approval processes across different markets. Demonstrating consistent crosslinking performance and barrier properties becomes essential for regulatory acceptance, requiring robust validation protocols and documentation systems integrated into production processes.

Material handling represents a critical factor in scalability, as bio-based polymers often exhibit different rheological behaviors compared to petroleum-based alternatives. Viscosity management during production becomes essential, particularly when incorporating natural crosslinking agents that may have variable reactivity based on their biological origin. Manufacturers must develop robust formulations that remain stable during storage and processing while maintaining consistent crosslinking performance.

Energy consumption during curing processes constitutes a significant consideration for industrial implementation. Traditional thermal curing methods may require substantial energy inputs, potentially offsetting the environmental benefits of bio-based materials. Alternative curing technologies such as UV, electron beam, or microwave-assisted processes offer potential energy savings but require specialized equipment and process validation. The selection of appropriate curing technology must balance crosslinking efficiency, production speed, and energy consumption.

Quality control systems for industrial-scale production must be adapted to monitor crosslinking reactions in real-time. Spectroscopic methods, rheological measurements, and barrier property testing need integration into production lines to ensure consistent performance. The development of rapid, non-destructive testing protocols becomes essential for maintaining quality without compromising production efficiency.

Supply chain considerations significantly impact the industrial feasibility of bio-based barrier coatings. The availability, consistency, and cost of bio-based raw materials may fluctuate seasonally or regionally, affecting production planning and economics. Establishing reliable sourcing networks and potentially developing secondary supplier relationships becomes crucial for maintaining consistent production. Additionally, manufacturers must consider storage stability of bio-based components, which may require modified handling protocols compared to conventional materials.

Regulatory compliance presents another dimension of industrial implementation. As bio-based barrier coatings often target food packaging and similar sensitive applications, manufacturers must navigate complex approval processes across different markets. Demonstrating consistent crosslinking performance and barrier properties becomes essential for regulatory acceptance, requiring robust validation protocols and documentation systems integrated into production processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!