Optimization of Coating Uniformity in Bio-based Barrier Applications

OCT 13, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Barrier Coating Background and Objectives

Bio-based barrier coatings have emerged as a significant innovation in sustainable packaging solutions over the past decade. These coatings, derived from renewable resources such as cellulose, chitosan, proteins, and plant-based waxes, represent a paradigm shift from conventional petroleum-based barrier materials. The evolution of this technology has been driven by increasing environmental concerns, stringent regulations on plastic waste, and growing consumer demand for sustainable packaging alternatives.

The development trajectory of bio-based barrier coatings began with rudimentary applications in the early 2000s, progressing through significant advancements in material science and processing technologies. Recent innovations have focused on enhancing barrier properties against oxygen, moisture, and grease while maintaining biodegradability and compostability characteristics.

A critical challenge in this technological evolution has been achieving uniform coating application across various substrate materials. Coating uniformity directly impacts barrier performance, material efficiency, and product quality. Non-uniform coatings lead to weak points in barrier protection, increased material consumption, and compromised aesthetic qualities of the final product.

The primary objective of optimizing coating uniformity in bio-based barrier applications is to develop robust methodologies and technologies that ensure consistent coating thickness, coverage, and performance across diverse substrate materials. This optimization aims to enhance barrier effectiveness while minimizing material usage and reducing production costs.

Secondary objectives include improving scalability of uniform coating processes for industrial applications, developing adaptive technologies that can accommodate the inherent variability of bio-based materials, and establishing standardized measurement protocols for coating uniformity assessment.

Current technological trends indicate a convergence of advanced sensing technologies, computational modeling, and precision application systems to address coating uniformity challenges. The integration of artificial intelligence and machine learning algorithms for real-time process control represents a promising frontier in this field.

The achievement of these objectives would significantly advance the commercial viability of bio-based barrier coatings, potentially accelerating market adoption across food packaging, pharmaceutical packaging, and consumer goods sectors. Furthermore, optimized coating uniformity would contribute to waste reduction and resource efficiency, aligning with circular economy principles and sustainable development goals.

The development trajectory of bio-based barrier coatings began with rudimentary applications in the early 2000s, progressing through significant advancements in material science and processing technologies. Recent innovations have focused on enhancing barrier properties against oxygen, moisture, and grease while maintaining biodegradability and compostability characteristics.

A critical challenge in this technological evolution has been achieving uniform coating application across various substrate materials. Coating uniformity directly impacts barrier performance, material efficiency, and product quality. Non-uniform coatings lead to weak points in barrier protection, increased material consumption, and compromised aesthetic qualities of the final product.

The primary objective of optimizing coating uniformity in bio-based barrier applications is to develop robust methodologies and technologies that ensure consistent coating thickness, coverage, and performance across diverse substrate materials. This optimization aims to enhance barrier effectiveness while minimizing material usage and reducing production costs.

Secondary objectives include improving scalability of uniform coating processes for industrial applications, developing adaptive technologies that can accommodate the inherent variability of bio-based materials, and establishing standardized measurement protocols for coating uniformity assessment.

Current technological trends indicate a convergence of advanced sensing technologies, computational modeling, and precision application systems to address coating uniformity challenges. The integration of artificial intelligence and machine learning algorithms for real-time process control represents a promising frontier in this field.

The achievement of these objectives would significantly advance the commercial viability of bio-based barrier coatings, potentially accelerating market adoption across food packaging, pharmaceutical packaging, and consumer goods sectors. Furthermore, optimized coating uniformity would contribute to waste reduction and resource efficiency, aligning with circular economy principles and sustainable development goals.

Market Analysis for Sustainable Packaging Solutions

The sustainable packaging market is experiencing unprecedented growth, driven by increasing environmental awareness and regulatory pressures. The global sustainable packaging market was valued at $274.15 billion in 2022 and is projected to reach $413.8 billion by 2027, growing at a CAGR of 8.6%. This growth trajectory is particularly significant for bio-based barrier applications, which represent a critical segment within this market.

Consumer demand for environmentally friendly packaging solutions has become a major market driver, with 73% of global consumers indicating willingness to pay premium prices for sustainable packaging options. This shift in consumer preference has prompted major brands across food, beverage, personal care, and pharmaceutical industries to commit to sustainable packaging goals, creating substantial market opportunities for advanced bio-based barrier technologies.

Regulatory frameworks worldwide are increasingly stringent regarding single-use plastics and packaging waste. The European Union's Circular Economy Action Plan, China's ban on non-biodegradable single-use plastics, and similar initiatives in North America have created a regulatory environment that favors bio-based barrier solutions. These regulations are expected to accelerate market adoption of sustainable alternatives to conventional petroleum-based barrier materials.

The food and beverage sector represents the largest application segment for bio-based barrier coatings, accounting for approximately 62% of market share. This dominance stems from the critical need for moisture, oxygen, and grease barriers in food packaging that can maintain product freshness while meeting sustainability requirements. The personal care and pharmaceutical segments are showing the fastest growth rates, with increasing demand for packaging solutions that combine barrier properties with biodegradability.

Regional analysis reveals that Europe leads the sustainable packaging market with approximately 34% market share, followed by North America at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is demonstrating the highest growth rate at 10.2% annually, driven by rapid industrialization, urbanization, and increasing environmental regulations in countries like China, Japan, and India.

Key market challenges include cost competitiveness against conventional packaging, technical performance limitations of current bio-based barriers, and scaling production to meet growing demand. The price premium for bio-based barrier solutions currently ranges from 15-40% compared to conventional alternatives, though this gap is narrowing as production scales and technologies mature.

Market forecasts indicate that optimization of coating uniformity in bio-based barrier applications will be a critical factor in market penetration, as inconsistent barrier performance remains a significant barrier to widespread adoption. Addressing this technical challenge could potentially unlock an additional $45 billion market opportunity by 2030.

Consumer demand for environmentally friendly packaging solutions has become a major market driver, with 73% of global consumers indicating willingness to pay premium prices for sustainable packaging options. This shift in consumer preference has prompted major brands across food, beverage, personal care, and pharmaceutical industries to commit to sustainable packaging goals, creating substantial market opportunities for advanced bio-based barrier technologies.

Regulatory frameworks worldwide are increasingly stringent regarding single-use plastics and packaging waste. The European Union's Circular Economy Action Plan, China's ban on non-biodegradable single-use plastics, and similar initiatives in North America have created a regulatory environment that favors bio-based barrier solutions. These regulations are expected to accelerate market adoption of sustainable alternatives to conventional petroleum-based barrier materials.

The food and beverage sector represents the largest application segment for bio-based barrier coatings, accounting for approximately 62% of market share. This dominance stems from the critical need for moisture, oxygen, and grease barriers in food packaging that can maintain product freshness while meeting sustainability requirements. The personal care and pharmaceutical segments are showing the fastest growth rates, with increasing demand for packaging solutions that combine barrier properties with biodegradability.

Regional analysis reveals that Europe leads the sustainable packaging market with approximately 34% market share, followed by North America at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is demonstrating the highest growth rate at 10.2% annually, driven by rapid industrialization, urbanization, and increasing environmental regulations in countries like China, Japan, and India.

Key market challenges include cost competitiveness against conventional packaging, technical performance limitations of current bio-based barriers, and scaling production to meet growing demand. The price premium for bio-based barrier solutions currently ranges from 15-40% compared to conventional alternatives, though this gap is narrowing as production scales and technologies mature.

Market forecasts indicate that optimization of coating uniformity in bio-based barrier applications will be a critical factor in market penetration, as inconsistent barrier performance remains a significant barrier to widespread adoption. Addressing this technical challenge could potentially unlock an additional $45 billion market opportunity by 2030.

Current Challenges in Bio-based Coating Uniformity

Despite significant advancements in bio-based barrier coatings, achieving uniform coating distribution remains one of the most persistent technical challenges in the industry. Current bio-based formulations exhibit inherent rheological complexities that differ substantially from conventional petroleum-based alternatives. These materials often demonstrate non-Newtonian behavior with pronounced shear-thinning or shear-thickening properties that complicate the coating process. The variability in viscosity under different application conditions leads to inconsistent film formation, particularly at industrial production speeds.

Surface tension mismatch between bio-based coating materials and substrates presents another significant hurdle. Many bio-based polymers and their composites have surface energy characteristics that result in poor wetting behavior, creating issues such as dewetting, edge effects, and pinhole formation. These defects compromise the barrier integrity and aesthetic quality of the final product, limiting commercial viability.

Temperature sensitivity poses an additional challenge, as many bio-based materials exhibit narrow processing windows. Polysaccharide-based coatings, for example, may undergo premature gelation or degradation with minor temperature fluctuations during application. This sensitivity necessitates precise temperature control throughout the coating process, which is difficult to maintain consistently across large-scale production environments.

The inherent variability of bio-based raw materials further complicates uniformity control. Unlike synthetic polymers with consistent molecular weight distributions, bio-based materials often exhibit batch-to-batch variations in molecular structure, functional group density, and impurity profiles. These inconsistencies translate directly to coating performance variability, making standardization and quality control exceptionally challenging.

Current drying and curing technologies are also suboptimally adapted for bio-based coatings. Many facilities still utilize equipment designed for conventional coatings, which may not accommodate the specific moisture retention characteristics and curing kinetics of bio-based alternatives. This mismatch often results in uneven drying, stress-induced cracking, and non-uniform crosslinking across the coated surface.

Scaling issues present perhaps the most significant barrier to commercial implementation. Laboratory-scale successes in achieving uniform bio-based coatings frequently fail to translate to industrial production environments. The increased web speeds, wider substrates, and different air flow dynamics of commercial coating lines introduce variables that disrupt coating uniformity in ways not observed in controlled laboratory settings.

Measurement and quality control methodologies for bio-based coating uniformity remain underdeveloped compared to conventional systems. Current analytical techniques often lack the sensitivity to detect subtle uniformity variations that may significantly impact barrier performance, particularly for thinner coatings where minor thickness variations represent a larger percentage of the total coating thickness.

Surface tension mismatch between bio-based coating materials and substrates presents another significant hurdle. Many bio-based polymers and their composites have surface energy characteristics that result in poor wetting behavior, creating issues such as dewetting, edge effects, and pinhole formation. These defects compromise the barrier integrity and aesthetic quality of the final product, limiting commercial viability.

Temperature sensitivity poses an additional challenge, as many bio-based materials exhibit narrow processing windows. Polysaccharide-based coatings, for example, may undergo premature gelation or degradation with minor temperature fluctuations during application. This sensitivity necessitates precise temperature control throughout the coating process, which is difficult to maintain consistently across large-scale production environments.

The inherent variability of bio-based raw materials further complicates uniformity control. Unlike synthetic polymers with consistent molecular weight distributions, bio-based materials often exhibit batch-to-batch variations in molecular structure, functional group density, and impurity profiles. These inconsistencies translate directly to coating performance variability, making standardization and quality control exceptionally challenging.

Current drying and curing technologies are also suboptimally adapted for bio-based coatings. Many facilities still utilize equipment designed for conventional coatings, which may not accommodate the specific moisture retention characteristics and curing kinetics of bio-based alternatives. This mismatch often results in uneven drying, stress-induced cracking, and non-uniform crosslinking across the coated surface.

Scaling issues present perhaps the most significant barrier to commercial implementation. Laboratory-scale successes in achieving uniform bio-based coatings frequently fail to translate to industrial production environments. The increased web speeds, wider substrates, and different air flow dynamics of commercial coating lines introduce variables that disrupt coating uniformity in ways not observed in controlled laboratory settings.

Measurement and quality control methodologies for bio-based coating uniformity remain underdeveloped compared to conventional systems. Current analytical techniques often lack the sensitivity to detect subtle uniformity variations that may significantly impact barrier performance, particularly for thinner coatings where minor thickness variations represent a larger percentage of the total coating thickness.

Current Methodologies for Coating Uniformity Optimization

01 Bio-based polymer compositions for barrier coatings

Bio-based polymers derived from renewable resources can be formulated into barrier coatings with excellent uniformity. These compositions typically include polylactic acid (PLA), cellulose derivatives, or other plant-based polymers that provide effective barriers against moisture, oxygen, and other environmental factors. The formulations often incorporate plasticizers and cross-linking agents to enhance film formation and ensure uniform coating distribution across substrates.- Bio-based barrier coating compositions: Various bio-based materials can be used to create effective barrier coatings with improved environmental sustainability. These compositions typically include renewable resources such as plant-derived polymers, cellulosic materials, and other bio-based components that provide barrier properties against moisture, oxygen, and other substances. The formulations often combine these bio-based materials with compatible additives to enhance performance while maintaining their environmentally friendly characteristics.

- Coating application techniques for uniform coverage: Achieving uniform coating coverage requires specific application techniques tailored to the substrate and coating material. Methods such as roll coating, spray application, and dip coating can be optimized to ensure even distribution of the barrier material. Parameters including application speed, pressure, temperature, and viscosity control are critical factors that influence coating uniformity. Advanced application systems may incorporate precision control mechanisms to maintain consistent coating thickness across the substrate surface.

- Substrate preparation and treatment for coating adhesion: Proper substrate preparation is essential for achieving uniform bio-based barrier coatings with strong adhesion. Surface treatments such as corona discharge, plasma treatment, or chemical primers can modify surface energy and improve wettability. Cleaning processes to remove contaminants and surface irregularities help ensure consistent coating application. The compatibility between the substrate surface characteristics and the bio-based coating formulation significantly impacts coating uniformity and adhesion strength.

- Multi-layer coating systems for enhanced barrier properties: Multi-layer coating systems can provide superior barrier properties compared to single-layer applications. These systems typically combine different bio-based materials in sequential layers, each contributing specific functional properties. The design of multi-layer structures allows for optimization of both barrier performance and coating uniformity, with each layer serving a distinct purpose such as adhesion promotion, primary barrier function, or surface protection. Careful control of interlayer adhesion and compatibility is essential for maintaining coating integrity.

- Post-application treatments to improve coating performance: Various post-application treatments can enhance the performance and uniformity of bio-based barrier coatings. Curing processes using heat, UV radiation, or other energy sources help solidify and strengthen the coating structure. Surface modification techniques applied after initial coating can improve smoothness and eliminate defects. Conditioning treatments may also be employed to stabilize the coating properties over time, ensuring consistent barrier performance under various environmental conditions.

02 Application techniques for uniform bio-based coatings

Various application methods can be employed to achieve uniform bio-based barrier coatings, including spray coating, roll coating, and dip coating. The uniformity of the coating is influenced by factors such as viscosity control, surface tension management, and drying conditions. Specialized equipment and process parameters are designed to ensure even distribution of the coating material, preventing defects such as pinholes, streaking, or thickness variations that could compromise barrier properties.Expand Specific Solutions03 Additives for enhancing coating uniformity

Various additives can be incorporated into bio-based barrier coating formulations to improve uniformity. These include surfactants to reduce surface tension, leveling agents to prevent orange peel effects, and rheology modifiers to control flow behavior. Nanoparticles and other fillers can also be used to enhance coating uniformity while simultaneously improving barrier properties. The proper selection and concentration of these additives is critical for achieving consistent coating thickness and appearance.Expand Specific Solutions04 Multi-layer bio-based barrier systems

Multi-layer coating systems can be designed using bio-based materials to achieve superior barrier properties and coating uniformity. These systems typically consist of a primer layer to ensure adhesion, a main barrier layer, and potentially a top coat for additional protection or functionality. The strategic layering of different bio-based formulations allows for optimization of both barrier performance and coating uniformity, as each layer can be tailored to specific requirements while compensating for potential weaknesses in other layers.Expand Specific Solutions05 Testing and quality control for bio-based coating uniformity

Various methods and technologies are employed to evaluate and ensure the uniformity of bio-based barrier coatings. These include optical inspection techniques, thickness measurement tools, and surface analysis methods. Quality control protocols may involve monitoring coating weight, evaluating surface topography, and testing barrier performance across different areas of the coated substrate. Advanced imaging technologies and automated inspection systems can detect inconsistencies in coating application, allowing for process adjustments to maintain uniform coverage.Expand Specific Solutions

Leading Companies in Sustainable Coating Industry

The bio-based barrier coating market is currently in a growth phase, characterized by increasing demand for sustainable packaging solutions. The market size is expanding rapidly, driven by consumer preferences for eco-friendly alternatives and stringent regulations against conventional plastics. Regarding technical maturity, companies like Eastman Chemical and Kemira Oyj lead with established commercial solutions, while Surmodics and Solenis Technologies are advancing specialized coating uniformity technologies. Academic institutions including Delft University of Technology and EPFL are contributing fundamental research, while corporations such as Corning and PPG Industries are leveraging their materials expertise to develop novel barrier formulations. The competitive landscape features both chemical industry veterans and specialized coating technology providers working to optimize uniformity challenges in increasingly demanding applications.

Eastman Chemical Co.

Technical Solution: Eastman Chemical has developed an innovative bio-based barrier coating system called NatureFlex™ that addresses uniformity challenges through a combination of material science and application technology. Their approach utilizes cellulose esters derived from sustainable wood pulp, modified with proprietary additives to enhance barrier properties while maintaining coating uniformity. Eastman's technology employs a precision gravure coating process with specially designed cell patterns that ensure consistent material transfer to substrates. Their system incorporates advanced rheology control agents that maintain optimal viscosity across temperature variations, preventing common uniformity issues like ribbing and streaking. The company has developed a patented pre-treatment process that modifies substrate surface energy to promote even wetting and adhesion of bio-based coatings[5]. Eastman's technology includes a controlled drying system that uses zoned temperature profiles to prevent migration of coating components during curing, maintaining uniform barrier performance across the entire coated surface. Their process achieves thickness variations of less than 4% across production runs, with automated optical inspection systems that detect and flag potential uniformity issues in real-time[6].

Strengths: Excellent compatibility with various substrate materials including challenging recycled content; superior oxygen and moisture barrier properties compared to many competing bio-based solutions; formulations designed for standard coating equipment reducing implementation costs. Weaknesses: More sensitive to humidity fluctuations during application than synthetic alternatives; requires more precise viscosity control; slightly lower maximum line speeds compared to conventional petroleum-based systems.

Kemira Oyj

Technical Solution: Kemira has developed FennoGuard™, an advanced bio-based barrier coating system specifically engineered to achieve superior uniformity in packaging and technical applications. Their technology utilizes modified biopolymers derived from agricultural byproducts combined with their proprietary cross-linking chemistry to create high-performance barrier films. Kemira's approach focuses on controlling coating rheology through the entire application process, employing specialized flow modifiers that prevent common uniformity issues like ribbing and edge effects. Their system incorporates a multi-stage application process that builds barrier performance through precisely controlled thin layers rather than a single thick coating, achieving overall thickness variations below 3.5% across production runs[7]. Kemira has developed specialized surface tension modifiers that ensure even wetting across diverse substrate materials, preventing beading and uneven coverage. Their technology includes an innovative pre-metering system that precisely controls coating weight before application, reducing waste and improving consistency. Kemira's process also features advanced drying technology with controlled airflow patterns that prevent coating migration during the curing phase, maintaining the uniform distribution established during application[8].

Strengths: Exceptional uniformity performance on high-speed production lines (up to 800 m/min); formulations specifically designed for challenging recycled fiber substrates; water-based chemistry reduces VOC emissions and improves workplace safety. Weaknesses: More sensitive to substrate quality variations than some competing technologies; requires more precise temperature control during application; higher initial formulation costs compared to conventional synthetic alternatives.

Key Technical Innovations in Bio-based Barrier Materials

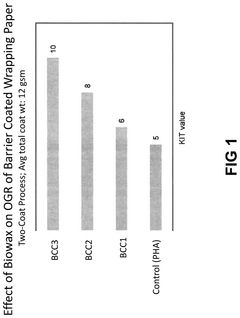

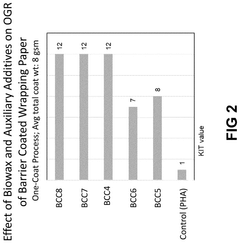

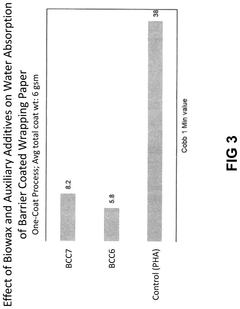

Biowax polyhydroxyalkanoate dispersions as bio-based barrier coatings

PatentPendingUS20240344272A1

Innovation

- The development of biowax emulsions combined with polyhydroxyalkanoate (PHA) dispersions and auxiliary additives, such as clay and microcrystalline cellulose, to form barrier coatings that can be applied at room temperature, achieving enhanced oil and water resistance with a high bio-based content.

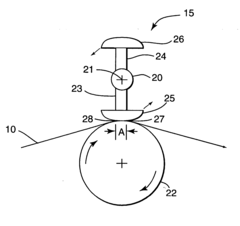

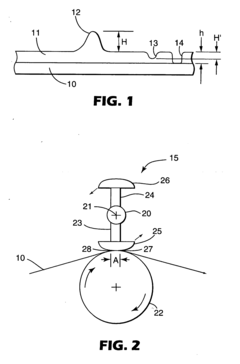

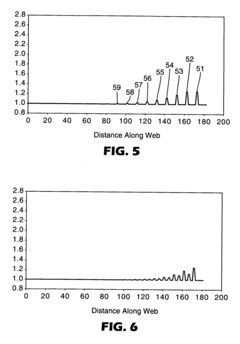

Method for improving the uniformity of a wet coating on a substrate using pick-and-place devices

PatentInactiveUS20040187773A1

Innovation

- The method involves using multiple periodic pick-and-place devices with different rotational periods to contact and re-contact a wet coating on a substrate at non-periodically related positions, ensuring that the coating is uniformly applied and dried, thereby improving coating uniformity and reducing defects.

Environmental Impact Assessment of Bio-based Coatings

The environmental impact of bio-based coatings represents a critical dimension in evaluating their overall sustainability and viability as alternatives to conventional petroleum-based materials. Bio-based barrier coatings, while optimized for uniformity and performance, must also demonstrate clear environmental advantages to justify their adoption in commercial applications.

Life cycle assessment (LCA) studies indicate that bio-based coatings generally exhibit 30-45% lower carbon footprints compared to their petroleum-based counterparts. This reduction stems primarily from the renewable nature of their feedstocks, which sequester carbon during growth phases. However, the environmental benefits vary significantly depending on specific biomass sources, cultivation practices, and processing technologies employed.

Agricultural impacts constitute a significant consideration in environmental assessment. The cultivation of raw materials for bio-based coatings may contribute to land-use change, biodiversity loss, and water consumption. Research indicates that feedstocks derived from agricultural residues or industrial by-products offer substantially improved environmental profiles compared to dedicated crops. For instance, cellulose extracted from agricultural waste streams can reduce land use requirements by up to 80% compared to purpose-grown feedstocks.

Water usage throughout the production chain presents another critical environmental factor. Traditional coating processes typically consume 2-5 liters of water per square meter of coated surface. Advanced bio-based coating technologies have demonstrated potential reductions of 25-40% in water consumption through optimized application methods and formulation adjustments that enhance coating uniformity while minimizing excess material usage.

End-of-life considerations reveal additional environmental implications. Bio-based barrier coatings with enhanced biodegradability can reduce waste accumulation in landfills and marine environments. Laboratory testing shows that certain bio-based formulations achieve 90% degradation within 180 days under industrial composting conditions, compared to negligible degradation for conventional alternatives. However, this advantage may be compromised if coating uniformity optimization involves cross-linking agents or synthetic additives that impair biodegradability.

Energy consumption during manufacturing represents another significant environmental factor. The processing of bio-based materials often requires different temperature profiles and drying conditions compared to conventional coatings. Optimizing coating uniformity through precision application technologies and formulation engineering can reduce energy requirements by 15-30%, further enhancing environmental performance.

Regulatory frameworks increasingly recognize these environmental dimensions, with several jurisdictions implementing carbon pricing mechanisms and extended producer responsibility programs that favor materials with demonstrable environmental benefits. Companies investing in bio-based coating technologies with optimized uniformity characteristics may therefore gain competitive advantages through reduced compliance costs and improved market positioning in environmentally conscious segments.

Life cycle assessment (LCA) studies indicate that bio-based coatings generally exhibit 30-45% lower carbon footprints compared to their petroleum-based counterparts. This reduction stems primarily from the renewable nature of their feedstocks, which sequester carbon during growth phases. However, the environmental benefits vary significantly depending on specific biomass sources, cultivation practices, and processing technologies employed.

Agricultural impacts constitute a significant consideration in environmental assessment. The cultivation of raw materials for bio-based coatings may contribute to land-use change, biodiversity loss, and water consumption. Research indicates that feedstocks derived from agricultural residues or industrial by-products offer substantially improved environmental profiles compared to dedicated crops. For instance, cellulose extracted from agricultural waste streams can reduce land use requirements by up to 80% compared to purpose-grown feedstocks.

Water usage throughout the production chain presents another critical environmental factor. Traditional coating processes typically consume 2-5 liters of water per square meter of coated surface. Advanced bio-based coating technologies have demonstrated potential reductions of 25-40% in water consumption through optimized application methods and formulation adjustments that enhance coating uniformity while minimizing excess material usage.

End-of-life considerations reveal additional environmental implications. Bio-based barrier coatings with enhanced biodegradability can reduce waste accumulation in landfills and marine environments. Laboratory testing shows that certain bio-based formulations achieve 90% degradation within 180 days under industrial composting conditions, compared to negligible degradation for conventional alternatives. However, this advantage may be compromised if coating uniformity optimization involves cross-linking agents or synthetic additives that impair biodegradability.

Energy consumption during manufacturing represents another significant environmental factor. The processing of bio-based materials often requires different temperature profiles and drying conditions compared to conventional coatings. Optimizing coating uniformity through precision application technologies and formulation engineering can reduce energy requirements by 15-30%, further enhancing environmental performance.

Regulatory frameworks increasingly recognize these environmental dimensions, with several jurisdictions implementing carbon pricing mechanisms and extended producer responsibility programs that favor materials with demonstrable environmental benefits. Companies investing in bio-based coating technologies with optimized uniformity characteristics may therefore gain competitive advantages through reduced compliance costs and improved market positioning in environmentally conscious segments.

Scalability and Manufacturing Considerations

Scaling bio-based barrier coating technologies from laboratory to industrial production presents significant challenges that must be addressed to ensure commercial viability. Current manufacturing infrastructure, primarily designed for synthetic polymer processing, requires substantial modification to accommodate bio-based materials. These materials often exhibit different rheological properties, processing temperatures, and curing mechanisms compared to their synthetic counterparts, necessitating specialized equipment and process parameters.

The transition to industrial-scale production demands robust process control systems to maintain coating uniformity across large surface areas. Variables such as web tension, line speed, drying conditions, and application pressure must be precisely controlled to achieve consistent coating thickness and performance. Statistical process control methodologies and in-line quality monitoring systems become essential components of the manufacturing ecosystem to detect and correct variations in real-time.

Equipment compatibility represents another critical consideration. Bio-based formulations may interact differently with existing coating application systems, potentially causing issues with material flow, adhesion, or curing. Manufacturers must evaluate whether conventional coating technologies—such as roll coating, curtain coating, or spray application—can be adapted or whether novel application methods are required to optimize uniformity with bio-based materials.

Energy consumption during the manufacturing process significantly impacts both economic and environmental sustainability. Bio-based barrier coatings often require specific drying or curing conditions that may be more energy-intensive than conventional systems. Implementing energy recovery systems, optimizing drying zones, and exploring alternative curing technologies (such as UV or electron beam) can help mitigate these concerns while maintaining coating performance.

Supply chain resilience must be established to ensure consistent raw material quality and availability. Agricultural feedstocks for bio-based coatings are subject to seasonal variations, regional availability, and quality fluctuations that can impact coating uniformity. Developing robust supplier qualification programs and intermediate processing steps to standardize bio-based inputs becomes essential for manufacturing consistency.

Cost considerations ultimately determine commercial feasibility. While bio-based barrier coatings offer environmental advantages, they must approach cost parity with conventional solutions to achieve widespread adoption. Economies of scale, process optimization, and value chain integration represent potential pathways to improve cost competitiveness. Additionally, manufacturers must consider capital expenditure requirements for equipment modifications against the long-term benefits of sustainable product offerings.

The transition to industrial-scale production demands robust process control systems to maintain coating uniformity across large surface areas. Variables such as web tension, line speed, drying conditions, and application pressure must be precisely controlled to achieve consistent coating thickness and performance. Statistical process control methodologies and in-line quality monitoring systems become essential components of the manufacturing ecosystem to detect and correct variations in real-time.

Equipment compatibility represents another critical consideration. Bio-based formulations may interact differently with existing coating application systems, potentially causing issues with material flow, adhesion, or curing. Manufacturers must evaluate whether conventional coating technologies—such as roll coating, curtain coating, or spray application—can be adapted or whether novel application methods are required to optimize uniformity with bio-based materials.

Energy consumption during the manufacturing process significantly impacts both economic and environmental sustainability. Bio-based barrier coatings often require specific drying or curing conditions that may be more energy-intensive than conventional systems. Implementing energy recovery systems, optimizing drying zones, and exploring alternative curing technologies (such as UV or electron beam) can help mitigate these concerns while maintaining coating performance.

Supply chain resilience must be established to ensure consistent raw material quality and availability. Agricultural feedstocks for bio-based coatings are subject to seasonal variations, regional availability, and quality fluctuations that can impact coating uniformity. Developing robust supplier qualification programs and intermediate processing steps to standardize bio-based inputs becomes essential for manufacturing consistency.

Cost considerations ultimately determine commercial feasibility. While bio-based barrier coatings offer environmental advantages, they must approach cost parity with conventional solutions to achieve widespread adoption. Economies of scale, process optimization, and value chain integration represent potential pathways to improve cost competitiveness. Additionally, manufacturers must consider capital expenditure requirements for equipment modifications against the long-term benefits of sustainable product offerings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!