Analysis of induction motor adaptations for seismic resilience

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Seismic Resilience Goals

Seismic resilience goals for induction motors in earthquake-prone regions are primarily focused on ensuring continuous operation and minimizing damage during seismic events. These objectives are crucial for maintaining critical infrastructure and industrial processes in areas susceptible to earthquakes. The primary aim is to develop induction motors that can withstand the intense vibrations and structural stresses associated with seismic activity without compromising their performance or safety.

One of the key goals is to enhance the structural integrity of induction motors. This involves redesigning motor components to better absorb and dissipate seismic energy, reducing the risk of mechanical failure during an earthquake. Engineers aim to develop more robust motor housings, bearings, and mounting systems that can withstand lateral and vertical forces experienced during seismic events.

Another critical objective is to improve the motor's ability to maintain proper alignment and balance during and after an earthquake. This includes developing advanced rotor and stator designs that are less susceptible to misalignment caused by seismic vibrations. The goal is to ensure that the motor can continue to operate efficiently and safely even after experiencing significant ground motion.

Seismic resilience goals also encompass the development of intelligent monitoring and control systems. These systems aim to detect seismic activity in real-time and automatically adjust motor operation to prevent damage and ensure safety. This may include features such as rapid shutdown mechanisms or adaptive control algorithms that can modify motor parameters in response to changing seismic conditions.

Furthermore, researchers are working on improving the electrical resilience of induction motors during seismic events. This involves developing more robust insulation systems and electrical connections that can withstand the mechanical stresses induced by earthquakes without causing short circuits or other electrical failures.

Another important goal is to enhance the motor's ability to quickly recover from seismic events. This includes designing motors that can easily be realigned or recalibrated after an earthquake, minimizing downtime and reducing the need for extensive repairs or replacements. The aim is to develop motors that can quickly return to normal operation following a seismic event, ensuring minimal disruption to critical systems and processes.

Lastly, seismic resilience goals for induction motors also focus on improving their overall reliability and lifespan in earthquake-prone environments. This involves developing materials and manufacturing techniques that can withstand repeated seismic stresses without degradation of performance or premature failure. The ultimate goal is to create induction motors that maintain their efficiency and reliability throughout their operational life, even in areas with frequent seismic activity.

One of the key goals is to enhance the structural integrity of induction motors. This involves redesigning motor components to better absorb and dissipate seismic energy, reducing the risk of mechanical failure during an earthquake. Engineers aim to develop more robust motor housings, bearings, and mounting systems that can withstand lateral and vertical forces experienced during seismic events.

Another critical objective is to improve the motor's ability to maintain proper alignment and balance during and after an earthquake. This includes developing advanced rotor and stator designs that are less susceptible to misalignment caused by seismic vibrations. The goal is to ensure that the motor can continue to operate efficiently and safely even after experiencing significant ground motion.

Seismic resilience goals also encompass the development of intelligent monitoring and control systems. These systems aim to detect seismic activity in real-time and automatically adjust motor operation to prevent damage and ensure safety. This may include features such as rapid shutdown mechanisms or adaptive control algorithms that can modify motor parameters in response to changing seismic conditions.

Furthermore, researchers are working on improving the electrical resilience of induction motors during seismic events. This involves developing more robust insulation systems and electrical connections that can withstand the mechanical stresses induced by earthquakes without causing short circuits or other electrical failures.

Another important goal is to enhance the motor's ability to quickly recover from seismic events. This includes designing motors that can easily be realigned or recalibrated after an earthquake, minimizing downtime and reducing the need for extensive repairs or replacements. The aim is to develop motors that can quickly return to normal operation following a seismic event, ensuring minimal disruption to critical systems and processes.

Lastly, seismic resilience goals for induction motors also focus on improving their overall reliability and lifespan in earthquake-prone environments. This involves developing materials and manufacturing techniques that can withstand repeated seismic stresses without degradation of performance or premature failure. The ultimate goal is to create induction motors that maintain their efficiency and reliability throughout their operational life, even in areas with frequent seismic activity.

Market Demand Analysis

The market demand for seismically resilient induction motors has been steadily increasing in recent years, driven by growing awareness of earthquake risks and the critical importance of maintaining operational continuity in various industries. Regions prone to seismic activity, such as the Pacific Ring of Fire, have shown particular interest in these adapted motors. Industries including power generation, oil and gas, manufacturing, and critical infrastructure are the primary drivers of this demand.

The global market for earthquake-resistant electrical equipment, including induction motors, is projected to expand significantly over the next decade. This growth is fueled by stringent building codes and regulations in seismically active areas, as well as the increasing focus on disaster preparedness and risk mitigation strategies among businesses and governments.

In the power generation sector, there is a strong demand for seismically resilient induction motors in both conventional and renewable energy plants. These motors are essential components in pumps, fans, and other critical equipment that must remain operational during and after seismic events to ensure continuous power supply.

The oil and gas industry, particularly in offshore platforms and refineries located in seismically active regions, represents another significant market segment. The high cost of downtime and potential environmental risks associated with equipment failure during earthquakes have led to increased investment in resilient motor technologies.

Manufacturing facilities, especially those in industries with high-value production processes or hazardous materials, are also driving demand for seismically adapted induction motors. These industries recognize the importance of maintaining operational integrity and worker safety during seismic events.

Critical infrastructure, including water treatment plants, hospitals, and data centers, represents a growing market for seismically resilient motors. The need for uninterrupted operation of essential services during natural disasters has heightened the focus on equipment reliability and resilience.

The market trend indicates a shift towards predictive maintenance and condition monitoring systems integrated with seismically resilient motors. This integration allows for real-time assessment of motor performance and early detection of potential issues, further enhancing the overall resilience of industrial systems in earthquake-prone areas.

As urbanization continues and more infrastructure is developed in seismically active regions, the demand for adapted induction motors is expected to grow. This trend is particularly evident in rapidly developing countries in Asia and South America, where both industrial expansion and seismic risk awareness are on the rise.

The global market for earthquake-resistant electrical equipment, including induction motors, is projected to expand significantly over the next decade. This growth is fueled by stringent building codes and regulations in seismically active areas, as well as the increasing focus on disaster preparedness and risk mitigation strategies among businesses and governments.

In the power generation sector, there is a strong demand for seismically resilient induction motors in both conventional and renewable energy plants. These motors are essential components in pumps, fans, and other critical equipment that must remain operational during and after seismic events to ensure continuous power supply.

The oil and gas industry, particularly in offshore platforms and refineries located in seismically active regions, represents another significant market segment. The high cost of downtime and potential environmental risks associated with equipment failure during earthquakes have led to increased investment in resilient motor technologies.

Manufacturing facilities, especially those in industries with high-value production processes or hazardous materials, are also driving demand for seismically adapted induction motors. These industries recognize the importance of maintaining operational integrity and worker safety during seismic events.

Critical infrastructure, including water treatment plants, hospitals, and data centers, represents a growing market for seismically resilient motors. The need for uninterrupted operation of essential services during natural disasters has heightened the focus on equipment reliability and resilience.

The market trend indicates a shift towards predictive maintenance and condition monitoring systems integrated with seismically resilient motors. This integration allows for real-time assessment of motor performance and early detection of potential issues, further enhancing the overall resilience of industrial systems in earthquake-prone areas.

As urbanization continues and more infrastructure is developed in seismically active regions, the demand for adapted induction motors is expected to grow. This trend is particularly evident in rapidly developing countries in Asia and South America, where both industrial expansion and seismic risk awareness are on the rise.

Current Challenges

The adaptation of induction motors for seismic resilience faces several significant challenges in the current technological landscape. One of the primary obstacles is the inherent vulnerability of traditional motor designs to seismic events. Conventional induction motors are not typically engineered to withstand the intense vibrations and structural stresses associated with earthquakes, leading to potential failures and operational disruptions in seismically active regions.

Another critical challenge lies in the complex interplay between motor performance and seismic protection measures. Implementing robust seismic resilience features often results in trade-offs with motor efficiency, power output, and overall size. Engineers must navigate this delicate balance to ensure that seismic adaptations do not significantly compromise the motor's primary functions or economic viability.

The lack of standardized testing protocols and certification processes for seismically resilient induction motors presents a substantial hurdle. Without universally accepted benchmarks, it becomes difficult to assess and compare the effectiveness of different seismic adaptation strategies across various motor designs and manufacturers. This absence of standardization also complicates regulatory compliance and market acceptance of seismically adapted motors.

Material limitations pose another significant challenge. Current materials used in motor construction may not possess the ideal combination of strength, flexibility, and durability required to withstand seismic events while maintaining optimal motor performance. The search for advanced materials that can meet these conflicting demands remains an ongoing challenge in the field.

The integration of seismic monitoring and response systems into induction motors presents both technical and cost-related challenges. While such systems could potentially enhance motor resilience by enabling real-time adjustments during seismic events, their implementation requires sophisticated sensor technologies, control algorithms, and fail-safe mechanisms. The added complexity and cost of these systems may limit their widespread adoption, particularly in cost-sensitive applications.

Retrofitting existing induction motors with seismic resilience features presents its own set of challenges. Many industrial facilities rely on legacy motor systems, and upgrading these to meet modern seismic standards can be technically complex and economically prohibitive. Developing cost-effective and minimally disruptive retrofitting solutions remains a significant challenge for the industry.

Lastly, the variability in seismic conditions across different geographical regions complicates the development of universally applicable seismic adaptation strategies. Motors designed for high seismic activity zones may be overengineered and unnecessarily expensive for use in areas with lower seismic risks. Conversely, motors with minimal seismic adaptations may be inadequate in high-risk zones. Addressing this variability while maintaining economic feasibility across diverse markets remains a persistent challenge in the field of seismically resilient induction motor design.

Another critical challenge lies in the complex interplay between motor performance and seismic protection measures. Implementing robust seismic resilience features often results in trade-offs with motor efficiency, power output, and overall size. Engineers must navigate this delicate balance to ensure that seismic adaptations do not significantly compromise the motor's primary functions or economic viability.

The lack of standardized testing protocols and certification processes for seismically resilient induction motors presents a substantial hurdle. Without universally accepted benchmarks, it becomes difficult to assess and compare the effectiveness of different seismic adaptation strategies across various motor designs and manufacturers. This absence of standardization also complicates regulatory compliance and market acceptance of seismically adapted motors.

Material limitations pose another significant challenge. Current materials used in motor construction may not possess the ideal combination of strength, flexibility, and durability required to withstand seismic events while maintaining optimal motor performance. The search for advanced materials that can meet these conflicting demands remains an ongoing challenge in the field.

The integration of seismic monitoring and response systems into induction motors presents both technical and cost-related challenges. While such systems could potentially enhance motor resilience by enabling real-time adjustments during seismic events, their implementation requires sophisticated sensor technologies, control algorithms, and fail-safe mechanisms. The added complexity and cost of these systems may limit their widespread adoption, particularly in cost-sensitive applications.

Retrofitting existing induction motors with seismic resilience features presents its own set of challenges. Many industrial facilities rely on legacy motor systems, and upgrading these to meet modern seismic standards can be technically complex and economically prohibitive. Developing cost-effective and minimally disruptive retrofitting solutions remains a significant challenge for the industry.

Lastly, the variability in seismic conditions across different geographical regions complicates the development of universally applicable seismic adaptation strategies. Motors designed for high seismic activity zones may be overengineered and unnecessarily expensive for use in areas with lower seismic risks. Conversely, motors with minimal seismic adaptations may be inadequate in high-risk zones. Addressing this variability while maintaining economic feasibility across diverse markets remains a persistent challenge in the field of seismically resilient induction motor design.

Existing Solutions

01 Structural reinforcement for seismic resilience

Enhancing the structural integrity of induction motors to withstand seismic events. This involves reinforcing motor components, such as the frame, bearings, and mounting systems, to minimize damage during earthquakes. Techniques may include using shock-absorbing materials, flexible couplings, and improved fastening methods.- Structural reinforcement for seismic resilience: Enhancing the structural integrity of induction motors to withstand seismic events. This includes reinforcing motor housings, mounting systems, and internal components to minimize damage and maintain operational stability during earthquakes.

- Vibration isolation and damping systems: Implementing advanced vibration isolation and damping mechanisms to protect induction motors from seismic shocks. These systems absorb and dissipate seismic energy, reducing the impact on the motor's components and improving overall resilience.

- Seismic monitoring and adaptive control: Integrating seismic monitoring sensors and adaptive control systems into induction motors. These systems detect seismic activity and automatically adjust motor operation or initiate protective measures to prevent damage and maintain performance during earthquakes.

- Materials selection for seismic resistance: Utilizing advanced materials with superior shock-absorbing and stress-resistant properties in the construction of induction motor components. This includes the use of composite materials, high-strength alloys, and flexible connectors to enhance the motor's ability to withstand seismic forces.

- Seismic testing and certification protocols: Developing and implementing rigorous seismic testing and certification protocols for induction motors. These procedures involve simulating earthquake conditions to assess motor performance, identify vulnerabilities, and validate seismic resilience improvements.

02 Vibration isolation and damping systems

Implementing vibration isolation and damping systems to reduce the impact of seismic forces on induction motors. This can include the use of specialized mounts, springs, or hydraulic dampers to absorb and dissipate seismic energy, protecting the motor from excessive movement and potential damage.Expand Specific Solutions03 Seismic monitoring and protection systems

Integrating seismic monitoring and protection systems into induction motor installations. These systems can detect seismic activity and automatically shut down or adjust motor operation to prevent damage. They may include accelerometers, control algorithms, and emergency shutdown mechanisms.Expand Specific Solutions04 Adaptive control strategies for seismic events

Developing adaptive control strategies that allow induction motors to respond dynamically to seismic events. This can involve real-time adjustments to motor speed, torque, and power output based on detected vibrations or ground movement, helping to maintain stability and prevent damage during earthquakes.Expand Specific Solutions05 Seismic-resistant motor design and materials

Incorporating seismic-resistant design principles and advanced materials in induction motor construction. This may include using lightweight yet durable materials, optimizing component geometries for improved stress distribution, and employing flexible or deformable elements to absorb seismic energy without compromising motor functionality.Expand Specific Solutions

Key Industry Players

The analysis of induction motor adaptations for seismic resilience is in a developing stage, with a growing market driven by increasing awareness of seismic risks in industrial applications. The technology is moderately mature, with ongoing research to enhance performance and reliability. Key players like Exxonmobil Upstream Research Co. and China National Petroleum Corp. are investing in R&D to improve motor resilience. Universities such as Chang'an University and Xi'an Jiaotong University are contributing to academic research, while companies like CGG Services SAS and Schlumberger are likely applying these technologies in their seismic exploration services. The market is expected to expand as more industries prioritize equipment resilience in earthquake-prone regions.

Exxonmobil Upstream Research Co.

Technical Solution: Exxonmobil has developed advanced seismic-resistant induction motor designs for use in oil and gas facilities. Their approach involves implementing flexible mounting systems that absorb seismic vibrations, reducing stress on motor components. They have also incorporated reinforced bearings and enhanced rotor balancing techniques to improve stability during seismic events. Exxonmobil's motors feature specialized winding designs that minimize the risk of short circuits caused by excessive movement[1]. Additionally, they have implemented advanced control systems that can detect seismic activity and adjust motor operation to prevent damage[3].

Strengths: Extensive experience in oil and gas industry applications, robust design for harsh environments. Weaknesses: Solutions may be tailored specifically for oil and gas sector, potentially limiting broader applicability.

China General Nuclear Power Corp.

Technical Solution: China General Nuclear Power Corp. has developed seismic-resistant induction motors for nuclear power plant applications. Their approach focuses on enhancing structural integrity through reinforced motor casings and specialized mounting systems designed to withstand high-magnitude seismic events. The company has implemented advanced vibration dampening technologies in their motor designs, including the use of composite materials to absorb shocks[2]. They have also developed intelligent monitoring systems that can detect abnormal vibrations and automatically adjust motor operation to prevent damage during seismic activity[4].

Strengths: Expertise in nuclear power plant applications, focus on high safety standards. Weaknesses: Solutions may be overengineered for less critical applications, potentially increasing costs.

Core Innovations

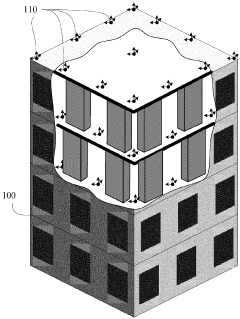

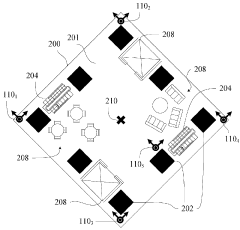

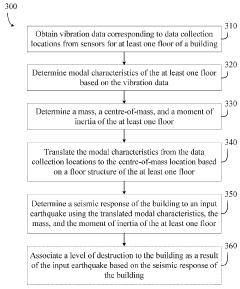

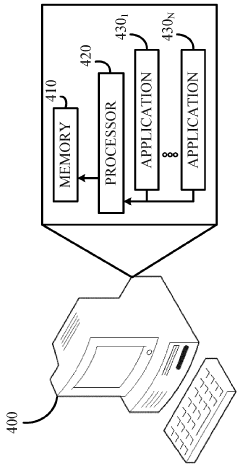

Seismic response assessment of man-made structures

PatentActiveUS20180106696A1

Innovation

- A method and system that utilize sensors to collect vibration data, determine modal characteristics, mass, center-of-mass, and moment of inertia, and translate these to the center-of-mass for calculating the seismic response of a man-made structure to an input earthquake, incorporating linear and nonlinear analysis and modal modification factors.

Regulatory Framework

The regulatory framework surrounding seismic resilience for induction motors plays a crucial role in ensuring the safety and reliability of electrical systems in earthquake-prone regions. Various international and national standards have been developed to address the specific requirements for motor adaptations in seismic environments.

The International Electrotechnical Commission (IEC) has established several standards relevant to seismic resilience in electrical equipment. IEC 60068-2-57 provides guidelines for testing electrical, mechanical, and electromechanical components under conditions of shock and vibration. This standard is particularly applicable to induction motors operating in seismic zones.

In the United States, the Institute of Electrical and Electronics Engineers (IEEE) has developed IEEE 344, which outlines recommended practices for seismic qualification of equipment for nuclear power generating stations. While primarily focused on nuclear facilities, this standard has broader implications for induction motor adaptations in various industries.

The American Society of Civil Engineers (ASCE) has published ASCE 7, which provides minimum design loads and associated criteria for buildings and other structures. This standard includes seismic design requirements that indirectly affect the installation and operation of induction motors in buildings.

National building codes, such as the International Building Code (IBC) in the United States, incorporate seismic design provisions that impact the installation and anchoring of electrical equipment, including induction motors. These codes often reference standards like ASCE 7 for specific seismic design criteria.

In Japan, a country with significant seismic activity, the Japan Electrical Manufacturers' Association (JEMA) has established guidelines for earthquake-resistant design of rotating electrical machines. These guidelines provide specific recommendations for induction motor adaptations to enhance seismic resilience.

The European Union has implemented the Machinery Directive (2006/42/EC), which includes general safety requirements for machinery. While not specifically focused on seismic resilience, this directive influences the design and adaptation of induction motors for use in potentially hazardous environments.

Compliance with these regulatory frameworks often requires manufacturers to conduct extensive testing and provide documentation demonstrating the seismic resilience of their induction motors. This may include shake table tests, finite element analysis, and other simulation techniques to validate the motor's performance under seismic conditions.

As seismic events continue to pose significant risks to infrastructure and industrial operations, regulatory bodies are likely to update and refine their standards for induction motor adaptations. This ongoing evolution of the regulatory framework will drive innovation in motor design and installation practices, ultimately leading to more resilient electrical systems in seismically active regions.

The International Electrotechnical Commission (IEC) has established several standards relevant to seismic resilience in electrical equipment. IEC 60068-2-57 provides guidelines for testing electrical, mechanical, and electromechanical components under conditions of shock and vibration. This standard is particularly applicable to induction motors operating in seismic zones.

In the United States, the Institute of Electrical and Electronics Engineers (IEEE) has developed IEEE 344, which outlines recommended practices for seismic qualification of equipment for nuclear power generating stations. While primarily focused on nuclear facilities, this standard has broader implications for induction motor adaptations in various industries.

The American Society of Civil Engineers (ASCE) has published ASCE 7, which provides minimum design loads and associated criteria for buildings and other structures. This standard includes seismic design requirements that indirectly affect the installation and operation of induction motors in buildings.

National building codes, such as the International Building Code (IBC) in the United States, incorporate seismic design provisions that impact the installation and anchoring of electrical equipment, including induction motors. These codes often reference standards like ASCE 7 for specific seismic design criteria.

In Japan, a country with significant seismic activity, the Japan Electrical Manufacturers' Association (JEMA) has established guidelines for earthquake-resistant design of rotating electrical machines. These guidelines provide specific recommendations for induction motor adaptations to enhance seismic resilience.

The European Union has implemented the Machinery Directive (2006/42/EC), which includes general safety requirements for machinery. While not specifically focused on seismic resilience, this directive influences the design and adaptation of induction motors for use in potentially hazardous environments.

Compliance with these regulatory frameworks often requires manufacturers to conduct extensive testing and provide documentation demonstrating the seismic resilience of their induction motors. This may include shake table tests, finite element analysis, and other simulation techniques to validate the motor's performance under seismic conditions.

As seismic events continue to pose significant risks to infrastructure and industrial operations, regulatory bodies are likely to update and refine their standards for induction motor adaptations. This ongoing evolution of the regulatory framework will drive innovation in motor design and installation practices, ultimately leading to more resilient electrical systems in seismically active regions.

Economic Impact Assessment

The economic impact of adapting induction motors for seismic resilience extends far beyond the immediate costs of implementation. This assessment explores the broader economic implications of such adaptations across various sectors and stakeholders.

Firstly, the direct costs associated with retrofitting existing induction motors or designing new seismically resilient models must be considered. These expenses include research and development, materials, manufacturing processes, and installation. While initially significant, these costs should be weighed against the potential long-term savings from reduced damage and downtime during seismic events.

The industrial sector stands to benefit substantially from seismically resilient induction motors. Manufacturing plants, power generation facilities, and other critical infrastructure relying on these motors can minimize production losses and maintain operational continuity during and after earthquakes. This resilience translates to reduced economic disruptions and faster recovery times for affected regions.

Insurance companies may also see a shift in their risk assessments and premium structures for businesses utilizing seismically adapted induction motors. The reduced likelihood of motor failure and subsequent damage could lead to lower insurance costs for companies, potentially offsetting the initial investment in resilient technology.

The construction and engineering sectors may experience increased demand for expertise in seismic adaptation, creating new job opportunities and fostering innovation in motor design and installation practices. This could stimulate economic growth in related industries and contribute to the development of specialized skills in the workforce.

From a macroeconomic perspective, regions prone to seismic activity may become more attractive for industrial investment due to the enhanced reliability of critical equipment. This could lead to increased foreign direct investment and economic development in areas previously considered high-risk for certain industries.

However, it is crucial to consider the potential economic disparities that may arise. Smaller businesses or developing regions may face challenges in adopting this technology due to high initial costs, potentially widening the gap between large corporations and smaller enterprises in terms of operational resilience.

In conclusion, while the upfront costs of adapting induction motors for seismic resilience are significant, the long-term economic benefits in terms of reduced losses, increased operational stability, and potential for innovation and growth suggest a positive overall economic impact. Policymakers and industry leaders should consider incentives and support mechanisms to encourage widespread adoption and mitigate potential economic disparities.

Firstly, the direct costs associated with retrofitting existing induction motors or designing new seismically resilient models must be considered. These expenses include research and development, materials, manufacturing processes, and installation. While initially significant, these costs should be weighed against the potential long-term savings from reduced damage and downtime during seismic events.

The industrial sector stands to benefit substantially from seismically resilient induction motors. Manufacturing plants, power generation facilities, and other critical infrastructure relying on these motors can minimize production losses and maintain operational continuity during and after earthquakes. This resilience translates to reduced economic disruptions and faster recovery times for affected regions.

Insurance companies may also see a shift in their risk assessments and premium structures for businesses utilizing seismically adapted induction motors. The reduced likelihood of motor failure and subsequent damage could lead to lower insurance costs for companies, potentially offsetting the initial investment in resilient technology.

The construction and engineering sectors may experience increased demand for expertise in seismic adaptation, creating new job opportunities and fostering innovation in motor design and installation practices. This could stimulate economic growth in related industries and contribute to the development of specialized skills in the workforce.

From a macroeconomic perspective, regions prone to seismic activity may become more attractive for industrial investment due to the enhanced reliability of critical equipment. This could lead to increased foreign direct investment and economic development in areas previously considered high-risk for certain industries.

However, it is crucial to consider the potential economic disparities that may arise. Smaller businesses or developing regions may face challenges in adopting this technology due to high initial costs, potentially widening the gap between large corporations and smaller enterprises in terms of operational resilience.

In conclusion, while the upfront costs of adapting induction motors for seismic resilience are significant, the long-term economic benefits in terms of reduced losses, increased operational stability, and potential for innovation and growth suggest a positive overall economic impact. Policymakers and industry leaders should consider incentives and support mechanisms to encourage widespread adoption and mitigate potential economic disparities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!