How induction motors support disaster relief energy solutions

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Fundamentals and Disaster Relief Goals

Induction motors have long been a cornerstone of industrial power systems, and their potential in disaster relief scenarios is increasingly recognized. These robust and reliable machines convert electrical energy into mechanical energy through electromagnetic induction, making them ideal for powering essential equipment in emergency situations.

The fundamental principle of induction motors lies in the interaction between a rotating magnetic field in the stator and induced currents in the rotor. This design allows for efficient and consistent power delivery, crucial in disaster-stricken areas where energy resources may be limited. The simplicity of their construction, coupled with their ability to operate under varying load conditions, makes induction motors particularly suited for the unpredictable demands of disaster relief operations.

In the context of disaster relief, the primary goal is to restore and maintain critical infrastructure and services. Induction motors play a vital role in this effort by powering water pumps for flood control and clean water distribution, driving ventilation systems in temporary shelters, and operating heavy machinery for debris removal and reconstruction. Their versatility allows for rapid deployment across various applications, addressing immediate needs in the aftermath of natural disasters.

Another key objective in disaster relief is to establish reliable and sustainable energy solutions. Induction motors, when coupled with generators or renewable energy sources, can form the backbone of temporary power grids. Their ability to start under load and handle power fluctuations makes them ideal for use in makeshift power distribution systems, ensuring a stable supply of electricity to critical facilities such as field hospitals, communication centers, and emergency response headquarters.

The durability of induction motors is particularly valuable in harsh post-disaster environments. Their sealed design protects against dust, debris, and moisture, reducing the risk of failure in challenging conditions. This resilience aligns with the disaster relief goal of maintaining operational continuity, as equipment downtime can have severe consequences in emergency situations.

Furthermore, the scalability of induction motor technology supports the phased approach often required in disaster relief efforts. From small portable units powering individual pieces of equipment to larger systems supporting entire temporary communities, induction motors can be adapted to meet evolving energy needs as relief operations progress from immediate response to long-term recovery.

As we explore the role of induction motors in disaster relief, it becomes clear that their fundamental characteristics align closely with the goals of providing rapid, reliable, and adaptable energy solutions in crisis situations. Their integration into disaster relief strategies represents a critical link between established industrial technology and innovative approaches to emergency management.

The fundamental principle of induction motors lies in the interaction between a rotating magnetic field in the stator and induced currents in the rotor. This design allows for efficient and consistent power delivery, crucial in disaster-stricken areas where energy resources may be limited. The simplicity of their construction, coupled with their ability to operate under varying load conditions, makes induction motors particularly suited for the unpredictable demands of disaster relief operations.

In the context of disaster relief, the primary goal is to restore and maintain critical infrastructure and services. Induction motors play a vital role in this effort by powering water pumps for flood control and clean water distribution, driving ventilation systems in temporary shelters, and operating heavy machinery for debris removal and reconstruction. Their versatility allows for rapid deployment across various applications, addressing immediate needs in the aftermath of natural disasters.

Another key objective in disaster relief is to establish reliable and sustainable energy solutions. Induction motors, when coupled with generators or renewable energy sources, can form the backbone of temporary power grids. Their ability to start under load and handle power fluctuations makes them ideal for use in makeshift power distribution systems, ensuring a stable supply of electricity to critical facilities such as field hospitals, communication centers, and emergency response headquarters.

The durability of induction motors is particularly valuable in harsh post-disaster environments. Their sealed design protects against dust, debris, and moisture, reducing the risk of failure in challenging conditions. This resilience aligns with the disaster relief goal of maintaining operational continuity, as equipment downtime can have severe consequences in emergency situations.

Furthermore, the scalability of induction motor technology supports the phased approach often required in disaster relief efforts. From small portable units powering individual pieces of equipment to larger systems supporting entire temporary communities, induction motors can be adapted to meet evolving energy needs as relief operations progress from immediate response to long-term recovery.

As we explore the role of induction motors in disaster relief, it becomes clear that their fundamental characteristics align closely with the goals of providing rapid, reliable, and adaptable energy solutions in crisis situations. Their integration into disaster relief strategies represents a critical link between established industrial technology and innovative approaches to emergency management.

Disaster Relief Energy Demand Analysis

In the wake of natural disasters, the demand for reliable and efficient energy solutions becomes paramount. Disaster relief operations require immediate access to power for critical services such as medical facilities, communication systems, water purification, and temporary shelters. The energy demand in these scenarios is characterized by its urgency, variability, and the need for mobility.

The primary energy requirements during disaster relief efforts can be categorized into several key areas. Emergency medical services demand a consistent power supply for life-saving equipment, refrigeration of medicines, and operation of diagnostic tools. Communication infrastructure, crucial for coordinating relief efforts, requires power for mobile networks, satellite phones, and command centers. Water treatment and distribution systems need energy to purify contaminated water sources and pump water to affected areas.

Temporary housing and community centers also contribute significantly to the energy demand. These facilities require power for lighting, heating or cooling, and basic appliances to provide comfort and safety to displaced individuals. Food preservation and preparation for large numbers of people add to the energy requirements, necessitating refrigeration and cooking equipment.

The scale of energy demand varies greatly depending on the disaster's magnitude and the affected population size. Small-scale operations might require portable generators producing a few kilowatts, while large-scale relief efforts could demand megawatts of power. The energy demand profile is typically characterized by sudden spikes followed by sustained periods of moderate consumption as relief efforts stabilize.

Flexibility and scalability are crucial aspects of disaster relief energy solutions. The ability to quickly deploy and adapt power generation to changing needs is essential. This often necessitates a combination of fixed and mobile power sources, with the capacity to integrate with existing infrastructure when possible.

Reliability under adverse conditions is another critical factor. Energy solutions must be robust enough to function in challenging environments, often with limited access to fuel or maintenance resources. This drives the need for durable, low-maintenance systems that can operate continuously for extended periods.

Environmental considerations also play a role in modern disaster relief energy planning. There is an increasing emphasis on clean and sustainable power sources to minimize the environmental impact of relief operations and reduce dependence on fuel supply chains, which may be disrupted in disaster scenarios.

Understanding these diverse and dynamic energy demands is crucial for developing effective disaster relief power solutions. It informs the design of energy systems that can meet immediate needs while remaining adaptable to evolving situations, ultimately supporting more efficient and impactful disaster response efforts.

The primary energy requirements during disaster relief efforts can be categorized into several key areas. Emergency medical services demand a consistent power supply for life-saving equipment, refrigeration of medicines, and operation of diagnostic tools. Communication infrastructure, crucial for coordinating relief efforts, requires power for mobile networks, satellite phones, and command centers. Water treatment and distribution systems need energy to purify contaminated water sources and pump water to affected areas.

Temporary housing and community centers also contribute significantly to the energy demand. These facilities require power for lighting, heating or cooling, and basic appliances to provide comfort and safety to displaced individuals. Food preservation and preparation for large numbers of people add to the energy requirements, necessitating refrigeration and cooking equipment.

The scale of energy demand varies greatly depending on the disaster's magnitude and the affected population size. Small-scale operations might require portable generators producing a few kilowatts, while large-scale relief efforts could demand megawatts of power. The energy demand profile is typically characterized by sudden spikes followed by sustained periods of moderate consumption as relief efforts stabilize.

Flexibility and scalability are crucial aspects of disaster relief energy solutions. The ability to quickly deploy and adapt power generation to changing needs is essential. This often necessitates a combination of fixed and mobile power sources, with the capacity to integrate with existing infrastructure when possible.

Reliability under adverse conditions is another critical factor. Energy solutions must be robust enough to function in challenging environments, often with limited access to fuel or maintenance resources. This drives the need for durable, low-maintenance systems that can operate continuously for extended periods.

Environmental considerations also play a role in modern disaster relief energy planning. There is an increasing emphasis on clean and sustainable power sources to minimize the environmental impact of relief operations and reduce dependence on fuel supply chains, which may be disrupted in disaster scenarios.

Understanding these diverse and dynamic energy demands is crucial for developing effective disaster relief power solutions. It informs the design of energy systems that can meet immediate needs while remaining adaptable to evolving situations, ultimately supporting more efficient and impactful disaster response efforts.

Induction Motor Capabilities and Limitations in Harsh Environments

Induction motors possess several key capabilities that make them suitable for disaster relief energy solutions, but they also face limitations in harsh environments. These motors are known for their robustness, reliability, and relatively simple construction, which are advantageous in emergency situations. They can operate efficiently under varying load conditions, making them adaptable to the unpredictable power demands often encountered in disaster-stricken areas.

One of the primary strengths of induction motors in disaster relief scenarios is their ability to start and run on a wide range of power sources. This flexibility allows them to be powered by emergency generators, temporary power grids, or even improvised energy solutions, which are common in post-disaster environments. Additionally, their low maintenance requirements and durability make them ideal for prolonged use in challenging conditions where regular servicing may be difficult.

However, induction motors also face several limitations when operating in harsh environments typical of disaster areas. High ambient temperatures can lead to overheating, potentially causing insulation breakdown and reduced efficiency. Excessive moisture or flooding can compromise the motor's electrical integrity, leading to short circuits or corrosion of internal components. Dust and debris, often prevalent in disaster zones, can clog ventilation systems and bearings, affecting the motor's cooling capabilities and overall performance.

Extreme mechanical stress, such as that caused by earthquakes or structural collapses, can misalign motor shafts or damage bearings, significantly impacting the motor's operation. Furthermore, the potential for exposure to corrosive substances or saltwater in coastal disaster areas can accelerate the degradation of motor components, reducing their lifespan and reliability.

To mitigate these limitations, specialized designs and protective measures are often implemented. These may include enhanced insulation systems, sealed enclosures to prevent ingress of contaminants, and reinforced mechanical components to withstand physical shocks. Some advanced induction motors for disaster relief applications incorporate built-in monitoring systems to detect abnormal operating conditions and prevent catastrophic failures.

Despite these challenges, the fundamental simplicity and robustness of induction motors continue to make them a valuable asset in disaster relief energy solutions. Their ability to provide reliable mechanical power under adverse conditions supports critical functions such as water pumping, ventilation, and powering essential equipment. As technology advances, ongoing research focuses on further improving the resilience of induction motors to harsh environments, enhancing their effectiveness in disaster relief scenarios.

One of the primary strengths of induction motors in disaster relief scenarios is their ability to start and run on a wide range of power sources. This flexibility allows them to be powered by emergency generators, temporary power grids, or even improvised energy solutions, which are common in post-disaster environments. Additionally, their low maintenance requirements and durability make them ideal for prolonged use in challenging conditions where regular servicing may be difficult.

However, induction motors also face several limitations when operating in harsh environments typical of disaster areas. High ambient temperatures can lead to overheating, potentially causing insulation breakdown and reduced efficiency. Excessive moisture or flooding can compromise the motor's electrical integrity, leading to short circuits or corrosion of internal components. Dust and debris, often prevalent in disaster zones, can clog ventilation systems and bearings, affecting the motor's cooling capabilities and overall performance.

Extreme mechanical stress, such as that caused by earthquakes or structural collapses, can misalign motor shafts or damage bearings, significantly impacting the motor's operation. Furthermore, the potential for exposure to corrosive substances or saltwater in coastal disaster areas can accelerate the degradation of motor components, reducing their lifespan and reliability.

To mitigate these limitations, specialized designs and protective measures are often implemented. These may include enhanced insulation systems, sealed enclosures to prevent ingress of contaminants, and reinforced mechanical components to withstand physical shocks. Some advanced induction motors for disaster relief applications incorporate built-in monitoring systems to detect abnormal operating conditions and prevent catastrophic failures.

Despite these challenges, the fundamental simplicity and robustness of induction motors continue to make them a valuable asset in disaster relief energy solutions. Their ability to provide reliable mechanical power under adverse conditions supports critical functions such as water pumping, ventilation, and powering essential equipment. As technology advances, ongoing research focuses on further improving the resilience of induction motors to harsh environments, enhancing their effectiveness in disaster relief scenarios.

Current Induction Motor-Based Emergency Power Systems

01 Design and construction of induction motors

This category covers the fundamental design and construction aspects of induction motors, including stator and rotor configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.- Design and construction of induction motors: This category focuses on the fundamental design and construction aspects of induction motors. It includes innovations in motor structure, winding configurations, and material selection to improve efficiency and performance. These advancements aim to enhance power output, reduce losses, and optimize overall motor operation.

- Control systems for induction motors: This point covers various control strategies and systems developed for induction motors. It includes methods for speed regulation, torque control, and power factor correction. Advanced control techniques such as vector control and direct torque control are also addressed to improve motor performance and efficiency across different operating conditions.

- Energy efficiency improvements in induction motors: This category focuses on techniques and technologies aimed at improving the energy efficiency of induction motors. It includes innovations in rotor and stator designs, use of advanced materials, and optimization of magnetic circuits to reduce losses and increase overall motor efficiency. These improvements contribute to energy savings and reduced operating costs.

- Specialized applications of induction motors: This point covers induction motors designed for specific applications or operating environments. It includes motors adapted for use in harsh conditions, high-speed operations, or specialized industrial processes. These motors may feature unique designs or materials to meet the requirements of their intended applications.

- Diagnostics and maintenance of induction motors: This category focuses on methods and systems for monitoring, diagnosing, and maintaining induction motors. It includes techniques for fault detection, condition monitoring, and predictive maintenance. These innovations aim to improve motor reliability, reduce downtime, and extend the operational life of induction motors.

02 Control systems for induction motors

Control systems play a crucial role in regulating the speed, torque, and efficiency of induction motors. This category encompasses various control strategies, including vector control, direct torque control, and advanced algorithms for optimizing motor performance under different operating conditions.Expand Specific Solutions03 Energy efficiency improvements in induction motors

This category focuses on techniques and technologies aimed at enhancing the energy efficiency of induction motors. This includes the use of advanced materials, improved cooling systems, and innovative designs to reduce losses and increase overall motor efficiency.Expand Specific Solutions04 Specialized applications of induction motors

Induction motors are used in a wide range of specialized applications, each with unique requirements. This category covers innovations tailored for specific industries or operating conditions, such as high-speed motors, submersible motors, or motors designed for extreme environments.Expand Specific Solutions05 Diagnostics and maintenance of induction motors

This category encompasses methods and systems for monitoring, diagnosing, and maintaining induction motors. It includes techniques for fault detection, predictive maintenance, and condition monitoring to ensure optimal motor performance and longevity.Expand Specific Solutions

Key Players in Disaster Relief Power Solutions

The induction motor technology for disaster relief energy solutions is in a growth phase, with increasing market size driven by rising demand for reliable power in emergency situations. The market is characterized by moderate technological maturity, with established players like Siemens AG and Robert Bosch GmbH leading innovation. Emerging companies such as KPIT Technologies Ltd. and Precision Combustion, Inc. are also contributing to advancements. The competitive landscape is diverse, including traditional industrial giants like Caterpillar, Inc. and Isuzu Motors Ltd., as well as specialized energy solution providers like Planet A Energy, Inc. This mix of players indicates a dynamic market with opportunities for both incremental improvements and disruptive innovations in induction motor technology for disaster relief applications.

Robert Bosch GmbH

Technical Solution: Bosch has developed innovative induction motor solutions for disaster relief energy applications, focusing on compact and efficient designs. Their e-axle system, which incorporates advanced induction motors, has been adapted for use in mobile power generation units for disaster relief[7]. These motors feature high power density and efficiency, allowing for smaller, more portable generator sets. Bosch has also integrated their induction motor technology with smart inverter systems, enabling seamless integration with renewable energy sources such as solar panels, which is crucial for sustainable disaster relief operations[8]. The company's motor management systems incorporate predictive maintenance algorithms, reducing the risk of unexpected failures during critical relief efforts[9].

Strengths: Compact and efficient motor designs, integration with renewable energy sources, and advanced predictive maintenance capabilities. Weaknesses: Limited experience in large-scale power generation compared to some competitors.

Rosenbauer International AG

Technical Solution: Rosenbauer, a leading manufacturer of firefighting equipment, has developed specialized induction motor applications for disaster relief vehicles. Their "Revolutionary Technology" (RT) concept incorporates high-performance induction motors in firefighting and rescue vehicles, providing both propulsion and power generation capabilities[10]. These vehicles can serve as mobile power stations in disaster-stricken areas, utilizing the vehicle's induction motor to generate electricity for relief operations. Rosenbauer's system includes advanced power management software that optimizes energy distribution between vehicle functions and external power needs. The company has also developed a modular approach, allowing for easy integration of their induction motor-based power systems into various vehicle types used in disaster relief[11].

Strengths: Dual-purpose vehicles (transport and power generation), specialized for disaster relief scenarios, and modular design for versatility. Weaknesses: Limited to vehicle-based applications, potentially higher cost due to specialized nature.

Innovations in Ruggedized Induction Motor Design

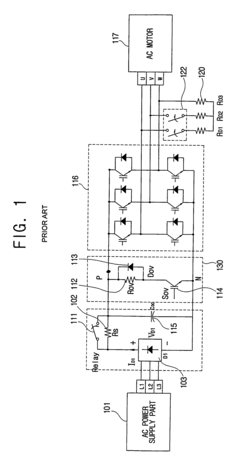

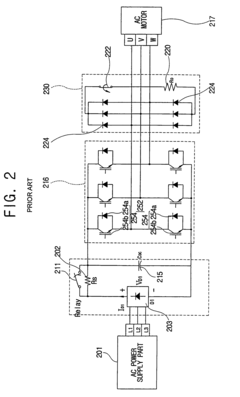

Power supply device for permanent magnet field type linear motor and pwm inverter for permanent magnet field type motor

PatentWO2008026642A1

Innovation

- A power supply device and PWM inverter system that adjusts the current supplied to each phase coil, specifically reducing the current to coils not at the ends, ensuring uniform thrust generation by using a resistor in parallel with the W-phase coil and controlling switching elements to manage current distribution across the U, V, and W phases.

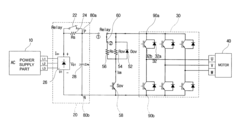

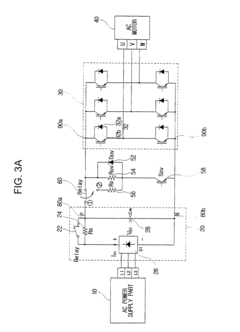

Motor power supply control apparatus

PatentInactiveUS7170245B2

Innovation

- A motor power supply design that shares diodes between the dynamic braking circuit and inverter, incorporating a braking resistor with a control switching element and motor speed detector to adjust resistance values dynamically based on motor speed, allowing for variable resistance in braking mode.

Regulatory Framework for Emergency Power Equipment

The regulatory framework for emergency power equipment plays a crucial role in ensuring the safety, reliability, and effectiveness of disaster relief energy solutions. In the context of induction motors supporting these solutions, several key regulations and standards come into play.

Firstly, the National Electrical Code (NEC) provides comprehensive guidelines for the installation and operation of electrical systems, including those used in emergency situations. Article 700 of the NEC specifically addresses emergency systems, outlining requirements for power sources, wiring, and equipment. These regulations ensure that induction motors used in disaster relief scenarios meet stringent safety and performance standards.

The Federal Emergency Management Agency (FEMA) also sets forth guidelines for emergency power systems. FEMA's P-1019 document, "Emergency Power Systems for Critical Facilities: A Best Practices Approach to Improving Reliability," offers valuable insights into the design and implementation of robust power solutions. While not specifically focused on induction motors, these guidelines influence the overall system architecture in which these motors operate.

International standards, such as ISO 8528, provide specifications for reciprocating internal combustion engine-driven alternating current generating sets. This standard is particularly relevant when induction motors are integrated into generator systems for emergency power provision. Compliance with ISO 8528 ensures interoperability and reliability across different equipment manufacturers.

The Occupational Safety and Health Administration (OSHA) mandates safety requirements for electrical equipment used in hazardous environments, which often characterize disaster relief scenarios. OSHA's 29 CFR 1910.307 standard addresses electrical equipment in Class I hazardous locations, potentially impacting the design and operation of induction motors in certain emergency situations.

Environmental regulations also play a significant role in shaping the use of induction motors for disaster relief. The Environmental Protection Agency (EPA) sets emissions standards for emergency generators through its Tier 4 regulations. While these primarily target engine emissions, they indirectly influence the design and application of induction motors in integrated power systems.

Lastly, local and state regulations often supplement federal guidelines, adding another layer of compliance requirements. These may include specific noise ordinances, zoning restrictions, or additional safety measures that affect the deployment and operation of emergency power equipment, including induction motor-based solutions.

Firstly, the National Electrical Code (NEC) provides comprehensive guidelines for the installation and operation of electrical systems, including those used in emergency situations. Article 700 of the NEC specifically addresses emergency systems, outlining requirements for power sources, wiring, and equipment. These regulations ensure that induction motors used in disaster relief scenarios meet stringent safety and performance standards.

The Federal Emergency Management Agency (FEMA) also sets forth guidelines for emergency power systems. FEMA's P-1019 document, "Emergency Power Systems for Critical Facilities: A Best Practices Approach to Improving Reliability," offers valuable insights into the design and implementation of robust power solutions. While not specifically focused on induction motors, these guidelines influence the overall system architecture in which these motors operate.

International standards, such as ISO 8528, provide specifications for reciprocating internal combustion engine-driven alternating current generating sets. This standard is particularly relevant when induction motors are integrated into generator systems for emergency power provision. Compliance with ISO 8528 ensures interoperability and reliability across different equipment manufacturers.

The Occupational Safety and Health Administration (OSHA) mandates safety requirements for electrical equipment used in hazardous environments, which often characterize disaster relief scenarios. OSHA's 29 CFR 1910.307 standard addresses electrical equipment in Class I hazardous locations, potentially impacting the design and operation of induction motors in certain emergency situations.

Environmental regulations also play a significant role in shaping the use of induction motors for disaster relief. The Environmental Protection Agency (EPA) sets emissions standards for emergency generators through its Tier 4 regulations. While these primarily target engine emissions, they indirectly influence the design and application of induction motors in integrated power systems.

Lastly, local and state regulations often supplement federal guidelines, adding another layer of compliance requirements. These may include specific noise ordinances, zoning restrictions, or additional safety measures that affect the deployment and operation of emergency power equipment, including induction motor-based solutions.

Environmental Impact of Induction Motor-Based Relief Solutions

Induction motor-based disaster relief energy solutions offer significant environmental benefits compared to traditional fossil fuel-powered generators. These systems leverage the efficiency and reliability of induction motors to provide clean, sustainable power in emergency situations. The environmental impact of such solutions is multifaceted, encompassing both immediate and long-term effects on ecosystems and climate.

One of the primary environmental advantages of induction motor-based relief solutions is their reduced carbon footprint. Unlike diesel generators, which emit substantial amounts of greenhouse gases and particulate matter, induction motors powered by renewable energy sources produce zero direct emissions during operation. This characteristic is particularly crucial in disaster-stricken areas where air quality may already be compromised due to infrastructure damage or natural phenomena.

The use of induction motors in disaster relief also contributes to noise pollution reduction. Conventional generators often produce high levels of noise, which can be disruptive to both human populations and local wildlife. In contrast, induction motors operate more quietly, minimizing acoustic disturbances in sensitive environments and allowing for better communication and coordination among relief workers and affected communities.

Furthermore, induction motor-based solutions typically have a smaller physical footprint compared to large diesel generators. This compact design reduces the need for extensive site preparation and minimizes habitat disruption when deploying emergency power systems in ecologically sensitive areas. The reduced land use requirements also facilitate quicker installation and removal, limiting the long-term impact on local ecosystems.

Another environmental benefit lies in the potential for integrating these systems with renewable energy sources. Induction motors can be easily coupled with solar panels, wind turbines, or micro-hydro systems, enabling the use of clean, locally available energy resources. This integration not only reduces the reliance on fossil fuels but also promotes the development of sustainable energy infrastructure in disaster-prone regions.

The longevity and durability of induction motors contribute to their positive environmental impact. These motors have fewer moving parts compared to internal combustion engines, resulting in less wear and tear and reduced maintenance requirements. This durability translates to a longer operational lifespan, reducing the frequency of replacement and the associated environmental costs of manufacturing and disposing of power generation equipment.

Moreover, the versatility of induction motor-based systems allows for their repurposing after the immediate disaster relief phase. These motors can be integrated into long-term rebuilding efforts, supporting sustainable development initiatives in affected areas. This adaptability ensures that the environmental benefits extend beyond the initial emergency response, contributing to the overall resilience and sustainability of recovering communities.

One of the primary environmental advantages of induction motor-based relief solutions is their reduced carbon footprint. Unlike diesel generators, which emit substantial amounts of greenhouse gases and particulate matter, induction motors powered by renewable energy sources produce zero direct emissions during operation. This characteristic is particularly crucial in disaster-stricken areas where air quality may already be compromised due to infrastructure damage or natural phenomena.

The use of induction motors in disaster relief also contributes to noise pollution reduction. Conventional generators often produce high levels of noise, which can be disruptive to both human populations and local wildlife. In contrast, induction motors operate more quietly, minimizing acoustic disturbances in sensitive environments and allowing for better communication and coordination among relief workers and affected communities.

Furthermore, induction motor-based solutions typically have a smaller physical footprint compared to large diesel generators. This compact design reduces the need for extensive site preparation and minimizes habitat disruption when deploying emergency power systems in ecologically sensitive areas. The reduced land use requirements also facilitate quicker installation and removal, limiting the long-term impact on local ecosystems.

Another environmental benefit lies in the potential for integrating these systems with renewable energy sources. Induction motors can be easily coupled with solar panels, wind turbines, or micro-hydro systems, enabling the use of clean, locally available energy resources. This integration not only reduces the reliance on fossil fuels but also promotes the development of sustainable energy infrastructure in disaster-prone regions.

The longevity and durability of induction motors contribute to their positive environmental impact. These motors have fewer moving parts compared to internal combustion engines, resulting in less wear and tear and reduced maintenance requirements. This durability translates to a longer operational lifespan, reducing the frequency of replacement and the associated environmental costs of manufacturing and disposing of power generation equipment.

Moreover, the versatility of induction motor-based systems allows for their repurposing after the immediate disaster relief phase. These motors can be integrated into long-term rebuilding efforts, supporting sustainable development initiatives in affected areas. This adaptability ensures that the environmental benefits extend beyond the initial emergency response, contributing to the overall resilience and sustainability of recovering communities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!