How induction motors promote eco-friendly agricultural solutions

AUG 18, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motors in Agriculture: Background and Objectives

Induction motors have played a pivotal role in the agricultural sector for decades, revolutionizing farming practices and contributing to increased productivity. As the world faces growing environmental challenges, the focus has shifted towards developing eco-friendly agricultural solutions. In this context, induction motors have emerged as a key technology in promoting sustainable farming practices.

The evolution of induction motors in agriculture can be traced back to the early 20th century when electrification began to reach rural areas. Initially used for simple tasks like water pumping, these motors gradually found applications in various farm operations, including irrigation systems, grain handling, and livestock management. Over time, advancements in motor design and control technologies have significantly improved their efficiency and versatility.

Today, the agricultural sector is at a critical juncture, facing the dual challenges of meeting increasing food demand and reducing environmental impact. Induction motors are at the forefront of addressing these challenges by enabling the development of more efficient and environmentally friendly farming equipment. Their ability to provide reliable, controllable power with minimal maintenance requirements makes them ideal for a wide range of agricultural applications.

The primary objective of integrating induction motors into eco-friendly agricultural solutions is to reduce the carbon footprint of farming operations while maintaining or improving productivity. This aligns with global efforts to mitigate climate change and promote sustainable development in the agricultural sector. By replacing fossil fuel-powered equipment with electric alternatives powered by induction motors, farmers can significantly reduce greenhouse gas emissions and dependence on non-renewable energy sources.

Another key goal is to enhance the precision and efficiency of agricultural processes. Induction motors, when coupled with advanced control systems and sensors, enable the development of smart farming technologies. These include automated irrigation systems, precision seeders, and intelligent harvesting equipment, all of which contribute to optimal resource utilization and reduced environmental impact.

Furthermore, the integration of induction motors in agriculture aims to improve the overall sustainability of farming practices. This includes reducing water consumption through efficient pumping systems, minimizing soil compaction with lighter electric machinery, and decreasing the use of chemical inputs through precise application methods. By achieving these objectives, induction motors contribute to the preservation of soil health, biodiversity, and water resources.

As we look towards the future, the role of induction motors in promoting eco-friendly agricultural solutions is expected to expand further. Ongoing research and development efforts are focused on improving motor efficiency, developing more compact and powerful designs, and integrating renewable energy sources to power these motors. These advancements will pave the way for even more sustainable and productive farming practices, helping to address the global challenges of food security and environmental conservation.

The evolution of induction motors in agriculture can be traced back to the early 20th century when electrification began to reach rural areas. Initially used for simple tasks like water pumping, these motors gradually found applications in various farm operations, including irrigation systems, grain handling, and livestock management. Over time, advancements in motor design and control technologies have significantly improved their efficiency and versatility.

Today, the agricultural sector is at a critical juncture, facing the dual challenges of meeting increasing food demand and reducing environmental impact. Induction motors are at the forefront of addressing these challenges by enabling the development of more efficient and environmentally friendly farming equipment. Their ability to provide reliable, controllable power with minimal maintenance requirements makes them ideal for a wide range of agricultural applications.

The primary objective of integrating induction motors into eco-friendly agricultural solutions is to reduce the carbon footprint of farming operations while maintaining or improving productivity. This aligns with global efforts to mitigate climate change and promote sustainable development in the agricultural sector. By replacing fossil fuel-powered equipment with electric alternatives powered by induction motors, farmers can significantly reduce greenhouse gas emissions and dependence on non-renewable energy sources.

Another key goal is to enhance the precision and efficiency of agricultural processes. Induction motors, when coupled with advanced control systems and sensors, enable the development of smart farming technologies. These include automated irrigation systems, precision seeders, and intelligent harvesting equipment, all of which contribute to optimal resource utilization and reduced environmental impact.

Furthermore, the integration of induction motors in agriculture aims to improve the overall sustainability of farming practices. This includes reducing water consumption through efficient pumping systems, minimizing soil compaction with lighter electric machinery, and decreasing the use of chemical inputs through precise application methods. By achieving these objectives, induction motors contribute to the preservation of soil health, biodiversity, and water resources.

As we look towards the future, the role of induction motors in promoting eco-friendly agricultural solutions is expected to expand further. Ongoing research and development efforts are focused on improving motor efficiency, developing more compact and powerful designs, and integrating renewable energy sources to power these motors. These advancements will pave the way for even more sustainable and productive farming practices, helping to address the global challenges of food security and environmental conservation.

Market Demand for Eco-Friendly Agricultural Solutions

The market demand for eco-friendly agricultural solutions has been steadily increasing in recent years, driven by growing environmental concerns and the need for sustainable farming practices. Induction motors play a crucial role in this shift towards greener agriculture, offering numerous benefits that align with the industry's sustainability goals.

Farmers and agricultural businesses are increasingly seeking energy-efficient equipment to reduce their carbon footprint and operational costs. Induction motors, known for their high efficiency and reliability, are well-positioned to meet this demand. These motors consume less energy compared to traditional alternatives, resulting in lower electricity bills and reduced greenhouse gas emissions.

The push for precision agriculture has also fueled the demand for advanced motor technologies. Induction motors, with their ability to provide precise control and variable speed operation, enable farmers to optimize resource usage, including water, fertilizers, and pesticides. This not only reduces environmental impact but also improves crop yields and quality.

Water conservation is another critical factor driving the adoption of eco-friendly agricultural solutions. Induction motors are increasingly being used in irrigation systems, allowing for more efficient water distribution and management. Their ability to operate at different speeds and adapt to varying water requirements helps minimize water waste and promotes sustainable water use in agriculture.

The growing trend of organic farming and sustainable agriculture practices has created a niche market for eco-friendly agricultural equipment. Induction motors, being free from brushes and commutators, produce less electromagnetic interference and are better suited for sensitive organic farming environments. This aligns well with the principles of organic farming and appeals to environmentally conscious farmers.

Government regulations and incentives aimed at promoting sustainable agriculture have also contributed to the increased demand for eco-friendly solutions. Many countries offer subsidies or tax benefits for adopting energy-efficient equipment, including those powered by induction motors. This has encouraged farmers to invest in greener technologies, further driving market growth.

The rise of smart farming and Internet of Things (IoT) applications in agriculture has created new opportunities for induction motor integration. These motors can be easily incorporated into automated systems, allowing for remote monitoring and control of various agricultural processes. This not only improves efficiency but also enables data-driven decision-making, leading to more sustainable farming practices.

As consumers become more environmentally conscious, there is a growing demand for sustainably produced food. This has put pressure on farmers to adopt eco-friendly practices throughout their production processes. Induction motors, with their energy efficiency and reduced environmental impact, help farmers meet these consumer expectations and potentially command premium prices for their products.

Farmers and agricultural businesses are increasingly seeking energy-efficient equipment to reduce their carbon footprint and operational costs. Induction motors, known for their high efficiency and reliability, are well-positioned to meet this demand. These motors consume less energy compared to traditional alternatives, resulting in lower electricity bills and reduced greenhouse gas emissions.

The push for precision agriculture has also fueled the demand for advanced motor technologies. Induction motors, with their ability to provide precise control and variable speed operation, enable farmers to optimize resource usage, including water, fertilizers, and pesticides. This not only reduces environmental impact but also improves crop yields and quality.

Water conservation is another critical factor driving the adoption of eco-friendly agricultural solutions. Induction motors are increasingly being used in irrigation systems, allowing for more efficient water distribution and management. Their ability to operate at different speeds and adapt to varying water requirements helps minimize water waste and promotes sustainable water use in agriculture.

The growing trend of organic farming and sustainable agriculture practices has created a niche market for eco-friendly agricultural equipment. Induction motors, being free from brushes and commutators, produce less electromagnetic interference and are better suited for sensitive organic farming environments. This aligns well with the principles of organic farming and appeals to environmentally conscious farmers.

Government regulations and incentives aimed at promoting sustainable agriculture have also contributed to the increased demand for eco-friendly solutions. Many countries offer subsidies or tax benefits for adopting energy-efficient equipment, including those powered by induction motors. This has encouraged farmers to invest in greener technologies, further driving market growth.

The rise of smart farming and Internet of Things (IoT) applications in agriculture has created new opportunities for induction motor integration. These motors can be easily incorporated into automated systems, allowing for remote monitoring and control of various agricultural processes. This not only improves efficiency but also enables data-driven decision-making, leading to more sustainable farming practices.

As consumers become more environmentally conscious, there is a growing demand for sustainably produced food. This has put pressure on farmers to adopt eco-friendly practices throughout their production processes. Induction motors, with their energy efficiency and reduced environmental impact, help farmers meet these consumer expectations and potentially command premium prices for their products.

Current State and Challenges of Induction Motors in Agriculture

Induction motors have gained significant traction in agricultural applications, offering eco-friendly solutions to various farming challenges. Currently, these motors are widely used in irrigation systems, grain processing equipment, and various farm machinery. Their popularity stems from their robust design, high efficiency, and low maintenance requirements, making them ideal for the demanding agricultural environment.

In recent years, there has been a notable shift towards more sustainable farming practices, driving the adoption of induction motors as a replacement for traditional diesel-powered equipment. This transition has led to reduced carbon emissions and lower operational costs for farmers. Additionally, the integration of variable frequency drives (VFDs) with induction motors has further enhanced their efficiency and versatility in agricultural applications.

Despite these advancements, several challenges persist in the widespread adoption of induction motors in agriculture. One significant hurdle is the initial cost of implementation, particularly for small-scale farmers who may struggle to justify the upfront investment. The need for reliable power infrastructure in rural areas also poses a challenge, as many farming regions lack consistent access to electricity grids.

Another critical issue is the adaptation of existing agricultural machinery to accommodate induction motor systems. This often requires significant modifications or complete replacement of equipment, which can be both costly and time-consuming. Furthermore, there is a knowledge gap among farmers and agricultural workers regarding the operation and maintenance of induction motor-based systems, necessitating comprehensive training programs.

The harsh environmental conditions typical in agricultural settings present additional challenges for induction motors. Exposure to dust, moisture, and extreme temperatures can impact motor performance and longevity, requiring the development of more robust and weather-resistant designs. Manufacturers are actively working on improving motor insulation and cooling systems to address these issues.

As the agricultural sector continues to embrace automation and precision farming techniques, there is a growing demand for more sophisticated control systems for induction motors. This includes the integration of IoT technologies and smart sensors to optimize motor performance based on real-time environmental and crop data. However, implementing these advanced features while maintaining the simplicity and reliability that farmers value remains a significant challenge.

In conclusion, while induction motors have made substantial inroads in promoting eco-friendly agricultural solutions, there are still several hurdles to overcome. Addressing these challenges will be crucial in fully realizing the potential of induction motors to revolutionize sustainable farming practices and contribute to a more environmentally friendly agricultural sector.

In recent years, there has been a notable shift towards more sustainable farming practices, driving the adoption of induction motors as a replacement for traditional diesel-powered equipment. This transition has led to reduced carbon emissions and lower operational costs for farmers. Additionally, the integration of variable frequency drives (VFDs) with induction motors has further enhanced their efficiency and versatility in agricultural applications.

Despite these advancements, several challenges persist in the widespread adoption of induction motors in agriculture. One significant hurdle is the initial cost of implementation, particularly for small-scale farmers who may struggle to justify the upfront investment. The need for reliable power infrastructure in rural areas also poses a challenge, as many farming regions lack consistent access to electricity grids.

Another critical issue is the adaptation of existing agricultural machinery to accommodate induction motor systems. This often requires significant modifications or complete replacement of equipment, which can be both costly and time-consuming. Furthermore, there is a knowledge gap among farmers and agricultural workers regarding the operation and maintenance of induction motor-based systems, necessitating comprehensive training programs.

The harsh environmental conditions typical in agricultural settings present additional challenges for induction motors. Exposure to dust, moisture, and extreme temperatures can impact motor performance and longevity, requiring the development of more robust and weather-resistant designs. Manufacturers are actively working on improving motor insulation and cooling systems to address these issues.

As the agricultural sector continues to embrace automation and precision farming techniques, there is a growing demand for more sophisticated control systems for induction motors. This includes the integration of IoT technologies and smart sensors to optimize motor performance based on real-time environmental and crop data. However, implementing these advanced features while maintaining the simplicity and reliability that farmers value remains a significant challenge.

In conclusion, while induction motors have made substantial inroads in promoting eco-friendly agricultural solutions, there are still several hurdles to overcome. Addressing these challenges will be crucial in fully realizing the potential of induction motors to revolutionize sustainable farming practices and contribute to a more environmentally friendly agricultural sector.

Existing Eco-Friendly Applications of Induction Motors

01 Design and construction of induction motors

This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve efficiency, power output, and overall performance of the motors.- Design and construction of induction motors: This category focuses on the fundamental design and construction aspects of induction motors. It includes innovations in motor structure, winding configurations, and material selection to improve efficiency and performance. These advancements aim to enhance power output, reduce losses, and optimize overall motor operation.

- Control systems for induction motors: This point covers various control strategies and systems developed for induction motors. It includes methods for speed control, torque regulation, and power factor correction. Advanced control techniques such as vector control and direct torque control are also addressed, aiming to improve motor performance and energy efficiency in different applications.

- Efficiency improvements in induction motors: This category focuses on techniques and innovations aimed at improving the energy efficiency of induction motors. It includes advancements in rotor and stator designs, use of high-performance materials, and optimization of magnetic circuits. These improvements help reduce power losses and increase the overall efficiency of the motor.

- Specialized applications of induction motors: This point covers the adaptation and optimization of induction motors for specific applications. It includes designs for high-speed operations, heavy-duty industrial use, and integration with renewable energy systems. Innovations in this category aim to meet the unique requirements of different industries and operating conditions.

- Diagnostics and maintenance of induction motors: This category focuses on methods and systems for monitoring, diagnosing, and maintaining induction motors. It includes techniques for fault detection, condition monitoring, and predictive maintenance. These innovations aim to improve motor reliability, reduce downtime, and extend the operational life of induction motors.

02 Control systems for induction motors

This point focuses on the development of control systems and methods for induction motors. It includes advancements in speed control, torque regulation, and power factor correction. These control systems aim to enhance motor performance, energy efficiency, and adaptability to various load conditions.Expand Specific Solutions03 Efficiency improvements in induction motors

This category encompasses innovations aimed at improving the energy efficiency of induction motors. It includes advancements in motor design, materials, and manufacturing techniques to reduce losses and increase overall efficiency. These improvements contribute to energy savings and reduced operating costs.Expand Specific Solutions04 Specialized applications of induction motors

This point covers the adaptation and optimization of induction motors for specific applications. It includes designs tailored for industrial machinery, electric vehicles, renewable energy systems, and other specialized uses. These motors are engineered to meet the unique requirements of their intended applications.Expand Specific Solutions05 Diagnostics and maintenance of induction motors

This category focuses on methods and systems for monitoring, diagnosing, and maintaining induction motors. It includes techniques for fault detection, condition monitoring, and predictive maintenance. These innovations aim to improve motor reliability, reduce downtime, and extend the operational life of induction motors.Expand Specific Solutions

Key Players in Agricultural Induction Motor Industry

The induction motor technology for eco-friendly agricultural solutions is in a growth phase, with increasing market size driven by the global push for sustainable farming practices. The market is characterized by a mix of established automotive giants like Hyundai Motor Co., Kia Corp., and Mahindra & Mahindra Ltd., alongside specialized agricultural equipment manufacturers such as Yanmar Agricultural Equipment Co. Ltd. and Alois Pöttinger Maschinenfabrik GmbH. The technology's maturity is advancing, with companies like Altigreen Propulsion Labs and N C Quest Inc. developing innovative applications. Academic institutions, including Zhejiang University and South China Agricultural University, are contributing to research and development, indicating a collaborative ecosystem that is propelling the technology forward.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed advanced induction motor technology for agricultural applications, focusing on eco-friendly solutions. Their induction motors utilize high-efficiency designs, reducing energy consumption by up to 20% compared to conventional motors[1]. The company has implemented advanced cooling systems and optimized winding configurations to enhance motor performance in harsh agricultural environments. Hyundai's induction motors also incorporate smart control systems that adjust power output based on load requirements, further improving energy efficiency and reducing emissions[3]. These motors are designed to be compatible with various agricultural machinery, from tractors to irrigation systems, promoting sustainable farming practices.

Strengths: High energy efficiency, advanced cooling systems, and smart control technology. Weaknesses: May have higher initial costs compared to traditional motors, and potential complexity in maintenance for some users.

Mahindra & Mahindra Ltd.

Technical Solution: Mahindra & Mahindra has developed a range of eco-friendly agricultural solutions utilizing induction motors. Their technology focuses on integrating high-efficiency induction motors into electric tractors and farm equipment. These motors offer up to 25% higher torque compared to conventional diesel engines[2], enabling improved performance in various agricultural tasks. Mahindra's induction motors are designed with advanced thermal management systems, allowing for sustained operation in challenging field conditions. The company has also implemented regenerative braking technology in their electric farm vehicles, recovering energy during deceleration and further enhancing overall efficiency[4]. Additionally, Mahindra's induction motor-powered equipment is compatible with solar charging systems, promoting the use of renewable energy in agriculture.

Strengths: High torque output, integration with renewable energy systems, and improved overall efficiency. Weaknesses: Limited range compared to diesel-powered equipment and potential higher upfront costs.

Core Innovations in Agricultural Induction Motor Technology

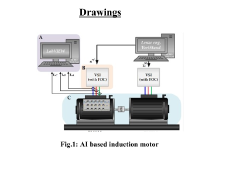

Ai-based control of induction motor in agriculture: enhancing efficiency and sustainability

PatentPendingIN202341061198A

Innovation

- The integration of AI algorithms and machine learning for real-time dynamic control of induction motors, enabling adaptive speed adjustments, predictive maintenance, and remote monitoring to optimize energy use and motor performance.

PROCESS AND PRODUCT FOR OBTAINING AN INOCULANT BASED ON BIOCOAL FROM GRAVIOLA SEED PIE AND TRICHODERMA AUREOVIRIDE

PatentPendingBR102020019060A2

Innovation

- A process is developed to produce an inoculant by pyrolyzing soursop seed cake into biochar and inoculating it with Trichoderma aureoviride, which is then incubated to create a product that controls phytopathogens, promotes plant growth, and enhances soil quality.

Environmental Impact Assessment of Induction Motors in Agriculture

The environmental impact of induction motors in agriculture is a critical consideration as the agricultural sector seeks to adopt more sustainable practices. These motors, widely used in various agricultural applications, offer significant potential for promoting eco-friendly solutions. Their efficiency and reliability contribute to reduced energy consumption and lower greenhouse gas emissions compared to traditional motor types.

Induction motors in agriculture primarily impact the environment through their energy consumption and the associated carbon footprint. However, their high efficiency and long operational life help mitigate these effects. Modern induction motors can achieve efficiency ratings of up to 95%, meaning less energy is wasted as heat during operation. This translates to reduced electricity demand and, consequently, lower emissions from power generation.

The manufacturing process of induction motors also plays a role in their environmental impact. While the production of these motors requires resources and energy, their durability and long service life offset the initial environmental cost. Induction motors typically last for decades with proper maintenance, reducing the need for frequent replacements and the associated manufacturing emissions.

In agricultural applications, induction motors contribute to more precise and efficient operations. For instance, in irrigation systems, variable frequency drives coupled with induction motors allow for precise control of water flow, reducing water waste and energy consumption. This not only conserves precious water resources but also minimizes the energy required for pumping and distribution.

The use of induction motors in agricultural machinery, such as tractors and harvesters, can lead to more efficient fuel consumption. Electric drives powered by induction motors offer better torque control and energy recovery during braking, resulting in reduced fuel consumption and lower emissions compared to purely mechanical drive systems.

Furthermore, induction motors facilitate the integration of renewable energy sources in agricultural operations. Their compatibility with solar and wind power systems allows farms to reduce their reliance on fossil fuels, further decreasing their carbon footprint. This synergy between induction motors and renewable energy sources represents a significant step towards more sustainable agricultural practices.

However, the environmental benefits of induction motors in agriculture are not without challenges. The disposal and recycling of these motors at the end of their life cycle present environmental concerns. Proper recycling processes must be implemented to recover valuable materials and minimize waste. Additionally, the rare earth elements used in some high-efficiency motor designs pose extraction and processing challenges that need to be addressed for truly sustainable production.

Induction motors in agriculture primarily impact the environment through their energy consumption and the associated carbon footprint. However, their high efficiency and long operational life help mitigate these effects. Modern induction motors can achieve efficiency ratings of up to 95%, meaning less energy is wasted as heat during operation. This translates to reduced electricity demand and, consequently, lower emissions from power generation.

The manufacturing process of induction motors also plays a role in their environmental impact. While the production of these motors requires resources and energy, their durability and long service life offset the initial environmental cost. Induction motors typically last for decades with proper maintenance, reducing the need for frequent replacements and the associated manufacturing emissions.

In agricultural applications, induction motors contribute to more precise and efficient operations. For instance, in irrigation systems, variable frequency drives coupled with induction motors allow for precise control of water flow, reducing water waste and energy consumption. This not only conserves precious water resources but also minimizes the energy required for pumping and distribution.

The use of induction motors in agricultural machinery, such as tractors and harvesters, can lead to more efficient fuel consumption. Electric drives powered by induction motors offer better torque control and energy recovery during braking, resulting in reduced fuel consumption and lower emissions compared to purely mechanical drive systems.

Furthermore, induction motors facilitate the integration of renewable energy sources in agricultural operations. Their compatibility with solar and wind power systems allows farms to reduce their reliance on fossil fuels, further decreasing their carbon footprint. This synergy between induction motors and renewable energy sources represents a significant step towards more sustainable agricultural practices.

However, the environmental benefits of induction motors in agriculture are not without challenges. The disposal and recycling of these motors at the end of their life cycle present environmental concerns. Proper recycling processes must be implemented to recover valuable materials and minimize waste. Additionally, the rare earth elements used in some high-efficiency motor designs pose extraction and processing challenges that need to be addressed for truly sustainable production.

Energy Efficiency Standards and Regulations for Agricultural Motors

Energy efficiency standards and regulations for agricultural motors play a crucial role in promoting eco-friendly solutions within the agricultural sector. These standards are designed to ensure that induction motors used in various agricultural applications meet specific energy performance criteria, thereby reducing energy consumption and environmental impact.

In recent years, governments and regulatory bodies worldwide have implemented increasingly stringent energy efficiency requirements for electric motors, including those used in agriculture. The International Electrotechnical Commission (IEC) has established global standards, such as IEC 60034-30-1, which defines efficiency classes for electric motors. These classes range from IE1 (standard efficiency) to IE4 (super premium efficiency), with higher classes indicating greater energy efficiency.

Many countries have adopted these international standards or developed their own regulations based on them. For instance, the European Union's Ecodesign Directive mandates minimum energy performance standards for electric motors, including those used in agricultural applications. Similarly, the United States Department of Energy (DOE) has established energy conservation standards for electric motors under the Energy Policy and Conservation Act.

These regulations typically specify minimum efficiency levels for different motor types and power ratings. For induction motors used in agriculture, this often translates to requirements for higher efficiency designs, such as the use of premium-grade electrical steel, optimized stator and rotor geometries, and improved cooling systems. Manufacturers must ensure their products comply with these standards to be legally sold and used in regulated markets.

Compliance with energy efficiency standards often leads to the development and adoption of more advanced motor technologies. For example, the push for higher efficiency has accelerated the integration of variable frequency drives (VFDs) with induction motors in agricultural applications. VFDs allow for precise speed control and can significantly reduce energy consumption in variable load scenarios, such as irrigation pumps or ventilation systems.

Furthermore, these regulations have spurred innovation in motor design and materials. Manufacturers are investing in research and development to create more efficient motor designs that not only meet current standards but also anticipate future regulatory requirements. This proactive approach has led to the development of new materials and manufacturing techniques that further enhance motor efficiency and reliability.

The implementation of energy efficiency standards also has broader implications for the agricultural sector. By reducing energy consumption, these regulations help farmers lower their operating costs and improve their overall sustainability. This aligns with the growing emphasis on sustainable agriculture and the need to reduce the carbon footprint of food production.

In recent years, governments and regulatory bodies worldwide have implemented increasingly stringent energy efficiency requirements for electric motors, including those used in agriculture. The International Electrotechnical Commission (IEC) has established global standards, such as IEC 60034-30-1, which defines efficiency classes for electric motors. These classes range from IE1 (standard efficiency) to IE4 (super premium efficiency), with higher classes indicating greater energy efficiency.

Many countries have adopted these international standards or developed their own regulations based on them. For instance, the European Union's Ecodesign Directive mandates minimum energy performance standards for electric motors, including those used in agricultural applications. Similarly, the United States Department of Energy (DOE) has established energy conservation standards for electric motors under the Energy Policy and Conservation Act.

These regulations typically specify minimum efficiency levels for different motor types and power ratings. For induction motors used in agriculture, this often translates to requirements for higher efficiency designs, such as the use of premium-grade electrical steel, optimized stator and rotor geometries, and improved cooling systems. Manufacturers must ensure their products comply with these standards to be legally sold and used in regulated markets.

Compliance with energy efficiency standards often leads to the development and adoption of more advanced motor technologies. For example, the push for higher efficiency has accelerated the integration of variable frequency drives (VFDs) with induction motors in agricultural applications. VFDs allow for precise speed control and can significantly reduce energy consumption in variable load scenarios, such as irrigation pumps or ventilation systems.

Furthermore, these regulations have spurred innovation in motor design and materials. Manufacturers are investing in research and development to create more efficient motor designs that not only meet current standards but also anticipate future regulatory requirements. This proactive approach has led to the development of new materials and manufacturing techniques that further enhance motor efficiency and reliability.

The implementation of energy efficiency standards also has broader implications for the agricultural sector. By reducing energy consumption, these regulations help farmers lower their operating costs and improve their overall sustainability. This aligns with the growing emphasis on sustainable agriculture and the need to reduce the carbon footprint of food production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!