Induction motors in large-scale water distribution networks

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Evolution in Water Networks

The evolution of induction motors in water distribution networks has been a significant technological journey, marked by continuous improvements in efficiency, reliability, and adaptability. In the early stages, water distribution systems relied on simple, fixed-speed induction motors that were often oversized to meet peak demand, resulting in energy inefficiencies during periods of low demand.

As the complexity and scale of water networks grew, so did the need for more sophisticated motor control. The introduction of variable frequency drives (VFDs) in the 1980s marked a pivotal moment in this evolution. VFDs allowed for precise speed control of induction motors, enabling water utilities to match pump output to system demand more accurately. This innovation led to substantial energy savings and improved overall system efficiency.

The 1990s saw the integration of advanced sensors and control systems with induction motors in water networks. This integration allowed for real-time monitoring of motor performance, water flow rates, and pressure levels. The ability to collect and analyze this data in real-time enabled predictive maintenance strategies, reducing downtime and extending motor life.

In the early 2000s, the focus shifted towards enhancing the durability and reliability of induction motors in water distribution environments. Manufacturers developed specialized motor designs with improved sealing and corrosion-resistant materials to withstand the challenges of constant exposure to moisture and chemicals used in water treatment processes.

The advent of smart grid technologies in the late 2000s and early 2010s further revolutionized the role of induction motors in water networks. These motors became integral components of larger, interconnected systems that could respond dynamically to changes in electricity prices and grid demands. This integration allowed water utilities to optimize their operations not only for water distribution efficiency but also for energy cost management.

Recent years have seen a growing emphasis on sustainability and energy efficiency. High-efficiency induction motors, often exceeding IE4 and IE5 efficiency standards, have become increasingly common in water distribution networks. These motors, coupled with advanced control algorithms and IoT connectivity, are pushing the boundaries of operational efficiency and environmental sustainability in water management systems.

Looking ahead, the evolution of induction motors in water networks is likely to continue with a focus on further integration with AI and machine learning technologies. These advancements promise to deliver even more precise control, predictive maintenance capabilities, and optimization of water distribution processes, ensuring that induction motors remain at the heart of efficient and sustainable water management systems for years to come.

As the complexity and scale of water networks grew, so did the need for more sophisticated motor control. The introduction of variable frequency drives (VFDs) in the 1980s marked a pivotal moment in this evolution. VFDs allowed for precise speed control of induction motors, enabling water utilities to match pump output to system demand more accurately. This innovation led to substantial energy savings and improved overall system efficiency.

The 1990s saw the integration of advanced sensors and control systems with induction motors in water networks. This integration allowed for real-time monitoring of motor performance, water flow rates, and pressure levels. The ability to collect and analyze this data in real-time enabled predictive maintenance strategies, reducing downtime and extending motor life.

In the early 2000s, the focus shifted towards enhancing the durability and reliability of induction motors in water distribution environments. Manufacturers developed specialized motor designs with improved sealing and corrosion-resistant materials to withstand the challenges of constant exposure to moisture and chemicals used in water treatment processes.

The advent of smart grid technologies in the late 2000s and early 2010s further revolutionized the role of induction motors in water networks. These motors became integral components of larger, interconnected systems that could respond dynamically to changes in electricity prices and grid demands. This integration allowed water utilities to optimize their operations not only for water distribution efficiency but also for energy cost management.

Recent years have seen a growing emphasis on sustainability and energy efficiency. High-efficiency induction motors, often exceeding IE4 and IE5 efficiency standards, have become increasingly common in water distribution networks. These motors, coupled with advanced control algorithms and IoT connectivity, are pushing the boundaries of operational efficiency and environmental sustainability in water management systems.

Looking ahead, the evolution of induction motors in water networks is likely to continue with a focus on further integration with AI and machine learning technologies. These advancements promise to deliver even more precise control, predictive maintenance capabilities, and optimization of water distribution processes, ensuring that induction motors remain at the heart of efficient and sustainable water management systems for years to come.

Market Demand Analysis

The market demand for induction motors in large-scale water distribution networks has been steadily growing due to the increasing need for efficient and reliable water supply systems worldwide. As urbanization continues to accelerate, the demand for robust water infrastructure has become more pressing, driving the adoption of advanced motor technologies in pumping stations and distribution facilities.

In recent years, the global water and wastewater treatment market has experienced significant expansion, with a compound annual growth rate (CAGR) of approximately 6.5% projected through 2026. This growth directly impacts the demand for induction motors, as they are essential components in water distribution systems. The market for industrial motors, including those used in water networks, is expected to reach a substantial value by 2025, with induction motors accounting for a significant portion of this market.

The increasing focus on energy efficiency and sustainability in water management has further boosted the demand for high-efficiency induction motors. Governments and utilities worldwide are implementing stricter regulations and standards for motor efficiency, driving the replacement of older, less efficient motors with newer models. This trend is particularly evident in developed countries, where aging water infrastructure requires modernization to meet current environmental and operational standards.

Emerging economies, particularly in Asia and Africa, are experiencing rapid urbanization and industrialization, leading to a surge in water infrastructure projects. These regions represent substantial growth opportunities for induction motor manufacturers, as new water distribution networks are being established and existing ones expanded. The demand is not limited to new installations; there is also a growing market for retrofitting and upgrading existing water distribution systems with more efficient induction motors.

The increasing adoption of smart water management systems and the Internet of Things (IoT) in water distribution networks is creating new opportunities for advanced induction motor technologies. Motors equipped with sensors and connectivity features for real-time monitoring and predictive maintenance are gaining traction, as water utilities seek to optimize their operations and reduce downtime.

Climate change and water scarcity issues are driving investments in water conservation and efficient distribution technologies. This trend is expected to further boost the demand for high-performance induction motors capable of operating under varying load conditions and harsh environments. Additionally, the growing emphasis on reducing carbon emissions in industrial processes is likely to accelerate the adoption of energy-efficient motors in water distribution networks.

In conclusion, the market demand for induction motors in large-scale water distribution networks is robust and multifaceted, driven by urbanization, infrastructure modernization, energy efficiency requirements, and technological advancements. As water management becomes increasingly critical globally, the demand for reliable and efficient induction motors is expected to continue its upward trajectory in the coming years.

In recent years, the global water and wastewater treatment market has experienced significant expansion, with a compound annual growth rate (CAGR) of approximately 6.5% projected through 2026. This growth directly impacts the demand for induction motors, as they are essential components in water distribution systems. The market for industrial motors, including those used in water networks, is expected to reach a substantial value by 2025, with induction motors accounting for a significant portion of this market.

The increasing focus on energy efficiency and sustainability in water management has further boosted the demand for high-efficiency induction motors. Governments and utilities worldwide are implementing stricter regulations and standards for motor efficiency, driving the replacement of older, less efficient motors with newer models. This trend is particularly evident in developed countries, where aging water infrastructure requires modernization to meet current environmental and operational standards.

Emerging economies, particularly in Asia and Africa, are experiencing rapid urbanization and industrialization, leading to a surge in water infrastructure projects. These regions represent substantial growth opportunities for induction motor manufacturers, as new water distribution networks are being established and existing ones expanded. The demand is not limited to new installations; there is also a growing market for retrofitting and upgrading existing water distribution systems with more efficient induction motors.

The increasing adoption of smart water management systems and the Internet of Things (IoT) in water distribution networks is creating new opportunities for advanced induction motor technologies. Motors equipped with sensors and connectivity features for real-time monitoring and predictive maintenance are gaining traction, as water utilities seek to optimize their operations and reduce downtime.

Climate change and water scarcity issues are driving investments in water conservation and efficient distribution technologies. This trend is expected to further boost the demand for high-performance induction motors capable of operating under varying load conditions and harsh environments. Additionally, the growing emphasis on reducing carbon emissions in industrial processes is likely to accelerate the adoption of energy-efficient motors in water distribution networks.

In conclusion, the market demand for induction motors in large-scale water distribution networks is robust and multifaceted, driven by urbanization, infrastructure modernization, energy efficiency requirements, and technological advancements. As water management becomes increasingly critical globally, the demand for reliable and efficient induction motors is expected to continue its upward trajectory in the coming years.

Technical Challenges

The implementation of induction motors in large-scale water distribution networks faces several significant technical challenges. One of the primary issues is the need for precise speed control in varying load conditions. Water distribution systems often experience fluctuating demands, requiring motors to adjust their speed accordingly. This necessitates advanced control systems capable of real-time monitoring and adjustment, which can be complex to design and implement effectively.

Energy efficiency is another crucial challenge. While induction motors are generally robust and reliable, they may not always operate at optimal efficiency levels, especially when running at partial loads. This is particularly problematic in water distribution networks where energy consumption is a significant operational cost. Developing more efficient motor designs or implementing variable frequency drives (VFDs) to improve efficiency across different operating conditions is an ongoing technical hurdle.

The harsh operating environment of water distribution systems presents additional challenges. Motors are often exposed to moisture, varying temperatures, and potential contaminants. This requires the development of robust motor designs with enhanced insulation, sealing, and cooling systems to ensure long-term reliability and prevent premature failures.

Maintenance and monitoring of induction motors in expansive water distribution networks is another significant challenge. Traditional maintenance approaches may not be sufficient due to the scale and geographic dispersion of these systems. There is a growing need for advanced condition monitoring techniques, including the integration of sensors and IoT technologies, to enable predictive maintenance and reduce downtime.

The integration of induction motors with existing infrastructure and control systems in water distribution networks can also be technically challenging. Compatibility issues may arise when upgrading older systems or integrating new motor technologies with legacy control systems. This requires careful planning and potentially the development of custom interface solutions.

Lastly, the increasing focus on sustainability and environmental impact poses new challenges. There is a growing demand for motors that not only meet efficiency standards but also use environmentally friendly materials and manufacturing processes. This includes considerations for the entire lifecycle of the motor, from production to disposal, adding another layer of complexity to motor design and selection for water distribution applications.

Energy efficiency is another crucial challenge. While induction motors are generally robust and reliable, they may not always operate at optimal efficiency levels, especially when running at partial loads. This is particularly problematic in water distribution networks where energy consumption is a significant operational cost. Developing more efficient motor designs or implementing variable frequency drives (VFDs) to improve efficiency across different operating conditions is an ongoing technical hurdle.

The harsh operating environment of water distribution systems presents additional challenges. Motors are often exposed to moisture, varying temperatures, and potential contaminants. This requires the development of robust motor designs with enhanced insulation, sealing, and cooling systems to ensure long-term reliability and prevent premature failures.

Maintenance and monitoring of induction motors in expansive water distribution networks is another significant challenge. Traditional maintenance approaches may not be sufficient due to the scale and geographic dispersion of these systems. There is a growing need for advanced condition monitoring techniques, including the integration of sensors and IoT technologies, to enable predictive maintenance and reduce downtime.

The integration of induction motors with existing infrastructure and control systems in water distribution networks can also be technically challenging. Compatibility issues may arise when upgrading older systems or integrating new motor technologies with legacy control systems. This requires careful planning and potentially the development of custom interface solutions.

Lastly, the increasing focus on sustainability and environmental impact poses new challenges. There is a growing demand for motors that not only meet efficiency standards but also use environmentally friendly materials and manufacturing processes. This includes considerations for the entire lifecycle of the motor, from production to disposal, adding another layer of complexity to motor design and selection for water distribution applications.

Current Motor Solutions

01 Design and construction of induction motors

This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve efficiency, power output, and overall performance of the motors.- Design and construction of induction motors: This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.

- Control systems for induction motors: This point focuses on the development of advanced control systems for induction motors, including variable frequency drives, vector control techniques, and microprocessor-based controllers. These systems aim to enhance motor speed control, torque regulation, and energy efficiency across various operating conditions.

- Efficiency improvements in induction motors: This category encompasses innovations aimed at improving the energy efficiency of induction motors. This includes optimizing motor design, using advanced materials, and implementing energy-saving control strategies to reduce power consumption and heat losses.

- Specialized applications of induction motors: This point covers the adaptation and optimization of induction motors for specific industrial applications, such as in electric vehicles, renewable energy systems, and high-power industrial machinery. These specialized designs often involve modifications to meet unique performance requirements or environmental conditions.

- Maintenance and diagnostics of induction motors: This category focuses on methods and systems for monitoring, maintaining, and diagnosing induction motors. It includes techniques for fault detection, predictive maintenance, and condition monitoring to improve motor reliability and extend operational lifespan.

02 Control systems for induction motors

Control systems play a crucial role in regulating the speed, torque, and efficiency of induction motors. This category encompasses various control strategies, including vector control, direct torque control, and sensorless control techniques, as well as the implementation of advanced electronic control units.Expand Specific Solutions03 Energy efficiency improvements

This category focuses on innovations aimed at enhancing the energy efficiency of induction motors. It includes advancements in motor design, materials, and operating strategies to reduce power losses and improve overall performance, contributing to energy conservation and reduced operating costs.Expand Specific Solutions04 Specialized applications of induction motors

Induction motors are used in various specialized applications, each with unique requirements. This category covers adaptations and modifications of induction motors for specific industries or purposes, such as high-speed operations, harsh environments, or integration with particular machinery or systems.Expand Specific Solutions05 Manufacturing and assembly techniques

This category encompasses innovations in the manufacturing and assembly processes of induction motors. It includes advancements in production techniques, automation, quality control, and assembly methods that aim to improve motor reliability, reduce production costs, and enhance overall manufacturing efficiency.Expand Specific Solutions

Key Industry Players

The research on induction motors in large-scale water distribution networks is in a mature stage of development, with a significant market size due to the critical role of these motors in water infrastructure. The technology has reached a high level of maturity, as evidenced by the involvement of established players like Schlumberger Technologies, Rockwell Automation, and State Grid Corporation of China. These companies, along with others such as Eaton Intelligent Power and Hamilton Sundstrand, have contributed to advancing the technology through continuous innovation and research. The competitive landscape is diverse, with both specialized water equipment manufacturers like Qingdao Sanli Group and global industrial giants like IBM participating in the market, indicating a broad range of applications and opportunities for further development.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has developed advanced induction motor control systems for large-scale water distribution networks. Their solution incorporates variable frequency drives (VFDs) with intelligent control algorithms to optimize motor performance and energy efficiency. The system utilizes real-time monitoring and predictive maintenance techniques, leveraging big data analytics and machine learning to anticipate potential issues and adjust motor operations accordingly[1]. Additionally, they have implemented a distributed control architecture that allows for seamless integration with existing SCADA systems, enabling centralized management of multiple induction motors across vast geographical areas[2].

Strengths: Extensive experience in large-scale power systems, advanced control algorithms, and integration capabilities with existing infrastructure. Weaknesses: Potential high initial implementation costs and complexity in retrofitting older water distribution systems.

China Electric Power Research Institute Ltd.

Technical Solution: China Electric Power Research Institute Ltd. has developed a comprehensive solution for induction motors in water distribution networks, focusing on energy efficiency and reliability. Their approach includes the use of high-efficiency induction motors with advanced magnetic core designs and optimized winding configurations[3]. The institute has also created a smart motor management system that incorporates IoT sensors for real-time monitoring of motor performance, temperature, and vibration. This system uses edge computing for rapid data processing and decision-making, enabling immediate responses to changing network conditions[4]. Furthermore, they have implemented advanced power quality improvement techniques, such as active harmonic filters and power factor correction, to enhance overall system stability and efficiency[5].

Strengths: Strong focus on energy efficiency, innovative motor designs, and integration of IoT and edge computing technologies. Weaknesses: Potential challenges in adapting the technology to diverse existing water distribution infrastructures across different regions.

Core Innovations

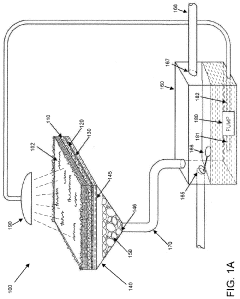

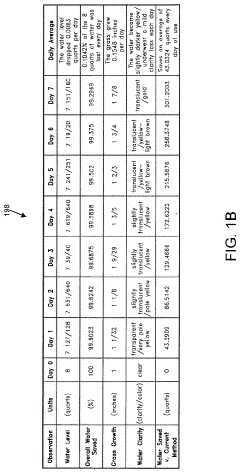

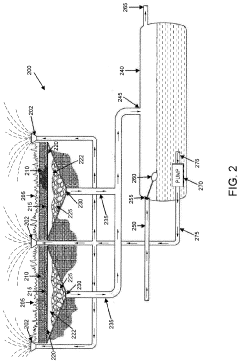

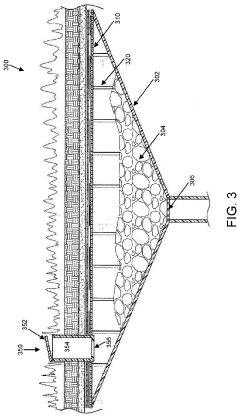

Systems and methods for water harvesting and recycling

PatentActiveUS20210274729A1

Innovation

- The implementation of a water harvesting and recycling system utilizing natural gravity flow and subterranean capture and channeling to collect and reuse rain and irrigation water, incorporating a fluid reclamation apparatus with a pump and distribution system, and a processor-based management system for remote monitoring and control.

Leak Detection Via a Stochastic Mass Balance

PatentInactiveUS20140149054A1

Innovation

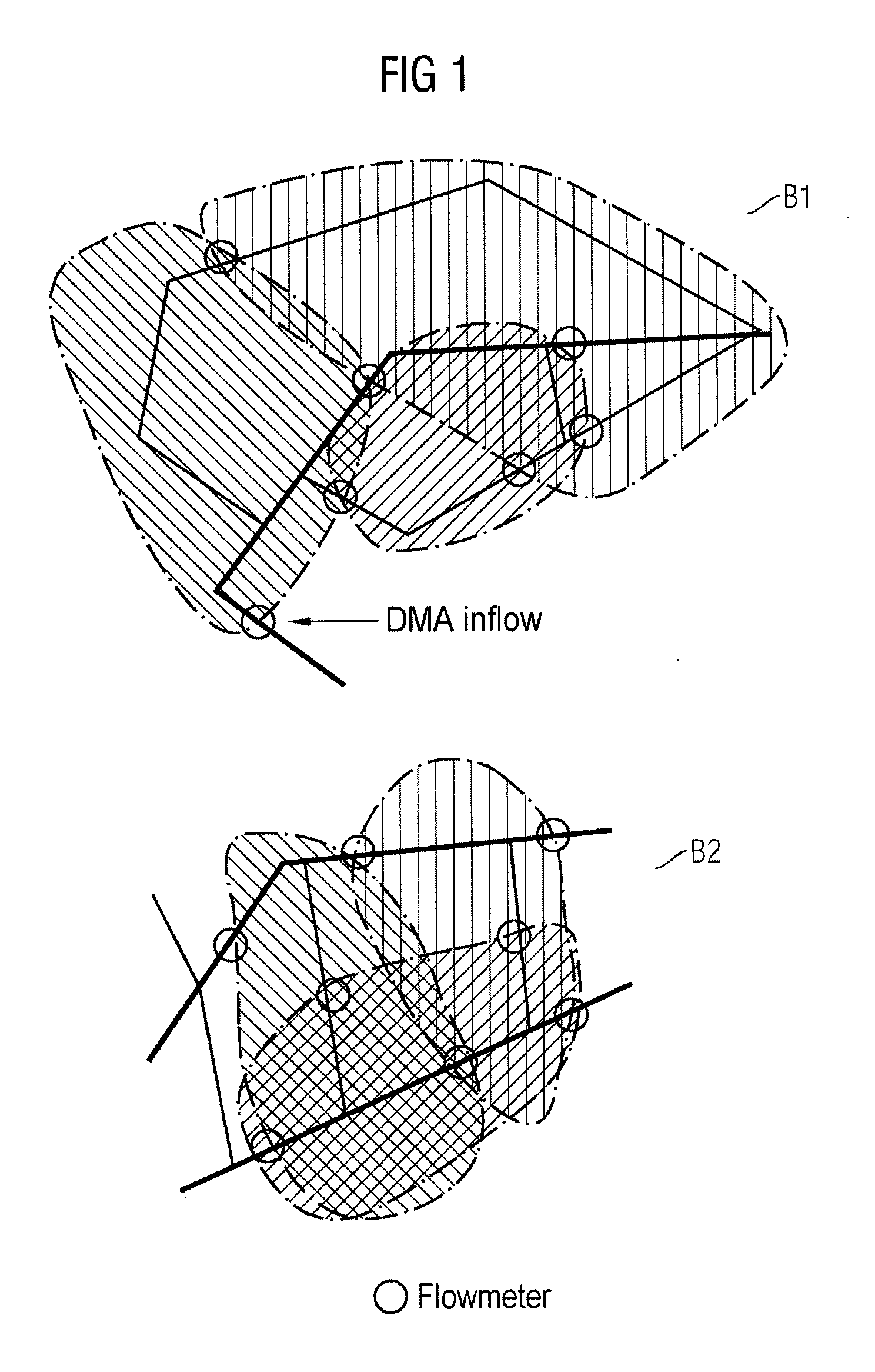

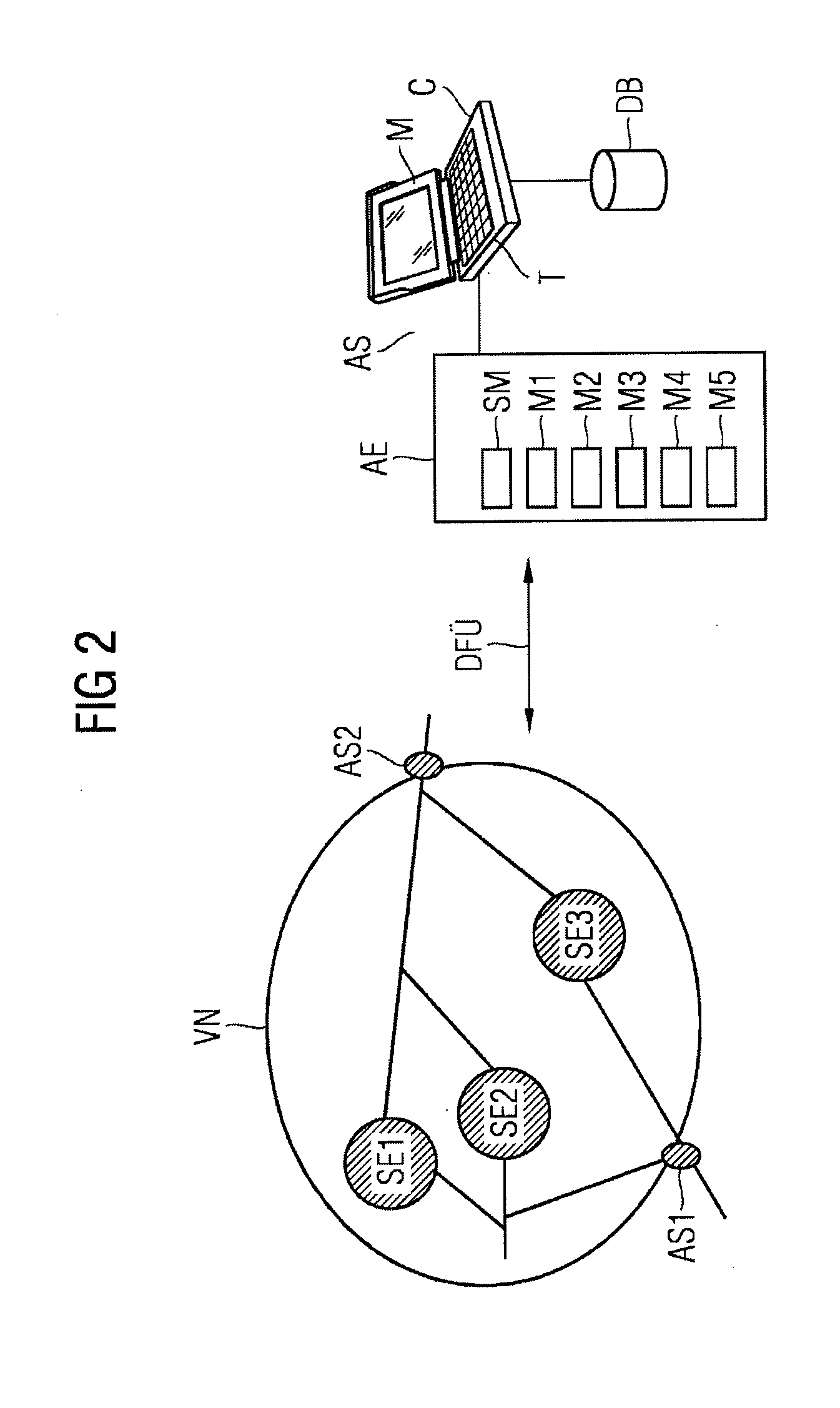

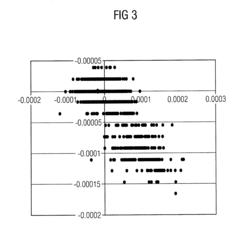

- A computer-aided method using flowmeters and sensors to measure water consumption and pressure within district meter areas, combined with Monte Carlo simulations to create a hydraulic model and detect leaks, allowing for continuous monitoring and reducing false alarms.

Energy Efficiency Regulations

Energy efficiency regulations play a crucial role in shaping the landscape of induction motor usage in large-scale water distribution networks. These regulations are designed to promote the adoption of energy-efficient technologies and practices, ultimately reducing energy consumption and environmental impact.

In recent years, many countries have implemented stringent energy efficiency standards for electric motors, including those used in water distribution systems. The International Electrotechnical Commission (IEC) has established global standards for motor efficiency, with IE1, IE2, IE3, and IE4 classifications representing increasing levels of efficiency. Most developed nations now require motors to meet at least IE3 standards, with some pushing for IE4 or even higher.

For large-scale water distribution networks, these regulations have significant implications. Induction motors are widely used in pumping stations and other critical components of these networks. As such, water utilities and operators must ensure compliance with energy efficiency regulations when selecting and implementing motor systems.

The European Union's Ecodesign Directive, for instance, mandates minimum efficiency requirements for electric motors, including those used in water distribution. Similarly, the United States Department of Energy has established energy conservation standards for certain types of electric motors through its Energy Policy and Conservation Act.

These regulations often include specific provisions for variable speed drives (VSDs) and other advanced motor control technologies. VSDs can significantly improve the energy efficiency of induction motors in water distribution networks by allowing for precise control of motor speed and power consumption based on demand fluctuations.

Compliance with energy efficiency regulations often requires water utilities to invest in upgrading or replacing older, less efficient motor systems. While this may involve substantial upfront costs, the long-term benefits in terms of reduced energy consumption and operational expenses can be significant.

Furthermore, many governments and utilities offer incentive programs to encourage the adoption of energy-efficient motor systems. These may include rebates, tax incentives, or low-interest financing options for upgrading to more efficient technologies.

As energy efficiency regulations continue to evolve, research on induction motors in large-scale water distribution networks must focus on developing and implementing increasingly efficient motor systems. This includes exploring advanced materials, improved motor designs, and innovative control strategies to meet and exceed regulatory requirements while optimizing performance and reliability in water distribution applications.

In recent years, many countries have implemented stringent energy efficiency standards for electric motors, including those used in water distribution systems. The International Electrotechnical Commission (IEC) has established global standards for motor efficiency, with IE1, IE2, IE3, and IE4 classifications representing increasing levels of efficiency. Most developed nations now require motors to meet at least IE3 standards, with some pushing for IE4 or even higher.

For large-scale water distribution networks, these regulations have significant implications. Induction motors are widely used in pumping stations and other critical components of these networks. As such, water utilities and operators must ensure compliance with energy efficiency regulations when selecting and implementing motor systems.

The European Union's Ecodesign Directive, for instance, mandates minimum efficiency requirements for electric motors, including those used in water distribution. Similarly, the United States Department of Energy has established energy conservation standards for certain types of electric motors through its Energy Policy and Conservation Act.

These regulations often include specific provisions for variable speed drives (VSDs) and other advanced motor control technologies. VSDs can significantly improve the energy efficiency of induction motors in water distribution networks by allowing for precise control of motor speed and power consumption based on demand fluctuations.

Compliance with energy efficiency regulations often requires water utilities to invest in upgrading or replacing older, less efficient motor systems. While this may involve substantial upfront costs, the long-term benefits in terms of reduced energy consumption and operational expenses can be significant.

Furthermore, many governments and utilities offer incentive programs to encourage the adoption of energy-efficient motor systems. These may include rebates, tax incentives, or low-interest financing options for upgrading to more efficient technologies.

As energy efficiency regulations continue to evolve, research on induction motors in large-scale water distribution networks must focus on developing and implementing increasingly efficient motor systems. This includes exploring advanced materials, improved motor designs, and innovative control strategies to meet and exceed regulatory requirements while optimizing performance and reliability in water distribution applications.

Environmental Impact Assessment

The environmental impact of induction motors in large-scale water distribution networks is a critical consideration for sustainable urban development. These motors, while essential for efficient water distribution, can have significant ecological implications if not properly managed.

Energy consumption is a primary concern. Induction motors in water distribution systems are often large and operate continuously, leading to substantial electricity usage. This increased energy demand can contribute to higher greenhouse gas emissions if the power source is not renewable. However, modern high-efficiency induction motors can help mitigate this impact by reducing overall energy consumption.

Noise pollution is another environmental factor to consider. Induction motors, especially in older or poorly maintained systems, can generate significant noise levels. This can disturb local ecosystems, particularly in areas where water distribution facilities are located near sensitive habitats. Implementing sound-dampening technologies and regular maintenance can help minimize this issue.

Water quality can also be affected by the operation of induction motors. The vibrations and heat generated by these motors can potentially impact water chemistry, especially if the motors are in direct contact with the water supply. Proper insulation and cooling systems are essential to prevent any adverse effects on water quality.

The manufacturing and disposal of induction motors also have environmental implications. The production process involves the use of various materials, including metals and insulating compounds, which can have ecological impacts during extraction and processing. End-of-life disposal of these motors requires careful management to prevent the release of potentially harmful substances into the environment.

On a positive note, the use of induction motors in water distribution networks can contribute to more efficient water management. By enabling precise control of water flow and pressure, these systems can reduce water waste and energy consumption associated with over-pumping. This efficiency can lead to conservation of water resources and reduced strain on natural water bodies.

The environmental impact assessment of induction motors in water distribution networks should also consider the potential for technological advancements. Research into more environmentally friendly materials, improved energy efficiency, and integration with smart grid technologies could further reduce the ecological footprint of these essential components in urban infrastructure.

Energy consumption is a primary concern. Induction motors in water distribution systems are often large and operate continuously, leading to substantial electricity usage. This increased energy demand can contribute to higher greenhouse gas emissions if the power source is not renewable. However, modern high-efficiency induction motors can help mitigate this impact by reducing overall energy consumption.

Noise pollution is another environmental factor to consider. Induction motors, especially in older or poorly maintained systems, can generate significant noise levels. This can disturb local ecosystems, particularly in areas where water distribution facilities are located near sensitive habitats. Implementing sound-dampening technologies and regular maintenance can help minimize this issue.

Water quality can also be affected by the operation of induction motors. The vibrations and heat generated by these motors can potentially impact water chemistry, especially if the motors are in direct contact with the water supply. Proper insulation and cooling systems are essential to prevent any adverse effects on water quality.

The manufacturing and disposal of induction motors also have environmental implications. The production process involves the use of various materials, including metals and insulating compounds, which can have ecological impacts during extraction and processing. End-of-life disposal of these motors requires careful management to prevent the release of potentially harmful substances into the environment.

On a positive note, the use of induction motors in water distribution networks can contribute to more efficient water management. By enabling precise control of water flow and pressure, these systems can reduce water waste and energy consumption associated with over-pumping. This efficiency can lead to conservation of water resources and reduced strain on natural water bodies.

The environmental impact assessment of induction motors in water distribution networks should also consider the potential for technological advancements. Research into more environmentally friendly materials, improved energy efficiency, and integration with smart grid technologies could further reduce the ecological footprint of these essential components in urban infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!