How induction motors enhance productivity in smart factory setups

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Evolution

Induction motors have undergone significant evolution since their inception in the late 19th century. The development of these motors has been closely tied to the advancement of industrial automation and, more recently, the emergence of smart factories. This evolution can be traced through several key stages, each marked by technological breakthroughs and improvements in efficiency, control, and integration capabilities.

In the early stages, induction motors were primarily used for simple, constant-speed applications. The introduction of variable frequency drives (VFDs) in the 1960s marked a pivotal moment in their evolution. VFDs allowed for precise speed control and energy efficiency improvements, making induction motors more versatile and suitable for a wider range of industrial applications.

The 1980s and 1990s saw further advancements in motor design and materials. The use of high-efficiency copper rotors and advanced magnetic materials led to significant improvements in motor performance and energy efficiency. These developments coincided with the growing emphasis on energy conservation in industrial settings, positioning induction motors as a key component in energy-efficient manufacturing processes.

The turn of the millennium brought about the integration of smart technologies into motor systems. The incorporation of sensors, microprocessors, and communication interfaces transformed induction motors into intelligent devices capable of self-monitoring and real-time data transmission. This shift aligned perfectly with the emerging concept of Industry 4.0 and the vision of smart factories.

In recent years, the evolution of induction motors has been characterized by their seamless integration into Industrial Internet of Things (IIoT) ecosystems. Advanced motor control algorithms, coupled with big data analytics and machine learning, have enabled predictive maintenance strategies and optimized motor performance in real-time. This has significantly enhanced the reliability and efficiency of manufacturing processes in smart factory setups.

The latest developments in induction motor technology focus on further improving energy efficiency, reducing environmental impact, and enhancing connectivity. Innovations such as synchronous reluctance motors and permanent magnet-assisted synchronous reluctance motors are pushing the boundaries of what's possible in terms of motor efficiency and power density.

As we look to the future, the evolution of induction motors is likely to continue in parallel with advancements in artificial intelligence, edge computing, and advanced materials science. These developments promise to further enhance the role of induction motors in smart factories, contributing to increased productivity, reduced downtime, and more sustainable manufacturing processes.

In the early stages, induction motors were primarily used for simple, constant-speed applications. The introduction of variable frequency drives (VFDs) in the 1960s marked a pivotal moment in their evolution. VFDs allowed for precise speed control and energy efficiency improvements, making induction motors more versatile and suitable for a wider range of industrial applications.

The 1980s and 1990s saw further advancements in motor design and materials. The use of high-efficiency copper rotors and advanced magnetic materials led to significant improvements in motor performance and energy efficiency. These developments coincided with the growing emphasis on energy conservation in industrial settings, positioning induction motors as a key component in energy-efficient manufacturing processes.

The turn of the millennium brought about the integration of smart technologies into motor systems. The incorporation of sensors, microprocessors, and communication interfaces transformed induction motors into intelligent devices capable of self-monitoring and real-time data transmission. This shift aligned perfectly with the emerging concept of Industry 4.0 and the vision of smart factories.

In recent years, the evolution of induction motors has been characterized by their seamless integration into Industrial Internet of Things (IIoT) ecosystems. Advanced motor control algorithms, coupled with big data analytics and machine learning, have enabled predictive maintenance strategies and optimized motor performance in real-time. This has significantly enhanced the reliability and efficiency of manufacturing processes in smart factory setups.

The latest developments in induction motor technology focus on further improving energy efficiency, reducing environmental impact, and enhancing connectivity. Innovations such as synchronous reluctance motors and permanent magnet-assisted synchronous reluctance motors are pushing the boundaries of what's possible in terms of motor efficiency and power density.

As we look to the future, the evolution of induction motors is likely to continue in parallel with advancements in artificial intelligence, edge computing, and advanced materials science. These developments promise to further enhance the role of induction motors in smart factories, contributing to increased productivity, reduced downtime, and more sustainable manufacturing processes.

Smart Factory Demand

The demand for smart factory solutions has been steadily increasing as industries worldwide embrace digital transformation and Industry 4.0 principles. Smart factories leverage advanced technologies to enhance productivity, efficiency, and flexibility in manufacturing processes. Induction motors play a crucial role in this transformation, serving as the backbone of many industrial applications within smart factory setups.

The market for smart factory solutions is projected to grow significantly in the coming years, driven by the need for improved operational efficiency, reduced downtime, and increased production output. Industries such as automotive, electronics, aerospace, and consumer goods are at the forefront of adopting smart factory technologies, including advanced motor systems.

One of the key drivers for the adoption of induction motors in smart factories is the increasing focus on energy efficiency and sustainability. As energy costs continue to rise and environmental regulations become more stringent, manufacturers are seeking ways to optimize their energy consumption. Induction motors, particularly when coupled with variable frequency drives (VFDs), offer substantial energy savings compared to traditional motor systems.

The integration of Industrial Internet of Things (IIoT) technologies has also fueled the demand for smart motor solutions. Induction motors equipped with sensors and connectivity capabilities enable real-time monitoring, predictive maintenance, and data-driven decision-making. This aligns with the broader trend of digital transformation in manufacturing, where data analytics and artificial intelligence are used to optimize production processes.

Another factor contributing to the growing demand for induction motors in smart factories is the need for increased flexibility and adaptability in production lines. As consumer preferences shift rapidly and product lifecycles shorten, manufacturers require motor systems that can quickly adjust to changing production requirements. Induction motors with advanced control systems provide the necessary flexibility to support agile manufacturing practices.

The global push for automation and robotics in manufacturing has further amplified the demand for high-performance motor solutions. Induction motors are essential components in robotic systems, conveyor belts, and other automated equipment that form the backbone of smart factories. As automation continues to expand across industries, the demand for reliable and efficient motor systems is expected to grow proportionally.

In conclusion, the smart factory demand for induction motors is driven by a combination of factors, including energy efficiency requirements, digital transformation initiatives, the need for production flexibility, and the ongoing automation trend. As industries continue to invest in smart manufacturing technologies, the market for advanced induction motor solutions is poised for substantial growth in the coming years.

The market for smart factory solutions is projected to grow significantly in the coming years, driven by the need for improved operational efficiency, reduced downtime, and increased production output. Industries such as automotive, electronics, aerospace, and consumer goods are at the forefront of adopting smart factory technologies, including advanced motor systems.

One of the key drivers for the adoption of induction motors in smart factories is the increasing focus on energy efficiency and sustainability. As energy costs continue to rise and environmental regulations become more stringent, manufacturers are seeking ways to optimize their energy consumption. Induction motors, particularly when coupled with variable frequency drives (VFDs), offer substantial energy savings compared to traditional motor systems.

The integration of Industrial Internet of Things (IIoT) technologies has also fueled the demand for smart motor solutions. Induction motors equipped with sensors and connectivity capabilities enable real-time monitoring, predictive maintenance, and data-driven decision-making. This aligns with the broader trend of digital transformation in manufacturing, where data analytics and artificial intelligence are used to optimize production processes.

Another factor contributing to the growing demand for induction motors in smart factories is the need for increased flexibility and adaptability in production lines. As consumer preferences shift rapidly and product lifecycles shorten, manufacturers require motor systems that can quickly adjust to changing production requirements. Induction motors with advanced control systems provide the necessary flexibility to support agile manufacturing practices.

The global push for automation and robotics in manufacturing has further amplified the demand for high-performance motor solutions. Induction motors are essential components in robotic systems, conveyor belts, and other automated equipment that form the backbone of smart factories. As automation continues to expand across industries, the demand for reliable and efficient motor systems is expected to grow proportionally.

In conclusion, the smart factory demand for induction motors is driven by a combination of factors, including energy efficiency requirements, digital transformation initiatives, the need for production flexibility, and the ongoing automation trend. As industries continue to invest in smart manufacturing technologies, the market for advanced induction motor solutions is poised for substantial growth in the coming years.

Motor Tech Challenges

Induction motors have long been the workhorses of industrial automation, but their integration into smart factory setups presents both opportunities and challenges. One of the primary technical hurdles is achieving precise speed control in variable load conditions. Traditional methods often struggle to maintain optimal performance across diverse operational scenarios, leading to efficiency losses and reduced productivity.

Another significant challenge lies in the real-time monitoring and predictive maintenance of induction motors. While smart factories demand continuous operation, the ability to accurately predict and prevent motor failures remains limited. Current sensor technologies and data analysis methods often fall short in providing comprehensive insights into motor health, resulting in unexpected downtimes and decreased overall equipment effectiveness.

Energy efficiency optimization poses yet another technical obstacle. As industries strive for sustainability, there is a pressing need to minimize energy consumption without compromising performance. However, existing control algorithms frequently struggle to balance power efficiency with the dynamic requirements of smart manufacturing processes, leading to suboptimal energy utilization.

The integration of induction motors with Industrial Internet of Things (IIoT) platforms presents interoperability challenges. Ensuring seamless communication between motors, controllers, and higher-level management systems often requires overcoming compatibility issues and developing standardized protocols. This integration is crucial for realizing the full potential of smart factories but remains a complex technical endeavor.

Thermal management in high-performance applications is an ongoing concern. As smart factories push induction motors to their limits, heat dissipation becomes increasingly critical. Current cooling solutions may not adequately address the thermal stress experienced in advanced manufacturing environments, potentially leading to reduced motor lifespan and reliability issues.

Lastly, the development of advanced control algorithms for induction motors in smart factory contexts presents a significant challenge. While traditional control methods suffice for basic operations, they often lack the sophistication required for adaptive, self-optimizing systems. Creating intelligent control strategies that can dynamically adjust to changing production demands, while maintaining optimal efficiency and productivity, remains an area of active research and development.

Addressing these technical challenges is crucial for fully leveraging the potential of induction motors in smart factory setups. Overcoming these hurdles will not only enhance productivity but also pave the way for more flexible, efficient, and sustainable manufacturing processes in the era of Industry 4.0.

Another significant challenge lies in the real-time monitoring and predictive maintenance of induction motors. While smart factories demand continuous operation, the ability to accurately predict and prevent motor failures remains limited. Current sensor technologies and data analysis methods often fall short in providing comprehensive insights into motor health, resulting in unexpected downtimes and decreased overall equipment effectiveness.

Energy efficiency optimization poses yet another technical obstacle. As industries strive for sustainability, there is a pressing need to minimize energy consumption without compromising performance. However, existing control algorithms frequently struggle to balance power efficiency with the dynamic requirements of smart manufacturing processes, leading to suboptimal energy utilization.

The integration of induction motors with Industrial Internet of Things (IIoT) platforms presents interoperability challenges. Ensuring seamless communication between motors, controllers, and higher-level management systems often requires overcoming compatibility issues and developing standardized protocols. This integration is crucial for realizing the full potential of smart factories but remains a complex technical endeavor.

Thermal management in high-performance applications is an ongoing concern. As smart factories push induction motors to their limits, heat dissipation becomes increasingly critical. Current cooling solutions may not adequately address the thermal stress experienced in advanced manufacturing environments, potentially leading to reduced motor lifespan and reliability issues.

Lastly, the development of advanced control algorithms for induction motors in smart factory contexts presents a significant challenge. While traditional control methods suffice for basic operations, they often lack the sophistication required for adaptive, self-optimizing systems. Creating intelligent control strategies that can dynamically adjust to changing production demands, while maintaining optimal efficiency and productivity, remains an area of active research and development.

Addressing these technical challenges is crucial for fully leveraging the potential of induction motors in smart factory setups. Overcoming these hurdles will not only enhance productivity but also pave the way for more flexible, efficient, and sustainable manufacturing processes in the era of Industry 4.0.

Current Motor Solutions

01 Optimization of induction motor design

Improving the design of induction motors can significantly enhance their productivity. This includes optimizing the rotor and stator configurations, using advanced materials for core and windings, and implementing efficient cooling systems. These design improvements can lead to increased power output, reduced energy losses, and improved overall performance.- Optimization of induction motor design: Improving the design of induction motors can lead to increased productivity. This includes optimizing the motor's components, such as the rotor and stator, to enhance efficiency and performance. Advanced materials and manufacturing techniques can be employed to reduce losses and improve overall motor output.

- Implementation of advanced control systems: Utilizing sophisticated control systems can significantly improve the productivity of induction motors. These systems can include variable frequency drives, adaptive control algorithms, and real-time monitoring capabilities. By optimizing motor operation based on load conditions and environmental factors, energy efficiency and output can be maximized.

- Integration with IoT and data analytics: Incorporating Internet of Things (IoT) technology and data analytics can enhance induction motor productivity. By collecting and analyzing operational data in real-time, predictive maintenance can be implemented, downtime can be reduced, and motor performance can be continuously optimized based on historical and current data trends.

- Energy efficiency improvements: Focusing on energy efficiency can lead to increased productivity in induction motors. This can involve the use of high-efficiency materials, improved cooling systems, and optimized motor designs that reduce energy losses. Additionally, implementing energy recovery systems can further enhance overall system efficiency.

- Automation and smart manufacturing integration: Integrating induction motors into automated and smart manufacturing systems can boost productivity. This includes the use of robotics, artificial intelligence, and machine learning to optimize motor operation within the broader manufacturing process. Automated diagnostics and self-adjusting systems can ensure consistent high performance and reduced downtime.

02 Advanced control systems for induction motors

Implementing sophisticated control systems can boost the productivity of induction motors. This involves using advanced algorithms for speed and torque control, employing vector control techniques, and integrating smart sensors for real-time monitoring. These control systems can optimize motor operation, reduce energy consumption, and enhance overall efficiency.Expand Specific Solutions03 Energy efficiency improvements

Enhancing the energy efficiency of induction motors is crucial for increasing productivity. This can be achieved through the use of high-efficiency core materials, optimized winding designs, and the implementation of energy recovery systems. Improved energy efficiency leads to reduced operating costs and increased output per unit of energy consumed.Expand Specific Solutions04 Predictive maintenance and condition monitoring

Implementing predictive maintenance strategies and condition monitoring systems can significantly improve the productivity of induction motors. This involves using sensors, data analytics, and machine learning algorithms to predict potential failures, optimize maintenance schedules, and minimize downtime. These approaches ensure continuous operation and extend the lifespan of the motors.Expand Specific Solutions05 Integration with industrial automation systems

Integrating induction motors with advanced industrial automation systems can enhance overall productivity. This includes connecting motors to industrial IoT platforms, implementing smart factory concepts, and utilizing data-driven decision-making processes. Such integration allows for better coordination of motor operations with other production processes, leading to improved overall efficiency and output.Expand Specific Solutions

Industry Leaders

The induction motor market in smart factory setups is in a growth phase, driven by increasing industrial automation and Industry 4.0 initiatives. The global market size is projected to expand significantly, with key players like Siemens Energy, ABB Group, and Mitsubishi Electric leading technological advancements. These companies are focusing on developing more efficient, compact, and intelligent induction motors integrated with IoT capabilities. The technology is maturing rapidly, with innovations in motor design, control systems, and energy efficiency. Emerging players like Nidec Motor Corp. and LS Electric are also contributing to market competitiveness, pushing the boundaries of induction motor applications in smart manufacturing environments.

Schneider Electric Industries SASU

Technical Solution: Schneider Electric's approach to enhancing productivity with induction motors in smart factories centers on their EcoStruxure platform. Their induction motors are integrated with smart sensors and connected to the EcoStruxure Machine system, enabling real-time monitoring and analytics[1]. Schneider's motors feature IE4 and IE5 efficiency ratings, significantly reducing energy consumption in industrial processes[2]. The company's Altivar Process variable speed drives, when paired with their induction motors, offer advanced control algorithms that optimize motor performance based on load conditions[3]. Schneider's motor management system includes predictive maintenance capabilities, using machine learning to forecast potential failures and schedule maintenance proactively[4]. Their motors are designed with cybersecurity in mind, incorporating features to protect against unauthorized access and data breaches in connected factory environments[5]. Schneider also offers augmented reality tools for motor installation and maintenance, reducing downtime and improving technician efficiency in smart factory setups[6].

Strengths: Comprehensive integration with EcoStruxure platform, high energy efficiency, and strong focus on cybersecurity. Weaknesses: May require significant investment in Schneider's ecosystem for full benefits, potential complexity for smaller operations.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy's induction motor solutions for smart factories focus on digitalization and energy efficiency. Their SIMOTICS series of induction motors are designed with digital twin technology, allowing for virtual commissioning and optimization before physical implementation[1]. Siemens' motors incorporate advanced sensor technology that enables condition monitoring and predictive maintenance through their MindSphere IoT platform[2]. The company's SINAMICS variable frequency drives, when paired with their induction motors, offer vector control for precise speed and torque regulation, enhancing productivity in various industrial applications[3]. Siemens' motors feature innovative cooling designs, including their SIMOTICS FD series with forced ventilation, allowing for high power density and improved efficiency in compact designs[4]. Their motors are also designed for seamless integration with Siemens' TIA (Totally Integrated Automation) Portal, facilitating easy configuration and diagnostics in smart factory environments[5]. Additionally, Siemens offers AI-powered analytics for motor fleet management, enabling predictive maintenance and energy optimization across entire production lines[6].

Strengths: Advanced digital twin capabilities, comprehensive integration with Siemens' automation ecosystem, and high energy efficiency. Weaknesses: Potential vendor lock-in, may require significant investment in Siemens' technology stack for full benefits.

Key Motor Patents

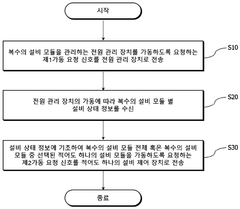

Electronic device for remotely controlling facility module, remote management system including same, and remote control method of electronic device

PatentWO2025100671A1

Innovation

- An electronic device that remotely controls multiple facility modules, transmitting operation and inspection requests to power management and facility control devices, allowing for real-time monitoring and control of facility status and sample inspection processes.

Method for production in a production cell of a production system and production system for performing the method

PatentInactiveEP3446278A1

Innovation

- A manufacturing cell with workstations and a vehicle system that receives orders electronically, uses inductive energy transfer for efficient power management, and employs marking and gesture recognition for part identification and processing, allowing for flexible production and reduced error rates.

Energy Efficiency

Energy efficiency is a critical aspect of induction motors in smart factory setups, directly impacting productivity and operational costs. Modern induction motors are designed with advanced materials and technologies to minimize energy losses and maximize power output. High-efficiency motors, such as those meeting IE3 or IE4 standards, can significantly reduce energy consumption compared to standard motors.

Smart factory environments leverage the energy efficiency of induction motors through intelligent control systems. Variable frequency drives (VFDs) allow for precise speed control, adjusting motor output to match the exact requirements of the production process. This dynamic adjustment eliminates unnecessary energy consumption during periods of low demand or idle time.

The integration of IoT sensors and real-time monitoring systems further enhances energy efficiency. These systems continuously track motor performance, load conditions, and energy consumption patterns. By analyzing this data, smart factories can optimize motor operation, schedule preventive maintenance, and identify opportunities for energy savings.

Energy recovery systems are increasingly being implemented in smart factories to harness the kinetic energy from induction motors during deceleration or braking. This recovered energy can be fed back into the power grid or used to power other equipment, further improving overall energy efficiency.

The use of advanced insulation materials and improved cooling systems in modern induction motors contributes to reduced energy losses and increased efficiency. These enhancements allow motors to operate at higher temperatures without compromising performance or lifespan, resulting in more efficient energy conversion.

Smart factories also benefit from the implementation of power factor correction systems, which optimize the power drawn by induction motors. By maintaining a high power factor, these systems reduce reactive power consumption, minimize transmission losses, and improve overall electrical system efficiency.

The adoption of energy-efficient induction motors in smart factories not only reduces operational costs but also contributes to sustainability goals. As industries face increasing pressure to reduce their carbon footprint, the role of energy-efficient motors becomes even more crucial in enhancing productivity while minimizing environmental impact.

Smart factory environments leverage the energy efficiency of induction motors through intelligent control systems. Variable frequency drives (VFDs) allow for precise speed control, adjusting motor output to match the exact requirements of the production process. This dynamic adjustment eliminates unnecessary energy consumption during periods of low demand or idle time.

The integration of IoT sensors and real-time monitoring systems further enhances energy efficiency. These systems continuously track motor performance, load conditions, and energy consumption patterns. By analyzing this data, smart factories can optimize motor operation, schedule preventive maintenance, and identify opportunities for energy savings.

Energy recovery systems are increasingly being implemented in smart factories to harness the kinetic energy from induction motors during deceleration or braking. This recovered energy can be fed back into the power grid or used to power other equipment, further improving overall energy efficiency.

The use of advanced insulation materials and improved cooling systems in modern induction motors contributes to reduced energy losses and increased efficiency. These enhancements allow motors to operate at higher temperatures without compromising performance or lifespan, resulting in more efficient energy conversion.

Smart factories also benefit from the implementation of power factor correction systems, which optimize the power drawn by induction motors. By maintaining a high power factor, these systems reduce reactive power consumption, minimize transmission losses, and improve overall electrical system efficiency.

The adoption of energy-efficient induction motors in smart factories not only reduces operational costs but also contributes to sustainability goals. As industries face increasing pressure to reduce their carbon footprint, the role of energy-efficient motors becomes even more crucial in enhancing productivity while minimizing environmental impact.

IoT Integration

The integration of Internet of Things (IoT) technology with induction motors in smart factory setups has revolutionized productivity and efficiency in manufacturing processes. IoT sensors and devices connected to induction motors enable real-time monitoring, data collection, and analysis of motor performance, leading to predictive maintenance, optimized energy consumption, and enhanced overall equipment effectiveness (OEE).

IoT-enabled induction motors can transmit crucial operational data, such as temperature, vibration, current, and voltage, to centralized control systems. This continuous stream of information allows for the early detection of potential issues, reducing unplanned downtime and extending the motor's lifespan. By leveraging machine learning algorithms, these systems can predict maintenance needs, scheduling interventions before failures occur, thus minimizing production disruptions.

Energy efficiency is another significant benefit of IoT integration in induction motors. Smart sensors can monitor power consumption patterns and adjust motor speed and torque in real-time to optimize energy usage. This not only reduces operational costs but also contributes to sustainability efforts by lowering the factory's carbon footprint.

The interconnectivity provided by IoT allows for seamless communication between induction motors and other factory equipment. This enables the creation of adaptive production lines that can automatically adjust to changing demands or conditions. For instance, if one motor experiences a performance issue, the system can redistribute the workload to other motors, maintaining production flow and preventing bottlenecks.

Data analytics powered by IoT integration offers valuable insights into motor performance trends and production patterns. Manufacturers can use this information to identify inefficiencies, streamline processes, and make data-driven decisions to improve overall productivity. The ability to analyze historical data alongside real-time information enables more accurate forecasting and planning of production schedules.

Remote monitoring and control capabilities facilitated by IoT integration allow for centralized management of multiple induction motors across different locations. This not only reduces the need for on-site personnel but also enables rapid response to issues and the implementation of uniform operational standards across various facilities.

As IoT technology continues to evolve, the integration with induction motors is expected to become more sophisticated. Future developments may include advanced AI-driven optimization algorithms, enhanced cybersecurity measures to protect against potential vulnerabilities, and increased interoperability with other smart factory systems, further amplifying the productivity gains in smart manufacturing environments.

IoT-enabled induction motors can transmit crucial operational data, such as temperature, vibration, current, and voltage, to centralized control systems. This continuous stream of information allows for the early detection of potential issues, reducing unplanned downtime and extending the motor's lifespan. By leveraging machine learning algorithms, these systems can predict maintenance needs, scheduling interventions before failures occur, thus minimizing production disruptions.

Energy efficiency is another significant benefit of IoT integration in induction motors. Smart sensors can monitor power consumption patterns and adjust motor speed and torque in real-time to optimize energy usage. This not only reduces operational costs but also contributes to sustainability efforts by lowering the factory's carbon footprint.

The interconnectivity provided by IoT allows for seamless communication between induction motors and other factory equipment. This enables the creation of adaptive production lines that can automatically adjust to changing demands or conditions. For instance, if one motor experiences a performance issue, the system can redistribute the workload to other motors, maintaining production flow and preventing bottlenecks.

Data analytics powered by IoT integration offers valuable insights into motor performance trends and production patterns. Manufacturers can use this information to identify inefficiencies, streamline processes, and make data-driven decisions to improve overall productivity. The ability to analyze historical data alongside real-time information enables more accurate forecasting and planning of production schedules.

Remote monitoring and control capabilities facilitated by IoT integration allow for centralized management of multiple induction motors across different locations. This not only reduces the need for on-site personnel but also enables rapid response to issues and the implementation of uniform operational standards across various facilities.

As IoT technology continues to evolve, the integration with induction motors is expected to become more sophisticated. Future developments may include advanced AI-driven optimization algorithms, enhanced cybersecurity measures to protect against potential vulnerabilities, and increased interoperability with other smart factory systems, further amplifying the productivity gains in smart manufacturing environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!