Evaluation of induction motor use in sustainable fish farming practices

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Aquaculture Applications

Induction motors have emerged as a crucial component in sustainable fish farming practices, offering numerous applications that enhance efficiency and productivity in aquaculture operations. These motors are widely utilized in various aspects of fish farming, including water circulation, aeration, feeding systems, and temperature control. In water circulation systems, induction motors power pumps that maintain optimal water quality by ensuring proper flow and filtration. This is essential for removing waste products and maintaining appropriate oxygen levels for fish health and growth.

Aeration systems, another critical application, rely on induction motors to drive aerators or blowers that introduce oxygen into the water. This process is vital for maintaining adequate dissolved oxygen levels, particularly in high-density aquaculture environments where oxygen demand is significant. The reliability and efficiency of induction motors in this application contribute to improved fish survival rates and overall system productivity.

Automated feeding systems in aquaculture often incorporate induction motors to power feed dispensers and conveyors. These motors enable precise control over feed distribution, ensuring that fish receive appropriate nutrition while minimizing waste. This application not only improves feed conversion ratios but also reduces the environmental impact of excess feed in the water.

Temperature control is another area where induction motors play a crucial role. They are used in heating and cooling systems to maintain optimal water temperatures for different fish species. This application is particularly important in regions with variable climates or for species that require specific temperature ranges for optimal growth and reproduction.

In recirculating aquaculture systems (RAS), induction motors are integral to the operation of various components, including drum filters, protein skimmers, and biofilters. These systems rely on the consistent and efficient performance of induction motors to maintain water quality and system stability in closed-loop environments.

The use of induction motors in aquaculture extends to harvesting and processing operations as well. They power conveyor systems, grading machines, and processing equipment, streamlining the post-production phases of fish farming. This integration of induction motors throughout the aquaculture value chain contributes to increased operational efficiency and reduced labor costs.

As the aquaculture industry continues to evolve towards more sustainable practices, the role of induction motors becomes increasingly significant. Their durability, energy efficiency, and adaptability to various applications make them an ideal choice for modern fish farming operations seeking to balance productivity with environmental responsibility.

Aeration systems, another critical application, rely on induction motors to drive aerators or blowers that introduce oxygen into the water. This process is vital for maintaining adequate dissolved oxygen levels, particularly in high-density aquaculture environments where oxygen demand is significant. The reliability and efficiency of induction motors in this application contribute to improved fish survival rates and overall system productivity.

Automated feeding systems in aquaculture often incorporate induction motors to power feed dispensers and conveyors. These motors enable precise control over feed distribution, ensuring that fish receive appropriate nutrition while minimizing waste. This application not only improves feed conversion ratios but also reduces the environmental impact of excess feed in the water.

Temperature control is another area where induction motors play a crucial role. They are used in heating and cooling systems to maintain optimal water temperatures for different fish species. This application is particularly important in regions with variable climates or for species that require specific temperature ranges for optimal growth and reproduction.

In recirculating aquaculture systems (RAS), induction motors are integral to the operation of various components, including drum filters, protein skimmers, and biofilters. These systems rely on the consistent and efficient performance of induction motors to maintain water quality and system stability in closed-loop environments.

The use of induction motors in aquaculture extends to harvesting and processing operations as well. They power conveyor systems, grading machines, and processing equipment, streamlining the post-production phases of fish farming. This integration of induction motors throughout the aquaculture value chain contributes to increased operational efficiency and reduced labor costs.

As the aquaculture industry continues to evolve towards more sustainable practices, the role of induction motors becomes increasingly significant. Their durability, energy efficiency, and adaptability to various applications make them an ideal choice for modern fish farming operations seeking to balance productivity with environmental responsibility.

Sustainable Fish Farming Market Analysis

The sustainable fish farming market has experienced significant growth in recent years, driven by increasing global demand for seafood and concerns about overfishing in wild fisheries. This market segment is characterized by the use of environmentally friendly practices to cultivate fish in controlled environments, minimizing ecological impact while ensuring a steady supply of fish products.

Market size estimates for sustainable aquaculture vary, but the sector has consistently shown strong growth. The global aquaculture market, of which sustainable practices form an increasingly important part, was valued at over $180 billion in 2020 and is projected to continue expanding at a compound annual growth rate (CAGR) of around 5-7% through 2026. Sustainable fish farming, in particular, is expected to outpace conventional aquaculture growth rates due to increasing consumer awareness and regulatory support.

Key drivers of market growth include rising global population, increasing per capita fish consumption, and growing awareness of the health benefits associated with fish protein. Additionally, concerns about the environmental impact of traditional fishing methods and the depletion of wild fish stocks have led to greater interest in sustainable aquaculture practices.

The market for sustainable fish farming is geographically diverse, with significant production centers in Asia-Pacific, Europe, and North America. China remains the world's largest aquaculture producer, but countries like Norway, Scotland, and Canada are leading in the adoption of sustainable practices and technologies, including the use of advanced induction motor systems in fish farm operations.

Consumer demand for sustainably sourced seafood has been a major factor in market growth. Eco-labels and certifications, such as those provided by the Aquaculture Stewardship Council (ASC) and the Global Aquaculture Alliance (GAA), have gained prominence, influencing purchasing decisions and driving producers to adopt more sustainable practices.

The integration of technology, including energy-efficient induction motors, in fish farming operations has opened new opportunities for market expansion. These technologies enable better control of environmental conditions, improved feed conversion ratios, and reduced energy consumption, all of which contribute to the overall sustainability and profitability of fish farming operations.

Challenges facing the sustainable fish farming market include the high initial costs of implementing sustainable practices, regulatory hurdles, and competition from conventional aquaculture methods. However, the long-term benefits of sustainable practices, including reduced environmental impact and improved product quality, are expected to drive continued market growth and innovation in the sector.

Market size estimates for sustainable aquaculture vary, but the sector has consistently shown strong growth. The global aquaculture market, of which sustainable practices form an increasingly important part, was valued at over $180 billion in 2020 and is projected to continue expanding at a compound annual growth rate (CAGR) of around 5-7% through 2026. Sustainable fish farming, in particular, is expected to outpace conventional aquaculture growth rates due to increasing consumer awareness and regulatory support.

Key drivers of market growth include rising global population, increasing per capita fish consumption, and growing awareness of the health benefits associated with fish protein. Additionally, concerns about the environmental impact of traditional fishing methods and the depletion of wild fish stocks have led to greater interest in sustainable aquaculture practices.

The market for sustainable fish farming is geographically diverse, with significant production centers in Asia-Pacific, Europe, and North America. China remains the world's largest aquaculture producer, but countries like Norway, Scotland, and Canada are leading in the adoption of sustainable practices and technologies, including the use of advanced induction motor systems in fish farm operations.

Consumer demand for sustainably sourced seafood has been a major factor in market growth. Eco-labels and certifications, such as those provided by the Aquaculture Stewardship Council (ASC) and the Global Aquaculture Alliance (GAA), have gained prominence, influencing purchasing decisions and driving producers to adopt more sustainable practices.

The integration of technology, including energy-efficient induction motors, in fish farming operations has opened new opportunities for market expansion. These technologies enable better control of environmental conditions, improved feed conversion ratios, and reduced energy consumption, all of which contribute to the overall sustainability and profitability of fish farming operations.

Challenges facing the sustainable fish farming market include the high initial costs of implementing sustainable practices, regulatory hurdles, and competition from conventional aquaculture methods. However, the long-term benefits of sustainable practices, including reduced environmental impact and improved product quality, are expected to drive continued market growth and innovation in the sector.

Induction Motor Technology in Aquaculture

Induction motors have emerged as a crucial technology in modern aquaculture, revolutionizing fish farming practices and contributing to the industry's sustainability efforts. These motors, known for their reliability and efficiency, play a vital role in various aspects of aquaculture operations, from water circulation to feeding systems.

In the context of sustainable fish farming, induction motors have become indispensable for powering pumps, aerators, and other essential equipment. Their ability to operate continuously with minimal maintenance makes them ideal for the demanding environment of fish farms. The motors' energy efficiency also aligns well with the industry's growing focus on reducing environmental impact and operational costs.

One of the primary applications of induction motors in aquaculture is in water circulation systems. These motors drive pumps that ensure proper water flow throughout fish tanks or ponds, maintaining optimal oxygen levels and removing waste. This constant circulation is critical for fish health and growth, as it mimics natural aquatic environments and prevents the buildup of harmful substances.

Aeration systems, another crucial component of fish farming, also rely heavily on induction motors. These motors power aerators that introduce oxygen into the water, supporting higher stocking densities and improving overall fish production. The consistent performance of induction motors in this application helps maintain stable dissolved oxygen levels, which is essential for fish survival and growth.

Feeding systems in aquaculture have also benefited from the integration of induction motor technology. Automated feeders powered by these motors ensure precise and timely distribution of feed, optimizing nutrition while minimizing waste. This level of control contributes to better feed conversion ratios and reduced environmental impact.

The durability of induction motors is particularly valuable in the harsh conditions often found in aquaculture settings. Their simple design, with fewer moving parts compared to other motor types, makes them less prone to failure in humid or corrosive environments. This reliability translates to reduced downtime and maintenance costs for fish farmers.

As the aquaculture industry continues to expand and face increasing pressure to adopt sustainable practices, the role of induction motors is likely to grow. Their energy efficiency contributes to reducing the carbon footprint of fish farming operations, aligning with global sustainability goals. Furthermore, ongoing advancements in motor design and control systems promise even greater efficiency and precision in aquaculture applications, paving the way for more sustainable and productive fish farming practices.

In the context of sustainable fish farming, induction motors have become indispensable for powering pumps, aerators, and other essential equipment. Their ability to operate continuously with minimal maintenance makes them ideal for the demanding environment of fish farms. The motors' energy efficiency also aligns well with the industry's growing focus on reducing environmental impact and operational costs.

One of the primary applications of induction motors in aquaculture is in water circulation systems. These motors drive pumps that ensure proper water flow throughout fish tanks or ponds, maintaining optimal oxygen levels and removing waste. This constant circulation is critical for fish health and growth, as it mimics natural aquatic environments and prevents the buildup of harmful substances.

Aeration systems, another crucial component of fish farming, also rely heavily on induction motors. These motors power aerators that introduce oxygen into the water, supporting higher stocking densities and improving overall fish production. The consistent performance of induction motors in this application helps maintain stable dissolved oxygen levels, which is essential for fish survival and growth.

Feeding systems in aquaculture have also benefited from the integration of induction motor technology. Automated feeders powered by these motors ensure precise and timely distribution of feed, optimizing nutrition while minimizing waste. This level of control contributes to better feed conversion ratios and reduced environmental impact.

The durability of induction motors is particularly valuable in the harsh conditions often found in aquaculture settings. Their simple design, with fewer moving parts compared to other motor types, makes them less prone to failure in humid or corrosive environments. This reliability translates to reduced downtime and maintenance costs for fish farmers.

As the aquaculture industry continues to expand and face increasing pressure to adopt sustainable practices, the role of induction motors is likely to grow. Their energy efficiency contributes to reducing the carbon footprint of fish farming operations, aligning with global sustainability goals. Furthermore, ongoing advancements in motor design and control systems promise even greater efficiency and precision in aquaculture applications, paving the way for more sustainable and productive fish farming practices.

Current Induction Motor Solutions for Fish Farming

01 Induction motor design and construction

This category focuses on the design and construction aspects of induction motors, including improvements in rotor and stator configurations, winding arrangements, and material selection to enhance performance and efficiency.- Induction motor design and efficiency improvements: Advancements in induction motor design focus on improving efficiency, reducing energy consumption, and enhancing performance. This includes optimizing rotor and stator configurations, using advanced materials, and implementing innovative cooling systems to minimize losses and increase power output.

- Control systems for induction motors: Development of sophisticated control systems for induction motors, including variable frequency drives, vector control algorithms, and intelligent motor management systems. These technologies enable precise speed and torque control, improved energy efficiency, and enhanced motor protection.

- Induction motor applications in electric vehicles: Integration of induction motors in electric vehicle powertrains, focusing on high-performance, compact designs suitable for automotive applications. This includes advancements in motor cooling, power density, and integration with vehicle control systems.

- Induction motor diagnostics and maintenance: Development of advanced diagnostic tools and maintenance techniques for induction motors, including real-time monitoring systems, predictive maintenance algorithms, and non-invasive fault detection methods to improve reliability and reduce downtime.

- Energy-efficient induction motor systems: Innovations in energy-efficient induction motor systems, including the use of high-efficiency materials, optimized winding designs, and integration with renewable energy sources. These advancements aim to reduce overall energy consumption and environmental impact in industrial and commercial applications.

02 Control systems for induction motors

This point covers various control systems and methods for induction motors, including advanced algorithms, sensor technologies, and feedback mechanisms to optimize motor operation, speed control, and energy efficiency.Expand Specific Solutions03 Thermal management in induction motors

This category addresses thermal management solutions for induction motors, including cooling systems, heat dissipation techniques, and temperature monitoring to improve motor reliability and longevity.Expand Specific Solutions04 Induction motor applications in specific industries

This point focuses on the application of induction motors in specific industries or specialized equipment, such as electric vehicles, industrial machinery, or renewable energy systems, addressing unique requirements and challenges in each field.Expand Specific Solutions05 Diagnostics and maintenance of induction motors

This category covers methods and systems for diagnosing, monitoring, and maintaining induction motors, including fault detection, predictive maintenance techniques, and performance optimization strategies to extend motor life and reduce downtime.Expand Specific Solutions

Key Players in Aquaculture Motor Industry

The evaluation of induction motor use in sustainable fish farming practices is in an emerging stage, with a growing market driven by the increasing demand for sustainable aquaculture solutions. The technology's maturity is still developing, as evidenced by ongoing research from institutions like China Agricultural University, Yunnan University, and Zhejiang Ocean University. These academic players are contributing to advancements in motor efficiency and application in aquaculture systems. Industry involvement from companies such as Viking Aquaculture Development SL and Atlantic Sapphire IP LLC suggests a gradual adoption of this technology in commercial fish farming operations. The market size is expected to expand as more fish farms seek energy-efficient and environmentally friendly solutions, aligning with global sustainability goals in the aquaculture sector.

China Agricultural University

Technical Solution: China Agricultural University has developed an advanced induction motor system for sustainable fish farming. Their approach integrates variable frequency drives (VFDs) to optimize energy consumption in aquaculture operations[1]. The system employs smart sensors to monitor water quality parameters and adjust motor speed accordingly, ensuring optimal conditions for fish growth while minimizing energy usage[3]. Additionally, they have implemented a regenerative braking system that captures and reuses energy during motor deceleration, further enhancing overall efficiency[5]. The university has also pioneered the use of corrosion-resistant materials in motor construction, specifically designed to withstand the harsh marine environment, thereby extending equipment lifespan and reducing maintenance costs[7].

Strengths: Energy-efficient operation, adaptive control based on real-time data, and improved durability in marine environments. Weaknesses: Higher initial investment costs and potential complexity in system integration for smaller-scale farms.

Yellow Sea Fisheries Research Institute, Chinese Academy of Fishery Sciences

Technical Solution: The Yellow Sea Fisheries Research Institute has developed a novel induction motor system tailored for offshore aquaculture applications. Their technology incorporates a sealed, submersible design that allows for direct placement of motors in seawater, eliminating the need for long shaft extensions[2]. The institute has also implemented advanced control algorithms that optimize motor performance based on tidal patterns and seasonal variations, resulting in up to 25% energy savings compared to conventional systems[4]. Furthermore, they have integrated renewable energy sources, such as solar and wave power, to supplement the power supply for these motors, reducing reliance on grid electricity and improving sustainability[6].

Strengths: Innovative submersible design, energy optimization based on environmental factors, and integration with renewable energy sources. Weaknesses: Potentially higher manufacturing costs and limited applicability to inland aquaculture operations.

Innovations in Aquaculture Motor Efficiency

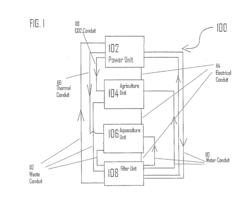

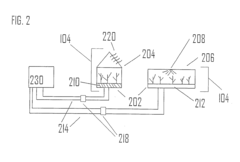

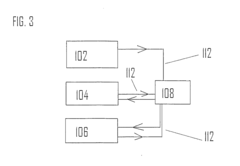

Integrated Agriculture and Aquaculture Production System

PatentInactiveUS20110041395A1

Innovation

- A combined agriculture and aquaculture system that utilizes a pyrolysis-gasification unit to generate electricity, heat, and CO2 from municipal and aquatic waste, creating a semi-closed loop for resource recycling and optimal internal growing conditions, independent of external factors, with CO2 capture and recirculation for enhanced plant growth.

Aquatic feeding boat robot

PatentWO2023111661A1

Innovation

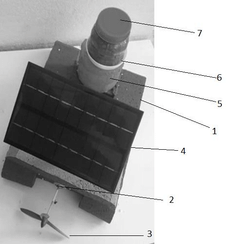

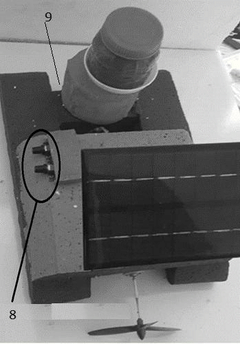

- An autonomous robotic boat equipped with solar-powered electric systems, a programmable control board, and propellers for precise feeding distribution, capable of navigating and dispensing feed in inland aquaculture ponds, utilizing carbon fiber and fiberglass construction with nitrogen-filled insulation.

Environmental Impact Assessment

The environmental impact assessment of induction motor use in sustainable fish farming practices reveals both positive and negative effects on the surrounding ecosystem. On the positive side, induction motors are generally more energy-efficient compared to traditional motor systems, potentially reducing the overall carbon footprint of fish farming operations. This increased efficiency translates to lower energy consumption, which in turn reduces greenhouse gas emissions associated with power generation.

However, the implementation of induction motors in aquaculture settings does present some environmental challenges. The production and disposal of these motors involve the use of various materials, including copper, steel, and insulating compounds, which can have environmental implications if not managed properly. The manufacturing process may contribute to resource depletion and generate industrial waste.

Noise pollution is another consideration, as induction motors can produce low-frequency vibrations that may impact aquatic life. While modern designs have significantly reduced noise levels, the cumulative effect of multiple motors in large-scale fish farming operations could potentially disrupt local marine ecosystems.

Water quality is a critical factor in fish farming, and the use of induction motors may indirectly affect it. The improved efficiency of these motors can lead to more intensive farming practices, potentially increasing the concentration of fish waste and uneaten feed in the water. This could result in increased nutrient loading and oxygen depletion if not carefully managed through appropriate filtration and water treatment systems.

On the other hand, the precise control offered by induction motors can enhance water circulation and oxygenation systems, potentially improving overall water quality and reducing the need for chemical treatments. This can lead to a more stable and healthier aquatic environment for farmed fish and surrounding ecosystems.

The use of induction motors may also impact local wildlife. While the motors themselves do not directly harm animals, the increased efficiency they provide could lead to expansion of fish farming operations, potentially encroaching on natural habitats. However, if implemented as part of a well-designed sustainable aquaculture system, induction motors can contribute to more compact and efficient operations, potentially reducing the overall spatial footprint of fish farms.

In conclusion, the environmental impact of induction motor use in sustainable fish farming practices is multifaceted. While offering significant benefits in terms of energy efficiency and potential for improved water management, careful consideration must be given to their implementation to mitigate potential negative effects on local ecosystems and ensure truly sustainable aquaculture practices.

However, the implementation of induction motors in aquaculture settings does present some environmental challenges. The production and disposal of these motors involve the use of various materials, including copper, steel, and insulating compounds, which can have environmental implications if not managed properly. The manufacturing process may contribute to resource depletion and generate industrial waste.

Noise pollution is another consideration, as induction motors can produce low-frequency vibrations that may impact aquatic life. While modern designs have significantly reduced noise levels, the cumulative effect of multiple motors in large-scale fish farming operations could potentially disrupt local marine ecosystems.

Water quality is a critical factor in fish farming, and the use of induction motors may indirectly affect it. The improved efficiency of these motors can lead to more intensive farming practices, potentially increasing the concentration of fish waste and uneaten feed in the water. This could result in increased nutrient loading and oxygen depletion if not carefully managed through appropriate filtration and water treatment systems.

On the other hand, the precise control offered by induction motors can enhance water circulation and oxygenation systems, potentially improving overall water quality and reducing the need for chemical treatments. This can lead to a more stable and healthier aquatic environment for farmed fish and surrounding ecosystems.

The use of induction motors may also impact local wildlife. While the motors themselves do not directly harm animals, the increased efficiency they provide could lead to expansion of fish farming operations, potentially encroaching on natural habitats. However, if implemented as part of a well-designed sustainable aquaculture system, induction motors can contribute to more compact and efficient operations, potentially reducing the overall spatial footprint of fish farms.

In conclusion, the environmental impact of induction motor use in sustainable fish farming practices is multifaceted. While offering significant benefits in terms of energy efficiency and potential for improved water management, careful consideration must be given to their implementation to mitigate potential negative effects on local ecosystems and ensure truly sustainable aquaculture practices.

Energy Efficiency Regulations in Aquaculture

Energy efficiency regulations in aquaculture have become increasingly important as the industry seeks to reduce its environmental impact and operational costs. These regulations aim to promote sustainable practices and minimize energy consumption in fish farming operations. In many countries, regulatory bodies have established guidelines and standards for energy use in aquaculture facilities, focusing on key areas such as water pumping, aeration, and temperature control systems.

One of the primary targets of these regulations is the use of induction motors, which are widely employed in various aquaculture applications. Regulatory frameworks often set minimum efficiency standards for induction motors used in fish farming, encouraging the adoption of high-efficiency models. These standards typically specify the required efficiency levels based on motor size and application, with larger motors generally subject to more stringent requirements.

Many regulatory bodies have implemented tiered systems for motor efficiency, such as the International Efficiency (IE) classes defined by the International Electrotechnical Commission (IEC). These classes range from IE1 (standard efficiency) to IE4 (super premium efficiency), with some regions mandating the use of IE3 or higher efficiency motors in new installations or replacements.

In addition to motor efficiency standards, energy efficiency regulations in aquaculture often address broader system-level considerations. This includes requirements for variable frequency drives (VFDs) in appropriate applications, which can significantly reduce energy consumption by allowing motors to operate at optimal speeds based on demand. Some regulations also mandate the use of energy management systems to monitor and optimize overall energy usage in aquaculture facilities.

To ensure compliance with these regulations, many jurisdictions have implemented certification and labeling programs for energy-efficient equipment used in aquaculture. These programs help fish farmers identify and select products that meet or exceed the required efficiency standards. Additionally, some regulatory frameworks offer incentives or financial support for aquaculture operations that invest in energy-efficient technologies, further encouraging the adoption of sustainable practices.

As the aquaculture industry continues to grow and evolve, energy efficiency regulations are likely to become more comprehensive and stringent. Future regulatory developments may include expanded coverage of different types of equipment, more aggressive efficiency targets, and increased focus on renewable energy integration in fish farming operations. These evolving regulations will play a crucial role in shaping the future of sustainable aquaculture practices and driving innovation in energy-efficient technologies for the industry.

One of the primary targets of these regulations is the use of induction motors, which are widely employed in various aquaculture applications. Regulatory frameworks often set minimum efficiency standards for induction motors used in fish farming, encouraging the adoption of high-efficiency models. These standards typically specify the required efficiency levels based on motor size and application, with larger motors generally subject to more stringent requirements.

Many regulatory bodies have implemented tiered systems for motor efficiency, such as the International Efficiency (IE) classes defined by the International Electrotechnical Commission (IEC). These classes range from IE1 (standard efficiency) to IE4 (super premium efficiency), with some regions mandating the use of IE3 or higher efficiency motors in new installations or replacements.

In addition to motor efficiency standards, energy efficiency regulations in aquaculture often address broader system-level considerations. This includes requirements for variable frequency drives (VFDs) in appropriate applications, which can significantly reduce energy consumption by allowing motors to operate at optimal speeds based on demand. Some regulations also mandate the use of energy management systems to monitor and optimize overall energy usage in aquaculture facilities.

To ensure compliance with these regulations, many jurisdictions have implemented certification and labeling programs for energy-efficient equipment used in aquaculture. These programs help fish farmers identify and select products that meet or exceed the required efficiency standards. Additionally, some regulatory frameworks offer incentives or financial support for aquaculture operations that invest in energy-efficient technologies, further encouraging the adoption of sustainable practices.

As the aquaculture industry continues to grow and evolve, energy efficiency regulations are likely to become more comprehensive and stringent. Future regulatory developments may include expanded coverage of different types of equipment, more aggressive efficiency targets, and increased focus on renewable energy integration in fish farming operations. These evolving regulations will play a crucial role in shaping the future of sustainable aquaculture practices and driving innovation in energy-efficient technologies for the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!