Contributions of induction motors to the circular economy initiatives

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Circular Economy Background

The concept of circular economy has gained significant traction in recent years as a sustainable alternative to the traditional linear economic model. In the context of induction motors, which are widely used in various industrial applications, the circular economy approach offers promising opportunities for resource conservation and environmental protection.

Induction motors, also known as asynchronous motors, have been a cornerstone of industrial electromechanical systems for over a century. These motors convert electrical energy into mechanical energy through electromagnetic induction, making them essential components in manufacturing, transportation, and numerous other sectors. However, the traditional lifecycle of induction motors often follows a linear "take-make-dispose" model, which contributes to resource depletion and waste accumulation.

The circular economy initiatives for induction motors aim to address these challenges by promoting a more sustainable and regenerative approach. This involves designing motors for longevity, repairability, and recyclability, as well as implementing strategies for remanufacturing and refurbishment. By extending the lifespan of induction motors and recovering valuable materials at the end of their useful life, these initiatives seek to minimize waste and reduce the demand for raw materials.

One of the key drivers behind the circular economy approach for induction motors is the growing awareness of the environmental impact of industrial processes. As global energy consumption continues to rise, there is an increasing focus on improving the efficiency and sustainability of electrical systems. Induction motors, which account for a significant portion of industrial electricity consumption, present a prime opportunity for implementing circular economy principles.

Furthermore, the circular economy model for induction motors aligns with broader sustainability goals and regulatory frameworks. Many countries and regions have introduced policies and regulations aimed at promoting resource efficiency and reducing waste. These initiatives create a favorable environment for the adoption of circular economy practices in the induction motor industry.

The transition to a circular economy for induction motors involves various stakeholders, including manufacturers, users, recyclers, and policymakers. Collaboration among these parties is essential for developing innovative solutions, establishing effective reverse logistics systems, and creating markets for remanufactured and recycled components.

As the circular economy concept continues to evolve, induction motors serve as a compelling case study for the potential benefits and challenges of implementing sustainable practices in industrial systems. The success of these initiatives could pave the way for broader adoption of circular economy principles across other sectors, contributing to a more sustainable and resilient global economy.

Induction motors, also known as asynchronous motors, have been a cornerstone of industrial electromechanical systems for over a century. These motors convert electrical energy into mechanical energy through electromagnetic induction, making them essential components in manufacturing, transportation, and numerous other sectors. However, the traditional lifecycle of induction motors often follows a linear "take-make-dispose" model, which contributes to resource depletion and waste accumulation.

The circular economy initiatives for induction motors aim to address these challenges by promoting a more sustainable and regenerative approach. This involves designing motors for longevity, repairability, and recyclability, as well as implementing strategies for remanufacturing and refurbishment. By extending the lifespan of induction motors and recovering valuable materials at the end of their useful life, these initiatives seek to minimize waste and reduce the demand for raw materials.

One of the key drivers behind the circular economy approach for induction motors is the growing awareness of the environmental impact of industrial processes. As global energy consumption continues to rise, there is an increasing focus on improving the efficiency and sustainability of electrical systems. Induction motors, which account for a significant portion of industrial electricity consumption, present a prime opportunity for implementing circular economy principles.

Furthermore, the circular economy model for induction motors aligns with broader sustainability goals and regulatory frameworks. Many countries and regions have introduced policies and regulations aimed at promoting resource efficiency and reducing waste. These initiatives create a favorable environment for the adoption of circular economy practices in the induction motor industry.

The transition to a circular economy for induction motors involves various stakeholders, including manufacturers, users, recyclers, and policymakers. Collaboration among these parties is essential for developing innovative solutions, establishing effective reverse logistics systems, and creating markets for remanufactured and recycled components.

As the circular economy concept continues to evolve, induction motors serve as a compelling case study for the potential benefits and challenges of implementing sustainable practices in industrial systems. The success of these initiatives could pave the way for broader adoption of circular economy principles across other sectors, contributing to a more sustainable and resilient global economy.

Market Demand Analysis

The market demand for induction motors in the context of circular economy initiatives has been steadily growing in recent years. This surge is driven by increasing awareness of environmental sustainability and the need for energy-efficient solutions across various industries. Induction motors, known for their robustness and reliability, are now being reevaluated for their potential contributions to circular economy principles.

In the industrial sector, which accounts for a significant portion of global energy consumption, there is a rising demand for induction motors that can be easily refurbished, repaired, or remanufactured. This trend aligns with the circular economy's emphasis on extending product lifecycles and minimizing waste. Companies are increasingly seeking motors that can be disassembled and reassembled with minimal loss of performance, creating a market for modular and easily serviceable designs.

The automotive industry, particularly with the shift towards electric vehicles, presents another substantial market for circular economy-oriented induction motors. As electric vehicle adoption accelerates, there is a growing need for motors that can be efficiently recycled or repurposed at the end of their initial life cycle. This demand is further amplified by regulatory pressures and consumer preferences for sustainable transportation solutions.

In the renewable energy sector, particularly wind power generation, induction motors play a crucial role. The market is showing a preference for designs that facilitate easy maintenance and component replacement, aligning with circular economy principles. This trend is expected to continue as the renewable energy sector expands and seeks to maximize the lifespan and recyclability of its equipment.

The building and construction industry is another significant market driver for circular economy-focused induction motors. With the increasing emphasis on green building practices, there is a growing demand for HVAC systems and elevators that incorporate motors designed for longevity, energy efficiency, and ease of recycling. This sector's shift towards sustainable practices is creating opportunities for innovative motor designs that support circular economy goals.

Agriculture and water management sectors are also showing increased interest in induction motors that align with circular economy principles. These industries require motors that can withstand harsh environments while being easily maintainable and recyclable. The demand in these sectors is driven by the need for sustainable water pumping and irrigation solutions, particularly in regions facing water scarcity and environmental challenges.

Overall, the market demand for induction motors contributing to circular economy initiatives is characterized by a shift towards designs that prioritize longevity, repairability, and recyclability. This trend is expected to continue as industries across the board seek to reduce their environmental footprint and align with global sustainability goals. The challenge for manufacturers lies in meeting these demands while maintaining competitive pricing and performance standards.

In the industrial sector, which accounts for a significant portion of global energy consumption, there is a rising demand for induction motors that can be easily refurbished, repaired, or remanufactured. This trend aligns with the circular economy's emphasis on extending product lifecycles and minimizing waste. Companies are increasingly seeking motors that can be disassembled and reassembled with minimal loss of performance, creating a market for modular and easily serviceable designs.

The automotive industry, particularly with the shift towards electric vehicles, presents another substantial market for circular economy-oriented induction motors. As electric vehicle adoption accelerates, there is a growing need for motors that can be efficiently recycled or repurposed at the end of their initial life cycle. This demand is further amplified by regulatory pressures and consumer preferences for sustainable transportation solutions.

In the renewable energy sector, particularly wind power generation, induction motors play a crucial role. The market is showing a preference for designs that facilitate easy maintenance and component replacement, aligning with circular economy principles. This trend is expected to continue as the renewable energy sector expands and seeks to maximize the lifespan and recyclability of its equipment.

The building and construction industry is another significant market driver for circular economy-focused induction motors. With the increasing emphasis on green building practices, there is a growing demand for HVAC systems and elevators that incorporate motors designed for longevity, energy efficiency, and ease of recycling. This sector's shift towards sustainable practices is creating opportunities for innovative motor designs that support circular economy goals.

Agriculture and water management sectors are also showing increased interest in induction motors that align with circular economy principles. These industries require motors that can withstand harsh environments while being easily maintainable and recyclable. The demand in these sectors is driven by the need for sustainable water pumping and irrigation solutions, particularly in regions facing water scarcity and environmental challenges.

Overall, the market demand for induction motors contributing to circular economy initiatives is characterized by a shift towards designs that prioritize longevity, repairability, and recyclability. This trend is expected to continue as industries across the board seek to reduce their environmental footprint and align with global sustainability goals. The challenge for manufacturers lies in meeting these demands while maintaining competitive pricing and performance standards.

Current State and Challenges

The current state of induction motors in the context of circular economy initiatives is characterized by both significant progress and persistent challenges. Globally, there is a growing recognition of the need to integrate these widely used electrical machines into sustainable practices, driven by increasing environmental concerns and resource scarcity.

Many manufacturers have begun implementing design strategies that align with circular economy principles. These include modular designs for easier repair and component replacement, the use of recyclable materials, and the development of more energy-efficient models. However, the adoption of these practices is not uniform across the industry, with some regions and companies lagging behind in implementation.

One of the primary challenges facing the industry is the complexity of recycling induction motors at the end of their lifecycle. While the copper windings and steel laminations are relatively easy to recycle, the separation and proper disposal of insulation materials and impregnating resins remain problematic. This issue is compounded by the lack of standardized recycling processes for induction motors across different regions.

Energy efficiency continues to be a focal point in the development of induction motors. While significant improvements have been made, with premium efficiency motors becoming more common, there is still room for further optimization. The challenge lies in balancing increased efficiency with cost-effectiveness, as higher-efficiency motors often come with a higher initial price tag.

The remanufacturing and refurbishment of induction motors present another area of opportunity within the circular economy framework. Many motors can be restored to like-new condition, extending their useful life and reducing waste. However, the industry faces challenges in establishing standardized processes for remanufacturing and in creating a robust market for refurbished motors.

Supply chain considerations also play a crucial role in the circular economy initiatives for induction motors. Sourcing sustainable materials and ensuring responsible production practices throughout the supply chain remain ongoing challenges. Additionally, the global nature of the supply chain can complicate efforts to implement circular economy principles consistently across different regions.

Regulatory frameworks and standards related to the circular economy vary widely across different countries and regions. This lack of uniformity creates challenges for manufacturers operating in global markets, as they must navigate diverse and sometimes conflicting requirements. Harmonizing these regulations and standards could significantly accelerate the adoption of circular economy practices in the induction motor industry.

In conclusion, while progress has been made in integrating induction motors into circular economy initiatives, significant challenges remain. Addressing these challenges will require collaborative efforts from manufacturers, policymakers, and researchers to develop innovative solutions and create a more sustainable future for induction motor production and use.

Many manufacturers have begun implementing design strategies that align with circular economy principles. These include modular designs for easier repair and component replacement, the use of recyclable materials, and the development of more energy-efficient models. However, the adoption of these practices is not uniform across the industry, with some regions and companies lagging behind in implementation.

One of the primary challenges facing the industry is the complexity of recycling induction motors at the end of their lifecycle. While the copper windings and steel laminations are relatively easy to recycle, the separation and proper disposal of insulation materials and impregnating resins remain problematic. This issue is compounded by the lack of standardized recycling processes for induction motors across different regions.

Energy efficiency continues to be a focal point in the development of induction motors. While significant improvements have been made, with premium efficiency motors becoming more common, there is still room for further optimization. The challenge lies in balancing increased efficiency with cost-effectiveness, as higher-efficiency motors often come with a higher initial price tag.

The remanufacturing and refurbishment of induction motors present another area of opportunity within the circular economy framework. Many motors can be restored to like-new condition, extending their useful life and reducing waste. However, the industry faces challenges in establishing standardized processes for remanufacturing and in creating a robust market for refurbished motors.

Supply chain considerations also play a crucial role in the circular economy initiatives for induction motors. Sourcing sustainable materials and ensuring responsible production practices throughout the supply chain remain ongoing challenges. Additionally, the global nature of the supply chain can complicate efforts to implement circular economy principles consistently across different regions.

Regulatory frameworks and standards related to the circular economy vary widely across different countries and regions. This lack of uniformity creates challenges for manufacturers operating in global markets, as they must navigate diverse and sometimes conflicting requirements. Harmonizing these regulations and standards could significantly accelerate the adoption of circular economy practices in the induction motor industry.

In conclusion, while progress has been made in integrating induction motors into circular economy initiatives, significant challenges remain. Addressing these challenges will require collaborative efforts from manufacturers, policymakers, and researchers to develop innovative solutions and create a more sustainable future for induction motor production and use.

Existing Circular Solutions

01 Design and construction of induction motors

This category focuses on the fundamental design and construction aspects of induction motors. It includes innovations in motor structure, winding configurations, and material selection to improve efficiency and performance. These advancements aim to enhance power output, reduce energy losses, and optimize overall motor operation.- Design and construction of induction motors: This category focuses on the fundamental design and construction aspects of induction motors. It includes innovations in motor structure, winding configurations, and material selection to improve efficiency and performance. Advancements in rotor and stator designs are also covered, along with techniques for optimizing magnetic flux distribution.

- Control systems for induction motors: This point covers various control strategies and systems developed for induction motors. It includes methods for speed control, torque regulation, and power factor correction. Advanced control techniques such as vector control, direct torque control, and adaptive control algorithms are also addressed to enhance motor performance and efficiency.

- Energy efficiency improvements in induction motors: This category focuses on techniques and innovations aimed at improving the energy efficiency of induction motors. It includes methods for reducing losses, optimizing motor design for specific applications, and implementing energy-saving control strategies. Advanced materials and manufacturing techniques for enhancing motor efficiency are also covered.

- Specialized applications of induction motors: This point addresses the adaptation and optimization of induction motors for specific applications. It covers designs tailored for industries such as automotive, aerospace, and renewable energy. Innovations in motor sizing, cooling systems, and integration with other components for specialized use cases are included.

- Diagnostics and maintenance of induction motors: This category focuses on methods and systems for monitoring, diagnosing, and maintaining induction motors. It includes techniques for fault detection, condition monitoring, and predictive maintenance. Innovations in sensor technologies, data analysis algorithms, and remote monitoring systems for improving motor reliability and lifespan are covered.

02 Control systems for induction motors

This point covers various control strategies and systems developed for induction motors. It includes advancements in speed control, torque regulation, and power factor correction. These control systems aim to improve motor performance, energy efficiency, and adaptability to different load conditions.Expand Specific Solutions03 Efficiency improvements in induction motors

This category encompasses techniques and innovations aimed at enhancing the energy efficiency of induction motors. It includes advancements in rotor and stator designs, magnetic materials, and cooling systems to reduce power losses and improve overall motor efficiency across various operating conditions.Expand Specific Solutions04 Specialized applications of induction motors

This point focuses on the adaptation and optimization of induction motors for specific industrial applications. It includes designs tailored for high-speed operations, heavy-duty industrial use, and integration with renewable energy systems. These specialized motors are engineered to meet the unique requirements of different sectors and operating environments.Expand Specific Solutions05 Diagnostic and maintenance techniques for induction motors

This category covers methods and systems for monitoring, diagnosing, and maintaining induction motors. It includes advancements in fault detection, predictive maintenance, and condition monitoring techniques. These innovations aim to improve motor reliability, reduce downtime, and extend the operational lifespan of induction motors.Expand Specific Solutions

Key Players and Initiatives

The induction motor industry's contribution to circular economy initiatives is in a nascent stage, with growing market potential as sustainability becomes a key focus. The global market for energy-efficient motors is expanding, driven by increasing environmental regulations and energy cost concerns. Technologically, major players like LG Electronics, Hitachi Industrial Products, and BorgWarner are advancing motor designs for improved efficiency and recyclability. Companies such as Nidec Motor Corp. and Mitsubishi Electric are developing smart motors with longer lifespans and easier maintenance. While progress is being made, the industry is still in the early phases of fully embracing circular economy principles, with opportunities for further innovation in materials, design, and end-of-life management.

HD Hyundai Electric Co., Ltd.

Technical Solution: HD Hyundai Electric has developed innovative induction motor technologies that contribute to circular economy initiatives. Their approach focuses on improving energy efficiency and reducing environmental impact throughout the motor's lifecycle. The company has introduced a series of high-efficiency motors that utilize advanced magnetic materials and optimized designs to reduce energy losses[13]. HD Hyundai Electric has implemented a comprehensive recycling program for motor components, including the recovery of rare earth materials from permanent magnets[14]. They have also developed a smart motor system that integrates IoT and big data analytics to optimize performance and predict maintenance needs, extending the motor's operational life[15].

Strengths: High-efficiency motors with advanced materials, comprehensive recycling program including rare earth recovery, smart motor systems for optimized performance. Weaknesses: Potential complexity in implementing advanced technologies, may require specialized infrastructure for recycling processes.

Nidec Motor Corp.

Technical Solution: Nidec Motor Corporation has made significant strides in contributing to circular economy initiatives through their induction motor innovations. They have developed a series of high-efficiency motors that exceed IE4 standards, reducing energy consumption by up to 40% compared to conventional models[4]. Nidec's approach includes the use of copper rotor technology and advanced magnetic materials to improve performance while reducing material usage. The company has implemented a comprehensive life cycle assessment program, considering the environmental impact from raw material extraction to end-of-life disposal[5]. Nidec also offers a motor refurbishment service, extending the lifespan of existing motors and reducing waste[6].

Strengths: High-efficiency motors exceeding IE4 standards, comprehensive life cycle assessment, motor refurbishment services. Weaknesses: Potential limitations in retrofitting older systems, higher upfront costs for advanced technologies.

Core Innovations in Motor Design

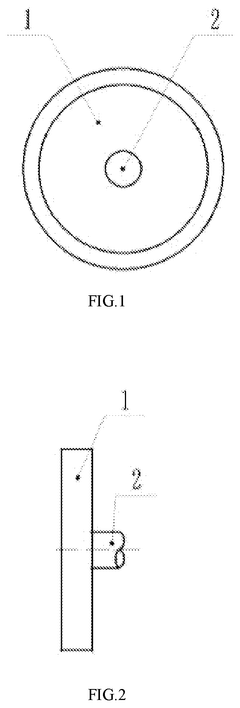

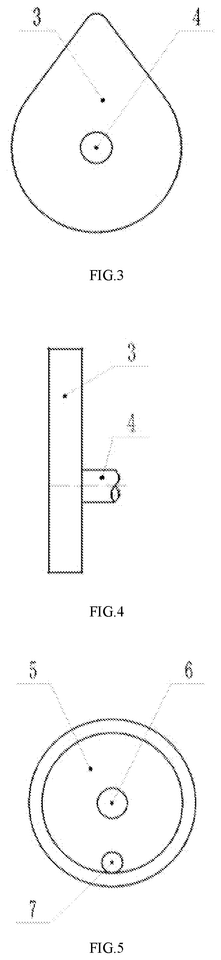

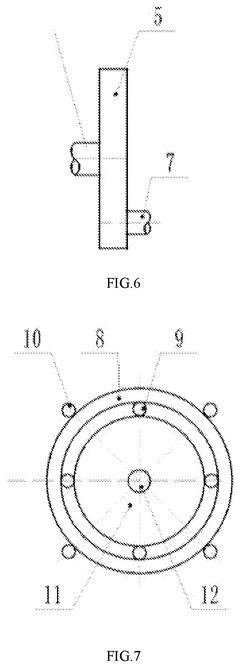

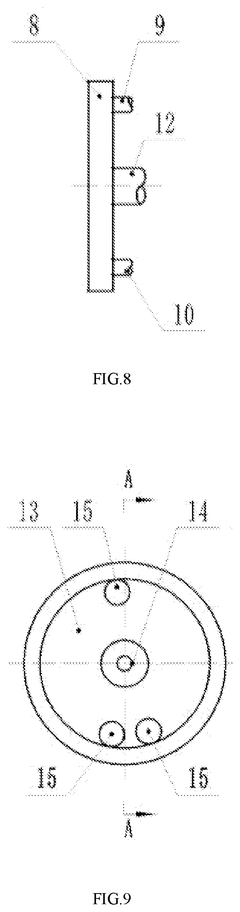

Circumferential engine

PatentPendingUS20240376870A1

Innovation

- The development of a circular engine that utilizes circular motion and gravitational potential energy to generate infinite clean energy, with circular bodies undergoing motion to produce potential energy force greater than the driving force, achieving zero consumption, zero emissions, and zero pollution.

Environmental Impact Assessment

The environmental impact assessment of induction motors in the context of circular economy initiatives reveals both positive and negative effects. On the positive side, the adoption of circular economy principles in the production and use of induction motors can significantly reduce their environmental footprint. By implementing strategies such as remanufacturing, refurbishing, and recycling, the demand for raw materials can be decreased, leading to reduced mining activities and associated environmental degradation.

Furthermore, the circular economy approach promotes the design of more durable and energy-efficient induction motors. This results in extended product lifespans and lower energy consumption during operation, contributing to reduced greenhouse gas emissions and overall environmental impact. The emphasis on repair and maintenance within the circular economy model also helps to minimize waste generation and landfill usage.

However, there are potential negative environmental impacts to consider. The processes involved in remanufacturing and recycling induction motors may require additional energy and resources, potentially offsetting some of the environmental benefits. Additionally, the transportation of used motors for refurbishment or recycling can contribute to increased carbon emissions if not managed efficiently.

The use of certain materials in induction motors, such as rare earth elements, poses environmental challenges. While circular economy initiatives aim to improve resource efficiency, the extraction and processing of these materials can still have significant environmental impacts, including habitat destruction and water pollution.

It is crucial to consider the entire lifecycle of induction motors when assessing their environmental impact within circular economy initiatives. This includes evaluating the environmental costs of production, use, maintenance, and end-of-life management. Life Cycle Assessment (LCA) studies have shown that the operational phase of induction motors typically accounts for the majority of their environmental impact, primarily due to energy consumption.

To maximize the environmental benefits of circular economy initiatives for induction motors, it is essential to focus on improving energy efficiency during operation, as well as optimizing the processes for remanufacturing and recycling. This may involve developing new technologies for material recovery, implementing more efficient logistics systems for reverse supply chains, and promoting the use of renewable energy sources in manufacturing and remanufacturing processes.

Furthermore, the circular economy approach promotes the design of more durable and energy-efficient induction motors. This results in extended product lifespans and lower energy consumption during operation, contributing to reduced greenhouse gas emissions and overall environmental impact. The emphasis on repair and maintenance within the circular economy model also helps to minimize waste generation and landfill usage.

However, there are potential negative environmental impacts to consider. The processes involved in remanufacturing and recycling induction motors may require additional energy and resources, potentially offsetting some of the environmental benefits. Additionally, the transportation of used motors for refurbishment or recycling can contribute to increased carbon emissions if not managed efficiently.

The use of certain materials in induction motors, such as rare earth elements, poses environmental challenges. While circular economy initiatives aim to improve resource efficiency, the extraction and processing of these materials can still have significant environmental impacts, including habitat destruction and water pollution.

It is crucial to consider the entire lifecycle of induction motors when assessing their environmental impact within circular economy initiatives. This includes evaluating the environmental costs of production, use, maintenance, and end-of-life management. Life Cycle Assessment (LCA) studies have shown that the operational phase of induction motors typically accounts for the majority of their environmental impact, primarily due to energy consumption.

To maximize the environmental benefits of circular economy initiatives for induction motors, it is essential to focus on improving energy efficiency during operation, as well as optimizing the processes for remanufacturing and recycling. This may involve developing new technologies for material recovery, implementing more efficient logistics systems for reverse supply chains, and promoting the use of renewable energy sources in manufacturing and remanufacturing processes.

Policy and Standardization

The development of policies and standards plays a crucial role in promoting the contributions of induction motors to circular economy initiatives. Governments and international organizations are increasingly recognizing the importance of sustainable practices in industrial sectors, leading to the implementation of various regulations and guidelines.

One of the key policy areas focuses on energy efficiency standards for induction motors. Many countries have adopted minimum energy performance standards (MEPS) to ensure that motors meet specific efficiency levels. These standards are continuously updated to reflect technological advancements and push manufacturers towards more sustainable designs. For instance, the European Union's Ecodesign Directive sets stringent requirements for motor efficiency, encouraging the adoption of high-efficiency motors across industries.

Standardization efforts also extend to the design and manufacturing processes of induction motors. International standards, such as those developed by the International Electrotechnical Commission (IEC), provide guidelines for motor design, testing, and performance evaluation. These standards facilitate the production of motors with improved durability, repairability, and recyclability, aligning with circular economy principles.

Policies promoting the remanufacturing and refurbishment of induction motors are gaining traction. Some governments offer incentives for companies that engage in motor remanufacturing, recognizing its potential to extend product lifespans and reduce waste. Additionally, standards for remanufactured motors are being developed to ensure their quality and performance meet industry requirements.

The circular economy concept is also being integrated into broader industrial policies. For example, the European Union's Circular Economy Action Plan includes specific measures related to electrical and electronic equipment, which encompass induction motors. These policies aim to promote eco-design, extend product lifespans, and improve recycling processes.

Standardization efforts are underway to establish common methodologies for assessing the environmental impact of induction motors throughout their lifecycle. Life Cycle Assessment (LCA) standards provide a framework for evaluating the environmental footprint of motors, from raw material extraction to end-of-life disposal. These assessments help manufacturers identify areas for improvement and support the development of more sustainable motor designs.

Policies addressing the end-of-life management of induction motors are also emerging. Extended Producer Responsibility (EPR) schemes are being implemented in various countries, requiring manufacturers to take responsibility for the collection and recycling of their products. These policies incentivize the design of motors that are easier to disassemble and recycle, contributing to the circular economy.

One of the key policy areas focuses on energy efficiency standards for induction motors. Many countries have adopted minimum energy performance standards (MEPS) to ensure that motors meet specific efficiency levels. These standards are continuously updated to reflect technological advancements and push manufacturers towards more sustainable designs. For instance, the European Union's Ecodesign Directive sets stringent requirements for motor efficiency, encouraging the adoption of high-efficiency motors across industries.

Standardization efforts also extend to the design and manufacturing processes of induction motors. International standards, such as those developed by the International Electrotechnical Commission (IEC), provide guidelines for motor design, testing, and performance evaluation. These standards facilitate the production of motors with improved durability, repairability, and recyclability, aligning with circular economy principles.

Policies promoting the remanufacturing and refurbishment of induction motors are gaining traction. Some governments offer incentives for companies that engage in motor remanufacturing, recognizing its potential to extend product lifespans and reduce waste. Additionally, standards for remanufactured motors are being developed to ensure their quality and performance meet industry requirements.

The circular economy concept is also being integrated into broader industrial policies. For example, the European Union's Circular Economy Action Plan includes specific measures related to electrical and electronic equipment, which encompass induction motors. These policies aim to promote eco-design, extend product lifespans, and improve recycling processes.

Standardization efforts are underway to establish common methodologies for assessing the environmental impact of induction motors throughout their lifecycle. Life Cycle Assessment (LCA) standards provide a framework for evaluating the environmental footprint of motors, from raw material extraction to end-of-life disposal. These assessments help manufacturers identify areas for improvement and support the development of more sustainable motor designs.

Policies addressing the end-of-life management of induction motors are also emerging. Extended Producer Responsibility (EPR) schemes are being implemented in various countries, requiring manufacturers to take responsibility for the collection and recycling of their products. These policies incentivize the design of motors that are easier to disassemble and recycle, contributing to the circular economy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!