Evaluation of induction motor integration for smarter food systems

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Integration Goals

The integration of induction motors into food systems represents a significant step towards creating smarter, more efficient, and sustainable food production and processing environments. The primary goal of this integration is to enhance the overall performance, energy efficiency, and control capabilities of various food system components, ultimately leading to improved productivity and reduced operational costs.

One of the key objectives is to optimize energy consumption across the food production chain. Induction motors, known for their high efficiency and reliability, can be strategically implemented in various stages of food processing, from initial preparation to packaging. By replacing older, less efficient motor systems with advanced induction motors, food manufacturers can significantly reduce their energy footprint and associated costs.

Another crucial aim is to improve the precision and control of food processing equipment. Induction motors, when coupled with sophisticated control systems, offer superior speed and torque control. This enhanced control allows for more precise operations in mixing, blending, and temperature regulation processes, which are critical in maintaining food quality and safety standards.

Durability and longevity of equipment are also primary considerations in the integration goals. Induction motors are renowned for their robust construction and minimal maintenance requirements. By incorporating these motors into food systems, manufacturers can expect extended equipment lifespan and reduced downtime, leading to improved operational efficiency and cost-effectiveness.

The integration also aims to facilitate the transition towards more automated and intelligent food systems. Induction motors can be seamlessly integrated with smart sensors and IoT (Internet of Things) devices, enabling real-time monitoring and data collection. This integration supports predictive maintenance strategies, allowing for timely interventions and preventing potential equipment failures before they occur.

Furthermore, the goal extends to enhancing the adaptability and flexibility of food processing systems. Modern induction motors with variable speed drives can easily adjust to changing production demands, allowing for quick modifications in processing parameters. This flexibility is crucial in today's dynamic food industry, where consumer preferences and production requirements can change rapidly.

Lastly, the integration of induction motors aligns with the broader goal of creating more sustainable food systems. By improving energy efficiency and reducing waste through precise control, this integration contributes to the reduction of the overall environmental impact of food production processes. This aspect is increasingly important as the food industry faces growing pressure to adopt more sustainable practices.

One of the key objectives is to optimize energy consumption across the food production chain. Induction motors, known for their high efficiency and reliability, can be strategically implemented in various stages of food processing, from initial preparation to packaging. By replacing older, less efficient motor systems with advanced induction motors, food manufacturers can significantly reduce their energy footprint and associated costs.

Another crucial aim is to improve the precision and control of food processing equipment. Induction motors, when coupled with sophisticated control systems, offer superior speed and torque control. This enhanced control allows for more precise operations in mixing, blending, and temperature regulation processes, which are critical in maintaining food quality and safety standards.

Durability and longevity of equipment are also primary considerations in the integration goals. Induction motors are renowned for their robust construction and minimal maintenance requirements. By incorporating these motors into food systems, manufacturers can expect extended equipment lifespan and reduced downtime, leading to improved operational efficiency and cost-effectiveness.

The integration also aims to facilitate the transition towards more automated and intelligent food systems. Induction motors can be seamlessly integrated with smart sensors and IoT (Internet of Things) devices, enabling real-time monitoring and data collection. This integration supports predictive maintenance strategies, allowing for timely interventions and preventing potential equipment failures before they occur.

Furthermore, the goal extends to enhancing the adaptability and flexibility of food processing systems. Modern induction motors with variable speed drives can easily adjust to changing production demands, allowing for quick modifications in processing parameters. This flexibility is crucial in today's dynamic food industry, where consumer preferences and production requirements can change rapidly.

Lastly, the integration of induction motors aligns with the broader goal of creating more sustainable food systems. By improving energy efficiency and reducing waste through precise control, this integration contributes to the reduction of the overall environmental impact of food production processes. This aspect is increasingly important as the food industry faces growing pressure to adopt more sustainable practices.

Smart Food System Market Analysis

The smart food system market is experiencing significant growth driven by increasing demand for efficient and sustainable food production and distribution. This market encompasses a wide range of technologies and solutions aimed at optimizing various aspects of the food supply chain, from farm to fork. The integration of induction motors in smart food systems represents a key technological advancement that is reshaping the industry landscape.

Market demand for smart food systems is primarily fueled by the need to address global food security challenges, reduce food waste, and improve overall efficiency in food production and distribution. The growing world population, coupled with urbanization and changing consumer preferences, has created a pressing need for innovative solutions in the food industry. Smart food systems offer the potential to increase crop yields, reduce resource consumption, and enhance food quality and safety.

The market for smart food systems is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) expected to exceed 10% through 2025. This growth is attributed to increasing investments in agricultural technology, government initiatives promoting sustainable farming practices, and the adoption of Internet of Things (IoT) and artificial intelligence (AI) in the food industry.

Induction motors play a crucial role in various applications within smart food systems, including automated harvesting equipment, processing machinery, and advanced packaging systems. The integration of these motors contributes to improved energy efficiency, precise control, and enhanced reliability in food production and processing operations. As a result, the demand for induction motors in smart food systems is expected to grow in tandem with the overall market expansion.

Key market segments within the smart food system industry include precision agriculture, smart greenhouse solutions, automated food processing, and intelligent food packaging. Each of these segments presents unique opportunities for the integration of induction motors to drive innovation and efficiency improvements. For instance, in precision agriculture, induction motors are being utilized in autonomous tractors and irrigation systems, enabling more precise and resource-efficient farming practices.

Geographically, North America and Europe currently lead the smart food system market, owing to their advanced technological infrastructure and strong focus on sustainable agriculture. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing food demand, and government initiatives to modernize agricultural practices.

As the smart food system market continues to evolve, the integration of induction motors is likely to play an increasingly important role in driving innovation and efficiency improvements across the food supply chain. This trend presents significant opportunities for motor manufacturers, system integrators, and technology providers to contribute to the development of more sustainable and productive food systems.

Market demand for smart food systems is primarily fueled by the need to address global food security challenges, reduce food waste, and improve overall efficiency in food production and distribution. The growing world population, coupled with urbanization and changing consumer preferences, has created a pressing need for innovative solutions in the food industry. Smart food systems offer the potential to increase crop yields, reduce resource consumption, and enhance food quality and safety.

The market for smart food systems is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) expected to exceed 10% through 2025. This growth is attributed to increasing investments in agricultural technology, government initiatives promoting sustainable farming practices, and the adoption of Internet of Things (IoT) and artificial intelligence (AI) in the food industry.

Induction motors play a crucial role in various applications within smart food systems, including automated harvesting equipment, processing machinery, and advanced packaging systems. The integration of these motors contributes to improved energy efficiency, precise control, and enhanced reliability in food production and processing operations. As a result, the demand for induction motors in smart food systems is expected to grow in tandem with the overall market expansion.

Key market segments within the smart food system industry include precision agriculture, smart greenhouse solutions, automated food processing, and intelligent food packaging. Each of these segments presents unique opportunities for the integration of induction motors to drive innovation and efficiency improvements. For instance, in precision agriculture, induction motors are being utilized in autonomous tractors and irrigation systems, enabling more precise and resource-efficient farming practices.

Geographically, North America and Europe currently lead the smart food system market, owing to their advanced technological infrastructure and strong focus on sustainable agriculture. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing food demand, and government initiatives to modernize agricultural practices.

As the smart food system market continues to evolve, the integration of induction motors is likely to play an increasingly important role in driving innovation and efficiency improvements across the food supply chain. This trend presents significant opportunities for motor manufacturers, system integrators, and technology providers to contribute to the development of more sustainable and productive food systems.

Induction Motor Tech Challenges

The integration of induction motors in food systems presents several technical challenges that need to be addressed for successful implementation. One of the primary obstacles is the precise control of motor speed and torque in varying load conditions, which is crucial for maintaining consistent food processing quality. Traditional control methods often struggle to adapt quickly to sudden changes in load, leading to inefficiencies and potential product quality issues.

Another significant challenge lies in the energy efficiency of induction motors in food processing applications. While induction motors are known for their robustness, they can be less efficient than some alternative motor types, especially at partial loads. This becomes particularly important in food systems where energy consumption directly impacts operational costs and sustainability goals.

The harsh operating environment in food processing facilities poses additional challenges for induction motor integration. Exposure to moisture, temperature fluctuations, and potentially corrosive substances can accelerate motor wear and reduce reliability. Developing adequate protection and sealing solutions without compromising motor performance or increasing maintenance complexity is a critical technical hurdle.

Electromagnetic interference (EMI) generated by induction motors can also be problematic in food processing environments. EMI can disrupt sensitive electronic equipment used for process control and quality monitoring, necessitating effective shielding and filtering techniques that do not impede motor performance or system integration.

The need for precise positioning and motion control in certain food processing applications presents another challenge for induction motor systems. Achieving the required level of accuracy and repeatability, especially in high-speed operations, often demands advanced control algorithms and feedback systems that can be complex to implement and maintain.

Thermal management is a critical concern, particularly in applications where motors are integrated into compact food processing equipment. Efficient heat dissipation is essential to prevent overheating, which can lead to reduced motor lifespan and potential food safety issues. Developing effective cooling solutions that comply with food safety regulations adds another layer of complexity to the integration process.

Lastly, the integration of induction motors into smart food systems requires addressing the challenge of data acquisition and communication. Implementing sensors and communication interfaces that can reliably monitor motor performance, predict maintenance needs, and integrate with broader process control systems without compromising food safety or operational efficiency is a significant technical hurdle that requires innovative solutions.

Another significant challenge lies in the energy efficiency of induction motors in food processing applications. While induction motors are known for their robustness, they can be less efficient than some alternative motor types, especially at partial loads. This becomes particularly important in food systems where energy consumption directly impacts operational costs and sustainability goals.

The harsh operating environment in food processing facilities poses additional challenges for induction motor integration. Exposure to moisture, temperature fluctuations, and potentially corrosive substances can accelerate motor wear and reduce reliability. Developing adequate protection and sealing solutions without compromising motor performance or increasing maintenance complexity is a critical technical hurdle.

Electromagnetic interference (EMI) generated by induction motors can also be problematic in food processing environments. EMI can disrupt sensitive electronic equipment used for process control and quality monitoring, necessitating effective shielding and filtering techniques that do not impede motor performance or system integration.

The need for precise positioning and motion control in certain food processing applications presents another challenge for induction motor systems. Achieving the required level of accuracy and repeatability, especially in high-speed operations, often demands advanced control algorithms and feedback systems that can be complex to implement and maintain.

Thermal management is a critical concern, particularly in applications where motors are integrated into compact food processing equipment. Efficient heat dissipation is essential to prevent overheating, which can lead to reduced motor lifespan and potential food safety issues. Developing effective cooling solutions that comply with food safety regulations adds another layer of complexity to the integration process.

Lastly, the integration of induction motors into smart food systems requires addressing the challenge of data acquisition and communication. Implementing sensors and communication interfaces that can reliably monitor motor performance, predict maintenance needs, and integrate with broader process control systems without compromising food safety or operational efficiency is a significant technical hurdle that requires innovative solutions.

Current Motor Integration Solutions

01 Induction motor design and construction

This category focuses on the design and construction aspects of induction motors, including improvements in rotor and stator configurations, winding arrangements, and material selection to enhance performance and efficiency.- Induction motor design and construction: This category focuses on the design and construction aspects of induction motors, including improvements in rotor and stator configurations, winding arrangements, and material selection to enhance performance and efficiency.

- Control systems for induction motors: This point covers various control systems and methods for induction motors, including advanced algorithms, sensor technologies, and feedback mechanisms to optimize motor operation, speed control, and energy efficiency.

- Thermal management in induction motors: This category addresses thermal management solutions for induction motors, including cooling systems, heat dissipation techniques, and temperature monitoring to improve motor reliability and longevity.

- Induction motor applications in specific industries: This point focuses on the application of induction motors in various industries, such as automotive, renewable energy, and industrial automation, highlighting specialized designs and adaptations for specific use cases.

- Diagnostics and maintenance of induction motors: This category covers diagnostic tools, techniques, and maintenance strategies for induction motors, including condition monitoring, fault detection, and predictive maintenance approaches to ensure optimal motor performance and longevity.

02 Control systems for induction motors

This point covers various control systems and methods for induction motors, including advanced algorithms, sensor technologies, and feedback mechanisms to optimize motor operation, speed control, and energy efficiency.Expand Specific Solutions03 Induction motor applications in specific industries

This category explores the use of induction motors in particular industries or applications, such as automotive, renewable energy, or industrial automation, addressing specific requirements and challenges in these sectors.Expand Specific Solutions04 Thermal management and cooling systems

This point focuses on thermal management solutions for induction motors, including innovative cooling systems, heat dissipation techniques, and temperature monitoring to improve motor reliability and longevity.Expand Specific Solutions05 Fault detection and diagnostics

This category covers methods and systems for detecting and diagnosing faults in induction motors, including advanced sensing technologies, data analysis techniques, and predictive maintenance strategies to minimize downtime and improve reliability.Expand Specific Solutions

Key Players in Smart Food Tech

The integration of induction motors in food systems is in a growth phase, with increasing market size driven by the demand for smarter, more efficient appliances. The global market for smart kitchen appliances is expanding rapidly, with major players like Electrolux, BSH Hausgeräte, and Joyoung leading innovation. Technological maturity varies, with established companies like Mitsubishi Electric and Robert Bosch GmbH offering advanced solutions, while newer entrants like Chef Robotics are pushing boundaries in automation. The competitive landscape is diverse, featuring traditional appliance manufacturers, specialized induction technology firms like INDUCS AG and CookTek, and emerging players in food tech robotics, indicating a dynamic and evolving market.

Electrolux Appliances AB

Technical Solution: Electrolux has developed advanced induction motor integration for smarter food systems, focusing on energy efficiency and precise control. Their technology utilizes variable frequency drives to optimize motor performance based on load requirements. The system incorporates smart sensors and IoT connectivity to monitor and adjust motor parameters in real-time, enhancing overall system efficiency. Electrolux's solution also features adaptive control algorithms that learn from usage patterns to further improve energy consumption and performance over time [1][3]. The integration extends to kitchen appliances, enabling seamless communication between devices for coordinated operation and energy management.

Strengths: Energy efficiency, precise control, IoT integration, and adaptive learning capabilities. Weaknesses: Potentially higher initial cost and complexity in implementation.

BSH Hausgeräte GmbH

Technical Solution: BSH has implemented a comprehensive induction motor integration strategy for smarter food systems, focusing on sustainability and user experience. Their approach combines high-efficiency induction motors with advanced power electronics and intelligent control systems. The technology utilizes sensorless vector control algorithms to optimize motor performance across various operating conditions. BSH's solution incorporates predictive maintenance features, using motor current signature analysis to detect potential issues before they lead to failures [2][4]. The integration extends to connected kitchen ecosystems, allowing for synchronized operation of multiple appliances and energy optimization at the household level.

Strengths: High efficiency, predictive maintenance capabilities, and ecosystem integration. Weaknesses: May require specialized maintenance and potential compatibility issues with older systems.

Core Innovations in Food Motors

Improvements in induction motor systems

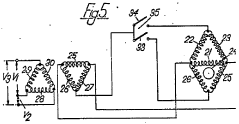

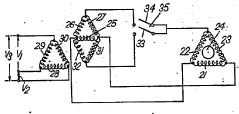

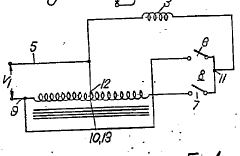

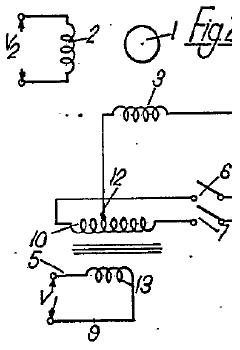

PatentInactiveGB1034443A

Innovation

- A bipolar switch device using paired opposed controlled rectifiers is employed to reverse the phase sequence of stator windings, allowing for efficient and rapid reversal of induction motor rotation by controlling the energization of stator windings through a solid-state switching mechanism.

Electronically controlled high efficiency induction motor

PatentActiveIN201741046575A

Innovation

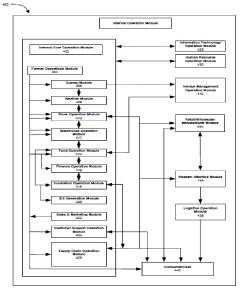

- A comprehensive system integrating advanced communication, artificial intelligence, sensor detection, and data processing to facilitate user interaction, optimize crop selection, and manage farm operations, incorporating data from various industry sources for improved decision-making and resource allocation.

Energy Efficiency Considerations

Energy efficiency is a critical consideration in the integration of induction motors for smarter food systems. As the food industry increasingly adopts automation and intelligent technologies, the energy consumption of these systems becomes a significant factor in both operational costs and environmental impact. Induction motors, being widely used in various food processing and handling equipment, play a crucial role in determining the overall energy efficiency of these systems.

The efficiency of induction motors in food systems can be improved through several strategies. Variable frequency drives (VFDs) are one of the most effective methods for enhancing energy efficiency. By allowing motors to operate at variable speeds, VFDs can match the motor's output to the actual load requirements, significantly reducing energy waste during periods of low demand. This is particularly beneficial in food processing applications where load requirements can fluctuate widely.

Motor sizing is another important aspect of energy efficiency. Properly sized motors that match the load requirements of the specific food system application can operate at their optimal efficiency point, minimizing energy losses. Oversized motors, which are common in many industrial settings, tend to operate at partial loads, leading to reduced efficiency and increased energy consumption.

Advanced motor designs, such as premium efficiency and super-premium efficiency motors, offer substantial energy savings compared to standard efficiency models. These motors utilize improved materials and construction techniques to minimize losses, resulting in higher efficiency across a wide range of operating conditions. While they may have a higher initial cost, the long-term energy savings often justify the investment, especially in food systems with high operating hours.

Power quality management is also crucial for maximizing the energy efficiency of induction motors in food systems. Harmonics, voltage imbalances, and power factor issues can all contribute to increased energy losses and reduced motor efficiency. Implementing power quality improvement measures, such as harmonic filters and power factor correction equipment, can help mitigate these issues and improve overall system efficiency.

Maintenance practices play a significant role in sustaining the energy efficiency of induction motors over time. Regular maintenance, including proper lubrication, alignment checks, and timely replacement of worn components, can prevent efficiency degradation and extend the motor's operational life. Predictive maintenance techniques, such as vibration analysis and thermal imaging, can help identify potential issues before they lead to significant energy losses or equipment failure.

In the context of smarter food systems, the integration of induction motors with intelligent control systems and IoT technologies offers new opportunities for energy optimization. Real-time monitoring of motor performance, coupled with data analytics, can provide insights into energy consumption patterns and identify opportunities for further efficiency improvements. This data-driven approach allows for dynamic adjustments to motor operation based on changing production demands and environmental conditions, maximizing energy efficiency across the entire food processing system.

The efficiency of induction motors in food systems can be improved through several strategies. Variable frequency drives (VFDs) are one of the most effective methods for enhancing energy efficiency. By allowing motors to operate at variable speeds, VFDs can match the motor's output to the actual load requirements, significantly reducing energy waste during periods of low demand. This is particularly beneficial in food processing applications where load requirements can fluctuate widely.

Motor sizing is another important aspect of energy efficiency. Properly sized motors that match the load requirements of the specific food system application can operate at their optimal efficiency point, minimizing energy losses. Oversized motors, which are common in many industrial settings, tend to operate at partial loads, leading to reduced efficiency and increased energy consumption.

Advanced motor designs, such as premium efficiency and super-premium efficiency motors, offer substantial energy savings compared to standard efficiency models. These motors utilize improved materials and construction techniques to minimize losses, resulting in higher efficiency across a wide range of operating conditions. While they may have a higher initial cost, the long-term energy savings often justify the investment, especially in food systems with high operating hours.

Power quality management is also crucial for maximizing the energy efficiency of induction motors in food systems. Harmonics, voltage imbalances, and power factor issues can all contribute to increased energy losses and reduced motor efficiency. Implementing power quality improvement measures, such as harmonic filters and power factor correction equipment, can help mitigate these issues and improve overall system efficiency.

Maintenance practices play a significant role in sustaining the energy efficiency of induction motors over time. Regular maintenance, including proper lubrication, alignment checks, and timely replacement of worn components, can prevent efficiency degradation and extend the motor's operational life. Predictive maintenance techniques, such as vibration analysis and thermal imaging, can help identify potential issues before they lead to significant energy losses or equipment failure.

In the context of smarter food systems, the integration of induction motors with intelligent control systems and IoT technologies offers new opportunities for energy optimization. Real-time monitoring of motor performance, coupled with data analytics, can provide insights into energy consumption patterns and identify opportunities for further efficiency improvements. This data-driven approach allows for dynamic adjustments to motor operation based on changing production demands and environmental conditions, maximizing energy efficiency across the entire food processing system.

Food Safety Regulations Impact

The integration of induction motors in food systems has significant implications for food safety regulations. As these advanced technologies become more prevalent in food processing and handling, regulatory bodies are adapting their frameworks to ensure consumer safety while fostering innovation.

One of the primary impacts of induction motor integration is the need for updated safety standards. Traditional food safety regulations often focus on manual processes and basic machinery. However, with the introduction of smart, motor-driven systems, regulators are developing new guidelines to address potential risks associated with automated equipment. These include protocols for monitoring motor performance, ensuring proper maintenance, and preventing contamination from motor-related components.

The increased precision and control offered by induction motors in food systems have led to more stringent requirements for temperature management and process consistency. Regulatory bodies are now emphasizing the importance of accurate sensor data and real-time monitoring capabilities. This shift has resulted in the development of new compliance measures that food manufacturers must adhere to, particularly in areas such as cooking, cooling, and storage processes.

Energy efficiency regulations are also evolving in response to the widespread adoption of induction motors. Many jurisdictions are implementing stricter energy consumption standards for food processing equipment, encouraging the use of high-efficiency motors and smart control systems. This regulatory push is driving manufacturers to invest in more advanced motor technologies that not only improve energy efficiency but also enhance overall food safety through better process control.

The integration of induction motors has also prompted regulators to address cybersecurity concerns in food systems. As these motors are often part of interconnected, smart manufacturing environments, new regulations are being introduced to protect against potential cyber threats that could compromise food safety. This includes guidelines for secure data transmission, access control, and system integrity verification.

Furthermore, the use of induction motors in food systems has led to changes in traceability requirements. Regulators are now demanding more comprehensive data logging and reporting capabilities from food manufacturers. This includes detailed records of motor performance, operational parameters, and any deviations from set processes, all of which contribute to a more robust food safety management system.

In response to these technological advancements, regulatory bodies are also updating their inspection and auditing procedures. Inspectors are being trained to evaluate the performance and safety of motor-integrated systems, requiring a new set of skills and knowledge. This has led to the development of specialized certification programs for both inspectors and food system operators.

One of the primary impacts of induction motor integration is the need for updated safety standards. Traditional food safety regulations often focus on manual processes and basic machinery. However, with the introduction of smart, motor-driven systems, regulators are developing new guidelines to address potential risks associated with automated equipment. These include protocols for monitoring motor performance, ensuring proper maintenance, and preventing contamination from motor-related components.

The increased precision and control offered by induction motors in food systems have led to more stringent requirements for temperature management and process consistency. Regulatory bodies are now emphasizing the importance of accurate sensor data and real-time monitoring capabilities. This shift has resulted in the development of new compliance measures that food manufacturers must adhere to, particularly in areas such as cooking, cooling, and storage processes.

Energy efficiency regulations are also evolving in response to the widespread adoption of induction motors. Many jurisdictions are implementing stricter energy consumption standards for food processing equipment, encouraging the use of high-efficiency motors and smart control systems. This regulatory push is driving manufacturers to invest in more advanced motor technologies that not only improve energy efficiency but also enhance overall food safety through better process control.

The integration of induction motors has also prompted regulators to address cybersecurity concerns in food systems. As these motors are often part of interconnected, smart manufacturing environments, new regulations are being introduced to protect against potential cyber threats that could compromise food safety. This includes guidelines for secure data transmission, access control, and system integrity verification.

Furthermore, the use of induction motors in food systems has led to changes in traceability requirements. Regulators are now demanding more comprehensive data logging and reporting capabilities from food manufacturers. This includes detailed records of motor performance, operational parameters, and any deviations from set processes, all of which contribute to a more robust food safety management system.

In response to these technological advancements, regulatory bodies are also updating their inspection and auditing procedures. Inspectors are being trained to evaluate the performance and safety of motor-integrated systems, requiring a new set of skills and knowledge. This has led to the development of specialized certification programs for both inspectors and food system operators.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!