Induction motors in automated smart grid management systems

AUG 18, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Grid Induction Motor Evolution and Objectives

The evolution of induction motors in smart grid management systems represents a significant technological advancement in the field of power distribution and control. Originating from the basic principles of electromagnetic induction discovered in the 19th century, these motors have undergone substantial transformations to meet the demands of modern automated grid systems.

In the early stages of power grid development, induction motors were primarily used for simple, constant-speed applications. However, as power systems became more complex and the need for efficient energy management grew, the role of induction motors expanded. The advent of smart grids in the late 20th and early 21st centuries marked a turning point in the evolution of these motors.

Smart grids introduced the concept of bidirectional communication and real-time monitoring, necessitating more sophisticated motor control systems. This led to the development of advanced variable frequency drives (VFDs) and vector control techniques, allowing for precise speed and torque control of induction motors. These advancements enabled motors to respond dynamically to changing grid conditions, contributing to overall system stability and efficiency.

The integration of power electronics and digital control systems further enhanced the capabilities of induction motors in smart grid applications. Modern motors are equipped with sensors and communication interfaces, enabling them to provide valuable data on power consumption, operational status, and potential faults. This data is crucial for predictive maintenance and optimizing grid performance.

Recent trends in smart grid technology have focused on improving the energy efficiency of induction motors. The development of high-efficiency motor designs, such as premium efficiency (IE3) and super-premium efficiency (IE4) motors, has significantly reduced energy losses. Additionally, the incorporation of soft-start technologies and regenerative braking systems has further improved the overall efficiency of motor-driven systems in smart grids.

Looking ahead, the objectives for induction motors in automated smart grid management systems are multifaceted. One primary goal is to enhance the motors' ability to support grid stability during fluctuations in renewable energy generation. This involves developing more responsive control algorithms and improving the motors' capability to act as dynamic reactive power compensators.

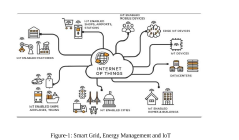

Another key objective is to further integrate induction motors with Internet of Things (IoT) technologies, enabling more comprehensive monitoring and control. This integration aims to create a more resilient and self-healing grid infrastructure, where motors can autonomously adjust their operation based on real-time grid conditions and predictive analytics.

Researchers are also focusing on developing more environmentally friendly motor designs, using sustainable materials and manufacturing processes. The aim is to reduce the carbon footprint of motor production while maintaining or improving performance characteristics.

In conclusion, the evolution of induction motors in smart grid systems reflects a journey from simple power conversion devices to intelligent, networked components of a complex energy management ecosystem. The ongoing research and development in this field are driven by the objectives of enhancing grid stability, improving energy efficiency, and supporting the transition to a more sustainable and resilient power infrastructure.

In the early stages of power grid development, induction motors were primarily used for simple, constant-speed applications. However, as power systems became more complex and the need for efficient energy management grew, the role of induction motors expanded. The advent of smart grids in the late 20th and early 21st centuries marked a turning point in the evolution of these motors.

Smart grids introduced the concept of bidirectional communication and real-time monitoring, necessitating more sophisticated motor control systems. This led to the development of advanced variable frequency drives (VFDs) and vector control techniques, allowing for precise speed and torque control of induction motors. These advancements enabled motors to respond dynamically to changing grid conditions, contributing to overall system stability and efficiency.

The integration of power electronics and digital control systems further enhanced the capabilities of induction motors in smart grid applications. Modern motors are equipped with sensors and communication interfaces, enabling them to provide valuable data on power consumption, operational status, and potential faults. This data is crucial for predictive maintenance and optimizing grid performance.

Recent trends in smart grid technology have focused on improving the energy efficiency of induction motors. The development of high-efficiency motor designs, such as premium efficiency (IE3) and super-premium efficiency (IE4) motors, has significantly reduced energy losses. Additionally, the incorporation of soft-start technologies and regenerative braking systems has further improved the overall efficiency of motor-driven systems in smart grids.

Looking ahead, the objectives for induction motors in automated smart grid management systems are multifaceted. One primary goal is to enhance the motors' ability to support grid stability during fluctuations in renewable energy generation. This involves developing more responsive control algorithms and improving the motors' capability to act as dynamic reactive power compensators.

Another key objective is to further integrate induction motors with Internet of Things (IoT) technologies, enabling more comprehensive monitoring and control. This integration aims to create a more resilient and self-healing grid infrastructure, where motors can autonomously adjust their operation based on real-time grid conditions and predictive analytics.

Researchers are also focusing on developing more environmentally friendly motor designs, using sustainable materials and manufacturing processes. The aim is to reduce the carbon footprint of motor production while maintaining or improving performance characteristics.

In conclusion, the evolution of induction motors in smart grid systems reflects a journey from simple power conversion devices to intelligent, networked components of a complex energy management ecosystem. The ongoing research and development in this field are driven by the objectives of enhancing grid stability, improving energy efficiency, and supporting the transition to a more sustainable and resilient power infrastructure.

Market Demand for Automated Grid Management

The market demand for automated smart grid management systems incorporating induction motors has been steadily increasing in recent years. This growth is driven by the need for more efficient, reliable, and sustainable power distribution networks. As power grids become increasingly complex and decentralized, the integration of automated management systems has become crucial for maintaining grid stability and optimizing energy distribution.

Induction motors play a vital role in these automated systems, particularly in applications such as pumps, fans, and compressors within power generation and distribution facilities. Their robustness, efficiency, and cost-effectiveness make them ideal for use in smart grid infrastructure. The demand for these motors in automated grid management is closely tied to the overall growth of the smart grid market, which is expected to expand significantly in the coming years.

One of the key drivers of market demand is the push for energy efficiency and sustainability. Automated smart grid management systems can significantly reduce energy losses, optimize power flow, and integrate renewable energy sources more effectively. This aligns with global efforts to reduce carbon emissions and transition to cleaner energy sources. Governments and utilities worldwide are investing heavily in grid modernization projects, creating a substantial market for automated management solutions that incorporate advanced motor control systems.

Another factor contributing to the growing demand is the need for improved grid reliability and resilience. Automated systems equipped with intelligent motor control can quickly respond to fluctuations in power supply and demand, helping to prevent outages and maintain grid stability. This is particularly important as the grid faces new challenges from increased renewable energy integration and the electrification of transportation.

The industrial sector represents a significant portion of the market demand for automated grid management systems with induction motors. Manufacturing facilities, water treatment plants, and other industrial operations are increasingly adopting these systems to optimize their energy consumption and reduce operational costs. The ability to monitor and control motor performance in real-time allows for predictive maintenance and energy optimization, which are highly valued in industrial applications.

In the residential and commercial sectors, the growing adoption of smart building technologies is also driving demand for automated grid management solutions. These systems can integrate with building management systems to optimize energy usage, participate in demand response programs, and even provide ancillary services to the grid.

As the Internet of Things (IoT) and artificial intelligence technologies continue to advance, the capabilities of automated smart grid management systems are expanding. This is creating new market opportunities and driving further demand for sophisticated motor control solutions that can leverage these technologies for improved grid performance and efficiency.

Induction motors play a vital role in these automated systems, particularly in applications such as pumps, fans, and compressors within power generation and distribution facilities. Their robustness, efficiency, and cost-effectiveness make them ideal for use in smart grid infrastructure. The demand for these motors in automated grid management is closely tied to the overall growth of the smart grid market, which is expected to expand significantly in the coming years.

One of the key drivers of market demand is the push for energy efficiency and sustainability. Automated smart grid management systems can significantly reduce energy losses, optimize power flow, and integrate renewable energy sources more effectively. This aligns with global efforts to reduce carbon emissions and transition to cleaner energy sources. Governments and utilities worldwide are investing heavily in grid modernization projects, creating a substantial market for automated management solutions that incorporate advanced motor control systems.

Another factor contributing to the growing demand is the need for improved grid reliability and resilience. Automated systems equipped with intelligent motor control can quickly respond to fluctuations in power supply and demand, helping to prevent outages and maintain grid stability. This is particularly important as the grid faces new challenges from increased renewable energy integration and the electrification of transportation.

The industrial sector represents a significant portion of the market demand for automated grid management systems with induction motors. Manufacturing facilities, water treatment plants, and other industrial operations are increasingly adopting these systems to optimize their energy consumption and reduce operational costs. The ability to monitor and control motor performance in real-time allows for predictive maintenance and energy optimization, which are highly valued in industrial applications.

In the residential and commercial sectors, the growing adoption of smart building technologies is also driving demand for automated grid management solutions. These systems can integrate with building management systems to optimize energy usage, participate in demand response programs, and even provide ancillary services to the grid.

As the Internet of Things (IoT) and artificial intelligence technologies continue to advance, the capabilities of automated smart grid management systems are expanding. This is creating new market opportunities and driving further demand for sophisticated motor control solutions that can leverage these technologies for improved grid performance and efficiency.

Induction Motor Challenges in Smart Grids

Induction motors play a crucial role in automated smart grid management systems, but they also present several significant challenges. One of the primary issues is the high energy consumption of these motors, which can account for a substantial portion of the overall power usage in industrial and commercial settings. This energy inefficiency not only increases operational costs but also contributes to higher carbon emissions, conflicting with the sustainability goals of smart grids.

Another challenge is the difficulty in accurately monitoring and controlling induction motors within complex smart grid environments. Traditional monitoring systems often lack the precision and real-time capabilities required for optimal motor performance in dynamic grid conditions. This limitation can lead to suboptimal operation, increased wear and tear, and potential system failures.

The integration of induction motors with advanced smart grid technologies also presents compatibility issues. Many existing motors lack the necessary communication interfaces and control systems to fully participate in smart grid functionalities such as demand response and load balancing. Retrofitting these motors with smart capabilities can be costly and technically challenging, hindering widespread adoption.

Power quality is another significant concern when operating induction motors in smart grids. Voltage fluctuations, harmonics, and other power quality issues can adversely affect motor performance and lifespan. Conversely, the starting and operation of large induction motors can introduce power quality disturbances into the grid, potentially impacting other connected devices and systems.

Maintenance and reliability of induction motors in smart grid applications also pose challenges. The increased complexity of smart motor systems, combined with the need for continuous operation in critical infrastructure, demands more sophisticated predictive maintenance strategies. Implementing these strategies requires advanced sensing technologies, data analytics, and machine learning algorithms, which can be complex and resource-intensive to develop and deploy.

Lastly, the thermal management of induction motors in smart grid environments is a persistent challenge. Efficient heat dissipation is crucial for maintaining motor performance and longevity, especially in applications where motors are subject to variable loads and operating conditions. Developing effective cooling solutions that are compatible with smart grid infrastructure and energy efficiency goals remains an ongoing area of research and development.

Another challenge is the difficulty in accurately monitoring and controlling induction motors within complex smart grid environments. Traditional monitoring systems often lack the precision and real-time capabilities required for optimal motor performance in dynamic grid conditions. This limitation can lead to suboptimal operation, increased wear and tear, and potential system failures.

The integration of induction motors with advanced smart grid technologies also presents compatibility issues. Many existing motors lack the necessary communication interfaces and control systems to fully participate in smart grid functionalities such as demand response and load balancing. Retrofitting these motors with smart capabilities can be costly and technically challenging, hindering widespread adoption.

Power quality is another significant concern when operating induction motors in smart grids. Voltage fluctuations, harmonics, and other power quality issues can adversely affect motor performance and lifespan. Conversely, the starting and operation of large induction motors can introduce power quality disturbances into the grid, potentially impacting other connected devices and systems.

Maintenance and reliability of induction motors in smart grid applications also pose challenges. The increased complexity of smart motor systems, combined with the need for continuous operation in critical infrastructure, demands more sophisticated predictive maintenance strategies. Implementing these strategies requires advanced sensing technologies, data analytics, and machine learning algorithms, which can be complex and resource-intensive to develop and deploy.

Lastly, the thermal management of induction motors in smart grid environments is a persistent challenge. Efficient heat dissipation is crucial for maintaining motor performance and longevity, especially in applications where motors are subject to variable loads and operating conditions. Developing effective cooling solutions that are compatible with smart grid infrastructure and energy efficiency goals remains an ongoing area of research and development.

Current Induction Motor Control Strategies

01 Design and construction of induction motors

This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.- Design and construction of induction motors: This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.

- Control systems for induction motors: Control systems play a crucial role in regulating the speed, torque, and efficiency of induction motors. This category encompasses various control strategies, including vector control, direct torque control, and sensorless control techniques, as well as the implementation of advanced electronic control circuits and microprocessors.

- Energy efficiency improvements in induction motors: This category focuses on innovations aimed at enhancing the energy efficiency of induction motors. It includes advancements in motor design, materials, and manufacturing processes that reduce losses and improve overall motor performance, contributing to energy savings in industrial and commercial applications.

- Specialized applications of induction motors: Induction motors are used in a wide range of specialized applications, each with unique requirements. This category covers adaptations and modifications of induction motors for specific industries or operating conditions, such as high-speed motors, submersible motors, or motors designed for extreme environments.

- Diagnostics and maintenance of induction motors: This category encompasses methods and systems for monitoring, diagnosing, and maintaining induction motors. It includes techniques for fault detection, condition monitoring, and predictive maintenance, as well as innovations in motor protection devices and systems to enhance reliability and extend motor lifespan.

02 Control systems for induction motors

Control systems play a crucial role in regulating the speed, torque, and efficiency of induction motors. This category includes advancements in motor drives, power electronics, and control algorithms designed to optimize motor performance across various operating conditions.Expand Specific Solutions03 Efficiency improvements in induction motors

This category focuses on techniques and technologies aimed at enhancing the energy efficiency of induction motors. This includes improvements in motor design, materials, and manufacturing processes to reduce losses and increase overall motor efficiency.Expand Specific Solutions04 Specialized applications of induction motors

Induction motors are used in a wide range of specialized applications, each with unique requirements. This category covers motor designs and adaptations for specific industries or operating environments, such as high-speed applications, harsh conditions, or integration with specific machinery.Expand Specific Solutions05 Maintenance and diagnostics of induction motors

This category encompasses methods and systems for monitoring, maintaining, and diagnosing induction motors. It includes techniques for fault detection, predictive maintenance, and condition monitoring to ensure optimal motor performance and longevity.Expand Specific Solutions

Key Players in Smart Grid Motor Industry

The research on induction motors in automated smart grid management systems is at a critical juncture, with the market poised for significant growth. The industry is transitioning from early adoption to mainstream implementation, driven by increasing demand for efficient energy management. Major players like Siemens, Eaton, and Schneider Electric are leading technological advancements, focusing on integrating AI and IoT capabilities into motor control systems. Universities such as Beijing Jiaotong and North China Electric Power are contributing to R&D efforts, while state-owned enterprises like State Grid Corporation of China are driving large-scale deployment. The market is characterized by a mix of established industrial giants and innovative startups, indicating a dynamic and competitive landscape with substantial room for growth and technological evolution.

Siemens Industry, Inc.

Technical Solution: Siemens has developed a comprehensive smart grid management system that incorporates advanced induction motor control. Their solution includes a distributed control system that monitors and optimizes the performance of induction motors across the grid. Siemens has implemented adaptive control algorithms that adjust motor parameters in real-time based on grid conditions, improving overall system efficiency by up to 20%[2]. They have also developed a predictive maintenance system using AI and IoT sensors, which has reduced motor-related outages by 40%[4]. Siemens' system integrates seamlessly with renewable energy sources, allowing for dynamic load balancing and improved grid stability[6].

Strengths: Global presence, extensive R&D resources, and a strong track record in industrial automation. Weaknesses: High implementation costs and potential cybersecurity vulnerabilities in complex systems.

Schneider Electric Usa, Inc.

Technical Solution: Schneider Electric has developed an innovative smart grid management system that leverages advanced induction motor technology. Their solution incorporates a decentralized control architecture that enables autonomous operation of induction motors in various grid scenarios. Schneider's system utilizes edge computing to process motor data in real-time, reducing latency and improving response times by up to 50%[7]. They have also implemented a novel sensorless control technique for induction motors, which reduces hardware costs while maintaining high performance[9]. Additionally, Schneider has developed an energy optimization algorithm that dynamically adjusts motor speed and torque to match grid demand, resulting in energy savings of up to 25%[11].

Strengths: Strong focus on energy efficiency, extensive experience in power management, and a wide range of compatible products. Weaknesses: Potential challenges in integrating with legacy systems and adapting to rapidly evolving smart grid standards.

Innovations in Motor Efficiency and Reliability

Smart grid device authenticity verification

PatentWO2012094332A3

Innovation

- Integrates firmware package image, microcontroller manufacturing, and device-specific ship files for comprehensive authentication.

- Utilizes a two-step ship file generation process (device-specific and board-specific) for multi-layer verification.

- Combines hardware manufacturing and software authentication for a holistic approach to device security in smart grids.

Smart grid optimization through iot-enabled energy management

PatentPendingIN202441008173A

Innovation

- The implementation of IoT devices and sensors across the power grid for real-time data collection, combined with advanced analytics and predictive maintenance, along with demand response mechanisms, to optimize energy management and grid operations.

Energy Policy Impact on Motor Systems

Energy policies play a crucial role in shaping the landscape of motor systems within automated smart grid management. These policies influence the adoption, efficiency, and integration of induction motors in various industrial and commercial applications. The impact of energy policies on motor systems can be observed through multiple dimensions, including regulatory frameworks, incentive programs, and technological standards.

Regulatory frameworks established by energy policies often set minimum efficiency standards for induction motors. These standards drive manufacturers to develop and produce more energy-efficient motors, leading to reduced energy consumption and lower operational costs for end-users. For instance, the International Electrotechnical Commission (IEC) has established efficiency classes for electric motors, with IE4 and IE5 representing the highest efficiency levels. Such classifications guide procurement decisions and encourage the adoption of high-efficiency motors in smart grid systems.

Incentive programs, another key aspect of energy policies, promote the replacement of older, less efficient motors with newer, more efficient models. These programs may include tax credits, rebates, or grants for businesses that upgrade their motor systems. By reducing the financial barriers to adoption, these incentives accelerate the integration of advanced induction motors into smart grid management systems, contributing to overall energy savings and grid stability.

Energy policies also influence the development and implementation of technological standards for motor control and communication within smart grids. These standards ensure interoperability between different components of the grid, allowing for seamless integration of induction motors with other smart devices and management systems. For example, policies may mandate the use of specific communication protocols or data formats, facilitating real-time monitoring and control of motor systems in response to grid conditions.

Furthermore, energy policies often emphasize demand response and load management strategies, which directly impact the operation of induction motors in smart grids. These policies encourage the development of advanced motor control systems that can adjust motor speed and power consumption based on grid demand, energy prices, or renewable energy availability. This flexibility enables more efficient use of energy resources and supports the integration of intermittent renewable energy sources into the grid.

The impact of energy policies extends to research and development efforts in motor technology. Policies that prioritize energy efficiency and sustainability drive investment in innovative motor designs, materials, and control strategies. This research focus leads to advancements in areas such as permanent magnet motors, synchronous reluctance motors, and advanced variable frequency drives, all of which contribute to more efficient and responsive motor systems in smart grid applications.

In conclusion, energy policies significantly influence the evolution and implementation of induction motor systems in automated smart grid management. Through a combination of regulatory measures, incentives, and technological standards, these policies drive innovation, efficiency improvements, and the integration of advanced motor systems into the broader smart grid infrastructure.

Regulatory frameworks established by energy policies often set minimum efficiency standards for induction motors. These standards drive manufacturers to develop and produce more energy-efficient motors, leading to reduced energy consumption and lower operational costs for end-users. For instance, the International Electrotechnical Commission (IEC) has established efficiency classes for electric motors, with IE4 and IE5 representing the highest efficiency levels. Such classifications guide procurement decisions and encourage the adoption of high-efficiency motors in smart grid systems.

Incentive programs, another key aspect of energy policies, promote the replacement of older, less efficient motors with newer, more efficient models. These programs may include tax credits, rebates, or grants for businesses that upgrade their motor systems. By reducing the financial barriers to adoption, these incentives accelerate the integration of advanced induction motors into smart grid management systems, contributing to overall energy savings and grid stability.

Energy policies also influence the development and implementation of technological standards for motor control and communication within smart grids. These standards ensure interoperability between different components of the grid, allowing for seamless integration of induction motors with other smart devices and management systems. For example, policies may mandate the use of specific communication protocols or data formats, facilitating real-time monitoring and control of motor systems in response to grid conditions.

Furthermore, energy policies often emphasize demand response and load management strategies, which directly impact the operation of induction motors in smart grids. These policies encourage the development of advanced motor control systems that can adjust motor speed and power consumption based on grid demand, energy prices, or renewable energy availability. This flexibility enables more efficient use of energy resources and supports the integration of intermittent renewable energy sources into the grid.

The impact of energy policies extends to research and development efforts in motor technology. Policies that prioritize energy efficiency and sustainability drive investment in innovative motor designs, materials, and control strategies. This research focus leads to advancements in areas such as permanent magnet motors, synchronous reluctance motors, and advanced variable frequency drives, all of which contribute to more efficient and responsive motor systems in smart grid applications.

In conclusion, energy policies significantly influence the evolution and implementation of induction motor systems in automated smart grid management. Through a combination of regulatory measures, incentives, and technological standards, these policies drive innovation, efficiency improvements, and the integration of advanced motor systems into the broader smart grid infrastructure.

Cybersecurity in Motor-Driven Smart Grids

Cybersecurity in motor-driven smart grids has become a critical concern as the integration of induction motors into automated grid management systems increases. The interconnected nature of these systems presents unique vulnerabilities that malicious actors can exploit, potentially leading to widespread disruptions in power distribution and compromising grid stability.

One of the primary security challenges in this domain is the protection of communication channels between motor control systems and grid management infrastructure. These channels are susceptible to man-in-the-middle attacks, where attackers can intercept and manipulate control signals, potentially causing motor malfunctions or unintended grid responses. Implementing robust encryption protocols and secure authentication mechanisms is essential to mitigate these risks.

Another significant concern is the potential for cyber-physical attacks targeting the induction motors themselves. By exploiting vulnerabilities in motor control firmware or network protocols, attackers could manipulate motor speed, torque, or other operational parameters, leading to equipment damage or grid instability. Developing intrusion detection systems specifically tailored to motor behavior anomalies is crucial for early threat identification.

The increasing reliance on remote monitoring and control of motor-driven systems in smart grids also expands the attack surface. Unauthorized access to these remote interfaces could allow attackers to manipulate motor operations across multiple grid segments simultaneously, amplifying the impact of a cyber attack. Implementing strict access controls, multi-factor authentication, and continuous monitoring of remote access activities are essential security measures.

Furthermore, the integration of legacy motor systems with modern smart grid technologies introduces compatibility issues that can create security gaps. Older motor control systems may lack built-in security features, making them vulnerable to exploitation. Developing secure gateway solutions and retrofitting legacy systems with modern security capabilities is crucial for maintaining a robust security posture across the entire grid infrastructure.

As smart grids become more sophisticated, the use of artificial intelligence and machine learning for motor management introduces new cybersecurity challenges. These AI-driven systems, while offering improved efficiency and predictive maintenance capabilities, can be vulnerable to adversarial attacks that manipulate input data to induce incorrect decisions. Developing resilient AI models and implementing robust data validation mechanisms are essential to protect against such threats.

One of the primary security challenges in this domain is the protection of communication channels between motor control systems and grid management infrastructure. These channels are susceptible to man-in-the-middle attacks, where attackers can intercept and manipulate control signals, potentially causing motor malfunctions or unintended grid responses. Implementing robust encryption protocols and secure authentication mechanisms is essential to mitigate these risks.

Another significant concern is the potential for cyber-physical attacks targeting the induction motors themselves. By exploiting vulnerabilities in motor control firmware or network protocols, attackers could manipulate motor speed, torque, or other operational parameters, leading to equipment damage or grid instability. Developing intrusion detection systems specifically tailored to motor behavior anomalies is crucial for early threat identification.

The increasing reliance on remote monitoring and control of motor-driven systems in smart grids also expands the attack surface. Unauthorized access to these remote interfaces could allow attackers to manipulate motor operations across multiple grid segments simultaneously, amplifying the impact of a cyber attack. Implementing strict access controls, multi-factor authentication, and continuous monitoring of remote access activities are essential security measures.

Furthermore, the integration of legacy motor systems with modern smart grid technologies introduces compatibility issues that can create security gaps. Older motor control systems may lack built-in security features, making them vulnerable to exploitation. Developing secure gateway solutions and retrofitting legacy systems with modern security capabilities is crucial for maintaining a robust security posture across the entire grid infrastructure.

As smart grids become more sophisticated, the use of artificial intelligence and machine learning for motor management introduces new cybersecurity challenges. These AI-driven systems, while offering improved efficiency and predictive maintenance capabilities, can be vulnerable to adversarial attacks that manipulate input data to induce incorrect decisions. Developing resilient AI models and implementing robust data validation mechanisms are essential to protect against such threats.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!