How induction motors impact water-efficient climate policy execution

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Technology and Water Efficiency Goals

Induction motors have played a significant role in shaping modern industrial processes, and their impact on water-efficient climate policy execution is becoming increasingly apparent. As global efforts to combat climate change intensify, the intersection of motor technology and water conservation has emerged as a critical area of focus. Induction motors, known for their reliability and efficiency, are widely used in various applications, including water pumping systems, which are essential for implementing water-efficient policies.

The primary goal of integrating induction motor technology with water efficiency objectives is to reduce energy consumption while optimizing water usage. This alignment is crucial for achieving sustainable development targets and mitigating the environmental impact of industrial operations. By improving the efficiency of induction motors in water-related applications, policymakers and industry leaders aim to decrease both energy demand and water consumption, thereby contributing to broader climate change mitigation efforts.

One of the key technological objectives in this domain is the development of advanced control systems for induction motors used in water management. These systems aim to precisely regulate motor speed and torque, allowing for more accurate control of water flow and pressure. This level of precision can significantly reduce water waste and energy consumption in various applications, from municipal water distribution to agricultural irrigation systems.

Another important goal is the integration of smart technologies with induction motor-driven water systems. This includes the implementation of Internet of Things (IoT) devices and data analytics to optimize motor performance based on real-time water demand and environmental conditions. By leveraging these technologies, water utilities and industrial facilities can achieve more efficient water distribution and usage patterns, directly supporting climate policy objectives.

The development of more energy-efficient induction motor designs specifically tailored for water applications is also a critical technological goal. This involves research into advanced materials, improved manufacturing techniques, and innovative motor topologies that can deliver higher efficiency across a wide range of operating conditions. These advancements aim to reduce the overall energy footprint of water management systems, aligning with broader energy conservation policies.

Furthermore, there is a growing focus on the lifecycle assessment of induction motors in water-efficient applications. This holistic approach considers not only the operational efficiency of motors but also their environmental impact during manufacturing, installation, and end-of-life disposal. By optimizing these aspects, the industry aims to create more sustainable solutions that support long-term climate policy goals.

The primary goal of integrating induction motor technology with water efficiency objectives is to reduce energy consumption while optimizing water usage. This alignment is crucial for achieving sustainable development targets and mitigating the environmental impact of industrial operations. By improving the efficiency of induction motors in water-related applications, policymakers and industry leaders aim to decrease both energy demand and water consumption, thereby contributing to broader climate change mitigation efforts.

One of the key technological objectives in this domain is the development of advanced control systems for induction motors used in water management. These systems aim to precisely regulate motor speed and torque, allowing for more accurate control of water flow and pressure. This level of precision can significantly reduce water waste and energy consumption in various applications, from municipal water distribution to agricultural irrigation systems.

Another important goal is the integration of smart technologies with induction motor-driven water systems. This includes the implementation of Internet of Things (IoT) devices and data analytics to optimize motor performance based on real-time water demand and environmental conditions. By leveraging these technologies, water utilities and industrial facilities can achieve more efficient water distribution and usage patterns, directly supporting climate policy objectives.

The development of more energy-efficient induction motor designs specifically tailored for water applications is also a critical technological goal. This involves research into advanced materials, improved manufacturing techniques, and innovative motor topologies that can deliver higher efficiency across a wide range of operating conditions. These advancements aim to reduce the overall energy footprint of water management systems, aligning with broader energy conservation policies.

Furthermore, there is a growing focus on the lifecycle assessment of induction motors in water-efficient applications. This holistic approach considers not only the operational efficiency of motors but also their environmental impact during manufacturing, installation, and end-of-life disposal. By optimizing these aspects, the industry aims to create more sustainable solutions that support long-term climate policy goals.

Market Demand for Water-Efficient Climate Solutions

The market demand for water-efficient climate solutions has been steadily increasing in recent years, driven by growing environmental concerns and the need for sustainable resource management. As climate change continues to impact water availability and distribution patterns globally, industries and governments are seeking innovative technologies to address these challenges.

In the industrial sector, there is a significant demand for water-efficient solutions, particularly in manufacturing processes that rely heavily on water consumption. Companies are increasingly recognizing the importance of reducing their water footprint not only for environmental reasons but also for cost-saving purposes. This has led to a surge in demand for advanced motor technologies, including high-efficiency induction motors, that can optimize water usage in various applications.

The agricultural sector, being one of the largest consumers of water resources, presents a substantial market opportunity for water-efficient climate solutions. Farmers and agribusinesses are actively seeking technologies that can improve irrigation efficiency and reduce water waste. Induction motors play a crucial role in powering pumps and other irrigation equipment, making them a key focus area for water-efficient innovations.

In the municipal water management sector, there is a growing demand for smart water systems that can minimize leakage, improve distribution efficiency, and reduce energy consumption. Induction motors are essential components in water treatment plants, pumping stations, and distribution networks. As cities strive to become more resilient to climate change impacts, the demand for advanced motor technologies that can contribute to water conservation efforts is expected to rise significantly.

The commercial and residential building sector also represents a substantial market for water-efficient climate solutions. With increasing urbanization and the push for green building certifications, there is a rising demand for energy-efficient HVAC systems and water-saving appliances. Induction motors used in these applications are being scrutinized for their potential to contribute to overall water and energy efficiency in buildings.

Government policies and regulations aimed at promoting water conservation and climate resilience are further driving the market demand for efficient technologies. Many countries have implemented stricter efficiency standards for motors and pumps, creating a regulatory environment that favors the adoption of water-efficient solutions.

The market size for water-efficient climate solutions is projected to grow substantially in the coming years. This growth is expected to be particularly strong in regions facing water scarcity issues and those with ambitious climate action plans. As awareness of the water-energy nexus increases, the demand for integrated solutions that address both water and energy efficiency is likely to accelerate, positioning induction motors as critical components in the broader landscape of climate-resilient technologies.

In the industrial sector, there is a significant demand for water-efficient solutions, particularly in manufacturing processes that rely heavily on water consumption. Companies are increasingly recognizing the importance of reducing their water footprint not only for environmental reasons but also for cost-saving purposes. This has led to a surge in demand for advanced motor technologies, including high-efficiency induction motors, that can optimize water usage in various applications.

The agricultural sector, being one of the largest consumers of water resources, presents a substantial market opportunity for water-efficient climate solutions. Farmers and agribusinesses are actively seeking technologies that can improve irrigation efficiency and reduce water waste. Induction motors play a crucial role in powering pumps and other irrigation equipment, making them a key focus area for water-efficient innovations.

In the municipal water management sector, there is a growing demand for smart water systems that can minimize leakage, improve distribution efficiency, and reduce energy consumption. Induction motors are essential components in water treatment plants, pumping stations, and distribution networks. As cities strive to become more resilient to climate change impacts, the demand for advanced motor technologies that can contribute to water conservation efforts is expected to rise significantly.

The commercial and residential building sector also represents a substantial market for water-efficient climate solutions. With increasing urbanization and the push for green building certifications, there is a rising demand for energy-efficient HVAC systems and water-saving appliances. Induction motors used in these applications are being scrutinized for their potential to contribute to overall water and energy efficiency in buildings.

Government policies and regulations aimed at promoting water conservation and climate resilience are further driving the market demand for efficient technologies. Many countries have implemented stricter efficiency standards for motors and pumps, creating a regulatory environment that favors the adoption of water-efficient solutions.

The market size for water-efficient climate solutions is projected to grow substantially in the coming years. This growth is expected to be particularly strong in regions facing water scarcity issues and those with ambitious climate action plans. As awareness of the water-energy nexus increases, the demand for integrated solutions that address both water and energy efficiency is likely to accelerate, positioning induction motors as critical components in the broader landscape of climate-resilient technologies.

Current Challenges in Motor-Driven Water Systems

The integration of induction motors in water systems presents significant challenges in the context of water-efficient climate policy execution. One of the primary issues is the energy inefficiency of older motor systems, which consume excessive electricity and contribute to increased carbon emissions. Many existing water pumping and distribution systems rely on outdated induction motors that operate at fixed speeds, regardless of the actual demand. This lack of adaptability results in unnecessary energy consumption and water waste.

Another challenge lies in the difficulty of retrofitting existing infrastructure with more efficient motor technologies. The replacement of large-scale induction motors in water treatment plants and distribution networks often requires substantial capital investment and can cause disruptions to water services. This creates a barrier for utilities and municipalities seeking to improve their water system efficiency in line with climate policy goals.

The absence of comprehensive monitoring and control systems in many motor-driven water infrastructures further exacerbates the problem. Without real-time data on motor performance, energy consumption, and water flow rates, it becomes challenging to optimize operations and identify areas for improvement. This lack of visibility hinders the implementation of data-driven strategies to enhance water and energy efficiency.

Moreover, the intermittent nature of renewable energy sources poses a challenge for motor-driven water systems. As climate policies push for greater integration of renewables, water utilities must adapt their motor operations to accommodate fluctuating power supplies. This requires advanced control systems and energy storage solutions, which are not yet widely implemented in existing water infrastructure.

The skill gap among operators and maintenance personnel also presents a significant hurdle. Many technicians lack the expertise to effectively manage and maintain advanced motor systems with variable frequency drives and smart controls. This knowledge deficit can lead to suboptimal performance and reduced efficiency gains, even when newer technologies are implemented.

Lastly, the regulatory landscape surrounding water and energy efficiency often fails to provide adequate incentives for upgrading motor-driven water systems. In many jurisdictions, policies and standards do not fully account for the potential energy savings and emissions reductions that can be achieved through motor efficiency improvements in water infrastructure. This regulatory gap hampers the widespread adoption of more efficient technologies and practices in the water sector.

Another challenge lies in the difficulty of retrofitting existing infrastructure with more efficient motor technologies. The replacement of large-scale induction motors in water treatment plants and distribution networks often requires substantial capital investment and can cause disruptions to water services. This creates a barrier for utilities and municipalities seeking to improve their water system efficiency in line with climate policy goals.

The absence of comprehensive monitoring and control systems in many motor-driven water infrastructures further exacerbates the problem. Without real-time data on motor performance, energy consumption, and water flow rates, it becomes challenging to optimize operations and identify areas for improvement. This lack of visibility hinders the implementation of data-driven strategies to enhance water and energy efficiency.

Moreover, the intermittent nature of renewable energy sources poses a challenge for motor-driven water systems. As climate policies push for greater integration of renewables, water utilities must adapt their motor operations to accommodate fluctuating power supplies. This requires advanced control systems and energy storage solutions, which are not yet widely implemented in existing water infrastructure.

The skill gap among operators and maintenance personnel also presents a significant hurdle. Many technicians lack the expertise to effectively manage and maintain advanced motor systems with variable frequency drives and smart controls. This knowledge deficit can lead to suboptimal performance and reduced efficiency gains, even when newer technologies are implemented.

Lastly, the regulatory landscape surrounding water and energy efficiency often fails to provide adequate incentives for upgrading motor-driven water systems. In many jurisdictions, policies and standards do not fully account for the potential energy savings and emissions reductions that can be achieved through motor efficiency improvements in water infrastructure. This regulatory gap hampers the widespread adoption of more efficient technologies and practices in the water sector.

Existing Water-Efficient Induction Motor Solutions

01 Efficiency improvement in induction motors

Various techniques are employed to enhance the efficiency of induction motors, particularly in water-related applications. These may include optimizing motor design, using advanced materials, and implementing improved control strategies to reduce energy losses and increase overall performance.- Efficiency improvement in induction motors: Various techniques are employed to enhance the efficiency of induction motors, particularly in water-related applications. These may include optimizing motor design, using advanced materials, and implementing improved control strategies to reduce energy losses and increase overall performance.

- Water cooling systems for induction motors: Water cooling systems are utilized to improve the thermal management of induction motors, leading to increased efficiency and prolonged motor life. These systems may involve innovative designs for water circulation, heat exchange, and temperature control within the motor structure.

- Smart control systems for water pump induction motors: Advanced control systems are developed to optimize the operation of induction motors in water pumping applications. These systems may incorporate sensors, variable frequency drives, and intelligent algorithms to adjust motor performance based on water demand and operating conditions, thereby improving overall efficiency.

- Energy-efficient induction motor designs for water treatment: Specialized induction motor designs are created for water treatment facilities, focusing on energy efficiency and reliability. These designs may feature improved rotor and stator configurations, optimized magnetic circuits, and materials selected for their performance in water-related environments.

- Monitoring and maintenance systems for water-based induction motors: Innovative monitoring and maintenance systems are developed to ensure the continued efficiency of induction motors in water applications. These may include real-time performance monitoring, predictive maintenance algorithms, and automated diagnostic tools to identify and address potential issues before they impact motor efficiency.

02 Water cooling systems for induction motors

Water cooling systems are utilized to improve the thermal management of induction motors, leading to increased efficiency and prolonged motor life. These systems may involve innovative cooling channel designs, water jacket configurations, or direct water cooling of motor components.Expand Specific Solutions03 Variable speed drive applications

The integration of variable speed drives with induction motors in water-related applications can significantly improve energy efficiency. These systems allow for precise control of motor speed and torque, optimizing performance based on varying load conditions and water flow requirements.Expand Specific Solutions04 Submersible induction motor designs

Specialized designs for submersible induction motors used in water pumping applications focus on enhancing efficiency and reliability in underwater environments. These designs may incorporate water-resistant materials, sealed construction, and optimized cooling mechanisms.Expand Specific Solutions05 Smart monitoring and control systems

Advanced monitoring and control systems are implemented to optimize the performance of induction motors in water-related applications. These systems may include sensors, data analytics, and intelligent algorithms to adjust motor operation in real-time, ensuring maximum efficiency and water conservation.Expand Specific Solutions

Key Players in Efficient Motor and Water Technology

The induction motor technology's impact on water-efficient climate policy execution is in a nascent stage, with the market still developing. The industry is transitioning from traditional motors to more efficient solutions, driven by increasing environmental concerns. Key players like Robert Bosch GmbH, Toyota Motor Corp., and Ford Global Technologies LLC are investing in research and development to improve motor efficiency and reduce water consumption. The technology's maturity varies, with established companies like Renault SA and Hyundai Motor Co., Ltd. making significant advancements, while newer entrants like Yundu New Energy Vehicle Co., Ltd. are also contributing to innovation. The market size is expected to grow as governments worldwide implement stricter climate policies, creating opportunities for companies to develop and commercialize water-efficient induction motor technologies.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced induction motor system for their hybrid and electric vehicles that contributes to water-efficient climate policy execution. Their technology incorporates a highly efficient cooling system that minimizes water usage while maintaining optimal motor performance. The motor design includes a sealed cooling jacket with advanced coolant circulation, reducing evaporation and water loss[1]. Additionally, Toyota has implemented a regenerative braking system that captures and reuses energy, further improving overall vehicle efficiency and reducing the environmental impact[2]. The company has also integrated smart climate control systems that work in tandem with the motor to optimize energy usage and minimize water consumption in vehicle climate management[3].

Strengths: Highly efficient cooling system, reduced water consumption, improved energy recovery. Weaknesses: Potentially higher initial costs, complexity in manufacturing and maintenance.

Renault SA

Technical Solution: Renault has developed a novel induction motor technology that aligns with water-efficient climate policies. Their approach focuses on a compact, high-efficiency motor design that reduces overall energy consumption, indirectly contributing to water conservation in power generation. The motor incorporates advanced materials and optimized electromagnetic design to minimize heat generation, reducing cooling requirements[4]. Renault's system also features an intelligent power management system that adapts motor performance based on driving conditions and climate control needs, further enhancing efficiency[5]. The company has implemented a closed-loop cooling system that significantly reduces water loss and improves overall system reliability[6].

Strengths: Compact design, reduced cooling needs, adaptive power management. Weaknesses: Potential limitations in high-performance applications, reliance on specialized components.

Innovations in Motor Design for Water Conservation

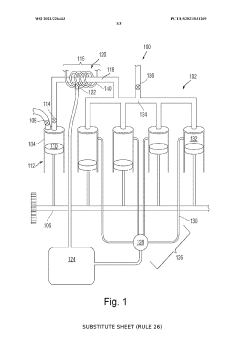

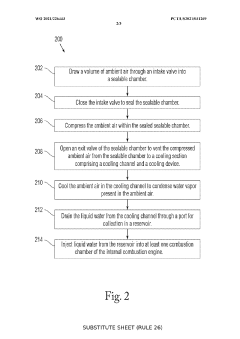

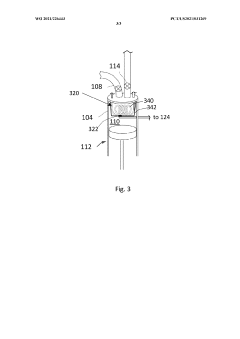

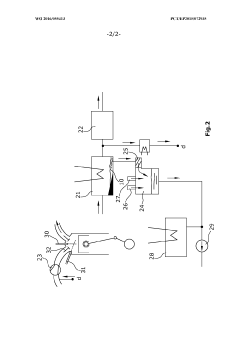

High compression boosting and water generation

PatentWO2021226443A1

Innovation

- A system that captures and compresses ambient air within a sealed chamber, cools it to condense water vapor into liquid form, and injects the liquid water into the engine's combustion chambers, utilizing a refrigeration unit to enhance energy efficiency and reduce emissions.

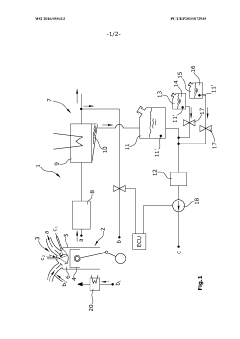

Vehicle having a cooler for condensing exhaust gas and method therefor

PatentWO2016055413A1

Innovation

- A vehicle system that includes a cooler in the exhaust line for condensate formation, a collection tank, and multiple injectors for cylinder-specific condensate injection, utilizing condensate from exhaust gases and potentially from air conditioning systems or rainwater, allowing for precise control of water injection based on engine operating conditions.

Policy Framework for Water-Efficient Technologies

The policy framework for water-efficient technologies plays a crucial role in addressing the impact of induction motors on climate policy execution. This framework encompasses a comprehensive set of guidelines, regulations, and incentives designed to promote the adoption and implementation of water-efficient technologies across various sectors.

At its core, the policy framework aims to align industrial practices with sustainable water management goals. It recognizes the significant water consumption associated with induction motors, particularly in industrial and agricultural applications. By establishing clear standards and benchmarks for water efficiency, the framework encourages manufacturers and end-users to prioritize water conservation in their operations.

One key aspect of the policy framework is the introduction of mandatory efficiency standards for induction motors. These standards set minimum requirements for water consumption and energy efficiency, pushing manufacturers to innovate and develop more sustainable motor designs. The framework also includes a labeling system that allows consumers to make informed choices based on the water efficiency ratings of different motor models.

Financial incentives form another critical component of the policy framework. Governments and regulatory bodies offer tax credits, rebates, and grants to businesses and individuals who invest in water-efficient induction motors. These incentives help offset the initial costs associated with upgrading to more efficient technologies, making the transition more economically viable for a broader range of stakeholders.

The framework also emphasizes research and development initiatives focused on improving the water efficiency of induction motors. It allocates funding for collaborative projects between academic institutions, industry partners, and government agencies to explore innovative solutions and technologies. This approach fosters a culture of continuous improvement and technological advancement in the field of water-efficient motor design.

Education and awareness programs are integral to the policy framework's success. These initiatives target various stakeholders, including manufacturers, industrial users, and the general public, to promote understanding of the importance of water conservation in motor applications. By raising awareness, the framework aims to create a shift in consumer behavior and industry practices towards more sustainable choices.

Monitoring and enforcement mechanisms are built into the policy framework to ensure compliance with established standards and regulations. Regular audits, reporting requirements, and penalties for non-compliance help maintain the integrity of the water efficiency goals. This approach creates a level playing field for all market participants and reinforces the importance of water conservation in industrial processes.

At its core, the policy framework aims to align industrial practices with sustainable water management goals. It recognizes the significant water consumption associated with induction motors, particularly in industrial and agricultural applications. By establishing clear standards and benchmarks for water efficiency, the framework encourages manufacturers and end-users to prioritize water conservation in their operations.

One key aspect of the policy framework is the introduction of mandatory efficiency standards for induction motors. These standards set minimum requirements for water consumption and energy efficiency, pushing manufacturers to innovate and develop more sustainable motor designs. The framework also includes a labeling system that allows consumers to make informed choices based on the water efficiency ratings of different motor models.

Financial incentives form another critical component of the policy framework. Governments and regulatory bodies offer tax credits, rebates, and grants to businesses and individuals who invest in water-efficient induction motors. These incentives help offset the initial costs associated with upgrading to more efficient technologies, making the transition more economically viable for a broader range of stakeholders.

The framework also emphasizes research and development initiatives focused on improving the water efficiency of induction motors. It allocates funding for collaborative projects between academic institutions, industry partners, and government agencies to explore innovative solutions and technologies. This approach fosters a culture of continuous improvement and technological advancement in the field of water-efficient motor design.

Education and awareness programs are integral to the policy framework's success. These initiatives target various stakeholders, including manufacturers, industrial users, and the general public, to promote understanding of the importance of water conservation in motor applications. By raising awareness, the framework aims to create a shift in consumer behavior and industry practices towards more sustainable choices.

Monitoring and enforcement mechanisms are built into the policy framework to ensure compliance with established standards and regulations. Regular audits, reporting requirements, and penalties for non-compliance help maintain the integrity of the water efficiency goals. This approach creates a level playing field for all market participants and reinforces the importance of water conservation in industrial processes.

Environmental Impact Assessment

The environmental impact of induction motors in the context of water-efficient climate policy execution is multifaceted and significant. These motors, widely used in industrial and residential applications, play a crucial role in various water-related systems, including pumping, treatment, and distribution. Their efficiency and performance directly influence energy consumption and, consequently, greenhouse gas emissions.

Induction motors contribute to both direct and indirect environmental effects. The manufacturing process of these motors involves resource extraction and energy-intensive production, leading to carbon emissions and potential ecosystem disruption. However, their long-term operation in water management systems can offset these initial impacts through improved efficiency and reduced energy consumption compared to older technologies.

In the context of water-efficient climate policies, induction motors can significantly enhance the overall sustainability of water infrastructure. By optimizing pump systems and water distribution networks, these motors help reduce water loss and minimize energy waste. This efficiency translates to lower carbon footprints for water utilities and industrial processes, aligning with broader climate mitigation goals.

The impact of induction motors extends to water treatment facilities, where they power critical processes such as aeration and filtration. By improving the energy efficiency of these operations, induction motors contribute to reducing the overall environmental footprint of water treatment, a sector known for its high energy demands. This efficiency gain is particularly important in regions facing water scarcity, where every drop of treated water carries a higher energy and carbon cost.

However, the environmental benefits of induction motors in water-efficient systems are not without challenges. The increased reliance on these motors for water management may lead to higher electricity demand, potentially straining power grids and indirectly contributing to emissions if the electricity is sourced from fossil fuels. This underscores the importance of coupling motor efficiency improvements with renewable energy integration to maximize environmental benefits.

The lifecycle assessment of induction motors in water systems reveals a complex interplay of environmental impacts. While their operation generally leads to net positive outcomes in terms of energy and water conservation, end-of-life disposal presents environmental concerns. Proper recycling and disposal practices are crucial to mitigate potential soil and water contamination from motor components.

In conclusion, induction motors play a pivotal role in executing water-efficient climate policies, offering significant potential for reducing both water and energy consumption. Their environmental impact, while largely positive, necessitates a holistic approach that considers manufacturing, operation, and disposal phases to ensure alignment with broader sustainability goals.

Induction motors contribute to both direct and indirect environmental effects. The manufacturing process of these motors involves resource extraction and energy-intensive production, leading to carbon emissions and potential ecosystem disruption. However, their long-term operation in water management systems can offset these initial impacts through improved efficiency and reduced energy consumption compared to older technologies.

In the context of water-efficient climate policies, induction motors can significantly enhance the overall sustainability of water infrastructure. By optimizing pump systems and water distribution networks, these motors help reduce water loss and minimize energy waste. This efficiency translates to lower carbon footprints for water utilities and industrial processes, aligning with broader climate mitigation goals.

The impact of induction motors extends to water treatment facilities, where they power critical processes such as aeration and filtration. By improving the energy efficiency of these operations, induction motors contribute to reducing the overall environmental footprint of water treatment, a sector known for its high energy demands. This efficiency gain is particularly important in regions facing water scarcity, where every drop of treated water carries a higher energy and carbon cost.

However, the environmental benefits of induction motors in water-efficient systems are not without challenges. The increased reliance on these motors for water management may lead to higher electricity demand, potentially straining power grids and indirectly contributing to emissions if the electricity is sourced from fossil fuels. This underscores the importance of coupling motor efficiency improvements with renewable energy integration to maximize environmental benefits.

The lifecycle assessment of induction motors in water systems reveals a complex interplay of environmental impacts. While their operation generally leads to net positive outcomes in terms of energy and water conservation, end-of-life disposal presents environmental concerns. Proper recycling and disposal practices are crucial to mitigate potential soil and water contamination from motor components.

In conclusion, induction motors play a pivotal role in executing water-efficient climate policies, offering significant potential for reducing both water and energy consumption. Their environmental impact, while largely positive, necessitates a holistic approach that considers manufacturing, operation, and disposal phases to ensure alignment with broader sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!