How induction motors enhance the sustainability of urban infrastructure

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Evolution

Induction motors have undergone significant evolution since their inception in the late 19th century, playing a crucial role in enhancing the sustainability of urban infrastructure. The development of these motors has been marked by continuous improvements in efficiency, reliability, and versatility, making them indispensable in various urban applications.

The early stages of induction motor evolution focused on basic design principles and manufacturing techniques. Inventors like Nikola Tesla and Galileo Ferraris laid the groundwork for polyphase induction motors, which quickly gained popularity due to their simplicity and robustness. As urbanization accelerated in the early 20th century, the demand for reliable electric motors in industrial and municipal applications grew rapidly.

The mid-20th century saw significant advancements in materials science and manufacturing processes, leading to more efficient and compact induction motors. The introduction of die-cast aluminum rotors and improved stator winding techniques resulted in motors with higher power density and lower losses. These improvements made induction motors more suitable for a wide range of urban infrastructure applications, from water pumping stations to HVAC systems in large buildings.

In the latter part of the 20th century, the focus shifted towards energy efficiency and environmental sustainability. The development of high-efficiency motors, often referred to as premium efficiency or IE3 motors, marked a significant milestone in induction motor evolution. These motors incorporated advanced magnetic materials, optimized designs, and improved cooling systems to minimize energy losses and reduce carbon footprints in urban environments.

The advent of power electronics and digital control systems in the late 20th and early 21st centuries revolutionized induction motor applications. Variable frequency drives (VFDs) enabled precise speed control and further energy savings, particularly in applications with variable load requirements, such as escalators and elevators in urban buildings. This technology significantly enhanced the flexibility and efficiency of induction motors in urban infrastructure.

Recent developments in induction motor technology have focused on smart and connected solutions. The integration of sensors, IoT capabilities, and advanced analytics has led to the emergence of smart motors that can self-diagnose, predict maintenance needs, and optimize their operation based on real-time data. These innovations contribute to the overall sustainability of urban infrastructure by reducing downtime, extending equipment lifespan, and further improving energy efficiency.

The ongoing evolution of induction motors continues to address the challenges of urbanization and sustainability. Research into new materials, such as high-temperature superconductors and advanced magnetic alloys, promises to push the boundaries of motor efficiency and power density even further. Additionally, the development of modular and easily recyclable motor designs aligns with the principles of circular economy, further enhancing the sustainability aspects of urban infrastructure.

The early stages of induction motor evolution focused on basic design principles and manufacturing techniques. Inventors like Nikola Tesla and Galileo Ferraris laid the groundwork for polyphase induction motors, which quickly gained popularity due to their simplicity and robustness. As urbanization accelerated in the early 20th century, the demand for reliable electric motors in industrial and municipal applications grew rapidly.

The mid-20th century saw significant advancements in materials science and manufacturing processes, leading to more efficient and compact induction motors. The introduction of die-cast aluminum rotors and improved stator winding techniques resulted in motors with higher power density and lower losses. These improvements made induction motors more suitable for a wide range of urban infrastructure applications, from water pumping stations to HVAC systems in large buildings.

In the latter part of the 20th century, the focus shifted towards energy efficiency and environmental sustainability. The development of high-efficiency motors, often referred to as premium efficiency or IE3 motors, marked a significant milestone in induction motor evolution. These motors incorporated advanced magnetic materials, optimized designs, and improved cooling systems to minimize energy losses and reduce carbon footprints in urban environments.

The advent of power electronics and digital control systems in the late 20th and early 21st centuries revolutionized induction motor applications. Variable frequency drives (VFDs) enabled precise speed control and further energy savings, particularly in applications with variable load requirements, such as escalators and elevators in urban buildings. This technology significantly enhanced the flexibility and efficiency of induction motors in urban infrastructure.

Recent developments in induction motor technology have focused on smart and connected solutions. The integration of sensors, IoT capabilities, and advanced analytics has led to the emergence of smart motors that can self-diagnose, predict maintenance needs, and optimize their operation based on real-time data. These innovations contribute to the overall sustainability of urban infrastructure by reducing downtime, extending equipment lifespan, and further improving energy efficiency.

The ongoing evolution of induction motors continues to address the challenges of urbanization and sustainability. Research into new materials, such as high-temperature superconductors and advanced magnetic alloys, promises to push the boundaries of motor efficiency and power density even further. Additionally, the development of modular and easily recyclable motor designs aligns with the principles of circular economy, further enhancing the sustainability aspects of urban infrastructure.

Urban Infrastructure Needs

Urban infrastructure faces significant challenges in the 21st century, driven by rapid urbanization, aging systems, and the pressing need for sustainability. Cities worldwide are grappling with the demands of growing populations, which strain existing infrastructure and necessitate expansion and modernization. Transportation networks, energy systems, water management, and waste disposal facilities are under increasing pressure to meet the needs of urban dwellers while minimizing environmental impact.

One of the primary concerns is the energy efficiency of urban systems. As cities consume a disproportionate amount of global energy, there is a critical need for solutions that can reduce energy consumption and improve overall sustainability. This is where induction motors play a crucial role. These motors are integral components in various urban infrastructure applications, from water pumps and HVAC systems to elevators and public transportation.

The demand for reliable and efficient power distribution is another key aspect of urban infrastructure needs. With the rise of smart grids and distributed energy resources, there is a growing requirement for motors that can operate efficiently across a wide range of loads and speeds. Induction motors, known for their robustness and adaptability, are well-suited to meet these evolving demands.

Water management presents another significant challenge for urban areas. Cities require advanced pumping systems for water distribution, wastewater treatment, and flood control. These systems must operate continuously and efficiently to ensure the health and safety of urban populations. Induction motors are essential in powering these critical water infrastructure components, and their performance directly impacts the sustainability of urban water systems.

Public transportation is a cornerstone of sustainable urban development. As cities strive to reduce traffic congestion and air pollution, there is an increasing focus on electric and hybrid vehicles for mass transit. Induction motors are at the heart of many electric propulsion systems, offering the potential for cleaner and more energy-efficient urban mobility solutions.

Building systems represent another area where induction motors can contribute to urban sustainability. From ventilation and air conditioning to elevators and escalators, buildings consume a significant portion of urban energy. The integration of high-efficiency induction motors in these applications can lead to substantial energy savings and reduced carbon footprints for urban structures.

As cities aim to become smarter and more connected, there is a growing need for infrastructure that can support IoT devices and advanced control systems. Induction motors with variable speed drives and smart controls can be integrated into these systems, allowing for more precise management of urban resources and improved overall efficiency.

One of the primary concerns is the energy efficiency of urban systems. As cities consume a disproportionate amount of global energy, there is a critical need for solutions that can reduce energy consumption and improve overall sustainability. This is where induction motors play a crucial role. These motors are integral components in various urban infrastructure applications, from water pumps and HVAC systems to elevators and public transportation.

The demand for reliable and efficient power distribution is another key aspect of urban infrastructure needs. With the rise of smart grids and distributed energy resources, there is a growing requirement for motors that can operate efficiently across a wide range of loads and speeds. Induction motors, known for their robustness and adaptability, are well-suited to meet these evolving demands.

Water management presents another significant challenge for urban areas. Cities require advanced pumping systems for water distribution, wastewater treatment, and flood control. These systems must operate continuously and efficiently to ensure the health and safety of urban populations. Induction motors are essential in powering these critical water infrastructure components, and their performance directly impacts the sustainability of urban water systems.

Public transportation is a cornerstone of sustainable urban development. As cities strive to reduce traffic congestion and air pollution, there is an increasing focus on electric and hybrid vehicles for mass transit. Induction motors are at the heart of many electric propulsion systems, offering the potential for cleaner and more energy-efficient urban mobility solutions.

Building systems represent another area where induction motors can contribute to urban sustainability. From ventilation and air conditioning to elevators and escalators, buildings consume a significant portion of urban energy. The integration of high-efficiency induction motors in these applications can lead to substantial energy savings and reduced carbon footprints for urban structures.

As cities aim to become smarter and more connected, there is a growing need for infrastructure that can support IoT devices and advanced control systems. Induction motors with variable speed drives and smart controls can be integrated into these systems, allowing for more precise management of urban resources and improved overall efficiency.

Sustainability Challenges

Urban infrastructure faces numerous sustainability challenges as cities continue to grow and evolve. The increasing demand for energy, coupled with the need to reduce carbon emissions, poses a significant challenge for urban planners and policymakers. Traditional infrastructure systems often rely on outdated technologies that are energy-intensive and contribute to environmental degradation.

One of the primary sustainability challenges in urban infrastructure is the inefficient use of energy in buildings, transportation systems, and industrial processes. Many existing systems are based on older technologies that consume excessive amounts of electricity, leading to higher operational costs and increased carbon footprints. This inefficiency not only strains energy resources but also contributes to air pollution and climate change.

Another critical challenge is the aging infrastructure in many cities, which requires frequent maintenance and replacement. This constant need for repairs and upgrades not only disrupts urban life but also consumes significant resources and energy. The disposal of outdated equipment and materials further adds to the environmental burden, creating waste management issues and potential hazards.

Water management presents another sustainability challenge in urban areas. Many cities struggle with outdated water distribution systems that suffer from leaks and inefficiencies, leading to water waste and increased energy consumption for pumping and treatment. Additionally, the growing demand for water in urban areas puts pressure on local water sources, necessitating more energy-intensive solutions such as desalination or long-distance water transfer.

The integration of renewable energy sources into urban infrastructure is also a significant challenge. While there is a growing push for cleaner energy, many cities face difficulties in implementing large-scale renewable energy projects due to space constraints, grid integration issues, and the intermittent nature of sources like solar and wind power.

Urban mobility and transportation systems contribute significantly to sustainability challenges. The reliance on fossil fuel-powered vehicles leads to air pollution, congestion, and high energy consumption. Developing efficient, low-emission transportation networks that can accommodate growing urban populations while minimizing environmental impact remains a complex issue for many cities.

Lastly, the resilience of urban infrastructure to climate change impacts poses a critical sustainability challenge. As extreme weather events become more frequent and severe, cities must adapt their infrastructure to withstand floods, heatwaves, and other climate-related stresses. This adaptation requires significant investments and innovative solutions to ensure the long-term sustainability and functionality of urban systems.

One of the primary sustainability challenges in urban infrastructure is the inefficient use of energy in buildings, transportation systems, and industrial processes. Many existing systems are based on older technologies that consume excessive amounts of electricity, leading to higher operational costs and increased carbon footprints. This inefficiency not only strains energy resources but also contributes to air pollution and climate change.

Another critical challenge is the aging infrastructure in many cities, which requires frequent maintenance and replacement. This constant need for repairs and upgrades not only disrupts urban life but also consumes significant resources and energy. The disposal of outdated equipment and materials further adds to the environmental burden, creating waste management issues and potential hazards.

Water management presents another sustainability challenge in urban areas. Many cities struggle with outdated water distribution systems that suffer from leaks and inefficiencies, leading to water waste and increased energy consumption for pumping and treatment. Additionally, the growing demand for water in urban areas puts pressure on local water sources, necessitating more energy-intensive solutions such as desalination or long-distance water transfer.

The integration of renewable energy sources into urban infrastructure is also a significant challenge. While there is a growing push for cleaner energy, many cities face difficulties in implementing large-scale renewable energy projects due to space constraints, grid integration issues, and the intermittent nature of sources like solar and wind power.

Urban mobility and transportation systems contribute significantly to sustainability challenges. The reliance on fossil fuel-powered vehicles leads to air pollution, congestion, and high energy consumption. Developing efficient, low-emission transportation networks that can accommodate growing urban populations while minimizing environmental impact remains a complex issue for many cities.

Lastly, the resilience of urban infrastructure to climate change impacts poses a critical sustainability challenge. As extreme weather events become more frequent and severe, cities must adapt their infrastructure to withstand floods, heatwaves, and other climate-related stresses. This adaptation requires significant investments and innovative solutions to ensure the long-term sustainability and functionality of urban systems.

Current Induction Solutions

01 Energy efficiency improvements in induction motors

Advancements in induction motor design and control strategies to enhance energy efficiency, reducing power consumption and operational costs. This includes optimizing motor components, implementing advanced control algorithms, and utilizing high-efficiency materials to minimize losses and improve overall performance.- Energy efficiency improvements in induction motors: Advancements in induction motor design and control strategies to enhance energy efficiency, reducing power consumption and operational costs. This includes optimizing motor components, implementing advanced control algorithms, and utilizing high-efficiency materials to minimize energy losses during operation.

- Sustainable manufacturing processes for induction motors: Development of eco-friendly manufacturing techniques for induction motors, focusing on reducing environmental impact throughout the production lifecycle. This involves using recycled materials, implementing cleaner production methods, and optimizing resource utilization in the manufacturing process.

- Integration of induction motors in renewable energy systems: Incorporation of induction motors in sustainable energy applications, such as wind turbines and hydroelectric systems. This includes adapting motor designs for variable speed operation, improving grid integration, and enhancing overall system efficiency in renewable energy generation.

- Predictive maintenance and condition monitoring for sustainability: Implementation of advanced monitoring and diagnostic techniques to enhance the longevity and reliability of induction motors. This involves using sensors, data analytics, and artificial intelligence to predict potential failures, optimize maintenance schedules, and extend the operational life of motors.

- Recycling and end-of-life management of induction motors: Development of strategies for the sustainable disposal and recycling of induction motors at the end of their operational life. This includes designing motors for easy disassembly, recovering valuable materials, and implementing circular economy principles to minimize waste and environmental impact.

02 Sustainable manufacturing processes for induction motors

Development of eco-friendly manufacturing techniques for induction motors, focusing on reducing environmental impact throughout the production lifecycle. This involves using recycled materials, implementing cleaner production methods, and optimizing resource utilization to minimize waste and emissions.Expand Specific Solutions03 Integration of induction motors in renewable energy systems

Innovative approaches to incorporate induction motors in renewable energy applications, such as wind turbines and hydroelectric systems. This includes designing motors specifically for variable speed operation, improving grid integration, and enhancing overall system efficiency in renewable energy generation.Expand Specific Solutions04 Predictive maintenance and condition monitoring for sustainable operation

Implementation of advanced monitoring and diagnostic techniques to enhance the longevity and reliability of induction motors. This involves using sensors, data analytics, and machine learning algorithms to predict potential failures, optimize maintenance schedules, and reduce downtime, thereby improving overall sustainability.Expand Specific Solutions05 Recycling and end-of-life management of induction motors

Development of strategies and technologies for efficient recycling and disposal of induction motors at the end of their operational life. This includes designing motors for easy disassembly, recovering valuable materials, and implementing circular economy principles to minimize environmental impact and promote sustainability.Expand Specific Solutions

Key Industry Players

The induction motor market for urban infrastructure sustainability is in a growth phase, driven by increasing urbanization and the need for energy-efficient solutions. The market size is expanding, with a projected CAGR of 7-8% over the next five years. Technologically, induction motors are mature but evolving, with companies like Robert Bosch GmbH, Toyota Motor Corp., and LG Electronics leading innovations in efficiency and smart control systems. Emerging players such as Altigreen Propulsion Labs are focusing on eco-friendly adaptations for emerging markets. Research institutions like MIT and Zhejiang University are contributing to advancements in motor design and performance, pushing the boundaries of sustainability in urban applications.

Robert Bosch GmbH

Technical Solution: Bosch has developed a range of high-efficiency induction motors tailored for urban infrastructure applications. Their motors feature advanced silicon steel laminations and copper rotor technology, achieving efficiency levels up to IE4 class. Bosch's induction motors incorporate smart sensors and IoT connectivity, enabling real-time monitoring and predictive maintenance in urban settings. This reduces downtime and extends motor lifespan by up to 30% [12]. The company has also introduced a line of compact, high-torque induction motors specifically designed for electric vehicle charging infrastructure, supporting the growth of sustainable urban transportation. Bosch's motors utilize advanced cooling systems, allowing for higher power density and improved performance in confined urban spaces [13].

Strengths: High efficiency, IoT integration, and specialized solutions for urban EV infrastructure. Weaknesses: Premium pricing may limit adoption in budget-constrained urban projects.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced induction motor technology for their hybrid and electric vehicles, contributing to urban sustainability. Their latest induction motors feature high power density and efficiency, utilizing advanced materials and cooling systems. Toyota's motors achieve over 95% efficiency [1], reducing energy consumption in urban transportation. They have also implemented regenerative braking systems that recover up to 70% of kinetic energy [2], further enhancing sustainability. Toyota's induction motors are designed for longevity, with an estimated lifespan of over 15 years or 150,000 miles [3], reducing the need for frequent replacements and minimizing waste in urban environments.

Strengths: High efficiency, energy recovery, and long lifespan contribute significantly to urban sustainability. Weaknesses: Higher initial cost compared to conventional motors may slow adoption in some markets.

Innovative Motor Designs

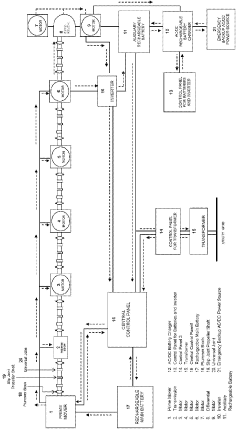

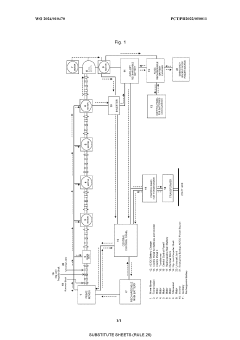

A generator multiplier process, system and or method to increase electrical energy output

PatentWO2024010470A1

Innovation

- A system of linked induction generators via transmission, gear shafts, and a rechargeable battery-powered prime mover creates a multiplier effect to increase electrical energy output, utilizing a single prime mover to drive multiple generators, thereby enhancing energy production without the space and location constraints of traditional systems.

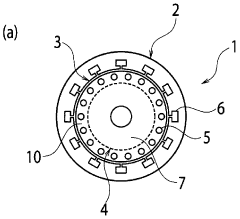

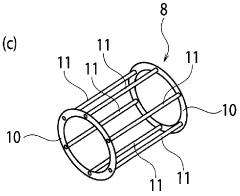

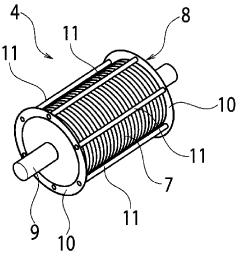

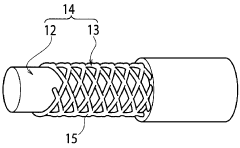

Rotor of induction motor, and induction motor using same

PatentWO2011148978A1

Innovation

- The use of a composite material for the rotor's conductors, comprising a conductive core conductor coated with a carbon nanotube structure, which reduces surface electrical resistance and heat generation, allowing for improved conductivity and reduced heat loss.

Energy Efficiency Policies

Energy efficiency policies play a crucial role in promoting the adoption of induction motors to enhance the sustainability of urban infrastructure. These policies are designed to incentivize the use of energy-efficient technologies and practices across various sectors, including industrial, commercial, and residential applications.

Many countries have implemented mandatory minimum energy performance standards (MEPS) for electric motors, including induction motors. These standards set the baseline for energy efficiency requirements, ensuring that only motors meeting or exceeding these standards can be sold in the market. The International Electrotechnical Commission (IEC) has established global efficiency classes for electric motors, with IE3 (Premium Efficiency) and IE4 (Super Premium Efficiency) becoming increasingly common targets for policy implementation.

Financial incentives are another key component of energy efficiency policies. Governments and utilities often offer rebates, tax credits, or low-interest loans to encourage the adoption of high-efficiency induction motors. These incentives help offset the higher initial costs associated with premium efficiency motors, making them more attractive to end-users and accelerating their market penetration.

Energy labeling programs complement MEPS by providing consumers with clear information about the energy performance of induction motors. These labels allow for easy comparison between different models and help inform purchasing decisions. The European Union's Energy Label and the U.S. Department of Energy's Energy Star program are examples of successful labeling initiatives that have been applied to electric motors.

Many countries have also implemented energy audit programs targeting industrial and commercial facilities. These audits identify opportunities for energy savings, often highlighting the potential benefits of upgrading to more efficient induction motors. Some policies mandate regular energy audits for large energy consumers, while others offer voluntary programs with incentives for participation.

Research and development support is another critical aspect of energy efficiency policies. Governments allocate funds to support the development of next-generation motor technologies, advanced control systems, and improved manufacturing processes. This investment in innovation helps drive continuous improvements in induction motor efficiency and performance.

Capacity building and awareness programs are essential for the successful implementation of energy efficiency policies. These initiatives provide training for engineers, facility managers, and other stakeholders on the benefits of high-efficiency motors and best practices for motor system optimization. Such programs help overcome knowledge barriers and promote the widespread adoption of energy-efficient technologies.

Many countries have implemented mandatory minimum energy performance standards (MEPS) for electric motors, including induction motors. These standards set the baseline for energy efficiency requirements, ensuring that only motors meeting or exceeding these standards can be sold in the market. The International Electrotechnical Commission (IEC) has established global efficiency classes for electric motors, with IE3 (Premium Efficiency) and IE4 (Super Premium Efficiency) becoming increasingly common targets for policy implementation.

Financial incentives are another key component of energy efficiency policies. Governments and utilities often offer rebates, tax credits, or low-interest loans to encourage the adoption of high-efficiency induction motors. These incentives help offset the higher initial costs associated with premium efficiency motors, making them more attractive to end-users and accelerating their market penetration.

Energy labeling programs complement MEPS by providing consumers with clear information about the energy performance of induction motors. These labels allow for easy comparison between different models and help inform purchasing decisions. The European Union's Energy Label and the U.S. Department of Energy's Energy Star program are examples of successful labeling initiatives that have been applied to electric motors.

Many countries have also implemented energy audit programs targeting industrial and commercial facilities. These audits identify opportunities for energy savings, often highlighting the potential benefits of upgrading to more efficient induction motors. Some policies mandate regular energy audits for large energy consumers, while others offer voluntary programs with incentives for participation.

Research and development support is another critical aspect of energy efficiency policies. Governments allocate funds to support the development of next-generation motor technologies, advanced control systems, and improved manufacturing processes. This investment in innovation helps drive continuous improvements in induction motor efficiency and performance.

Capacity building and awareness programs are essential for the successful implementation of energy efficiency policies. These initiatives provide training for engineers, facility managers, and other stakeholders on the benefits of high-efficiency motors and best practices for motor system optimization. Such programs help overcome knowledge barriers and promote the widespread adoption of energy-efficient technologies.

Life Cycle Assessment

Life Cycle Assessment (LCA) plays a crucial role in evaluating the sustainability of induction motors in urban infrastructure. This comprehensive approach examines the environmental impacts of these motors throughout their entire lifecycle, from raw material extraction to manufacturing, use, and end-of-life disposal.

In the production phase, LCA considers the energy consumption and emissions associated with sourcing and processing materials such as copper, steel, and insulation. The manufacturing process itself is scrutinized for its energy efficiency and waste generation. Transportation of components and finished products also contributes to the overall environmental footprint.

During the operational phase, which typically spans several decades, induction motors consume significant amounts of electricity. LCA quantifies this energy use and the resulting greenhouse gas emissions, taking into account regional energy mixes and potential improvements in grid decarbonization over time. Maintenance activities, including lubricant changes and part replacements, are also factored into the assessment.

The end-of-life stage presents both challenges and opportunities for sustainability. LCA evaluates the environmental impacts of motor disposal, including potential soil and water contamination from improper handling. However, it also considers the benefits of recycling and material recovery, which can significantly reduce the need for virgin materials in future motor production.

By applying LCA to induction motors in urban infrastructure, decision-makers can identify hotspots of environmental impact and prioritize improvement efforts. For instance, optimizing motor efficiency during operation often yields the greatest sustainability benefits due to the long service life of these devices. Additionally, LCA can guide the selection of more environmentally friendly materials and manufacturing processes.

Furthermore, LCA enables comparisons between different motor technologies and designs, helping urban planners and engineers choose the most sustainable options for specific applications. This analysis may reveal trade-offs between various environmental impacts, such as energy efficiency versus material toxicity, allowing for informed decision-making that aligns with broader sustainability goals.

In the context of urban infrastructure, LCA of induction motors extends beyond the devices themselves to consider their role in larger systems. For example, the use of high-efficiency motors in water pumping stations or HVAC systems can lead to cascading energy savings throughout the urban environment. By quantifying these system-wide effects, LCA provides a more complete picture of how induction motors contribute to urban sustainability.

In the production phase, LCA considers the energy consumption and emissions associated with sourcing and processing materials such as copper, steel, and insulation. The manufacturing process itself is scrutinized for its energy efficiency and waste generation. Transportation of components and finished products also contributes to the overall environmental footprint.

During the operational phase, which typically spans several decades, induction motors consume significant amounts of electricity. LCA quantifies this energy use and the resulting greenhouse gas emissions, taking into account regional energy mixes and potential improvements in grid decarbonization over time. Maintenance activities, including lubricant changes and part replacements, are also factored into the assessment.

The end-of-life stage presents both challenges and opportunities for sustainability. LCA evaluates the environmental impacts of motor disposal, including potential soil and water contamination from improper handling. However, it also considers the benefits of recycling and material recovery, which can significantly reduce the need for virgin materials in future motor production.

By applying LCA to induction motors in urban infrastructure, decision-makers can identify hotspots of environmental impact and prioritize improvement efforts. For instance, optimizing motor efficiency during operation often yields the greatest sustainability benefits due to the long service life of these devices. Additionally, LCA can guide the selection of more environmentally friendly materials and manufacturing processes.

Furthermore, LCA enables comparisons between different motor technologies and designs, helping urban planners and engineers choose the most sustainable options for specific applications. This analysis may reveal trade-offs between various environmental impacts, such as energy efficiency versus material toxicity, allowing for informed decision-making that aligns with broader sustainability goals.

In the context of urban infrastructure, LCA of induction motors extends beyond the devices themselves to consider their role in larger systems. For example, the use of high-efficiency motors in water pumping stations or HVAC systems can lead to cascading energy savings throughout the urban environment. By quantifying these system-wide effects, LCA provides a more complete picture of how induction motors contribute to urban sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!