Induction motors in combined heat and power (CHP) systems

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CHP Induction Motor Evolution and Objectives

Combined Heat and Power (CHP) systems have evolved significantly over the past decades, with induction motors playing a crucial role in their development. The journey of induction motors in CHP systems began in the early 20th century when the concept of cogeneration gained traction. Initially, these motors were primarily used for simple power generation tasks, but as technology advanced, their applications expanded.

The 1970s marked a turning point in CHP technology, driven by the global energy crisis. This period saw increased research into more efficient energy systems, leading to the integration of advanced induction motors in CHP applications. These motors offered improved efficiency and reliability, making them ideal for the demanding requirements of cogeneration systems.

Throughout the 1980s and 1990s, the focus shifted towards enhancing the performance and control of induction motors in CHP systems. The advent of power electronics and digital control systems allowed for more precise speed control and energy management, significantly improving the overall efficiency of CHP plants.

The turn of the millennium brought about a new era for induction motors in CHP systems. With growing concerns about climate change and energy sustainability, there was a renewed emphasis on maximizing energy efficiency. This led to the development of high-efficiency induction motors specifically designed for CHP applications, capable of operating at variable speeds and loads to optimize energy production.

Recent years have seen a trend towards the integration of smart technologies in CHP systems. Induction motors are now being equipped with advanced sensors and connectivity features, allowing for real-time monitoring, predictive maintenance, and integration with smart grid systems. This evolution aligns with the broader trend of Industry 4.0, where data-driven decision-making is becoming increasingly important in energy management.

Looking ahead, the objectives for induction motors in CHP systems are multifaceted. One primary goal is to further improve energy efficiency, aiming to reduce losses and increase the overall output of CHP plants. This involves research into advanced materials for motor construction, such as high-performance magnetic materials and more efficient conductor designs.

Another key objective is to enhance the flexibility and responsiveness of induction motors in CHP systems. As renewable energy sources become more prevalent, CHP systems need to adapt to fluctuating energy demands and variable input sources. This requires the development of more adaptable motor designs and control systems that can quickly adjust to changing conditions.

Sustainability is also a critical focus, with efforts directed towards developing more environmentally friendly motor designs. This includes research into reducing the use of rare earth materials, improving recyclability, and minimizing the environmental impact throughout the motor's lifecycle.

The 1970s marked a turning point in CHP technology, driven by the global energy crisis. This period saw increased research into more efficient energy systems, leading to the integration of advanced induction motors in CHP applications. These motors offered improved efficiency and reliability, making them ideal for the demanding requirements of cogeneration systems.

Throughout the 1980s and 1990s, the focus shifted towards enhancing the performance and control of induction motors in CHP systems. The advent of power electronics and digital control systems allowed for more precise speed control and energy management, significantly improving the overall efficiency of CHP plants.

The turn of the millennium brought about a new era for induction motors in CHP systems. With growing concerns about climate change and energy sustainability, there was a renewed emphasis on maximizing energy efficiency. This led to the development of high-efficiency induction motors specifically designed for CHP applications, capable of operating at variable speeds and loads to optimize energy production.

Recent years have seen a trend towards the integration of smart technologies in CHP systems. Induction motors are now being equipped with advanced sensors and connectivity features, allowing for real-time monitoring, predictive maintenance, and integration with smart grid systems. This evolution aligns with the broader trend of Industry 4.0, where data-driven decision-making is becoming increasingly important in energy management.

Looking ahead, the objectives for induction motors in CHP systems are multifaceted. One primary goal is to further improve energy efficiency, aiming to reduce losses and increase the overall output of CHP plants. This involves research into advanced materials for motor construction, such as high-performance magnetic materials and more efficient conductor designs.

Another key objective is to enhance the flexibility and responsiveness of induction motors in CHP systems. As renewable energy sources become more prevalent, CHP systems need to adapt to fluctuating energy demands and variable input sources. This requires the development of more adaptable motor designs and control systems that can quickly adjust to changing conditions.

Sustainability is also a critical focus, with efforts directed towards developing more environmentally friendly motor designs. This includes research into reducing the use of rare earth materials, improving recyclability, and minimizing the environmental impact throughout the motor's lifecycle.

CHP Market Demand Analysis

The combined heat and power (CHP) market has been experiencing significant growth in recent years, driven by increasing energy efficiency demands and environmental concerns. The global CHP market size was valued at approximately $26.6 billion in 2020 and is projected to reach $35.2 billion by 2026, growing at a CAGR of 5.2% during the forecast period. This growth is primarily attributed to the rising need for energy-efficient power generation systems and the increasing adoption of distributed energy resources.

The demand for CHP systems is particularly strong in industrial and commercial sectors, where there is a constant need for both electricity and heat. Industries such as chemicals, paper and pulp, food processing, and pharmaceuticals are major consumers of CHP systems due to their high energy requirements. In the commercial sector, hospitals, universities, and large office buildings are increasingly adopting CHP systems to reduce energy costs and improve reliability.

Geographically, Europe has been at the forefront of CHP adoption, with countries like Germany, Denmark, and the Netherlands leading the way. The European Union's energy efficiency directives have been a significant driver for CHP market growth in the region. In North America, the United States has seen a steady increase in CHP installations, particularly in states with supportive policies and incentives.

The Asia-Pacific region is expected to witness the highest growth rate in the CHP market, driven by rapid industrialization, urbanization, and increasing energy demand in countries like China and India. Government initiatives to promote clean energy and reduce carbon emissions are further fueling the adoption of CHP systems in these countries.

In terms of technology, gas turbine-based CHP systems currently dominate the market due to their high efficiency and reliability. However, there is a growing interest in renewable energy-based CHP systems, such as biomass and solar thermal, as organizations seek to further reduce their carbon footprint.

The market demand for induction motors in CHP systems is closely tied to the overall CHP market growth. Induction motors play a crucial role in CHP systems, particularly in applications where high power and reliability are required. The increasing focus on energy efficiency is driving the demand for high-efficiency induction motors in CHP applications.

Furthermore, the integration of smart technologies and IoT in CHP systems is creating new opportunities for advanced motor control and monitoring solutions. This trend is expected to drive innovation in induction motor design and control systems, further boosting market demand.

The demand for CHP systems is particularly strong in industrial and commercial sectors, where there is a constant need for both electricity and heat. Industries such as chemicals, paper and pulp, food processing, and pharmaceuticals are major consumers of CHP systems due to their high energy requirements. In the commercial sector, hospitals, universities, and large office buildings are increasingly adopting CHP systems to reduce energy costs and improve reliability.

Geographically, Europe has been at the forefront of CHP adoption, with countries like Germany, Denmark, and the Netherlands leading the way. The European Union's energy efficiency directives have been a significant driver for CHP market growth in the region. In North America, the United States has seen a steady increase in CHP installations, particularly in states with supportive policies and incentives.

The Asia-Pacific region is expected to witness the highest growth rate in the CHP market, driven by rapid industrialization, urbanization, and increasing energy demand in countries like China and India. Government initiatives to promote clean energy and reduce carbon emissions are further fueling the adoption of CHP systems in these countries.

In terms of technology, gas turbine-based CHP systems currently dominate the market due to their high efficiency and reliability. However, there is a growing interest in renewable energy-based CHP systems, such as biomass and solar thermal, as organizations seek to further reduce their carbon footprint.

The market demand for induction motors in CHP systems is closely tied to the overall CHP market growth. Induction motors play a crucial role in CHP systems, particularly in applications where high power and reliability are required. The increasing focus on energy efficiency is driving the demand for high-efficiency induction motors in CHP applications.

Furthermore, the integration of smart technologies and IoT in CHP systems is creating new opportunities for advanced motor control and monitoring solutions. This trend is expected to drive innovation in induction motor design and control systems, further boosting market demand.

Induction Motor Challenges in CHP Systems

Induction motors in combined heat and power (CHP) systems face several significant challenges that impact their performance, efficiency, and reliability. One of the primary issues is the harsh operating environment typically found in CHP plants. These motors are often exposed to high temperatures, vibrations, and potentially corrosive atmospheres, which can accelerate wear and tear on components, leading to reduced lifespan and increased maintenance requirements.

The variable load conditions inherent in CHP systems present another major challenge for induction motors. As the demand for heat and power fluctuates, motors must adapt to changing speed and torque requirements. This constant adjustment can lead to increased stress on the motor's components, particularly the rotor and stator windings. Furthermore, frequent start-stop cycles, common in CHP operations, can cause thermal and mechanical stresses that may result in premature failure of motor parts.

Power quality issues are also a significant concern in CHP environments. Voltage fluctuations, harmonics, and unbalanced supply voltages can adversely affect motor performance and efficiency. These power anomalies can cause overheating, increased losses, and reduced torque output, ultimately leading to decreased overall system efficiency and potential motor damage.

The need for high efficiency in CHP systems places additional demands on induction motors. While these motors are generally known for their robustness and reliability, achieving and maintaining peak efficiency across a wide range of operating conditions remains challenging. This is particularly true when considering the trade-offs between motor size, cost, and performance characteristics required for optimal CHP system integration.

Cooling and thermal management present another set of challenges for induction motors in CHP applications. The heat generated by the motor itself, combined with the high ambient temperatures often present in CHP plants, necessitates effective cooling solutions. Inadequate cooling can lead to insulation breakdown, bearing failures, and reduced motor lifespan.

Lastly, the integration of induction motors with advanced control systems and power electronics in modern CHP installations introduces complexities in motor design and operation. Ensuring compatibility with variable frequency drives, soft starters, and sophisticated monitoring systems while maintaining robust performance under various operating conditions requires careful consideration and engineering.

Addressing these challenges requires innovative approaches in motor design, materials selection, and system integration. Ongoing research and development efforts focus on improving motor efficiency, enhancing thermal management, developing more resilient insulation systems, and creating advanced control algorithms to optimize motor performance in the demanding CHP environment.

The variable load conditions inherent in CHP systems present another major challenge for induction motors. As the demand for heat and power fluctuates, motors must adapt to changing speed and torque requirements. This constant adjustment can lead to increased stress on the motor's components, particularly the rotor and stator windings. Furthermore, frequent start-stop cycles, common in CHP operations, can cause thermal and mechanical stresses that may result in premature failure of motor parts.

Power quality issues are also a significant concern in CHP environments. Voltage fluctuations, harmonics, and unbalanced supply voltages can adversely affect motor performance and efficiency. These power anomalies can cause overheating, increased losses, and reduced torque output, ultimately leading to decreased overall system efficiency and potential motor damage.

The need for high efficiency in CHP systems places additional demands on induction motors. While these motors are generally known for their robustness and reliability, achieving and maintaining peak efficiency across a wide range of operating conditions remains challenging. This is particularly true when considering the trade-offs between motor size, cost, and performance characteristics required for optimal CHP system integration.

Cooling and thermal management present another set of challenges for induction motors in CHP applications. The heat generated by the motor itself, combined with the high ambient temperatures often present in CHP plants, necessitates effective cooling solutions. Inadequate cooling can lead to insulation breakdown, bearing failures, and reduced motor lifespan.

Lastly, the integration of induction motors with advanced control systems and power electronics in modern CHP installations introduces complexities in motor design and operation. Ensuring compatibility with variable frequency drives, soft starters, and sophisticated monitoring systems while maintaining robust performance under various operating conditions requires careful consideration and engineering.

Addressing these challenges requires innovative approaches in motor design, materials selection, and system integration. Ongoing research and development efforts focus on improving motor efficiency, enhancing thermal management, developing more resilient insulation systems, and creating advanced control algorithms to optimize motor performance in the demanding CHP environment.

Current CHP Induction Motor Solutions

01 Design and construction of induction motors

This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.- Design and construction of induction motors: This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.

- Control systems for induction motors: Control systems play a crucial role in regulating the speed, torque, and efficiency of induction motors. This category encompasses various control strategies, including vector control, direct torque control, and sensorless control techniques, as well as the implementation of advanced control algorithms and hardware.

- Energy efficiency improvements in induction motors: This category focuses on innovations aimed at enhancing the energy efficiency of induction motors. It includes advancements in motor design, materials, and manufacturing processes that reduce losses and improve overall motor performance, contributing to energy savings in various applications.

- Specialized applications of induction motors: Induction motors are used in a wide range of specialized applications, each with unique requirements. This category covers adaptations and modifications of induction motors for specific industries or operating conditions, such as high-speed motors, submersible motors, or motors for extreme environments.

- Diagnostics and condition monitoring of induction motors: This category encompasses techniques and systems for monitoring the health and performance of induction motors. It includes methods for fault detection, predictive maintenance, and real-time monitoring of motor parameters to ensure optimal operation and prevent unexpected failures.

02 Control systems for induction motors

Control systems play a crucial role in regulating the speed, torque, and efficiency of induction motors. This category encompasses various control strategies, including vector control, direct torque control, and advanced algorithms for optimizing motor performance under different operating conditions.Expand Specific Solutions03 Energy efficiency improvements in induction motors

This category focuses on techniques and technologies aimed at enhancing the energy efficiency of induction motors. This includes the use of advanced materials, improved cooling systems, and innovative designs to reduce losses and increase overall motor efficiency.Expand Specific Solutions04 Specialized applications of induction motors

Induction motors are used in a wide range of specialized applications, each with unique requirements. This category covers innovations tailored for specific industries or applications, such as high-speed motors, submersible motors, or motors designed for harsh environments.Expand Specific Solutions05 Diagnostics and maintenance of induction motors

This category encompasses methods and systems for monitoring, diagnosing, and maintaining induction motors. It includes techniques for fault detection, predictive maintenance, and condition monitoring to ensure optimal motor performance and longevity.Expand Specific Solutions

Key CHP Induction Motor Manufacturers

The research on induction motors in combined heat and power (CHP) systems is in a mature stage of development, with a significant market size due to the growing demand for energy-efficient solutions. The technology's maturity is evident from the involvement of established players like Wärtsilä Finland Oy, Carrier Corp., and State Grid Corp. of China, who have extensive experience in power generation and distribution. The competitive landscape is diverse, including both large corporations and specialized firms such as Xinzhi Energy System Control Co., Ltd. and Jinneng Science & Technology Co., Ltd. Academic institutions like Ghent University contribute to ongoing research and innovation in this field, indicating a continuous evolution of the technology despite its maturity.

Wärtsilä Finland Oy

Technical Solution: Wärtsilä has developed advanced induction motor technology for CHP systems, focusing on high-efficiency and variable speed operation. Their motors incorporate advanced cooling systems and optimized rotor designs to enhance performance in CHP applications. The company has implemented a proprietary control algorithm that allows for precise speed control, resulting in improved overall system efficiency[1]. Wärtsilä's induction motors for CHP systems are designed to operate at temperatures up to 150°C, ensuring reliability in demanding industrial environments[2]. The company has also integrated smart diagnostics and predictive maintenance features, reducing downtime and operational costs for CHP plant operators[3].

Strengths: High efficiency, advanced cooling systems, and smart diagnostics. Weaknesses: Potentially higher initial cost compared to standard motors, and may require specialized maintenance.

Eaton Intelligent Power Ltd.

Technical Solution: Eaton has developed a range of intelligent induction motors specifically designed for CHP systems. Their motors feature advanced power electronics and digital control systems that enable seamless integration with CHP plant management systems. Eaton's induction motors incorporate a unique rotor design that minimizes losses and improves torque characteristics across a wide speed range[4]. The company has also implemented an innovative thermal management system that allows for higher power density and improved reliability in CHP applications[5]. Eaton's motors are equipped with built-in sensors and connectivity features, enabling real-time monitoring and performance optimization of the CHP system[6].

Strengths: Advanced control systems, high power density, and IoT integration capabilities. Weaknesses: May require specialized expertise for installation and maintenance, potentially limiting adoption in smaller CHP installations.

Core CHP Motor Innovations

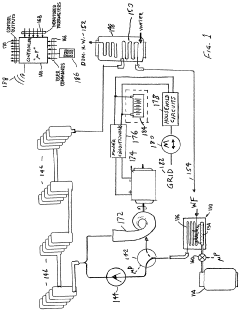

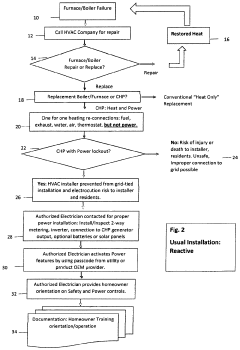

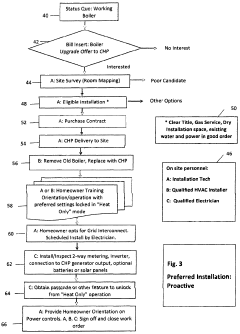

Installation of combined heat and power systems

PatentActiveUS11041631B2

Innovation

- Incorporating a mechanical or electrical 'power lock-out' feature in the CHP system that prevents immediate operation of the power generation mode, allowing a qualified HVAC installer to initially connect the system, while a certified electrician completes the power generation integration, ensuring safe and proper installation, with modes of operation including 'grid-tied' and 'off-grid' capabilities.

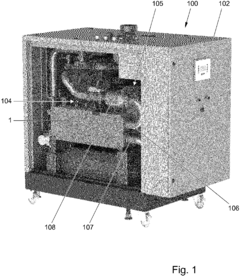

Combined heat and power (chp) system

PatentInactiveEP2778591A3

Innovation

- A CHP system featuring a heat exchanger with flue ducts formed by extrusion, made from light metals like aluminum, with low surface roughness and a design allowing for easy cleaning, which reduces contamination and maintains efficiency over time.

Energy Efficiency Regulations

Energy efficiency regulations play a crucial role in shaping the development and implementation of combined heat and power (CHP) systems, particularly concerning the use of induction motors. These regulations aim to optimize energy consumption, reduce greenhouse gas emissions, and promote sustainable energy practices across various industries.

In the context of CHP systems, energy efficiency regulations often focus on the performance standards of key components, including induction motors. These motors, widely used in CHP applications, are subject to stringent efficiency requirements to ensure optimal energy utilization. Regulatory bodies, such as the International Electrotechnical Commission (IEC) and the U.S. Department of Energy (DOE), have established specific standards for motor efficiency classifications.

The IEC 60034-30-1 standard, for instance, defines efficiency classes for induction motors, ranging from IE1 (standard efficiency) to IE4 (super premium efficiency). These classifications set minimum efficiency levels that manufacturers must meet, driving innovation in motor design and materials. Similarly, the DOE has implemented mandatory efficiency standards for electric motors, including those used in CHP systems, through its Energy Conservation Standards for Commercial and Industrial Electric Motors.

Compliance with these regulations often requires CHP system designers and operators to carefully select and integrate high-efficiency induction motors. This selection process involves considering factors such as motor size, load profile, and operating conditions to ensure optimal performance within the regulatory framework. Additionally, energy efficiency regulations may mandate the use of variable frequency drives (VFDs) in certain CHP applications to further enhance motor efficiency and system flexibility.

The impact of these regulations extends beyond individual motor performance, influencing the overall design and operation of CHP systems. For example, regulations may require the implementation of advanced monitoring and control systems to track energy consumption and efficiency metrics. This data-driven approach enables operators to optimize system performance and demonstrate compliance with regulatory standards.

Furthermore, energy efficiency regulations often incentivize the adoption of advanced technologies in CHP systems. This includes the integration of smart grid capabilities, which allow for more efficient load management and better integration with renewable energy sources. Such regulatory-driven innovations contribute to the overall improvement of CHP system efficiency and environmental performance.

As research on induction motors in CHP systems progresses, it is essential to consider the evolving landscape of energy efficiency regulations. Future regulatory developments may focus on further improving motor efficiency standards, promoting the use of alternative motor technologies, or addressing the specific challenges of integrating CHP systems with emerging smart grid infrastructures. Staying abreast of these regulatory trends is crucial for researchers and industry professionals working on advancing induction motor technology in CHP applications.

In the context of CHP systems, energy efficiency regulations often focus on the performance standards of key components, including induction motors. These motors, widely used in CHP applications, are subject to stringent efficiency requirements to ensure optimal energy utilization. Regulatory bodies, such as the International Electrotechnical Commission (IEC) and the U.S. Department of Energy (DOE), have established specific standards for motor efficiency classifications.

The IEC 60034-30-1 standard, for instance, defines efficiency classes for induction motors, ranging from IE1 (standard efficiency) to IE4 (super premium efficiency). These classifications set minimum efficiency levels that manufacturers must meet, driving innovation in motor design and materials. Similarly, the DOE has implemented mandatory efficiency standards for electric motors, including those used in CHP systems, through its Energy Conservation Standards for Commercial and Industrial Electric Motors.

Compliance with these regulations often requires CHP system designers and operators to carefully select and integrate high-efficiency induction motors. This selection process involves considering factors such as motor size, load profile, and operating conditions to ensure optimal performance within the regulatory framework. Additionally, energy efficiency regulations may mandate the use of variable frequency drives (VFDs) in certain CHP applications to further enhance motor efficiency and system flexibility.

The impact of these regulations extends beyond individual motor performance, influencing the overall design and operation of CHP systems. For example, regulations may require the implementation of advanced monitoring and control systems to track energy consumption and efficiency metrics. This data-driven approach enables operators to optimize system performance and demonstrate compliance with regulatory standards.

Furthermore, energy efficiency regulations often incentivize the adoption of advanced technologies in CHP systems. This includes the integration of smart grid capabilities, which allow for more efficient load management and better integration with renewable energy sources. Such regulatory-driven innovations contribute to the overall improvement of CHP system efficiency and environmental performance.

As research on induction motors in CHP systems progresses, it is essential to consider the evolving landscape of energy efficiency regulations. Future regulatory developments may focus on further improving motor efficiency standards, promoting the use of alternative motor technologies, or addressing the specific challenges of integrating CHP systems with emerging smart grid infrastructures. Staying abreast of these regulatory trends is crucial for researchers and industry professionals working on advancing induction motor technology in CHP applications.

Environmental Impact Assessment

The environmental impact assessment of induction motors in combined heat and power (CHP) systems is a critical aspect of evaluating their overall sustainability and efficiency. These systems, which simultaneously generate electricity and useful thermal energy, have the potential to significantly reduce greenhouse gas emissions and improve energy efficiency compared to separate heat and power generation.

Induction motors, as key components in CHP systems, contribute to both positive and negative environmental impacts. On the positive side, their high efficiency and reliability lead to reduced energy consumption and lower emissions over the system's lifetime. The improved energy utilization in CHP systems, partly due to the performance of induction motors, results in decreased fossil fuel consumption and associated pollutant emissions.

However, the manufacturing process of induction motors involves the use of various materials, including copper, steel, and rare earth elements, which can have environmental implications. The extraction and processing of these materials contribute to resource depletion and may involve energy-intensive processes that generate emissions. Additionally, the production of electrical components and insulation materials used in induction motors may involve the use of chemicals that could potentially harm the environment if not properly managed.

During operation, induction motors in CHP systems may contribute to noise pollution, which can have adverse effects on local ecosystems and human health. Proper insulation and noise reduction measures are essential to mitigate this impact. Furthermore, the cooling systems required for these motors may consume water resources, and the use of lubricants and coolants presents potential risks of soil and water contamination if not handled correctly.

End-of-life considerations for induction motors in CHP systems are also important from an environmental perspective. The disposal or recycling of these components must be carefully managed to prevent the release of harmful substances into the environment. Proper recycling of materials, particularly copper and steel, can significantly reduce the environmental footprint of these systems.

When assessing the overall environmental impact, it is crucial to consider the entire lifecycle of induction motors in CHP systems, from raw material extraction to disposal. Life Cycle Assessment (LCA) studies have shown that the operational phase typically accounts for the majority of environmental impacts due to energy consumption. However, improvements in motor efficiency and the integration of renewable energy sources in CHP systems can substantially reduce these impacts over time.

In conclusion, while induction motors in CHP systems contribute to improved energy efficiency and reduced emissions, their environmental impact must be carefully managed throughout their lifecycle. Ongoing research and development efforts focus on enhancing motor efficiency, exploring more sustainable materials, and improving recycling processes to further minimize the environmental footprint of these essential components in combined heat and power systems.

Induction motors, as key components in CHP systems, contribute to both positive and negative environmental impacts. On the positive side, their high efficiency and reliability lead to reduced energy consumption and lower emissions over the system's lifetime. The improved energy utilization in CHP systems, partly due to the performance of induction motors, results in decreased fossil fuel consumption and associated pollutant emissions.

However, the manufacturing process of induction motors involves the use of various materials, including copper, steel, and rare earth elements, which can have environmental implications. The extraction and processing of these materials contribute to resource depletion and may involve energy-intensive processes that generate emissions. Additionally, the production of electrical components and insulation materials used in induction motors may involve the use of chemicals that could potentially harm the environment if not properly managed.

During operation, induction motors in CHP systems may contribute to noise pollution, which can have adverse effects on local ecosystems and human health. Proper insulation and noise reduction measures are essential to mitigate this impact. Furthermore, the cooling systems required for these motors may consume water resources, and the use of lubricants and coolants presents potential risks of soil and water contamination if not handled correctly.

End-of-life considerations for induction motors in CHP systems are also important from an environmental perspective. The disposal or recycling of these components must be carefully managed to prevent the release of harmful substances into the environment. Proper recycling of materials, particularly copper and steel, can significantly reduce the environmental footprint of these systems.

When assessing the overall environmental impact, it is crucial to consider the entire lifecycle of induction motors in CHP systems, from raw material extraction to disposal. Life Cycle Assessment (LCA) studies have shown that the operational phase typically accounts for the majority of environmental impacts due to energy consumption. However, improvements in motor efficiency and the integration of renewable energy sources in CHP systems can substantially reduce these impacts over time.

In conclusion, while induction motors in CHP systems contribute to improved energy efficiency and reduced emissions, their environmental impact must be carefully managed throughout their lifecycle. Ongoing research and development efforts focus on enhancing motor efficiency, exploring more sustainable materials, and improving recycling processes to further minimize the environmental footprint of these essential components in combined heat and power systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!