How induction motors improve air conditioning system efficiency

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor AC Efficiency Background

Induction motors have played a pivotal role in revolutionizing air conditioning systems, significantly enhancing their efficiency and performance. The journey of integrating induction motors into AC systems began in the early 20th century, coinciding with the rapid development of electrical engineering and the growing demand for climate control solutions.

Initially, air conditioning systems relied on less efficient motor technologies, such as single-phase motors or DC motors. These early systems were often bulky, noisy, and consumed substantial amounts of energy. The introduction of induction motors marked a turning point in AC system design, offering a more reliable and energy-efficient alternative.

The fundamental principle behind induction motors' efficiency lies in their ability to convert electrical energy into mechanical energy with minimal losses. This is achieved through the interaction between a rotating magnetic field in the stator and induced currents in the rotor. As AC systems evolved, manufacturers began to recognize the potential of induction motors to drive compressors, fans, and other critical components more efficiently.

One of the key advantages of induction motors in AC systems is their ability to operate at variable speeds. This feature allows for precise control of cooling capacity, adapting to changing environmental conditions and user requirements. By modulating the motor speed, AC systems can maintain desired temperatures more accurately while consuming less energy during periods of lower demand.

The development of advanced control systems and power electronics further enhanced the efficiency of induction motors in AC applications. Variable frequency drives (VFDs) emerged as a game-changing technology, enabling seamless speed control and optimizing motor performance across a wide range of operating conditions. This innovation led to significant energy savings and improved overall system efficiency.

As environmental concerns and energy regulations became more stringent, the focus on improving AC system efficiency intensified. Induction motors, with their inherent efficiency advantages, became the preferred choice for manufacturers seeking to meet increasingly demanding energy standards. The continuous refinement of motor design, including the use of high-quality materials and improved manufacturing techniques, has resulted in even greater efficiency gains over time.

Today, induction motors remain a cornerstone of modern AC systems, contributing to their reliability, longevity, and energy efficiency. The ongoing research and development in motor technology continue to push the boundaries of performance, with innovations such as permanent magnet synchronous motors (PMSMs) building upon the foundation laid by induction motors. As the industry moves towards more sustainable and energy-efficient solutions, the legacy of induction motors in improving AC system efficiency serves as a testament to their enduring impact on climate control technology.

Initially, air conditioning systems relied on less efficient motor technologies, such as single-phase motors or DC motors. These early systems were often bulky, noisy, and consumed substantial amounts of energy. The introduction of induction motors marked a turning point in AC system design, offering a more reliable and energy-efficient alternative.

The fundamental principle behind induction motors' efficiency lies in their ability to convert electrical energy into mechanical energy with minimal losses. This is achieved through the interaction between a rotating magnetic field in the stator and induced currents in the rotor. As AC systems evolved, manufacturers began to recognize the potential of induction motors to drive compressors, fans, and other critical components more efficiently.

One of the key advantages of induction motors in AC systems is their ability to operate at variable speeds. This feature allows for precise control of cooling capacity, adapting to changing environmental conditions and user requirements. By modulating the motor speed, AC systems can maintain desired temperatures more accurately while consuming less energy during periods of lower demand.

The development of advanced control systems and power electronics further enhanced the efficiency of induction motors in AC applications. Variable frequency drives (VFDs) emerged as a game-changing technology, enabling seamless speed control and optimizing motor performance across a wide range of operating conditions. This innovation led to significant energy savings and improved overall system efficiency.

As environmental concerns and energy regulations became more stringent, the focus on improving AC system efficiency intensified. Induction motors, with their inherent efficiency advantages, became the preferred choice for manufacturers seeking to meet increasingly demanding energy standards. The continuous refinement of motor design, including the use of high-quality materials and improved manufacturing techniques, has resulted in even greater efficiency gains over time.

Today, induction motors remain a cornerstone of modern AC systems, contributing to their reliability, longevity, and energy efficiency. The ongoing research and development in motor technology continue to push the boundaries of performance, with innovations such as permanent magnet synchronous motors (PMSMs) building upon the foundation laid by induction motors. As the industry moves towards more sustainable and energy-efficient solutions, the legacy of induction motors in improving AC system efficiency serves as a testament to their enduring impact on climate control technology.

AC Market Demand Analysis

The global air conditioning market has been experiencing significant growth, driven by increasing urbanization, rising disposable incomes, and changing climate patterns. As energy efficiency becomes a paramount concern for both consumers and regulators, the demand for more efficient air conditioning systems has surged. This trend has placed induction motors at the forefront of technological advancements in the AC industry.

Market research indicates that the global air conditioning market is expected to reach substantial growth in the coming years. This expansion is particularly notable in developing regions such as Asia-Pacific and the Middle East, where rapid industrialization and improving living standards are fueling demand. In mature markets like North America and Europe, the focus has shifted towards replacing older, less efficient systems with more energy-efficient models.

The residential sector represents a significant portion of the AC market, with homeowners increasingly seeking energy-efficient solutions to reduce electricity costs and minimize environmental impact. Commercial and industrial sectors also contribute substantially to market growth, as businesses prioritize energy efficiency to lower operational expenses and meet sustainability goals.

Energy efficiency regulations and standards have become more stringent globally, pushing manufacturers to innovate and improve their products. This regulatory environment has created a strong market pull for advanced technologies like high-efficiency induction motors in air conditioning systems. Consumers are becoming more aware of energy ratings and lifecycle costs, influencing their purchasing decisions towards more efficient options.

The market demand for air conditioners with improved efficiency is also driven by the growing awareness of environmental issues and the need to reduce carbon emissions. Governments worldwide are implementing policies and incentives to promote the adoption of energy-efficient appliances, further stimulating market growth for advanced AC systems incorporating induction motors.

As urbanization continues and the effects of climate change become more pronounced, the demand for air conditioning is expected to rise, particularly in hot and humid regions. This trend underscores the importance of developing and implementing more efficient cooling technologies to meet the growing demand while minimizing energy consumption and environmental impact.

The integration of smart technologies and Internet of Things (IoT) capabilities in air conditioning systems is another factor shaping market demand. Consumers are increasingly seeking AC units that offer remote control, scheduling, and adaptive cooling features, which can be enhanced by the precise control capabilities of advanced induction motors.

Market research indicates that the global air conditioning market is expected to reach substantial growth in the coming years. This expansion is particularly notable in developing regions such as Asia-Pacific and the Middle East, where rapid industrialization and improving living standards are fueling demand. In mature markets like North America and Europe, the focus has shifted towards replacing older, less efficient systems with more energy-efficient models.

The residential sector represents a significant portion of the AC market, with homeowners increasingly seeking energy-efficient solutions to reduce electricity costs and minimize environmental impact. Commercial and industrial sectors also contribute substantially to market growth, as businesses prioritize energy efficiency to lower operational expenses and meet sustainability goals.

Energy efficiency regulations and standards have become more stringent globally, pushing manufacturers to innovate and improve their products. This regulatory environment has created a strong market pull for advanced technologies like high-efficiency induction motors in air conditioning systems. Consumers are becoming more aware of energy ratings and lifecycle costs, influencing their purchasing decisions towards more efficient options.

The market demand for air conditioners with improved efficiency is also driven by the growing awareness of environmental issues and the need to reduce carbon emissions. Governments worldwide are implementing policies and incentives to promote the adoption of energy-efficient appliances, further stimulating market growth for advanced AC systems incorporating induction motors.

As urbanization continues and the effects of climate change become more pronounced, the demand for air conditioning is expected to rise, particularly in hot and humid regions. This trend underscores the importance of developing and implementing more efficient cooling technologies to meet the growing demand while minimizing energy consumption and environmental impact.

The integration of smart technologies and Internet of Things (IoT) capabilities in air conditioning systems is another factor shaping market demand. Consumers are increasingly seeking AC units that offer remote control, scheduling, and adaptive cooling features, which can be enhanced by the precise control capabilities of advanced induction motors.

Induction Motor Tech Challenges

Induction motors, while widely used in air conditioning systems, face several technical challenges that impact their efficiency and overall performance. One of the primary issues is the inherent slip in these motors, which results in energy losses and reduced efficiency. As the rotor speed lags behind the stator's rotating magnetic field, a portion of the input energy is dissipated as heat, diminishing the motor's overall efficiency.

Another significant challenge is the difficulty in precisely controlling the speed of induction motors. Traditional methods often rely on inefficient mechanical means or complex electronic systems, which can be costly and may not provide the level of control required for optimal air conditioning performance. This limitation hampers the ability to fine-tune system operations in response to varying cooling demands and environmental conditions.

Heat management presents a further obstacle in induction motor design for air conditioning applications. As these motors operate, they generate substantial heat, which can lead to reduced efficiency and shortened lifespan if not properly addressed. The challenge lies in developing effective cooling mechanisms that do not significantly increase the motor's size or weight, while still maintaining optimal operating temperatures.

Power factor correction is another area of concern for induction motors in air conditioning systems. These motors typically operate at a lower power factor, which can lead to increased energy consumption and higher electrical costs. Improving the power factor without compromising motor performance or significantly increasing system complexity remains a technical hurdle.

The starting characteristics of induction motors also pose challenges in air conditioning applications. High starting currents can stress electrical systems and components, while slow acceleration times may impact the overall responsiveness of the cooling system. Balancing these factors with the need for reliable and efficient operation requires careful design considerations.

Noise and vibration reduction is an ongoing challenge, particularly in residential and commercial air conditioning installations where user comfort is paramount. Minimizing these issues without compromising motor performance or significantly increasing costs continues to be a focus of research and development efforts.

Lastly, the integration of advanced control systems and smart technologies with induction motors presents both opportunities and challenges. While these technologies offer the potential for improved efficiency and performance, they also introduce complexity in terms of motor design, control algorithms, and system integration. Ensuring seamless compatibility and realizing the full benefits of these advanced features remains a significant technical challenge in the ongoing development of induction motors for air conditioning systems.

Another significant challenge is the difficulty in precisely controlling the speed of induction motors. Traditional methods often rely on inefficient mechanical means or complex electronic systems, which can be costly and may not provide the level of control required for optimal air conditioning performance. This limitation hampers the ability to fine-tune system operations in response to varying cooling demands and environmental conditions.

Heat management presents a further obstacle in induction motor design for air conditioning applications. As these motors operate, they generate substantial heat, which can lead to reduced efficiency and shortened lifespan if not properly addressed. The challenge lies in developing effective cooling mechanisms that do not significantly increase the motor's size or weight, while still maintaining optimal operating temperatures.

Power factor correction is another area of concern for induction motors in air conditioning systems. These motors typically operate at a lower power factor, which can lead to increased energy consumption and higher electrical costs. Improving the power factor without compromising motor performance or significantly increasing system complexity remains a technical hurdle.

The starting characteristics of induction motors also pose challenges in air conditioning applications. High starting currents can stress electrical systems and components, while slow acceleration times may impact the overall responsiveness of the cooling system. Balancing these factors with the need for reliable and efficient operation requires careful design considerations.

Noise and vibration reduction is an ongoing challenge, particularly in residential and commercial air conditioning installations where user comfort is paramount. Minimizing these issues without compromising motor performance or significantly increasing costs continues to be a focus of research and development efforts.

Lastly, the integration of advanced control systems and smart technologies with induction motors presents both opportunities and challenges. While these technologies offer the potential for improved efficiency and performance, they also introduce complexity in terms of motor design, control algorithms, and system integration. Ensuring seamless compatibility and realizing the full benefits of these advanced features remains a significant technical challenge in the ongoing development of induction motors for air conditioning systems.

Current Induction Motor Solutions

01 Advanced control strategies for efficiency improvement

Implementing sophisticated control algorithms and strategies can significantly enhance the efficiency of induction motors. These may include vector control, direct torque control, or adaptive control techniques that optimize motor performance under various operating conditions. Such advanced control methods can reduce energy losses and improve overall system efficiency.- Improved motor design for efficiency: Enhancing induction motor efficiency through optimized design features such as improved rotor and stator configurations, advanced materials, and reduced losses in core and windings. These design improvements can lead to higher power output and reduced energy consumption.

- Advanced control strategies: Implementing sophisticated control algorithms and systems to optimize motor operation, including vector control, flux optimization, and adaptive control techniques. These strategies can improve motor efficiency across various operating conditions and load profiles.

- Energy recovery and regeneration: Incorporating energy recovery systems and regenerative braking techniques to capture and reuse energy that would otherwise be lost during motor operation. This approach can significantly improve overall system efficiency, particularly in applications with frequent starts and stops.

- Thermal management and cooling innovations: Developing advanced cooling systems and thermal management techniques to reduce heat-related losses and improve motor efficiency. This includes innovative cooling designs, heat dissipation methods, and temperature monitoring systems to maintain optimal operating conditions.

- Smart monitoring and predictive maintenance: Utilizing intelligent monitoring systems and predictive maintenance techniques to ensure optimal motor performance and efficiency. This includes real-time data analysis, condition monitoring, and predictive algorithms to identify potential issues before they impact efficiency.

02 Rotor design optimization

Optimizing the rotor design is crucial for improving induction motor efficiency. This may involve using advanced materials, modifying the rotor bar shape and configuration, or implementing novel rotor structures. These design improvements can reduce rotor losses and enhance the motor's overall performance and energy efficiency.Expand Specific Solutions03 Stator winding improvements

Enhancing stator winding design and materials can lead to significant efficiency gains in induction motors. This may include using high-quality copper windings, optimizing winding patterns, or implementing advanced insulation techniques. These improvements can reduce stator losses and improve the motor's power factor and overall efficiency.Expand Specific Solutions04 Thermal management and cooling systems

Implementing effective thermal management and cooling systems can improve induction motor efficiency by reducing temperature-related losses. This may involve advanced cooling techniques, improved heat dissipation designs, or the use of temperature-resistant materials. Better thermal management can lead to increased motor lifespan and improved overall efficiency.Expand Specific Solutions05 Power electronics and drive system optimization

Optimizing power electronics and drive systems can significantly enhance induction motor efficiency. This may include using advanced inverter technologies, implementing regenerative braking systems, or employing smart power management techniques. These improvements can reduce losses in the overall motor drive system and improve energy efficiency across various operating conditions.Expand Specific Solutions

Key AC Industry Players

The induction motor technology in air conditioning systems is in a mature stage, with significant market penetration and ongoing refinements. The global market for energy-efficient air conditioning systems is expanding rapidly, driven by increasing energy costs and environmental concerns. Major players like LG Electronics, Samsung Electronics, and Gree Electric Appliances are leading the innovation in this field, focusing on improving motor efficiency and integrating smart control systems. Companies such as Mitsubishi Electric and Haier Smart Home are also making significant contributions, particularly in developing advanced inverter technologies and IoT-enabled solutions. The competitive landscape is characterized by continuous R&D efforts to enhance energy efficiency and performance, with a growing emphasis on eco-friendly refrigerants and intelligent climate control features.

Gree Electric Appliances, Inc. of Zhuhai

Technical Solution: Gree has developed advanced induction motor technology for air conditioning systems, focusing on improving efficiency and reducing energy consumption. Their latest induction motors utilize a high-efficiency stator design with optimized winding patterns and advanced magnetic materials. This results in reduced copper losses and improved power factor. Gree has also implemented variable frequency drive (VFD) technology, allowing the motor to operate at different speeds based on cooling demand, further enhancing system efficiency[1][3]. Additionally, Gree's induction motors incorporate advanced thermal management techniques, such as improved heat dissipation structures and high-performance lubricants, to maintain optimal operating temperatures and extend motor lifespan[2].

Strengths: High energy efficiency, reduced operating costs, and improved system reliability. Weaknesses: Higher initial cost compared to conventional motors, and potential complexity in maintenance and repair.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed a high-efficiency induction motor system for air conditioning applications, focusing on both motor design and control strategies. Their approach includes the use of copper rotor technology, which offers lower resistance and improved efficiency compared to traditional aluminum rotors[4]. Mitsubishi's induction motors also feature advanced stator designs with optimized slot geometries and high-grade silicon steel laminations to minimize core losses. The company has implemented sophisticated vector control algorithms that enable precise speed and torque control, resulting in improved part-load efficiency[5]. Furthermore, Mitsubishi has integrated their induction motors with smart inverter technology, allowing for seamless communication between the motor and the air conditioning system's control unit, optimizing overall system performance[6].

Strengths: Excellent energy efficiency, particularly at part-load conditions, and advanced control capabilities. Weaknesses: Higher manufacturing costs due to premium materials and potential compatibility issues with older air conditioning systems.

Core Induction Motor Innovations

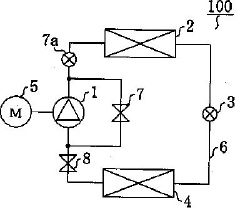

Air conditioner

PatentInactiveJP2001003864A

Innovation

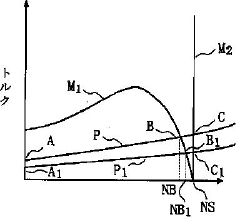

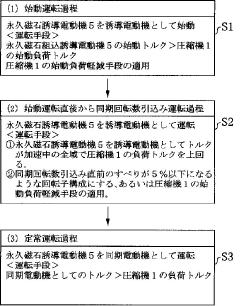

- The air conditioner employs a permanent magnet built-in induction motor that starts as an induction motor, performs synchronous pull-in near synchronous speed, and incorporates bypass and high resistance means to reduce starting load, along with control mechanisms for intermittent power supply to adjust rotation speed.

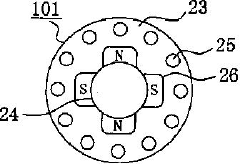

Induction motor

PatentInactiveUS6819026B2

Innovation

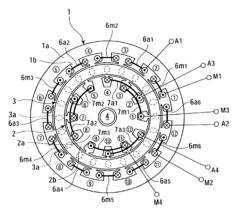

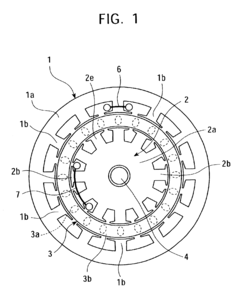

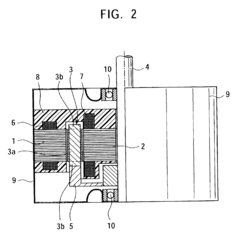

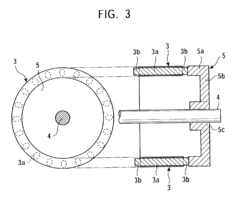

- The design incorporates a radial-air-gap induction motor with two stators and a rotor, featuring squirrel-cage windings and maximized radial air gaps to decrease the average magnetic-flux density, thereby reducing losses without increasing the core size, by optimizing the diameter and length of the air gaps and using a combination of concentrated and distributed windings.

Energy Regulations Impact

Energy regulations have a significant impact on the adoption and development of induction motors in air conditioning systems. As governments worldwide strive to reduce energy consumption and greenhouse gas emissions, they have implemented increasingly stringent efficiency standards for electrical appliances, including air conditioners. These regulations have become a driving force for innovation in motor technology, particularly in the realm of induction motors.

The implementation of minimum energy performance standards (MEPS) for air conditioning systems has led manufacturers to seek more efficient motor solutions. Induction motors, known for their reliability and cost-effectiveness, have been a primary focus for improvement. As a result, advanced induction motor designs have emerged, incorporating features such as copper rotors, improved stator winding configurations, and optimized magnetic circuit designs to meet and exceed these regulatory requirements.

Energy labeling programs, such as the European Union's Energy Label and the U.S. Environmental Protection Agency's ENERGY STAR, have also played a crucial role in promoting the use of high-efficiency induction motors in air conditioning systems. These programs provide consumers with clear information about the energy consumption of appliances, creating market demand for more efficient products. This consumer-driven demand has further incentivized manufacturers to invest in research and development of improved induction motor technologies.

The phase-out of less efficient motor types, mandated by regulations in various countries, has accelerated the transition to high-efficiency induction motors in air conditioning applications. For instance, the European Union's Ecodesign Directive has set progressive efficiency requirements for electric motors, effectively pushing the market towards premium efficiency (IE3) and super-premium efficiency (IE4) induction motors. This regulatory pressure has spurred innovation in motor design and manufacturing processes, leading to significant improvements in the overall efficiency of air conditioning systems.

Furthermore, energy regulations have influenced the development of variable speed drive (VSD) technologies for induction motors. Many energy efficiency standards now require air conditioning systems to operate efficiently across a range of load conditions. This has led to the widespread adoption of VSD-controlled induction motors, which can adjust their speed and power output to match the cooling demand, resulting in substantial energy savings compared to fixed-speed systems.

The impact of energy regulations extends beyond individual product efficiency to system-level performance. Regulations increasingly focus on the overall energy efficiency of complete air conditioning systems, considering factors such as part-load efficiency and seasonal performance. This holistic approach has encouraged the integration of high-efficiency induction motors with other energy-saving technologies, such as advanced control systems and heat exchangers, to create more efficient and compliant air conditioning solutions.

The implementation of minimum energy performance standards (MEPS) for air conditioning systems has led manufacturers to seek more efficient motor solutions. Induction motors, known for their reliability and cost-effectiveness, have been a primary focus for improvement. As a result, advanced induction motor designs have emerged, incorporating features such as copper rotors, improved stator winding configurations, and optimized magnetic circuit designs to meet and exceed these regulatory requirements.

Energy labeling programs, such as the European Union's Energy Label and the U.S. Environmental Protection Agency's ENERGY STAR, have also played a crucial role in promoting the use of high-efficiency induction motors in air conditioning systems. These programs provide consumers with clear information about the energy consumption of appliances, creating market demand for more efficient products. This consumer-driven demand has further incentivized manufacturers to invest in research and development of improved induction motor technologies.

The phase-out of less efficient motor types, mandated by regulations in various countries, has accelerated the transition to high-efficiency induction motors in air conditioning applications. For instance, the European Union's Ecodesign Directive has set progressive efficiency requirements for electric motors, effectively pushing the market towards premium efficiency (IE3) and super-premium efficiency (IE4) induction motors. This regulatory pressure has spurred innovation in motor design and manufacturing processes, leading to significant improvements in the overall efficiency of air conditioning systems.

Furthermore, energy regulations have influenced the development of variable speed drive (VSD) technologies for induction motors. Many energy efficiency standards now require air conditioning systems to operate efficiently across a range of load conditions. This has led to the widespread adoption of VSD-controlled induction motors, which can adjust their speed and power output to match the cooling demand, resulting in substantial energy savings compared to fixed-speed systems.

The impact of energy regulations extends beyond individual product efficiency to system-level performance. Regulations increasingly focus on the overall energy efficiency of complete air conditioning systems, considering factors such as part-load efficiency and seasonal performance. This holistic approach has encouraged the integration of high-efficiency induction motors with other energy-saving technologies, such as advanced control systems and heat exchangers, to create more efficient and compliant air conditioning solutions.

Cost-Benefit Analysis

The implementation of induction motors in air conditioning systems presents a compelling cost-benefit scenario. Initially, the upfront costs associated with integrating induction motors into existing or new air conditioning units may be higher compared to traditional motor systems. This includes expenses related to motor procurement, installation, and potential system redesigns to accommodate the new technology. However, the long-term financial benefits often outweigh these initial investments.

Energy efficiency is a primary advantage of induction motors in air conditioning systems. These motors typically consume 20-30% less electricity compared to conventional motors, resulting in substantial energy cost savings over the lifespan of the air conditioning unit. For large commercial buildings or industrial facilities with extensive cooling requirements, this reduction in energy consumption can translate to significant annual cost reductions.

Maintenance costs also factor into the cost-benefit analysis. Induction motors are known for their robustness and reliability, often requiring less frequent maintenance than their counterparts. This reduced need for repairs and replacements contributes to lower operational costs over time. Additionally, the longer lifespan of induction motors means fewer replacement cycles, further enhancing the long-term cost benefits.

The improved performance of air conditioning systems equipped with induction motors can lead to indirect cost benefits. Enhanced cooling efficiency may result in more consistent temperatures, potentially increasing productivity in work environments and reducing heat-related equipment failures in industrial settings. These factors, while harder to quantify, contribute to the overall economic advantages of implementing induction motor technology.

Environmental considerations also play a role in the cost-benefit analysis. The reduced energy consumption of induction motors aligns with sustainability goals and may help organizations comply with energy efficiency regulations. This can lead to potential tax incentives or avoid penalties associated with high energy consumption, further improving the financial outlook.

When evaluating the return on investment, businesses typically find that the energy savings and reduced maintenance costs offset the initial higher investment within a few years. The exact payback period varies depending on factors such as usage patterns, local energy costs, and the specific air conditioning system configuration. However, case studies often demonstrate payback periods ranging from 2 to 5 years, after which the cost benefits continue to accumulate throughout the system's operational life.

Energy efficiency is a primary advantage of induction motors in air conditioning systems. These motors typically consume 20-30% less electricity compared to conventional motors, resulting in substantial energy cost savings over the lifespan of the air conditioning unit. For large commercial buildings or industrial facilities with extensive cooling requirements, this reduction in energy consumption can translate to significant annual cost reductions.

Maintenance costs also factor into the cost-benefit analysis. Induction motors are known for their robustness and reliability, often requiring less frequent maintenance than their counterparts. This reduced need for repairs and replacements contributes to lower operational costs over time. Additionally, the longer lifespan of induction motors means fewer replacement cycles, further enhancing the long-term cost benefits.

The improved performance of air conditioning systems equipped with induction motors can lead to indirect cost benefits. Enhanced cooling efficiency may result in more consistent temperatures, potentially increasing productivity in work environments and reducing heat-related equipment failures in industrial settings. These factors, while harder to quantify, contribute to the overall economic advantages of implementing induction motor technology.

Environmental considerations also play a role in the cost-benefit analysis. The reduced energy consumption of induction motors aligns with sustainability goals and may help organizations comply with energy efficiency regulations. This can lead to potential tax incentives or avoid penalties associated with high energy consumption, further improving the financial outlook.

When evaluating the return on investment, businesses typically find that the energy savings and reduced maintenance costs offset the initial higher investment within a few years. The exact payback period varies depending on factors such as usage patterns, local energy costs, and the specific air conditioning system configuration. However, case studies often demonstrate payback periods ranging from 2 to 5 years, after which the cost benefits continue to accumulate throughout the system's operational life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!