How induction motors optimize hybrid energy system designs

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Evolution

Induction motors have undergone significant evolution since their inception in the late 19th century, playing a crucial role in the development of hybrid energy system designs. The journey of induction motor technology can be traced through several key stages, each marked by important advancements that have enhanced their efficiency, reliability, and versatility.

In the early 20th century, induction motors were primarily used in industrial applications, characterized by their robust design and simple operation. However, they were limited by their fixed-speed nature and relatively low efficiency. The introduction of variable frequency drives (VFDs) in the 1960s marked a turning point, allowing for speed control and improved energy efficiency.

The 1980s and 1990s saw rapid advancements in power electronics and control systems, leading to more sophisticated motor designs. This period witnessed the development of high-efficiency induction motors, which significantly reduced energy losses and operating costs. The integration of advanced materials, such as copper rotors and high-grade electrical steel, further improved motor performance.

As renewable energy sources gained prominence in the early 2000s, induction motors found new applications in hybrid energy systems. Their ability to operate as both motors and generators made them ideal for wind turbines and other renewable energy applications. This versatility allowed for better integration of various energy sources within a single system.

The advent of smart grid technologies in the 2010s brought about another evolution in induction motor design. Motors equipped with advanced sensors and communication capabilities became integral components of intelligent energy management systems. These smart motors could adapt their operation based on real-time grid conditions, optimizing energy consumption and contributing to grid stability.

Recent years have seen a focus on developing ultra-high-efficiency induction motors, pushing the boundaries of what was previously thought possible. Innovations in motor design, such as axial flux configurations and the use of superconducting materials, have led to motors with efficiency ratings exceeding 95%.

The ongoing evolution of induction motors continues to be driven by the need for more efficient and flexible energy systems. Current research is exploring the potential of Internet of Things (IoT) integration, predictive maintenance capabilities, and further improvements in motor efficiency. These advancements are crucial for optimizing hybrid energy system designs, as they enable better coordination between various energy sources and loads.

As we look to the future, the evolution of induction motors is likely to focus on even greater integration with renewable energy sources, enhanced adaptability to varying grid conditions, and further improvements in energy efficiency. These developments will play a vital role in creating more sustainable and resilient hybrid energy systems, contributing to the global transition towards cleaner and more efficient energy production and consumption.

In the early 20th century, induction motors were primarily used in industrial applications, characterized by their robust design and simple operation. However, they were limited by their fixed-speed nature and relatively low efficiency. The introduction of variable frequency drives (VFDs) in the 1960s marked a turning point, allowing for speed control and improved energy efficiency.

The 1980s and 1990s saw rapid advancements in power electronics and control systems, leading to more sophisticated motor designs. This period witnessed the development of high-efficiency induction motors, which significantly reduced energy losses and operating costs. The integration of advanced materials, such as copper rotors and high-grade electrical steel, further improved motor performance.

As renewable energy sources gained prominence in the early 2000s, induction motors found new applications in hybrid energy systems. Their ability to operate as both motors and generators made them ideal for wind turbines and other renewable energy applications. This versatility allowed for better integration of various energy sources within a single system.

The advent of smart grid technologies in the 2010s brought about another evolution in induction motor design. Motors equipped with advanced sensors and communication capabilities became integral components of intelligent energy management systems. These smart motors could adapt their operation based on real-time grid conditions, optimizing energy consumption and contributing to grid stability.

Recent years have seen a focus on developing ultra-high-efficiency induction motors, pushing the boundaries of what was previously thought possible. Innovations in motor design, such as axial flux configurations and the use of superconducting materials, have led to motors with efficiency ratings exceeding 95%.

The ongoing evolution of induction motors continues to be driven by the need for more efficient and flexible energy systems. Current research is exploring the potential of Internet of Things (IoT) integration, predictive maintenance capabilities, and further improvements in motor efficiency. These advancements are crucial for optimizing hybrid energy system designs, as they enable better coordination between various energy sources and loads.

As we look to the future, the evolution of induction motors is likely to focus on even greater integration with renewable energy sources, enhanced adaptability to varying grid conditions, and further improvements in energy efficiency. These developments will play a vital role in creating more sustainable and resilient hybrid energy systems, contributing to the global transition towards cleaner and more efficient energy production and consumption.

Hybrid Energy Demand

The demand for hybrid energy systems has been steadily increasing in recent years, driven by the global push for cleaner and more sustainable energy solutions. These systems, which typically combine renewable energy sources with conventional power generation, offer numerous advantages in terms of reliability, efficiency, and environmental impact. The integration of induction motors into hybrid energy system designs plays a crucial role in optimizing their performance and expanding their applicability across various sectors.

In the industrial sector, hybrid energy systems are gaining traction as companies seek to reduce their carbon footprint and energy costs. Large manufacturing facilities, for instance, are increasingly adopting hybrid systems that incorporate solar panels, wind turbines, and energy storage solutions alongside traditional grid connections. Induction motors, known for their robustness and efficiency, are essential components in these setups, powering everything from conveyor belts to heavy machinery.

The commercial sector also presents significant opportunities for hybrid energy systems. Office buildings, shopping centers, and data centers are prime candidates for implementing these solutions. The demand for uninterrupted power supply in these environments aligns well with the capabilities of hybrid systems. Induction motors in HVAC systems, elevators, and other building services can be optimized to work seamlessly with the varying power sources in a hybrid setup, ensuring smooth operations and energy efficiency.

In the residential sector, there is a growing interest in microgrids and small-scale hybrid energy systems. Homeowners are increasingly looking to reduce their reliance on the grid and maximize the use of renewable energy sources. Induction motors in household appliances, such as refrigerators, washing machines, and heat pumps, can be designed to operate efficiently within these hybrid systems, adapting to the available power sources and contributing to overall energy savings.

The transportation sector is another area where hybrid energy systems are making significant inroads. Electric and hybrid vehicles are becoming more prevalent, and charging infrastructure is evolving to incorporate renewable energy sources. Induction motors, being a key component in electric vehicle powertrains, play a vital role in this transition. The optimization of these motors for hybrid energy systems can lead to improved vehicle performance, extended range, and faster charging capabilities.

As the demand for hybrid energy systems continues to grow across these sectors, the role of induction motors in optimizing system designs becomes increasingly important. Engineers and researchers are focusing on developing advanced control strategies, improving motor efficiency, and enhancing the integration of induction motors with renewable energy sources and energy storage systems. This ongoing innovation is essential to meet the evolving needs of various industries and to support the broader transition towards sustainable energy solutions.

In the industrial sector, hybrid energy systems are gaining traction as companies seek to reduce their carbon footprint and energy costs. Large manufacturing facilities, for instance, are increasingly adopting hybrid systems that incorporate solar panels, wind turbines, and energy storage solutions alongside traditional grid connections. Induction motors, known for their robustness and efficiency, are essential components in these setups, powering everything from conveyor belts to heavy machinery.

The commercial sector also presents significant opportunities for hybrid energy systems. Office buildings, shopping centers, and data centers are prime candidates for implementing these solutions. The demand for uninterrupted power supply in these environments aligns well with the capabilities of hybrid systems. Induction motors in HVAC systems, elevators, and other building services can be optimized to work seamlessly with the varying power sources in a hybrid setup, ensuring smooth operations and energy efficiency.

In the residential sector, there is a growing interest in microgrids and small-scale hybrid energy systems. Homeowners are increasingly looking to reduce their reliance on the grid and maximize the use of renewable energy sources. Induction motors in household appliances, such as refrigerators, washing machines, and heat pumps, can be designed to operate efficiently within these hybrid systems, adapting to the available power sources and contributing to overall energy savings.

The transportation sector is another area where hybrid energy systems are making significant inroads. Electric and hybrid vehicles are becoming more prevalent, and charging infrastructure is evolving to incorporate renewable energy sources. Induction motors, being a key component in electric vehicle powertrains, play a vital role in this transition. The optimization of these motors for hybrid energy systems can lead to improved vehicle performance, extended range, and faster charging capabilities.

As the demand for hybrid energy systems continues to grow across these sectors, the role of induction motors in optimizing system designs becomes increasingly important. Engineers and researchers are focusing on developing advanced control strategies, improving motor efficiency, and enhancing the integration of induction motors with renewable energy sources and energy storage systems. This ongoing innovation is essential to meet the evolving needs of various industries and to support the broader transition towards sustainable energy solutions.

Induction Motor Challenges

Induction motors, while widely used in hybrid energy systems, face several challenges that impact their optimization and overall system performance. One of the primary issues is the inherent inefficiency at low speeds and partial loads. This characteristic can lead to increased energy consumption and reduced system efficiency, particularly in variable-speed applications common in hybrid energy systems.

Thermal management presents another significant challenge. As induction motors operate, they generate heat, which can lead to reduced efficiency and shortened lifespan if not properly managed. This issue is exacerbated in compact hybrid energy system designs where space for cooling systems is limited.

The starting current of induction motors is another area of concern. The high inrush current during motor start-up can cause voltage dips in the electrical system, potentially affecting other components in the hybrid energy setup. This challenge becomes more pronounced in systems with limited power capacity or weak grid connections.

Power factor correction is a persistent issue with induction motors. Their inherently low power factor, especially at partial loads, can lead to increased reactive power consumption. This not only reduces the overall system efficiency but also may require additional compensation equipment, adding to the complexity and cost of the hybrid energy system.

Control complexity is another challenge when integrating induction motors into hybrid energy systems. Achieving precise speed control and torque regulation, particularly in applications requiring dynamic response, can be difficult due to the motor's inherent slip characteristics. This complexity can impact the overall system performance and energy management strategies.

Harmonics generation is a concern in variable frequency drive (VFD) controlled induction motors, which are common in hybrid energy systems. These harmonics can cause power quality issues, potentially affecting other sensitive equipment in the system and reducing overall efficiency.

Weight and size considerations pose challenges in certain hybrid energy applications, particularly in mobile or space-constrained installations. The relatively high weight-to-power ratio of induction motors compared to some alternative motor technologies can impact system design and performance.

Lastly, the environmental impact of induction motors, including their manufacturing process and end-of-life disposal, presents challenges in creating truly sustainable hybrid energy systems. The use of materials like copper and electrical steel, while essential for motor performance, raises questions about resource sustainability and recycling potential.

Addressing these challenges is crucial for optimizing induction motors in hybrid energy system designs. Innovations in motor design, control strategies, and system integration are necessary to overcome these limitations and enhance the overall efficiency and sustainability of hybrid energy solutions.

Thermal management presents another significant challenge. As induction motors operate, they generate heat, which can lead to reduced efficiency and shortened lifespan if not properly managed. This issue is exacerbated in compact hybrid energy system designs where space for cooling systems is limited.

The starting current of induction motors is another area of concern. The high inrush current during motor start-up can cause voltage dips in the electrical system, potentially affecting other components in the hybrid energy setup. This challenge becomes more pronounced in systems with limited power capacity or weak grid connections.

Power factor correction is a persistent issue with induction motors. Their inherently low power factor, especially at partial loads, can lead to increased reactive power consumption. This not only reduces the overall system efficiency but also may require additional compensation equipment, adding to the complexity and cost of the hybrid energy system.

Control complexity is another challenge when integrating induction motors into hybrid energy systems. Achieving precise speed control and torque regulation, particularly in applications requiring dynamic response, can be difficult due to the motor's inherent slip characteristics. This complexity can impact the overall system performance and energy management strategies.

Harmonics generation is a concern in variable frequency drive (VFD) controlled induction motors, which are common in hybrid energy systems. These harmonics can cause power quality issues, potentially affecting other sensitive equipment in the system and reducing overall efficiency.

Weight and size considerations pose challenges in certain hybrid energy applications, particularly in mobile or space-constrained installations. The relatively high weight-to-power ratio of induction motors compared to some alternative motor technologies can impact system design and performance.

Lastly, the environmental impact of induction motors, including their manufacturing process and end-of-life disposal, presents challenges in creating truly sustainable hybrid energy systems. The use of materials like copper and electrical steel, while essential for motor performance, raises questions about resource sustainability and recycling potential.

Addressing these challenges is crucial for optimizing induction motors in hybrid energy system designs. Innovations in motor design, control strategies, and system integration are necessary to overcome these limitations and enhance the overall efficiency and sustainability of hybrid energy solutions.

Current Motor Solutions

01 Design and construction of induction motors

This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.- Design and construction of induction motors: This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.

- Control systems for induction motors: This point focuses on the development of control systems and methods for induction motors. It includes advancements in speed control, torque regulation, and power factor correction. These control systems aim to enhance motor performance, energy efficiency, and adaptability to various operating conditions.

- Efficiency improvements in induction motors: This category encompasses innovations aimed at improving the energy efficiency of induction motors. It includes advancements in motor design, materials, and manufacturing techniques that reduce losses and increase overall motor efficiency across various operating conditions.

- Specialized applications of induction motors: This point covers the adaptation and optimization of induction motors for specific applications. It includes designs tailored for industrial machinery, electric vehicles, renewable energy systems, and other specialized uses that require unique motor characteristics or performance attributes.

- Historical developments in induction motor technology: This category traces the historical evolution of induction motor technology, highlighting key innovations and breakthroughs that have shaped the field. It includes early patents and designs that laid the foundation for modern induction motor technology and showcases the progression of motor design over time.

02 Control systems for induction motors

Control systems play a crucial role in regulating the speed, torque, and efficiency of induction motors. This category encompasses various control strategies, including vector control, direct torque control, and advanced algorithms for optimizing motor performance under different operating conditions.Expand Specific Solutions03 Energy efficiency improvements in induction motors

This category focuses on techniques and technologies aimed at enhancing the energy efficiency of induction motors. This includes improvements in motor design, materials, and control strategies to reduce power losses and increase overall system efficiency.Expand Specific Solutions04 Specialized applications of induction motors

Induction motors are used in a wide range of specialized applications, each with unique requirements. This category covers innovations tailored for specific industries or use cases, such as high-speed motors, submersible motors, or motors designed for harsh environments.Expand Specific Solutions05 Advancements in induction motor manufacturing

This category encompasses innovations in the manufacturing processes and techniques used to produce induction motors. This includes advancements in automated production, new assembly methods, and improvements in quality control to enhance motor reliability and performance.Expand Specific Solutions

Key Industry Players

The induction motor optimization for hybrid energy systems is in a growth phase, with increasing market size driven by the rising demand for efficient and sustainable energy solutions. The technology is advancing rapidly, with companies like LG Electronics, BMW, and Renault leading innovation in this field. These firms are leveraging their expertise in electronics and automotive engineering to develop more efficient induction motor designs for hybrid systems. The market is characterized by intense competition and collaboration among established automotive manufacturers, electronics giants, and specialized engineering firms, all striving to improve motor performance, energy efficiency, and integration with hybrid powertrains.

Bayerische Motoren Werke AG

Technical Solution: BMW has developed advanced induction motor technologies for their hybrid and electric vehicle platforms. Their fifth-generation eDrive technology incorporates highly efficient induction motors with power densities exceeding 30 kW/L [10]. BMW has implemented innovative cooling strategies, including oil spray cooling, to maintain optimal motor performance under high-load conditions [11]. They have also developed sophisticated control algorithms that optimize torque distribution between the induction motor and internal combustion engine in hybrid powertrains, maximizing overall system efficiency [12]. Additionally, BMW has integrated their induction motors with advanced energy recovery systems, enhancing the overall efficiency of their hybrid energy systems [13].

Strengths: High power density, innovative cooling strategies, and optimized hybrid powertrain control. Weaknesses: Primarily focused on automotive applications, which may limit direct applicability to other hybrid energy system designs.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed innovative induction motor solutions for hybrid energy systems, focusing on compact designs and high power density. Their SMG180 series of induction motors utilize advanced cooling techniques and optimized stator designs to achieve power densities up to 5 kW/L [4]. Bosch has also implemented sophisticated control strategies, including model predictive control, to enhance the dynamic performance of induction motors in hybrid energy applications [5]. Additionally, they have developed integrated power electronics modules that optimize the overall system efficiency and reduce complexity in hybrid energy designs [6].

Strengths: High power density, advanced control strategies, and integrated power electronics. Weaknesses: Potential limitations in scalability for very large-scale energy systems.

Core Motor Innovations

Optimizing induction motors with corresponding three-phase balanced and symmetrical motors

PatentWO2025146669A1

Innovation

- A method is introduced to optimize single-phase induction motors by converting them into balanced and symmetrical three-phase or two-phase structures using an auxiliary capacitor, calculated based on the power factor of the primary three-phase motor, to achieve magnetic balance and enhance efficiency.

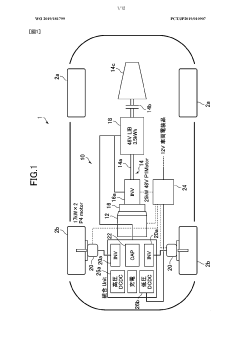

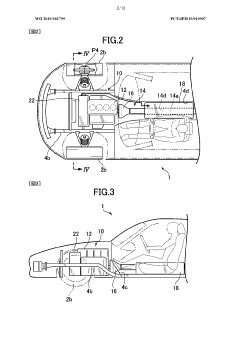

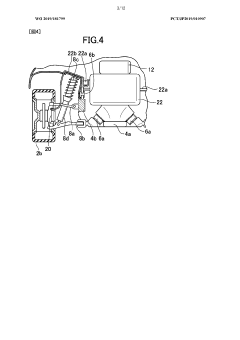

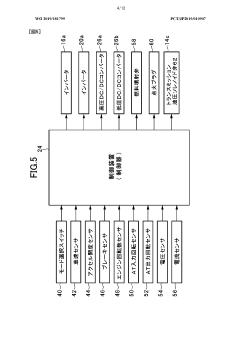

Hybrid drive device

PatentWO2019181799A1

Innovation

- A hybrid drive device incorporating an internal combustion engine, a permanent magnet motor for main drive wheels, and an induction motor for auxiliary drive wheels, with a control system that selectively uses electric motor drive mode and internal combustion engine drive mode to optimize weight reduction and energy efficiency, featuring a power transmission mechanism and a capacitor for regenerative power storage.

Energy Efficiency Regs

Energy efficiency regulations play a crucial role in shaping the design and implementation of hybrid energy systems incorporating induction motors. These regulations set standards and guidelines that manufacturers and system designers must adhere to, driving innovation and improvements in motor efficiency.

The International Electrotechnical Commission (IEC) has established global standards for motor efficiency, with IEC 60034-30-1 defining efficiency classes for induction motors. These classes, ranging from IE1 (standard efficiency) to IE4 (super premium efficiency), provide a framework for evaluating and comparing motor performance. In the context of hybrid energy systems, these standards encourage the use of higher efficiency motors to minimize energy losses and optimize overall system performance.

Many countries have adopted these international standards or developed their own regulations to promote energy-efficient motor usage. For instance, the European Union's Ecodesign Directive (2009/125/EC) mandates minimum efficiency requirements for electric motors sold within the EU. Similarly, the United States Department of Energy (DOE) has established minimum efficiency standards for electric motors through its Energy Conservation Standards program.

These regulations often include specific requirements for motor sizing, power factor correction, and variable speed drive integration, all of which are critical factors in optimizing hybrid energy system designs. By mandating the use of high-efficiency motors and promoting best practices in system design, these regulations drive manufacturers to develop more advanced motor technologies and control strategies.

Furthermore, energy efficiency regulations often extend beyond individual components to encompass entire systems. For example, the ISO 50001 standard provides a framework for organizations to develop an energy management system, which can include optimizing the use of induction motors within hybrid energy systems. This holistic approach encourages system-level optimization, considering factors such as load profiles, energy storage integration, and renewable energy sources.

As regulations continue to evolve, they are increasingly focusing on the integration of smart technologies and digital control systems. This trend is particularly relevant for hybrid energy systems, where advanced control algorithms and real-time monitoring can significantly enhance the efficiency and performance of induction motors. Future regulations are likely to emphasize the importance of data-driven optimization and predictive maintenance strategies in maximizing the energy efficiency of these systems.

The International Electrotechnical Commission (IEC) has established global standards for motor efficiency, with IEC 60034-30-1 defining efficiency classes for induction motors. These classes, ranging from IE1 (standard efficiency) to IE4 (super premium efficiency), provide a framework for evaluating and comparing motor performance. In the context of hybrid energy systems, these standards encourage the use of higher efficiency motors to minimize energy losses and optimize overall system performance.

Many countries have adopted these international standards or developed their own regulations to promote energy-efficient motor usage. For instance, the European Union's Ecodesign Directive (2009/125/EC) mandates minimum efficiency requirements for electric motors sold within the EU. Similarly, the United States Department of Energy (DOE) has established minimum efficiency standards for electric motors through its Energy Conservation Standards program.

These regulations often include specific requirements for motor sizing, power factor correction, and variable speed drive integration, all of which are critical factors in optimizing hybrid energy system designs. By mandating the use of high-efficiency motors and promoting best practices in system design, these regulations drive manufacturers to develop more advanced motor technologies and control strategies.

Furthermore, energy efficiency regulations often extend beyond individual components to encompass entire systems. For example, the ISO 50001 standard provides a framework for organizations to develop an energy management system, which can include optimizing the use of induction motors within hybrid energy systems. This holistic approach encourages system-level optimization, considering factors such as load profiles, energy storage integration, and renewable energy sources.

As regulations continue to evolve, they are increasingly focusing on the integration of smart technologies and digital control systems. This trend is particularly relevant for hybrid energy systems, where advanced control algorithms and real-time monitoring can significantly enhance the efficiency and performance of induction motors. Future regulations are likely to emphasize the importance of data-driven optimization and predictive maintenance strategies in maximizing the energy efficiency of these systems.

System Integration

System integration is a critical aspect of optimizing hybrid energy system designs using induction motors. The integration process involves seamlessly combining various components, including induction motors, renewable energy sources, energy storage systems, and control mechanisms, to create a cohesive and efficient hybrid energy system.

One of the primary challenges in system integration is ensuring compatibility between different components. Induction motors, being robust and versatile, can be effectively integrated with various renewable energy sources such as solar panels, wind turbines, and hydroelectric generators. The key lies in designing appropriate power electronics interfaces that can handle the variable nature of renewable energy outputs and convert them into suitable forms for induction motor operation.

Energy management systems (EMS) play a crucial role in the integration process. These systems utilize advanced algorithms to optimize the operation of induction motors within the hybrid energy framework. By continuously monitoring system parameters, such as power demand, renewable energy availability, and motor efficiency, the EMS can make real-time decisions to balance energy production and consumption, thereby maximizing overall system efficiency.

The integration of energy storage systems, such as batteries or flywheels, is another vital aspect of hybrid energy system design. These storage systems can help smooth out fluctuations in renewable energy generation and provide backup power during periods of low renewable output. Induction motors can be strategically coupled with these storage systems to ensure a stable and reliable power supply, even under varying environmental conditions.

Grid integration is an essential consideration for hybrid energy systems incorporating induction motors. The ability to seamlessly switch between grid-connected and islanded modes of operation enhances system flexibility and reliability. Advanced control strategies, such as droop control and virtual synchronous generator techniques, can be implemented to ensure smooth transitions and maintain system stability during mode changes.

Modular system design approaches can significantly enhance the integration process. By developing standardized interfaces and communication protocols, different system components can be easily interconnected and scaled according to specific application requirements. This modularity not only simplifies the initial integration but also facilitates future system upgrades and expansions.

Lastly, the integration of monitoring and diagnostic systems is crucial for maintaining optimal performance and reliability. These systems can continuously assess the health and efficiency of induction motors and other components, enabling predictive maintenance and rapid fault detection. By leveraging data analytics and machine learning algorithms, these integrated monitoring systems can provide valuable insights for further system optimization and long-term performance improvements.

One of the primary challenges in system integration is ensuring compatibility between different components. Induction motors, being robust and versatile, can be effectively integrated with various renewable energy sources such as solar panels, wind turbines, and hydroelectric generators. The key lies in designing appropriate power electronics interfaces that can handle the variable nature of renewable energy outputs and convert them into suitable forms for induction motor operation.

Energy management systems (EMS) play a crucial role in the integration process. These systems utilize advanced algorithms to optimize the operation of induction motors within the hybrid energy framework. By continuously monitoring system parameters, such as power demand, renewable energy availability, and motor efficiency, the EMS can make real-time decisions to balance energy production and consumption, thereby maximizing overall system efficiency.

The integration of energy storage systems, such as batteries or flywheels, is another vital aspect of hybrid energy system design. These storage systems can help smooth out fluctuations in renewable energy generation and provide backup power during periods of low renewable output. Induction motors can be strategically coupled with these storage systems to ensure a stable and reliable power supply, even under varying environmental conditions.

Grid integration is an essential consideration for hybrid energy systems incorporating induction motors. The ability to seamlessly switch between grid-connected and islanded modes of operation enhances system flexibility and reliability. Advanced control strategies, such as droop control and virtual synchronous generator techniques, can be implemented to ensure smooth transitions and maintain system stability during mode changes.

Modular system design approaches can significantly enhance the integration process. By developing standardized interfaces and communication protocols, different system components can be easily interconnected and scaled according to specific application requirements. This modularity not only simplifies the initial integration but also facilitates future system upgrades and expansions.

Lastly, the integration of monitoring and diagnostic systems is crucial for maintaining optimal performance and reliability. These systems can continuously assess the health and efficiency of induction motors and other components, enabling predictive maintenance and rapid fault detection. By leveraging data analytics and machine learning algorithms, these integrated monitoring systems can provide valuable insights for further system optimization and long-term performance improvements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!