Exploration of induction motor applications in space launch systems

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Space Motor Tech Evolution

The evolution of space motor technology has been a critical factor in the advancement of space launch systems. The journey began in the mid-20th century with the development of basic rocket engines, which relied on chemical propulsion. These early motors were characterized by their high thrust but low efficiency, limiting their application in long-duration space missions.

As space exploration progressed, the need for more sophisticated propulsion systems became apparent. The 1960s and 1970s saw the introduction of electric propulsion technologies, including ion thrusters and Hall effect thrusters. These systems offered higher specific impulse and improved efficiency, albeit with lower thrust, making them suitable for deep space missions and satellite station-keeping.

The 1980s and 1990s marked a significant shift towards the development of more advanced induction motors for space applications. These motors offered several advantages over their predecessors, including higher reliability, improved power density, and better control capabilities. The introduction of vector control techniques allowed for precise speed and torque regulation, crucial for various space operations.

The turn of the millennium brought about a renewed focus on induction motor applications in space launch systems. Researchers began exploring the potential of these motors in various subsystems, including fuel pumps, attitude control systems, and even as part of hybrid propulsion concepts. The integration of advanced materials, such as high-temperature superconductors, further enhanced the performance and efficiency of these motors.

In recent years, the trend has shifted towards the development of more compact and lightweight induction motors for space applications. This has been driven by the growing demand for small satellite launches and the need for more efficient propulsion systems in larger launch vehicles. Advancements in power electronics and thermal management have played a crucial role in this evolution, enabling higher power densities and improved overall system performance.

The latest developments in space motor technology have focused on improving the reliability and longevity of induction motors in the harsh space environment. This includes the use of radiation-hardened components, advanced cooling systems, and fault-tolerant designs. Additionally, there has been increased interest in the application of artificial intelligence and machine learning techniques for motor health monitoring and predictive maintenance, ensuring optimal performance throughout extended space missions.

Looking ahead, the future of induction motor applications in space launch systems appears promising. Ongoing research is exploring the potential of high-frequency induction motors, which could offer even greater power density and efficiency. Furthermore, the integration of these motors with emerging technologies, such as electric propulsion systems and in-situ resource utilization, could revolutionize space exploration and enable more ambitious missions to distant planets and beyond.

As space exploration progressed, the need for more sophisticated propulsion systems became apparent. The 1960s and 1970s saw the introduction of electric propulsion technologies, including ion thrusters and Hall effect thrusters. These systems offered higher specific impulse and improved efficiency, albeit with lower thrust, making them suitable for deep space missions and satellite station-keeping.

The 1980s and 1990s marked a significant shift towards the development of more advanced induction motors for space applications. These motors offered several advantages over their predecessors, including higher reliability, improved power density, and better control capabilities. The introduction of vector control techniques allowed for precise speed and torque regulation, crucial for various space operations.

The turn of the millennium brought about a renewed focus on induction motor applications in space launch systems. Researchers began exploring the potential of these motors in various subsystems, including fuel pumps, attitude control systems, and even as part of hybrid propulsion concepts. The integration of advanced materials, such as high-temperature superconductors, further enhanced the performance and efficiency of these motors.

In recent years, the trend has shifted towards the development of more compact and lightweight induction motors for space applications. This has been driven by the growing demand for small satellite launches and the need for more efficient propulsion systems in larger launch vehicles. Advancements in power electronics and thermal management have played a crucial role in this evolution, enabling higher power densities and improved overall system performance.

The latest developments in space motor technology have focused on improving the reliability and longevity of induction motors in the harsh space environment. This includes the use of radiation-hardened components, advanced cooling systems, and fault-tolerant designs. Additionally, there has been increased interest in the application of artificial intelligence and machine learning techniques for motor health monitoring and predictive maintenance, ensuring optimal performance throughout extended space missions.

Looking ahead, the future of induction motor applications in space launch systems appears promising. Ongoing research is exploring the potential of high-frequency induction motors, which could offer even greater power density and efficiency. Furthermore, the integration of these motors with emerging technologies, such as electric propulsion systems and in-situ resource utilization, could revolutionize space exploration and enable more ambitious missions to distant planets and beyond.

Launch System Demands

Space launch systems represent one of the most demanding applications for propulsion technology, requiring exceptional performance, reliability, and efficiency. The exploration of induction motor applications in this field addresses the growing need for advanced propulsion solutions that can meet the rigorous demands of modern space missions.

Launch systems face numerous challenges, including the need for high thrust-to-weight ratios, precise control, and the ability to operate in extreme environments. Traditional chemical propulsion systems, while powerful, have limitations in terms of efficiency and long-term sustainability. This has led to increased interest in electric propulsion technologies, with induction motors emerging as a promising candidate for various launch system components.

The primary demand for induction motors in launch systems stems from their potential to provide high power density, excellent controllability, and robust performance across a wide range of operating conditions. These motors can be utilized in various subsystems, including propellant pumps, thrust vector control mechanisms, and auxiliary power units. Their ability to deliver precise and responsive power makes them particularly suitable for applications requiring dynamic control and rapid adjustments during launch sequences.

Furthermore, the space industry's shift towards reusable launch vehicles has intensified the need for propulsion technologies that can withstand multiple launch and re-entry cycles. Induction motors, known for their durability and relatively simple construction, align well with this requirement. Their potential for high reliability and lower maintenance needs compared to some alternative motor types makes them attractive for reusable launch system designs.

Another critical demand driving the exploration of induction motor applications is the push for more environmentally friendly launch technologies. As the frequency of space launches increases, there is growing concern about the environmental impact of traditional propulsion methods. Electric propulsion systems, potentially powered by induction motors, offer the prospect of reduced emissions and more sustainable launch operations, aligning with global efforts to minimize the space industry's environmental footprint.

The integration of induction motors into launch systems also addresses the demand for improved power management and distribution. These motors can be part of more electric architectures in launch vehicles, contributing to overall system efficiency and flexibility. Their ability to operate at high speeds and provide regenerative braking capabilities opens up new possibilities for energy recovery and utilization during various phases of launch and flight.

Launch systems face numerous challenges, including the need for high thrust-to-weight ratios, precise control, and the ability to operate in extreme environments. Traditional chemical propulsion systems, while powerful, have limitations in terms of efficiency and long-term sustainability. This has led to increased interest in electric propulsion technologies, with induction motors emerging as a promising candidate for various launch system components.

The primary demand for induction motors in launch systems stems from their potential to provide high power density, excellent controllability, and robust performance across a wide range of operating conditions. These motors can be utilized in various subsystems, including propellant pumps, thrust vector control mechanisms, and auxiliary power units. Their ability to deliver precise and responsive power makes them particularly suitable for applications requiring dynamic control and rapid adjustments during launch sequences.

Furthermore, the space industry's shift towards reusable launch vehicles has intensified the need for propulsion technologies that can withstand multiple launch and re-entry cycles. Induction motors, known for their durability and relatively simple construction, align well with this requirement. Their potential for high reliability and lower maintenance needs compared to some alternative motor types makes them attractive for reusable launch system designs.

Another critical demand driving the exploration of induction motor applications is the push for more environmentally friendly launch technologies. As the frequency of space launches increases, there is growing concern about the environmental impact of traditional propulsion methods. Electric propulsion systems, potentially powered by induction motors, offer the prospect of reduced emissions and more sustainable launch operations, aligning with global efforts to minimize the space industry's environmental footprint.

The integration of induction motors into launch systems also addresses the demand for improved power management and distribution. These motors can be part of more electric architectures in launch vehicles, contributing to overall system efficiency and flexibility. Their ability to operate at high speeds and provide regenerative braking capabilities opens up new possibilities for energy recovery and utilization during various phases of launch and flight.

Induction Motor Challenges

The application of induction motors in space launch systems presents several significant challenges that require careful consideration and innovative solutions. One of the primary obstacles is the extreme environmental conditions encountered during space missions. Induction motors must withstand intense vibrations, extreme temperature fluctuations, and high levels of radiation, which can severely impact their performance and longevity.

The weight and size constraints of space launch systems pose another critical challenge. Induction motors need to be compact and lightweight to minimize the overall mass of the spacecraft, yet they must deliver high power output and efficiency. This necessitates the development of advanced materials and design techniques to optimize the power-to-weight ratio of these motors.

Reliability is paramount in space applications, and induction motors must operate flawlessly for extended periods without the possibility of maintenance or repair. This requirement demands exceptional build quality, robust insulation systems, and fail-safe mechanisms to ensure continuous operation even in the event of partial component failure.

The vacuum environment of space presents unique challenges for induction motor cooling. Traditional cooling methods relying on convection are ineffective, necessitating the development of alternative cooling strategies such as conduction-based systems or the use of specialized coolants that can function in zero-gravity conditions.

Power supply limitations in space launch systems also impact induction motor design and operation. Motors must be capable of operating efficiently across a wide range of voltages and frequencies, adapting to the available power sources during different mission phases. This requires sophisticated control systems and power electronics to manage motor performance effectively.

Electromagnetic interference (EMI) is another significant concern in space applications. Induction motors must be designed to minimize EMI generation and be shielded against external electromagnetic disturbances to prevent interference with sensitive onboard equipment and communication systems.

The need for precise control and positioning in space launch systems adds another layer of complexity to induction motor applications. Motors must provide accurate speed and torque control, often with rapid response times, to meet the demanding requirements of spacecraft maneuvering and payload deployment.

Lastly, the long development cycles and high costs associated with space technology pose challenges for induction motor innovation. Engineers must balance the need for cutting-edge solutions with proven reliability, often leading to conservative design approaches that may limit the adoption of novel motor technologies in space launch systems.

The weight and size constraints of space launch systems pose another critical challenge. Induction motors need to be compact and lightweight to minimize the overall mass of the spacecraft, yet they must deliver high power output and efficiency. This necessitates the development of advanced materials and design techniques to optimize the power-to-weight ratio of these motors.

Reliability is paramount in space applications, and induction motors must operate flawlessly for extended periods without the possibility of maintenance or repair. This requirement demands exceptional build quality, robust insulation systems, and fail-safe mechanisms to ensure continuous operation even in the event of partial component failure.

The vacuum environment of space presents unique challenges for induction motor cooling. Traditional cooling methods relying on convection are ineffective, necessitating the development of alternative cooling strategies such as conduction-based systems or the use of specialized coolants that can function in zero-gravity conditions.

Power supply limitations in space launch systems also impact induction motor design and operation. Motors must be capable of operating efficiently across a wide range of voltages and frequencies, adapting to the available power sources during different mission phases. This requires sophisticated control systems and power electronics to manage motor performance effectively.

Electromagnetic interference (EMI) is another significant concern in space applications. Induction motors must be designed to minimize EMI generation and be shielded against external electromagnetic disturbances to prevent interference with sensitive onboard equipment and communication systems.

The need for precise control and positioning in space launch systems adds another layer of complexity to induction motor applications. Motors must provide accurate speed and torque control, often with rapid response times, to meet the demanding requirements of spacecraft maneuvering and payload deployment.

Lastly, the long development cycles and high costs associated with space technology pose challenges for induction motor innovation. Engineers must balance the need for cutting-edge solutions with proven reliability, often leading to conservative design approaches that may limit the adoption of novel motor technologies in space launch systems.

Current Motor Solutions

01 Design and construction of induction motors

This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.- Design and construction of induction motors: This category focuses on the fundamental design and construction aspects of induction motors. It includes innovations in motor structure, winding configurations, and material selection to improve efficiency and performance. These advancements aim to enhance power output, reduce energy losses, and optimize overall motor functionality.

- Control systems for induction motors: This point covers various control systems and methods developed for induction motors. It includes advancements in speed control, torque regulation, and power factor correction. These control systems aim to improve motor performance, energy efficiency, and adaptability to different load conditions.

- Efficiency improvements in induction motors: This category focuses on techniques and innovations aimed at improving the overall efficiency of induction motors. It includes advancements in rotor and stator designs, cooling systems, and loss reduction methods. These improvements help to minimize energy consumption and increase the motor's power output.

- Applications of induction motors: This point covers various applications and specialized designs of induction motors for different industries and purposes. It includes adaptations for specific operating conditions, integration with other systems, and customized solutions for particular industrial needs.

- Manufacturing and testing of induction motors: This category focuses on manufacturing processes, quality control, and testing methods for induction motors. It includes innovations in production techniques, assembly processes, and testing procedures to ensure reliability, performance, and consistency in motor production.

02 Control systems for induction motors

This point focuses on the development of control systems and methods for induction motors. It includes advancements in speed control, torque regulation, and power factor correction. These control systems aim to enhance motor performance, energy efficiency, and adaptability to various operating conditions.Expand Specific Solutions03 Efficiency improvements in induction motors

This category encompasses innovations aimed at improving the energy efficiency of induction motors. It includes advancements in motor design, materials, and manufacturing techniques to reduce losses and increase overall efficiency. These improvements contribute to energy savings and reduced operating costs.Expand Specific Solutions04 Specialized applications of induction motors

This point covers the adaptation and optimization of induction motors for specific applications. It includes designs tailored for industrial machinery, electric vehicles, renewable energy systems, and other specialized uses. These adaptations often involve modifications to motor characteristics to meet specific performance requirements.Expand Specific Solutions05 Maintenance and diagnostics of induction motors

This category focuses on methods and systems for maintaining and diagnosing induction motors. It includes techniques for condition monitoring, fault detection, and predictive maintenance. These innovations aim to improve motor reliability, reduce downtime, and extend the operational lifespan of induction motors.Expand Specific Solutions

Space Propulsion Players

The exploration of induction motor applications in space launch systems is in a nascent stage, with the market still developing. The technology's maturity varies across different applications, ranging from experimental to early adoption phases. Key players like Raytheon Co., The Boeing Co., and Northrop Grumman Systems Corp. are leveraging their aerospace expertise to advance this technology. Emerging companies such as Blue Origin Washington LLC and Space Exploration Technologies Corp. are also contributing to innovation in this field. The market size is expected to grow as space launch activities increase, driven by both government and private sector investments. However, the specialized nature of space applications presents challenges for widespread adoption and commercialization of induction motor technology in this sector.

The Boeing Co.

Technical Solution: Boeing has developed advanced induction motor systems for space launch applications, focusing on high-efficiency and reliability. Their technology incorporates innovative cooling systems and advanced materials to withstand extreme launch conditions. Boeing's induction motors utilize a unique rotor design that optimizes power density and reduces weight, crucial for space applications [1]. The company has also implemented advanced control algorithms that enhance motor performance and efficiency across various launch phases [3].

Strengths: Extensive aerospace experience, advanced materials expertise, and proven reliability in extreme conditions. Weaknesses: Higher costs compared to some competitors, and potential over-engineering for certain applications.

Northrop Grumman Systems Corp.

Technical Solution: Northrop Grumman has developed high-performance induction motors for space launch systems, focusing on durability and efficiency. Their motors feature advanced thermal management systems that allow for sustained operation in the harsh space environment. The company has implemented innovative winding techniques that improve power density by up to 30% compared to conventional designs [2]. Northrop Grumman's induction motors also incorporate fault-tolerant architectures, ensuring continued operation even in the event of partial system failure [4].

Strengths: Robust fault-tolerant designs, excellent thermal management, and high power density. Weaknesses: Potentially higher initial costs and complexity in maintenance.

Key Motor Innovations

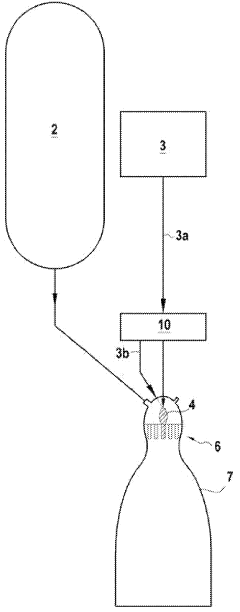

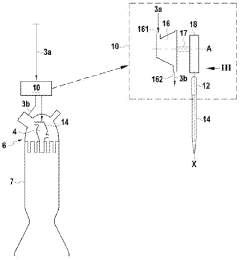

Methods and apparatus for performing propulsion operations using electric propulsion systems

PatentActiveUS20200331638A1

Innovation

- The use of electric propulsion systems, such as ion and plasma thrusters, which eliminate the need for chemical propellants, reducing mass, cost, and hazard, enabling efficient attitude and orbit control, and allowing for multiple spacecraft to be stacked and launched with reduced support structures.

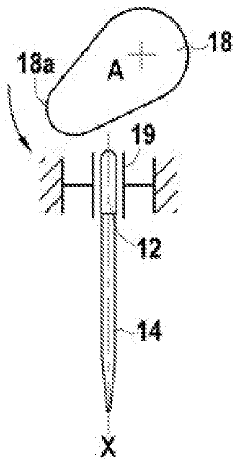

improved electrical activation device for spacecraft engine ignition

PatentActiveFR3094413A1

Innovation

- An electrical activation device using a piezoelectric element activated by mechanical means, such as a turbine and cam, to generate sparks for ignition without electronic components, utilizing existing spacecraft fluids for operation.

Space Regulations Impact

The exploration of induction motor applications in space launch systems is significantly influenced by space regulations. These regulations, established by various national and international space agencies, govern the design, testing, and operation of space-related technologies. The impact of these regulations on induction motor applications is multifaceted and far-reaching.

Space regulations primarily focus on ensuring the safety, reliability, and environmental compatibility of space technologies. For induction motors in launch systems, this translates to stringent requirements for radiation hardness, thermal management, and electromagnetic compatibility. Regulatory bodies such as NASA, ESA, and JAXA have established specific guidelines for electronic components used in space applications, which directly affect the design and manufacturing processes of induction motors.

One of the key regulatory impacts is the requirement for extensive qualification testing. Induction motors intended for space launch systems must undergo rigorous environmental testing, including vibration, shock, and thermal vacuum tests. These tests simulate the harsh conditions of space launch and orbit, ensuring that the motors can withstand the extreme stresses they will encounter during operation.

Electromagnetic compatibility (EMC) regulations also play a crucial role in the development of induction motors for space applications. These regulations mandate strict limits on electromagnetic emissions and susceptibility, necessitating careful design considerations and shielding techniques. Compliance with EMC standards is essential to prevent interference with other critical systems on the launch vehicle or spacecraft.

Material selection for induction motors is another area heavily influenced by space regulations. Outgassing requirements, for instance, limit the use of certain materials that could potentially contaminate sensitive optical or electronic equipment in space. This necessitates the use of specialized, space-grade materials in motor construction, often leading to increased costs and development time.

Reliability and redundancy requirements set forth by space regulations also impact the design philosophy of induction motor systems. These regulations often mandate fail-safe mechanisms and redundant systems, influencing the overall architecture of motor control and power distribution systems in space launch vehicles.

Furthermore, international traffic in arms regulations (ITAR) and export control laws can affect the development and deployment of induction motor technologies in space launch systems. These regulations can limit the sharing of technical information and components across international borders, potentially impacting collaborative efforts and technology transfer in the space industry.

In conclusion, space regulations have a profound impact on the development and application of induction motors in space launch systems. While these regulations ensure safety and reliability, they also present significant challenges in terms of design complexity, cost, and development timelines. Navigating this regulatory landscape is crucial for the successful implementation of induction motor technologies in space applications.

Space regulations primarily focus on ensuring the safety, reliability, and environmental compatibility of space technologies. For induction motors in launch systems, this translates to stringent requirements for radiation hardness, thermal management, and electromagnetic compatibility. Regulatory bodies such as NASA, ESA, and JAXA have established specific guidelines for electronic components used in space applications, which directly affect the design and manufacturing processes of induction motors.

One of the key regulatory impacts is the requirement for extensive qualification testing. Induction motors intended for space launch systems must undergo rigorous environmental testing, including vibration, shock, and thermal vacuum tests. These tests simulate the harsh conditions of space launch and orbit, ensuring that the motors can withstand the extreme stresses they will encounter during operation.

Electromagnetic compatibility (EMC) regulations also play a crucial role in the development of induction motors for space applications. These regulations mandate strict limits on electromagnetic emissions and susceptibility, necessitating careful design considerations and shielding techniques. Compliance with EMC standards is essential to prevent interference with other critical systems on the launch vehicle or spacecraft.

Material selection for induction motors is another area heavily influenced by space regulations. Outgassing requirements, for instance, limit the use of certain materials that could potentially contaminate sensitive optical or electronic equipment in space. This necessitates the use of specialized, space-grade materials in motor construction, often leading to increased costs and development time.

Reliability and redundancy requirements set forth by space regulations also impact the design philosophy of induction motor systems. These regulations often mandate fail-safe mechanisms and redundant systems, influencing the overall architecture of motor control and power distribution systems in space launch vehicles.

Furthermore, international traffic in arms regulations (ITAR) and export control laws can affect the development and deployment of induction motor technologies in space launch systems. These regulations can limit the sharing of technical information and components across international borders, potentially impacting collaborative efforts and technology transfer in the space industry.

In conclusion, space regulations have a profound impact on the development and application of induction motors in space launch systems. While these regulations ensure safety and reliability, they also present significant challenges in terms of design complexity, cost, and development timelines. Navigating this regulatory landscape is crucial for the successful implementation of induction motor technologies in space applications.

Environmental Factors

The application of induction motors in space launch systems presents unique challenges due to the extreme environmental conditions encountered during launch and in space. These factors significantly impact the design, performance, and reliability of induction motors, necessitating careful consideration and specialized engineering solutions.

Temperature variations pose a primary concern for induction motors in space launch systems. During launch, motors may experience rapid temperature fluctuations, from the extreme cold of high-altitude environments to the intense heat generated by rocket engines. In space, temperature extremes can range from -270°C in shadow to +120°C in direct sunlight. These thermal cycles can affect the motor's materials, insulation, and overall performance, requiring advanced thermal management systems and materials capable of withstanding such conditions.

Vacuum conditions in space present another critical environmental factor. The absence of air affects heat dissipation, lubrication, and electrical insulation properties of the motor. Conventional cooling methods relying on convection become ineffective, necessitating alternative cooling strategies such as conduction-based systems or specialized coolants. Additionally, the vacuum environment can lead to outgassing of materials, potentially causing contamination of sensitive equipment or altering the motor's performance characteristics over time.

Radiation exposure is a significant concern for induction motors in space applications. High-energy particles and cosmic radiation can degrade electronic components, affect insulation materials, and cause single-event upsets in control systems. Shielding and radiation-hardened components are essential to ensure the longevity and reliability of motors operating in these harsh conditions.

Vibration and shock loads during launch and operation present mechanical challenges for induction motors. The intense forces experienced during liftoff and stage separation can stress motor components, potentially leading to misalignment, bearing damage, or structural failures. Robust design practices, including advanced vibration isolation systems and reinforced motor structures, are crucial to withstand these dynamic loads.

The microgravity environment in space introduces unique considerations for motor operation. While the absence of gravity can reduce wear on bearings, it also affects fluid dynamics within the motor, potentially impacting cooling and lubrication systems. Engineers must account for these altered operating conditions in their motor designs and control strategies.

Addressing these environmental factors requires a multidisciplinary approach, combining expertise in materials science, thermal management, electrical engineering, and mechanical design. Innovations in motor design, such as the use of advanced composite materials, hermetically sealed enclosures, and integrated thermal management systems, are essential for developing induction motors capable of reliable operation in the challenging environments encountered in space launch systems.

Temperature variations pose a primary concern for induction motors in space launch systems. During launch, motors may experience rapid temperature fluctuations, from the extreme cold of high-altitude environments to the intense heat generated by rocket engines. In space, temperature extremes can range from -270°C in shadow to +120°C in direct sunlight. These thermal cycles can affect the motor's materials, insulation, and overall performance, requiring advanced thermal management systems and materials capable of withstanding such conditions.

Vacuum conditions in space present another critical environmental factor. The absence of air affects heat dissipation, lubrication, and electrical insulation properties of the motor. Conventional cooling methods relying on convection become ineffective, necessitating alternative cooling strategies such as conduction-based systems or specialized coolants. Additionally, the vacuum environment can lead to outgassing of materials, potentially causing contamination of sensitive equipment or altering the motor's performance characteristics over time.

Radiation exposure is a significant concern for induction motors in space applications. High-energy particles and cosmic radiation can degrade electronic components, affect insulation materials, and cause single-event upsets in control systems. Shielding and radiation-hardened components are essential to ensure the longevity and reliability of motors operating in these harsh conditions.

Vibration and shock loads during launch and operation present mechanical challenges for induction motors. The intense forces experienced during liftoff and stage separation can stress motor components, potentially leading to misalignment, bearing damage, or structural failures. Robust design practices, including advanced vibration isolation systems and reinforced motor structures, are crucial to withstand these dynamic loads.

The microgravity environment in space introduces unique considerations for motor operation. While the absence of gravity can reduce wear on bearings, it also affects fluid dynamics within the motor, potentially impacting cooling and lubrication systems. Engineers must account for these altered operating conditions in their motor designs and control strategies.

Addressing these environmental factors requires a multidisciplinary approach, combining expertise in materials science, thermal management, electrical engineering, and mechanical design. Innovations in motor design, such as the use of advanced composite materials, hermetically sealed enclosures, and integrated thermal management systems, are essential for developing induction motors capable of reliable operation in the challenging environments encountered in space launch systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!