Induction motors in high-performance electric locomotive systems

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Evolution in Locomotive Systems

The evolution of induction motors in locomotive systems has been a crucial factor in the advancement of high-performance electric locomotives. This journey began in the early 20th century when induction motors were first introduced to railway applications. Initially, these motors were relatively simple and inefficient, but they offered advantages over their direct current counterparts in terms of maintenance and reliability.

As technology progressed, so did the capabilities of induction motors. The 1960s and 1970s saw significant improvements in power electronics, which allowed for better control of motor speed and torque. This era marked the beginning of variable frequency drives, enabling more precise and efficient operation of induction motors in locomotives. The introduction of silicon-controlled rectifiers (SCRs) and later insulated-gate bipolar transistors (IGBTs) revolutionized motor control, leading to smoother acceleration and improved energy efficiency.

The 1980s and 1990s brought about further advancements in motor design and materials. The use of advanced magnetic materials and improved insulation systems allowed for higher power densities and better thermal management. This period also saw the development of more sophisticated control algorithms, such as vector control and direct torque control, which significantly enhanced the dynamic performance of induction motors in locomotive applications.

In the 21st century, the focus has shifted towards optimizing energy efficiency and reducing environmental impact. Modern induction motors in high-performance electric locomotives incorporate features like regenerative braking, which recovers energy during deceleration and feeds it back into the power system. Additionally, the integration of advanced sensors and real-time monitoring systems has improved the reliability and maintenance practices of these motors.

Recent years have seen a trend towards the use of permanent magnet synchronous motors (PMSMs) in some high-speed rail applications. However, induction motors continue to hold a significant place in locomotive systems due to their robustness, lower cost, and proven reliability. Ongoing research is focused on further improving the efficiency and power density of induction motors, exploring new materials and manufacturing techniques to push the boundaries of performance.

The evolution of induction motors in locomotive systems has been closely tied to advancements in power electronics, control systems, and materials science. This interdisciplinary progress has resulted in electric locomotives that are more powerful, efficient, and environmentally friendly than ever before. As we look to the future, the continued development of induction motor technology promises to play a vital role in shaping the next generation of high-performance electric locomotive systems.

As technology progressed, so did the capabilities of induction motors. The 1960s and 1970s saw significant improvements in power electronics, which allowed for better control of motor speed and torque. This era marked the beginning of variable frequency drives, enabling more precise and efficient operation of induction motors in locomotives. The introduction of silicon-controlled rectifiers (SCRs) and later insulated-gate bipolar transistors (IGBTs) revolutionized motor control, leading to smoother acceleration and improved energy efficiency.

The 1980s and 1990s brought about further advancements in motor design and materials. The use of advanced magnetic materials and improved insulation systems allowed for higher power densities and better thermal management. This period also saw the development of more sophisticated control algorithms, such as vector control and direct torque control, which significantly enhanced the dynamic performance of induction motors in locomotive applications.

In the 21st century, the focus has shifted towards optimizing energy efficiency and reducing environmental impact. Modern induction motors in high-performance electric locomotives incorporate features like regenerative braking, which recovers energy during deceleration and feeds it back into the power system. Additionally, the integration of advanced sensors and real-time monitoring systems has improved the reliability and maintenance practices of these motors.

Recent years have seen a trend towards the use of permanent magnet synchronous motors (PMSMs) in some high-speed rail applications. However, induction motors continue to hold a significant place in locomotive systems due to their robustness, lower cost, and proven reliability. Ongoing research is focused on further improving the efficiency and power density of induction motors, exploring new materials and manufacturing techniques to push the boundaries of performance.

The evolution of induction motors in locomotive systems has been closely tied to advancements in power electronics, control systems, and materials science. This interdisciplinary progress has resulted in electric locomotives that are more powerful, efficient, and environmentally friendly than ever before. As we look to the future, the continued development of induction motor technology promises to play a vital role in shaping the next generation of high-performance electric locomotive systems.

Electric Locomotive Market Demand Analysis

The global electric locomotive market is experiencing significant growth, driven by increasing demand for sustainable transportation solutions and the push for railway electrification. As countries worldwide aim to reduce carbon emissions and improve energy efficiency in their transportation sectors, electric locomotives have emerged as a key technology to achieve these goals.

The market demand for electric locomotives is primarily fueled by the expansion and modernization of railway networks, particularly in developing economies. Countries like China, India, and several European nations are investing heavily in high-speed rail projects and upgrading existing infrastructure, creating a substantial demand for advanced electric locomotive systems.

In the context of high-performance electric locomotive systems, induction motors play a crucial role. These motors offer several advantages, including robustness, reliability, and lower maintenance requirements compared to other motor types. The demand for induction motors in electric locomotives is closely tied to the overall market growth of electric rolling stock.

The freight transportation sector is a major driver of electric locomotive demand. With increasing global trade and the need for efficient long-distance cargo movement, electric locomotives offer a cost-effective and environmentally friendly solution. This has led to a growing interest in high-performance systems that can handle heavy loads over long distances while maintaining optimal energy efficiency.

Passenger rail services, including intercity and urban transit systems, also contribute significantly to the market demand. As urban populations grow and cities seek to reduce congestion and pollution, electric locomotives for commuter trains and light rail systems are seeing increased adoption.

The market is also influenced by government regulations and initiatives promoting clean energy and sustainable transportation. Many countries have set ambitious targets for reducing greenhouse gas emissions, which has accelerated the transition from diesel to electric locomotives. This regulatory environment is creating a favorable market for advanced electric propulsion technologies, including high-performance induction motor systems.

Technological advancements in power electronics, control systems, and energy storage are further driving the demand for sophisticated electric locomotive solutions. Innovations in these areas are enabling the development of more efficient, powerful, and reliable induction motor systems, which in turn is attracting investment from railway operators looking to upgrade their fleets.

The aftermarket and retrofit segment also presents significant opportunities. As railway operators seek to extend the life of existing rolling stock while improving performance and reducing emissions, there is a growing demand for upgrading older locomotives with modern electric propulsion systems, including advanced induction motors.

The market demand for electric locomotives is primarily fueled by the expansion and modernization of railway networks, particularly in developing economies. Countries like China, India, and several European nations are investing heavily in high-speed rail projects and upgrading existing infrastructure, creating a substantial demand for advanced electric locomotive systems.

In the context of high-performance electric locomotive systems, induction motors play a crucial role. These motors offer several advantages, including robustness, reliability, and lower maintenance requirements compared to other motor types. The demand for induction motors in electric locomotives is closely tied to the overall market growth of electric rolling stock.

The freight transportation sector is a major driver of electric locomotive demand. With increasing global trade and the need for efficient long-distance cargo movement, electric locomotives offer a cost-effective and environmentally friendly solution. This has led to a growing interest in high-performance systems that can handle heavy loads over long distances while maintaining optimal energy efficiency.

Passenger rail services, including intercity and urban transit systems, also contribute significantly to the market demand. As urban populations grow and cities seek to reduce congestion and pollution, electric locomotives for commuter trains and light rail systems are seeing increased adoption.

The market is also influenced by government regulations and initiatives promoting clean energy and sustainable transportation. Many countries have set ambitious targets for reducing greenhouse gas emissions, which has accelerated the transition from diesel to electric locomotives. This regulatory environment is creating a favorable market for advanced electric propulsion technologies, including high-performance induction motor systems.

Technological advancements in power electronics, control systems, and energy storage are further driving the demand for sophisticated electric locomotive solutions. Innovations in these areas are enabling the development of more efficient, powerful, and reliable induction motor systems, which in turn is attracting investment from railway operators looking to upgrade their fleets.

The aftermarket and retrofit segment also presents significant opportunities. As railway operators seek to extend the life of existing rolling stock while improving performance and reducing emissions, there is a growing demand for upgrading older locomotives with modern electric propulsion systems, including advanced induction motors.

Current Challenges in High-Performance Induction Motors

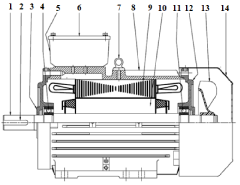

High-performance induction motors in electric locomotive systems face several significant challenges that hinder their optimal performance and efficiency. One of the primary issues is thermal management. As these motors operate at high power densities, they generate substantial heat, which can lead to reduced efficiency, decreased lifespan, and potential failure if not properly managed. Developing effective cooling systems that can dissipate heat quickly and uniformly across the motor components is crucial.

Another challenge lies in the optimization of motor design for high-speed operation. Electric locomotives require motors capable of maintaining high efficiency and torque across a wide speed range. This necessitates careful consideration of factors such as rotor design, magnetic circuit optimization, and minimization of losses at high frequencies. Balancing these requirements while keeping the motor compact and lightweight presents a significant engineering challenge.

Power electronics and control systems pose additional hurdles. The need for precise control of motor speed and torque, especially during acceleration and deceleration, demands sophisticated power electronic converters and control algorithms. These systems must be robust enough to handle the harsh operating conditions of locomotive environments, including vibrations, temperature fluctuations, and electromagnetic interference.

Material limitations also present ongoing challenges. The quest for higher power densities and efficiencies drives the need for advanced magnetic materials with superior properties. However, the development and integration of these materials, such as high-performance permanent magnets or advanced soft magnetic composites, often come with increased costs and manufacturing complexities.

Reliability and maintenance issues are critical concerns in locomotive applications. Induction motors in these systems must operate continuously for extended periods under varying load conditions. Ensuring long-term reliability while minimizing maintenance requirements is essential. This involves addressing issues such as bearing wear, insulation degradation, and the development of effective condition monitoring systems.

Lastly, energy efficiency remains a paramount challenge. While induction motors are known for their robustness, improving their efficiency, especially at partial loads, is crucial for reducing overall energy consumption in electric locomotive systems. This involves optimizing motor design, materials, and control strategies to minimize losses across the entire operating range.

Another challenge lies in the optimization of motor design for high-speed operation. Electric locomotives require motors capable of maintaining high efficiency and torque across a wide speed range. This necessitates careful consideration of factors such as rotor design, magnetic circuit optimization, and minimization of losses at high frequencies. Balancing these requirements while keeping the motor compact and lightweight presents a significant engineering challenge.

Power electronics and control systems pose additional hurdles. The need for precise control of motor speed and torque, especially during acceleration and deceleration, demands sophisticated power electronic converters and control algorithms. These systems must be robust enough to handle the harsh operating conditions of locomotive environments, including vibrations, temperature fluctuations, and electromagnetic interference.

Material limitations also present ongoing challenges. The quest for higher power densities and efficiencies drives the need for advanced magnetic materials with superior properties. However, the development and integration of these materials, such as high-performance permanent magnets or advanced soft magnetic composites, often come with increased costs and manufacturing complexities.

Reliability and maintenance issues are critical concerns in locomotive applications. Induction motors in these systems must operate continuously for extended periods under varying load conditions. Ensuring long-term reliability while minimizing maintenance requirements is essential. This involves addressing issues such as bearing wear, insulation degradation, and the development of effective condition monitoring systems.

Lastly, energy efficiency remains a paramount challenge. While induction motors are known for their robustness, improving their efficiency, especially at partial loads, is crucial for reducing overall energy consumption in electric locomotive systems. This involves optimizing motor design, materials, and control strategies to minimize losses across the entire operating range.

State-of-the-Art Induction Motor Solutions

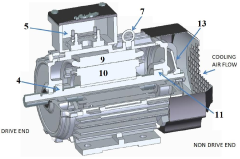

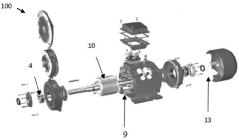

01 Design and construction of induction motors

This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.- Design and construction of induction motors: This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.

- Control systems for induction motors: Control systems play a crucial role in regulating the speed, torque, and efficiency of induction motors. This category includes advancements in motor drives, power electronics, and control algorithms designed to optimize motor performance across various operating conditions.

- Efficiency improvements in induction motors: This category focuses on techniques and technologies aimed at enhancing the energy efficiency of induction motors. This includes improvements in motor design, materials, and manufacturing processes to reduce losses and increase overall motor efficiency.

- Specialized applications of induction motors: Induction motors are used in a wide range of specialized applications, each with unique requirements. This category covers motor designs and modifications tailored for specific industries or operating environments, such as high-temperature, high-speed, or submersible applications.

- Maintenance and diagnostics of induction motors: This category encompasses methods and systems for monitoring, maintaining, and diagnosing induction motors. It includes techniques for fault detection, condition monitoring, and predictive maintenance to ensure optimal motor performance and longevity.

02 Control systems for induction motors

Control systems play a crucial role in regulating the speed, torque, and efficiency of induction motors. This category encompasses various control strategies, including vector control, direct torque control, and advanced algorithms for optimizing motor performance under different operating conditions.Expand Specific Solutions03 Energy efficiency improvements in induction motors

This category focuses on techniques and technologies aimed at enhancing the energy efficiency of induction motors. This includes advancements in motor design, materials, and control strategies to reduce power losses and improve overall motor efficiency across various load conditions.Expand Specific Solutions04 Specialized applications of induction motors

Induction motors are used in a wide range of specialized applications, each with unique requirements. This category covers innovations tailored for specific industries or operating environments, such as high-speed motors, submersible motors, or motors designed for extreme conditions.Expand Specific Solutions05 Diagnostics and maintenance of induction motors

This category encompasses methods and systems for monitoring, diagnosing, and maintaining induction motors. It includes techniques for fault detection, predictive maintenance, and condition monitoring to ensure optimal motor performance and longevity.Expand Specific Solutions

Key Players in Electric Locomotive Industry

The research on induction motors in high-performance electric locomotive systems is in a mature stage of development, with a significant market size driven by the growing demand for efficient and sustainable transportation solutions. The technology has reached a high level of maturity, with established players like Hitachi Ltd., Siemens Mobility GmbH, and Mitsubishi Electric Corp. leading the field. These companies have extensive experience in developing and implementing advanced induction motor technologies for electric locomotives. The competitive landscape is characterized by ongoing innovation and refinement of existing technologies, with a focus on improving efficiency, power density, and reliability. Emerging players and research institutions are also contributing to advancements in this field, fostering a dynamic and competitive environment.

Hitachi Ltd.

Technical Solution: Hitachi has developed cutting-edge induction motor technology for high-performance electric locomotives. Their approach focuses on high-power density and energy efficiency. Hitachi has implemented advanced magnetic circuit designs that minimize core losses and improve overall motor efficiency[7]. They have also developed a unique cooling system that allows for higher power output without compromising reliability. Hitachi's induction motors feature optimized stator and rotor designs that reduce harmonics and improve power factor[8]. Additionally, the company has integrated advanced control systems that allow for seamless integration with regenerative braking systems, further enhancing energy efficiency in locomotive applications[9].

Strengths: High power density, advanced cooling systems, and integration with regenerative braking. Weaknesses: Potentially higher manufacturing costs due to specialized designs.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed advanced induction motor technology for high-performance electric locomotives. Their approach focuses on improving efficiency and power density through innovative design and materials. They have implemented a high-frequency PWM inverter control system that allows for precise speed and torque control of the induction motors[1]. The company has also developed a unique rotor design with optimized slot geometry and advanced magnetic materials to reduce losses and improve overall performance[2]. Additionally, Mitsubishi Electric has integrated a sophisticated thermal management system to maintain optimal operating temperatures, enhancing reliability and extending motor lifespan in demanding locomotive applications[3].

Strengths: High efficiency, precise control, and advanced thermal management. Weaknesses: Potentially higher initial costs due to advanced materials and complex control systems.

Core Innovations in Locomotive Induction Motors

HIGH PERFORMANCE INDUCTION ELECTRIC motor

PatentInactiveBR102019023406A8

Innovation

- Magnetic effect that reduces inductance, resulting in a smaller angle between voltage and current.

- High power factor achieved through reduced inductance.

- Applicable to both three-phase and single-phase alternating current systems.

Three phase induction motor

PatentActiveIN202121018603A

Innovation

- A three-phase induction motor design utilizing high-grade silicon steel and copper materials, with increased stator and rotor slot areas, reduced number of turns per slot, and optimized copper wire diameter, eliminates the need for additional devices and synchronizations, while reducing losses through improved magnetic field production and rotor rotation.

Energy Efficiency and Environmental Impact

The energy efficiency and environmental impact of induction motors in high-performance electric locomotive systems are critical considerations in the development and implementation of modern rail transportation. Induction motors, known for their robustness and reliability, play a pivotal role in the propulsion of electric locomotives. However, their energy consumption and environmental footprint have become increasingly important factors in the face of global sustainability challenges.

In terms of energy efficiency, induction motors in electric locomotives have seen significant improvements over the years. Advanced control strategies, such as vector control and direct torque control, have enhanced the motors' performance and reduced energy losses. These techniques allow for precise control of motor speed and torque, optimizing power consumption across various operating conditions. Furthermore, the integration of regenerative braking systems has enabled the recovery of kinetic energy during deceleration, which can be fed back into the power grid or used to charge onboard energy storage systems.

The use of high-quality materials in motor construction, such as low-loss electrical steel and copper windings, has also contributed to increased efficiency. Improved thermal management systems help maintain optimal operating temperatures, reducing resistive losses and extending motor lifespan. Additionally, the adoption of advanced power electronics and variable frequency drives has further enhanced the overall system efficiency.

From an environmental perspective, the shift towards electric locomotives powered by induction motors has significantly reduced direct emissions compared to diesel-electric counterparts. This transition aligns with global efforts to decarbonize the transportation sector and mitigate climate change. However, the environmental impact of electric locomotives is closely tied to the source of electricity used to power them. As power grids increasingly incorporate renewable energy sources, the carbon footprint of electric locomotive systems continues to decrease.

The manufacturing process of induction motors also presents environmental considerations. Efforts are being made to reduce the use of rare earth materials and implement more sustainable production methods. Lifecycle assessments of induction motors in locomotive applications have highlighted areas for improvement, such as the recyclability of components and the reduction of hazardous materials.

Noise pollution is another environmental aspect addressed in the design of induction motor systems for electric locomotives. Advanced acoustic engineering and vibration dampening techniques have been employed to minimize noise emissions, improving the quality of life for communities along rail corridors.

As research in this field progresses, there is a growing focus on developing even more efficient and environmentally friendly induction motor systems. This includes exploring novel materials, such as high-temperature superconductors, and investigating alternative motor topologies that could further enhance energy efficiency and reduce environmental impact in high-performance electric locomotive applications.

In terms of energy efficiency, induction motors in electric locomotives have seen significant improvements over the years. Advanced control strategies, such as vector control and direct torque control, have enhanced the motors' performance and reduced energy losses. These techniques allow for precise control of motor speed and torque, optimizing power consumption across various operating conditions. Furthermore, the integration of regenerative braking systems has enabled the recovery of kinetic energy during deceleration, which can be fed back into the power grid or used to charge onboard energy storage systems.

The use of high-quality materials in motor construction, such as low-loss electrical steel and copper windings, has also contributed to increased efficiency. Improved thermal management systems help maintain optimal operating temperatures, reducing resistive losses and extending motor lifespan. Additionally, the adoption of advanced power electronics and variable frequency drives has further enhanced the overall system efficiency.

From an environmental perspective, the shift towards electric locomotives powered by induction motors has significantly reduced direct emissions compared to diesel-electric counterparts. This transition aligns with global efforts to decarbonize the transportation sector and mitigate climate change. However, the environmental impact of electric locomotives is closely tied to the source of electricity used to power them. As power grids increasingly incorporate renewable energy sources, the carbon footprint of electric locomotive systems continues to decrease.

The manufacturing process of induction motors also presents environmental considerations. Efforts are being made to reduce the use of rare earth materials and implement more sustainable production methods. Lifecycle assessments of induction motors in locomotive applications have highlighted areas for improvement, such as the recyclability of components and the reduction of hazardous materials.

Noise pollution is another environmental aspect addressed in the design of induction motor systems for electric locomotives. Advanced acoustic engineering and vibration dampening techniques have been employed to minimize noise emissions, improving the quality of life for communities along rail corridors.

As research in this field progresses, there is a growing focus on developing even more efficient and environmentally friendly induction motor systems. This includes exploring novel materials, such as high-temperature superconductors, and investigating alternative motor topologies that could further enhance energy efficiency and reduce environmental impact in high-performance electric locomotive applications.

Standardization and Safety Regulations

Standardization and safety regulations play a crucial role in the development and implementation of induction motors in high-performance electric locomotive systems. These regulations ensure consistency, reliability, and safety across the industry, promoting interoperability and facilitating global trade.

International standards organizations, such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), have established comprehensive guidelines for induction motors in railway applications. These standards cover various aspects, including performance requirements, testing procedures, and safety measures.

The IEC 60349 series specifically addresses electric traction motors for railway applications. It outlines specifications for rotating electrical machines in rolling stock, ensuring that induction motors meet the rigorous demands of high-performance electric locomotives. Additionally, the IEC 61373 standard focuses on shock and vibration tests for railway equipment, which is critical for ensuring the durability and reliability of induction motors in locomotive systems.

Safety regulations for induction motors in electric locomotives are primarily governed by the EN 50155 standard, which specifies requirements for electronic equipment used in railway applications. This standard covers aspects such as environmental conditions, electrical safety, and electromagnetic compatibility, all of which are essential for the safe operation of induction motors in high-performance locomotive systems.

The European Union Agency for Railways (ERA) has also established Technical Specifications for Interoperability (TSI), which include safety requirements for rolling stock. These specifications ensure that induction motors and associated systems comply with stringent safety standards across European rail networks.

In the United States, the Federal Railroad Administration (FRA) sets safety standards for locomotive electrical systems, including those utilizing induction motors. These regulations are outlined in the Code of Federal Regulations (CFR) Title 49, Part 229, which covers locomotive safety standards.

Compliance with these standards and regulations is mandatory for manufacturers and operators of high-performance electric locomotives. Regular inspections and certifications are required to ensure ongoing adherence to safety and performance standards. This rigorous regulatory framework not only enhances safety but also drives innovation in induction motor technology for electric locomotive systems.

As the industry continues to evolve, standardization bodies and regulatory agencies are working to update and refine these standards to address emerging technologies and challenges. This ongoing process ensures that induction motors in high-performance electric locomotive systems remain at the forefront of safety and efficiency in the rail transport sector.

International standards organizations, such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), have established comprehensive guidelines for induction motors in railway applications. These standards cover various aspects, including performance requirements, testing procedures, and safety measures.

The IEC 60349 series specifically addresses electric traction motors for railway applications. It outlines specifications for rotating electrical machines in rolling stock, ensuring that induction motors meet the rigorous demands of high-performance electric locomotives. Additionally, the IEC 61373 standard focuses on shock and vibration tests for railway equipment, which is critical for ensuring the durability and reliability of induction motors in locomotive systems.

Safety regulations for induction motors in electric locomotives are primarily governed by the EN 50155 standard, which specifies requirements for electronic equipment used in railway applications. This standard covers aspects such as environmental conditions, electrical safety, and electromagnetic compatibility, all of which are essential for the safe operation of induction motors in high-performance locomotive systems.

The European Union Agency for Railways (ERA) has also established Technical Specifications for Interoperability (TSI), which include safety requirements for rolling stock. These specifications ensure that induction motors and associated systems comply with stringent safety standards across European rail networks.

In the United States, the Federal Railroad Administration (FRA) sets safety standards for locomotive electrical systems, including those utilizing induction motors. These regulations are outlined in the Code of Federal Regulations (CFR) Title 49, Part 229, which covers locomotive safety standards.

Compliance with these standards and regulations is mandatory for manufacturers and operators of high-performance electric locomotives. Regular inspections and certifications are required to ensure ongoing adherence to safety and performance standards. This rigorous regulatory framework not only enhances safety but also drives innovation in induction motor technology for electric locomotive systems.

As the industry continues to evolve, standardization bodies and regulatory agencies are working to update and refine these standards to address emerging technologies and challenges. This ongoing process ensures that induction motors in high-performance electric locomotive systems remain at the forefront of safety and efficiency in the rail transport sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!