How induction motors integrate with self-sustaining habitats

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Integration Background and Objectives

Induction motors have been a cornerstone of industrial and residential power systems for over a century, providing reliable and efficient mechanical power for a wide range of applications. As we venture into the realm of self-sustaining habitats, the integration of these motors presents both challenges and opportunities. The evolution of induction motor technology has been marked by continuous improvements in efficiency, power density, and control systems, making them increasingly suitable for integration into closed-loop environments.

The primary objective of integrating induction motors with self-sustaining habitats is to create a symbiotic relationship between power generation, consumption, and environmental control. This integration aims to maximize energy efficiency, minimize waste, and ensure long-term sustainability of the habitat's ecosystem. By leveraging the inherent reliability and simplicity of induction motors, we seek to develop robust systems that can operate with minimal maintenance in isolated or resource-constrained environments.

One of the key trends driving this integration is the advancement in power electronics and control systems. Modern variable frequency drives (VFDs) allow for precise speed control and energy optimization of induction motors, making them more adaptable to the fluctuating power demands of self-sustaining habitats. This adaptability is crucial for managing the delicate balance of energy production and consumption within a closed system.

Another significant trend is the development of high-efficiency motor designs, such as premium efficiency and super-premium efficiency motors. These advancements reduce energy losses and heat generation, which is particularly important in controlled environments where thermal management is critical. The reduced heat output also contributes to the overall energy balance of the habitat, potentially decreasing the load on cooling systems.

The integration of induction motors into self-sustaining habitats also aligns with the broader trend of electrification in various sectors. As we move towards more sustainable and environmentally friendly technologies, electric motors are replacing traditional combustion engines in many applications. This shift creates a synergy between the power systems of self-sustaining habitats and the broader technological ecosystem.

Looking forward, the goal is to develop induction motor systems that can seamlessly interface with renewable energy sources, energy storage systems, and smart grid technologies. This integration will enable self-sustaining habitats to optimize their energy use, respond to environmental changes, and maintain long-term stability. The ultimate objective is to create a closed-loop system where induction motors not only consume power but also contribute to the overall energy management and sustainability of the habitat.

The primary objective of integrating induction motors with self-sustaining habitats is to create a symbiotic relationship between power generation, consumption, and environmental control. This integration aims to maximize energy efficiency, minimize waste, and ensure long-term sustainability of the habitat's ecosystem. By leveraging the inherent reliability and simplicity of induction motors, we seek to develop robust systems that can operate with minimal maintenance in isolated or resource-constrained environments.

One of the key trends driving this integration is the advancement in power electronics and control systems. Modern variable frequency drives (VFDs) allow for precise speed control and energy optimization of induction motors, making them more adaptable to the fluctuating power demands of self-sustaining habitats. This adaptability is crucial for managing the delicate balance of energy production and consumption within a closed system.

Another significant trend is the development of high-efficiency motor designs, such as premium efficiency and super-premium efficiency motors. These advancements reduce energy losses and heat generation, which is particularly important in controlled environments where thermal management is critical. The reduced heat output also contributes to the overall energy balance of the habitat, potentially decreasing the load on cooling systems.

The integration of induction motors into self-sustaining habitats also aligns with the broader trend of electrification in various sectors. As we move towards more sustainable and environmentally friendly technologies, electric motors are replacing traditional combustion engines in many applications. This shift creates a synergy between the power systems of self-sustaining habitats and the broader technological ecosystem.

Looking forward, the goal is to develop induction motor systems that can seamlessly interface with renewable energy sources, energy storage systems, and smart grid technologies. This integration will enable self-sustaining habitats to optimize their energy use, respond to environmental changes, and maintain long-term stability. The ultimate objective is to create a closed-loop system where induction motors not only consume power but also contribute to the overall energy management and sustainability of the habitat.

Market Analysis for Self-Sustaining Habitat Systems

The market for self-sustaining habitat systems is experiencing significant growth, driven by increasing environmental concerns, space exploration initiatives, and the need for sustainable living solutions. These systems, which integrate various technologies including induction motors, aim to create closed-loop environments that can support human life with minimal external inputs.

The global market for self-sustaining habitats is projected to expand rapidly in the coming years, with applications ranging from remote terrestrial locations to potential extraterrestrial settlements. Key market segments include research facilities, disaster relief shelters, off-grid housing, and space habitats. The integration of induction motors in these systems plays a crucial role in powering various subsystems, such as air circulation, water purification, and waste management.

In the terrestrial market, there is a growing demand for eco-friendly and self-sufficient living spaces. This trend is particularly strong in regions prone to natural disasters or areas with limited access to traditional infrastructure. The market for off-grid housing solutions incorporating self-sustaining technologies is expected to see substantial growth, especially in developing countries and remote locations.

The space exploration sector represents a significant driver for self-sustaining habitat technologies. As space agencies and private companies plan for long-duration missions and potential colonization efforts, the need for reliable and efficient life support systems becomes paramount. Induction motors, known for their robustness and efficiency, are well-suited for these challenging environments.

Market analysis indicates that the integration of induction motors in self-sustaining habitats offers several advantages. These motors provide high reliability, low maintenance requirements, and the ability to operate in harsh conditions. Their integration into habitat systems enables efficient energy conversion and distribution, critical for maintaining life support functions in closed environments.

The competitive landscape for self-sustaining habitat systems is diverse, with both established aerospace companies and innovative startups entering the market. Key players are focusing on developing integrated solutions that optimize the use of induction motors alongside other technologies such as renewable energy systems, advanced air and water recycling methods, and smart control systems.

Challenges in the market include high initial costs, regulatory hurdles, and the need for extensive testing and validation of these complex systems. However, ongoing technological advancements and increasing investment in sustainable technologies are expected to drive down costs and improve system performance over time.

As the market for self-sustaining habitats continues to evolve, the role of induction motors is likely to expand. Future developments may include more compact and efficient motor designs, improved integration with renewable energy sources, and advanced control systems for optimizing overall habitat performance. These advancements will be crucial in meeting the growing demand for sustainable living solutions both on Earth and in future space exploration endeavors.

The global market for self-sustaining habitats is projected to expand rapidly in the coming years, with applications ranging from remote terrestrial locations to potential extraterrestrial settlements. Key market segments include research facilities, disaster relief shelters, off-grid housing, and space habitats. The integration of induction motors in these systems plays a crucial role in powering various subsystems, such as air circulation, water purification, and waste management.

In the terrestrial market, there is a growing demand for eco-friendly and self-sufficient living spaces. This trend is particularly strong in regions prone to natural disasters or areas with limited access to traditional infrastructure. The market for off-grid housing solutions incorporating self-sustaining technologies is expected to see substantial growth, especially in developing countries and remote locations.

The space exploration sector represents a significant driver for self-sustaining habitat technologies. As space agencies and private companies plan for long-duration missions and potential colonization efforts, the need for reliable and efficient life support systems becomes paramount. Induction motors, known for their robustness and efficiency, are well-suited for these challenging environments.

Market analysis indicates that the integration of induction motors in self-sustaining habitats offers several advantages. These motors provide high reliability, low maintenance requirements, and the ability to operate in harsh conditions. Their integration into habitat systems enables efficient energy conversion and distribution, critical for maintaining life support functions in closed environments.

The competitive landscape for self-sustaining habitat systems is diverse, with both established aerospace companies and innovative startups entering the market. Key players are focusing on developing integrated solutions that optimize the use of induction motors alongside other technologies such as renewable energy systems, advanced air and water recycling methods, and smart control systems.

Challenges in the market include high initial costs, regulatory hurdles, and the need for extensive testing and validation of these complex systems. However, ongoing technological advancements and increasing investment in sustainable technologies are expected to drive down costs and improve system performance over time.

As the market for self-sustaining habitats continues to evolve, the role of induction motors is likely to expand. Future developments may include more compact and efficient motor designs, improved integration with renewable energy sources, and advanced control systems for optimizing overall habitat performance. These advancements will be crucial in meeting the growing demand for sustainable living solutions both on Earth and in future space exploration endeavors.

Technical Challenges in Motor-Habitat Integration

Integrating induction motors with self-sustaining habitats presents several significant technical challenges that require innovative solutions. One of the primary obstacles is the need for efficient power management and distribution within the closed ecosystem of a habitat. Induction motors, while reliable and widely used, can be energy-intensive, potentially straining the limited power resources of a self-sustaining environment.

The integration process must address the issue of electromagnetic interference (EMI) generated by induction motors. In a confined habitat space, EMI can disrupt sensitive electronic equipment crucial for life support systems, communication, and environmental monitoring. Developing effective shielding and grounding techniques becomes paramount to ensure the harmonious operation of motors alongside other critical habitat components.

Heat dissipation poses another substantial challenge. Induction motors generate considerable heat during operation, which can affect the delicate temperature balance within a closed habitat. Engineers must design innovative cooling systems that not only maintain optimal motor performance but also contribute to the habitat's overall thermal management without compromising its self-sustaining nature.

The requirement for compact design presents an additional hurdle. Self-sustaining habitats often have space constraints, necessitating the development of smaller, more efficient induction motors without sacrificing power output. This miniaturization effort must also consider the need for easy maintenance and repair, as access to external resources may be limited in isolated habitat scenarios.

Durability and longevity of the integrated motor systems are critical factors that demand attention. The harsh conditions often associated with self-sustaining habitats, such as extreme temperatures, humidity, or even radiation in space-based applications, require motors to be exceptionally robust. Engineers must develop advanced materials and protective coatings to ensure the motors can withstand these challenging environments over extended periods without frequent maintenance or replacement.

Another significant challenge lies in the integration of motor control systems with the habitat's central management infrastructure. Developing smart, adaptive control algorithms that can optimize motor performance based on the habitat's changing needs and resource availability is essential. These systems must be capable of real-time adjustments to maintain the delicate balance of energy consumption and production within the self-sustaining ecosystem.

Lastly, the challenge of sustainability and recyclability cannot be overlooked. As resources in a self-sustaining habitat are finite, the motor integration strategy must consider the entire lifecycle of the components. This includes designing for easy disassembly, using recyclable materials where possible, and implementing systems for the recovery and repurposing of motor parts at the end of their operational life.

The integration process must address the issue of electromagnetic interference (EMI) generated by induction motors. In a confined habitat space, EMI can disrupt sensitive electronic equipment crucial for life support systems, communication, and environmental monitoring. Developing effective shielding and grounding techniques becomes paramount to ensure the harmonious operation of motors alongside other critical habitat components.

Heat dissipation poses another substantial challenge. Induction motors generate considerable heat during operation, which can affect the delicate temperature balance within a closed habitat. Engineers must design innovative cooling systems that not only maintain optimal motor performance but also contribute to the habitat's overall thermal management without compromising its self-sustaining nature.

The requirement for compact design presents an additional hurdle. Self-sustaining habitats often have space constraints, necessitating the development of smaller, more efficient induction motors without sacrificing power output. This miniaturization effort must also consider the need for easy maintenance and repair, as access to external resources may be limited in isolated habitat scenarios.

Durability and longevity of the integrated motor systems are critical factors that demand attention. The harsh conditions often associated with self-sustaining habitats, such as extreme temperatures, humidity, or even radiation in space-based applications, require motors to be exceptionally robust. Engineers must develop advanced materials and protective coatings to ensure the motors can withstand these challenging environments over extended periods without frequent maintenance or replacement.

Another significant challenge lies in the integration of motor control systems with the habitat's central management infrastructure. Developing smart, adaptive control algorithms that can optimize motor performance based on the habitat's changing needs and resource availability is essential. These systems must be capable of real-time adjustments to maintain the delicate balance of energy consumption and production within the self-sustaining ecosystem.

Lastly, the challenge of sustainability and recyclability cannot be overlooked. As resources in a self-sustaining habitat are finite, the motor integration strategy must consider the entire lifecycle of the components. This includes designing for easy disassembly, using recyclable materials where possible, and implementing systems for the recovery and repurposing of motor parts at the end of their operational life.

Current Integration Solutions for Induction Motors

01 Design and construction of induction motors

This category covers the fundamental design and construction aspects of induction motors, including stator and rotor configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.- Design and construction of induction motors: This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.

- Control systems for induction motors: Control systems play a crucial role in regulating the speed, torque, and efficiency of induction motors. This category includes advancements in motor drives, power electronics, and control algorithms to enhance motor performance and energy efficiency across various applications.

- Efficiency improvements in induction motors: This category focuses on techniques and technologies aimed at improving the energy efficiency of induction motors. This includes optimizing motor design, using advanced materials, and implementing innovative cooling systems to reduce energy losses and improve overall motor performance.

- Specialized applications of induction motors: Induction motors are used in a wide range of specialized applications, each with unique requirements. This category covers innovations tailored for specific industries or use cases, such as high-power industrial motors, compact motors for automotive applications, or motors designed for harsh environments.

- Maintenance and diagnostics of induction motors: This category encompasses technologies and methods for monitoring, maintaining, and diagnosing induction motors. It includes advancements in sensor technologies, predictive maintenance algorithms, and fault detection systems to improve motor reliability and reduce downtime.

02 Control systems for induction motors

Control systems play a crucial role in regulating the speed, torque, and efficiency of induction motors. This category encompasses various control strategies, including vector control, direct torque control, and sensorless control techniques, as well as the implementation of advanced control algorithms and hardware.Expand Specific Solutions03 Energy efficiency improvements in induction motors

This category focuses on innovations aimed at enhancing the energy efficiency of induction motors. It includes advancements in motor design, materials, and manufacturing processes that reduce losses and improve overall motor performance, contributing to energy savings in various applications.Expand Specific Solutions04 Specialized applications of induction motors

Induction motors are used in a wide range of specialized applications, each with unique requirements. This category covers innovations tailored to specific industries or use cases, such as high-speed motors, submersible motors, or motors designed for harsh environments.Expand Specific Solutions05 Advancements in induction motor manufacturing

This category encompasses innovations in the manufacturing processes and techniques used to produce induction motors. It includes advancements in automation, precision engineering, and quality control methods that improve motor reliability, consistency, and cost-effectiveness.Expand Specific Solutions

Key Players in Sustainable Habitat and Motor Industries

The integration of induction motors with self-sustaining habitats is an emerging field at the intersection of sustainable energy and advanced motor technology. The market is in its early growth stage, with increasing demand driven by the global push for sustainable living solutions. While the market size is still relatively small, it is expected to expand rapidly as more countries invest in eco-friendly infrastructure. Technologically, the field is evolving, with companies like Toyota Motor Corp., Danfoss A/S, and Cummins, Inc. leading innovation in motor efficiency and integration. These firms are developing advanced control systems and energy management solutions to optimize induction motor performance in self-contained environments. However, the technology is not yet fully mature, with ongoing research focused on improving energy efficiency, reducing environmental impact, and enhancing overall system reliability in isolated habitats.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced induction motor system for self-sustaining habitats, focusing on energy efficiency and durability. Their system incorporates regenerative braking technology to capture and store energy during deceleration, which is then used to power auxiliary systems within the habitat [1]. The motor design features a high-efficiency copper rotor and advanced thermal management system, allowing for optimal performance in varied environmental conditions [3]. Toyota has also integrated their induction motors with smart grid technology, enabling seamless power distribution and load balancing within the habitat [5].

Strengths: High energy efficiency, advanced thermal management, and integration with smart grid systems. Weaknesses: Potentially higher initial cost and complexity compared to simpler motor designs.

Danfoss A/S

Technical Solution: Danfoss has developed a specialized induction motor solution for self-sustaining habitats, focusing on their VLT® AutomationDrive FC 302 series. This system incorporates advanced motor control algorithms that optimize energy consumption based on real-time habitat needs [2]. The motors feature integrated frequency converters that allow for precise speed control and energy management. Danfoss has also implemented their EC+ concept, which enables seamless integration of the motor system with other habitat components, such as HVAC and water management systems [4]. Their solution includes built-in harmonic mitigation technology to ensure power quality within the closed ecosystem of a self-sustaining habitat [6].

Strengths: Advanced energy management, seamless integration with other habitat systems, and power quality assurance. Weaknesses: May require specialized maintenance and potentially higher upfront costs.

Innovative Motor Designs for Habitat Applications

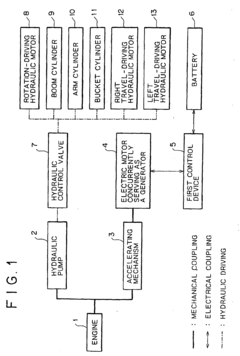

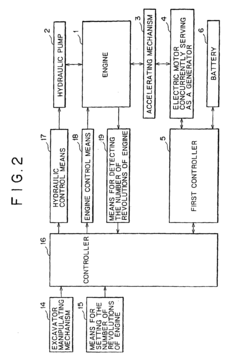

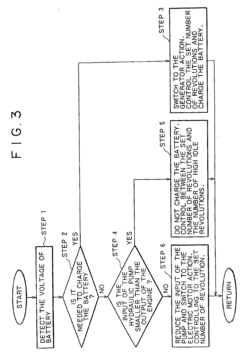

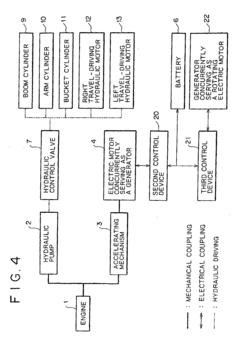

Excavator with hybrid drive apparatus

PatentInactiveEP1191155B1

Innovation

- The integration of an electric motor functioning as both a generator and motor, connected to the engine via an accelerating mechanism, allows for dynamic switching between power generation and assistance, optimizing engine output and maintaining stable engine speed through battery-powered assistance during high load conditions, while regenerative braking enhances energy reuse.

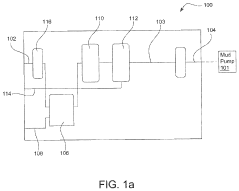

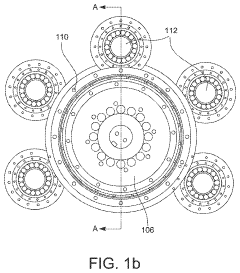

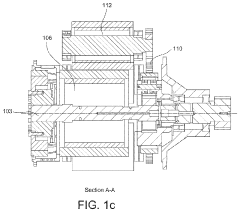

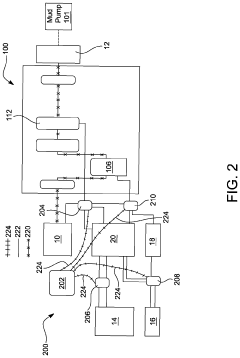

Drilling rig power supply bus management

PatentPendingUS20230223781A1

Innovation

- A rig mud pump drive system with an input power drive shaft connected to an ICE, an output power drive shaft connected to the mud pump, and a mechanical drive train with integrated electric generators or motors, along with a power management system using a processor and control communications network to optimize ICE operation within efficient ranges and maintain readiness without continuous ICE operation.

Energy Efficiency and Sustainability Considerations

The integration of induction motors with self-sustaining habitats presents a unique opportunity to enhance energy efficiency and promote sustainability. These motors, known for their robustness and reliability, can be optimized to operate in harmony with the closed-loop systems characteristic of self-sustaining environments. By leveraging regenerative braking and energy recovery techniques, induction motors can significantly reduce overall energy consumption within the habitat.

One key consideration is the implementation of advanced motor control strategies, such as vector control and direct torque control, which can maximize the efficiency of induction motors across various operating conditions. These techniques allow for precise speed and torque regulation, minimizing energy losses and extending the motor's operational lifespan. Furthermore, the integration of smart sensors and IoT technologies enables real-time monitoring and predictive maintenance, ensuring optimal performance and reducing unexpected downtime.

The use of high-efficiency materials in motor construction, such as copper rotor bars and low-loss electrical steel laminations, can further improve the energy efficiency of induction motors. Additionally, the incorporation of variable frequency drives (VFDs) allows for dynamic adjustment of motor speed and power consumption based on the habitat's changing energy demands, contributing to overall system efficiency.

In the context of self-sustaining habitats, the heat generated by induction motors can be harnessed for secondary purposes, such as water heating or climate control, thereby increasing the overall energy utilization within the closed system. This waste heat recovery approach aligns with the principles of circular economy and resource conservation inherent in sustainable habitat design.

The integration of induction motors with renewable energy sources, such as solar panels or wind turbines, is another critical aspect of sustainability. By synchronizing motor operation with periods of peak renewable energy generation, the habitat can maximize its use of clean energy and reduce reliance on stored power. This synergy between motor systems and renewable energy sources contributes to the habitat's energy independence and environmental sustainability.

Lastly, the development of biodegradable lubricants and environmentally friendly insulation materials for induction motors addresses end-of-life considerations, ensuring that the motors' environmental impact is minimized throughout their lifecycle. These sustainable design choices support the long-term viability of self-sustaining habitats and demonstrate a commitment to ecological responsibility in technological integration.

One key consideration is the implementation of advanced motor control strategies, such as vector control and direct torque control, which can maximize the efficiency of induction motors across various operating conditions. These techniques allow for precise speed and torque regulation, minimizing energy losses and extending the motor's operational lifespan. Furthermore, the integration of smart sensors and IoT technologies enables real-time monitoring and predictive maintenance, ensuring optimal performance and reducing unexpected downtime.

The use of high-efficiency materials in motor construction, such as copper rotor bars and low-loss electrical steel laminations, can further improve the energy efficiency of induction motors. Additionally, the incorporation of variable frequency drives (VFDs) allows for dynamic adjustment of motor speed and power consumption based on the habitat's changing energy demands, contributing to overall system efficiency.

In the context of self-sustaining habitats, the heat generated by induction motors can be harnessed for secondary purposes, such as water heating or climate control, thereby increasing the overall energy utilization within the closed system. This waste heat recovery approach aligns with the principles of circular economy and resource conservation inherent in sustainable habitat design.

The integration of induction motors with renewable energy sources, such as solar panels or wind turbines, is another critical aspect of sustainability. By synchronizing motor operation with periods of peak renewable energy generation, the habitat can maximize its use of clean energy and reduce reliance on stored power. This synergy between motor systems and renewable energy sources contributes to the habitat's energy independence and environmental sustainability.

Lastly, the development of biodegradable lubricants and environmentally friendly insulation materials for induction motors addresses end-of-life considerations, ensuring that the motors' environmental impact is minimized throughout their lifecycle. These sustainable design choices support the long-term viability of self-sustaining habitats and demonstrate a commitment to ecological responsibility in technological integration.

Regulatory Framework for Habitat Motor Systems

The regulatory framework for habitat motor systems in self-sustaining environments is a critical aspect of ensuring safe, efficient, and sustainable operations. As induction motors become increasingly integrated into these habitats, a comprehensive set of regulations and standards has been developed to govern their implementation and use.

At the international level, organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) have established guidelines for the design, installation, and operation of motor systems in enclosed habitats. These standards address issues such as electromagnetic compatibility, energy efficiency, and safety requirements specific to self-sustaining environments.

National regulatory bodies have also adapted these international standards to their specific contexts. For example, in the United States, the National Electrical Code (NEC) provides detailed regulations for electrical installations, including those in self-contained habitats. Similarly, the European Union has developed the Machinery Directive and the Low Voltage Directive, which apply to motor systems in various settings, including self-sustaining habitats.

One key aspect of the regulatory framework is the emphasis on energy efficiency. Given the limited resources available in self-sustaining habitats, regulations often mandate the use of high-efficiency motors and drive systems. This includes requirements for minimum efficiency levels, as well as guidelines for optimal motor sizing and load management to minimize energy consumption.

Safety regulations form another crucial component of the framework. These include specifications for motor enclosures to prevent contamination of the habitat environment, as well as protection against electrical hazards. Regulations also address the need for redundancy and fail-safe mechanisms in critical motor systems to ensure continuous operation of essential habitat functions.

Environmental considerations are also prominent in the regulatory landscape. Guidelines often stipulate the use of materials and lubricants that are compatible with closed-loop life support systems. Additionally, regulations may require the implementation of noise and vibration control measures to maintain a habitable environment.

Maintenance and monitoring requirements are typically outlined in the regulatory framework as well. This includes schedules for regular inspections, testing procedures, and documentation requirements. Many regulations now incorporate provisions for predictive maintenance techniques, leveraging data analytics to optimize motor performance and longevity.

As the technology for self-sustaining habitats continues to evolve, regulatory frameworks are adapting to keep pace. Recent updates have begun to address the integration of smart motor systems, incorporating guidelines for cybersecurity and data management in networked motor control systems. These regulations aim to ensure the resilience and reliability of habitat motor systems in increasingly complex and interconnected environments.

At the international level, organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) have established guidelines for the design, installation, and operation of motor systems in enclosed habitats. These standards address issues such as electromagnetic compatibility, energy efficiency, and safety requirements specific to self-sustaining environments.

National regulatory bodies have also adapted these international standards to their specific contexts. For example, in the United States, the National Electrical Code (NEC) provides detailed regulations for electrical installations, including those in self-contained habitats. Similarly, the European Union has developed the Machinery Directive and the Low Voltage Directive, which apply to motor systems in various settings, including self-sustaining habitats.

One key aspect of the regulatory framework is the emphasis on energy efficiency. Given the limited resources available in self-sustaining habitats, regulations often mandate the use of high-efficiency motors and drive systems. This includes requirements for minimum efficiency levels, as well as guidelines for optimal motor sizing and load management to minimize energy consumption.

Safety regulations form another crucial component of the framework. These include specifications for motor enclosures to prevent contamination of the habitat environment, as well as protection against electrical hazards. Regulations also address the need for redundancy and fail-safe mechanisms in critical motor systems to ensure continuous operation of essential habitat functions.

Environmental considerations are also prominent in the regulatory landscape. Guidelines often stipulate the use of materials and lubricants that are compatible with closed-loop life support systems. Additionally, regulations may require the implementation of noise and vibration control measures to maintain a habitable environment.

Maintenance and monitoring requirements are typically outlined in the regulatory framework as well. This includes schedules for regular inspections, testing procedures, and documentation requirements. Many regulations now incorporate provisions for predictive maintenance techniques, leveraging data analytics to optimize motor performance and longevity.

As the technology for self-sustaining habitats continues to evolve, regulatory frameworks are adapting to keep pace. Recent updates have begun to address the integration of smart motor systems, incorporating guidelines for cybersecurity and data management in networked motor control systems. These regulations aim to ensure the resilience and reliability of habitat motor systems in increasingly complex and interconnected environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!