How induction motors drive society towards a more sustainable future

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Evolution

The evolution of induction motors has been a cornerstone in the advancement of sustainable technologies and practices across various industries. From their inception in the late 19th century to the present day, these motors have undergone significant improvements in efficiency, reliability, and versatility.

In the early stages of development, induction motors were primarily used in industrial applications, powering machinery and equipment in factories. As the technology matured, their use expanded to include transportation, household appliances, and power generation. This widespread adoption was driven by the motor's simple design, robust construction, and relatively low maintenance requirements.

The mid-20th century saw a surge in research and development focused on enhancing the efficiency of induction motors. This period marked the introduction of advanced materials, such as high-grade silicon steel for motor cores and copper alloys for windings, which significantly reduced energy losses. Improved insulation materials also allowed for higher operating temperatures, leading to more compact and powerful motor designs.

The advent of power electronics in the latter half of the 20th century revolutionized induction motor control. Variable frequency drives (VFDs) enabled precise speed control and energy optimization, dramatically improving the motor's efficiency across a wide range of operating conditions. This development was particularly crucial for applications in renewable energy systems, such as wind turbines and hydroelectric generators.

In recent decades, the focus has shifted towards creating more environmentally friendly induction motors. Manufacturers have been developing motors with higher efficiency ratings, such as IE4 and IE5 classifications, which significantly reduce energy consumption and carbon emissions. The use of recycled materials in motor construction and the implementation of life cycle assessment practices have further enhanced the sustainability profile of induction motors.

The integration of smart technologies and the Internet of Things (IoT) has ushered in a new era for induction motors. Advanced sensors and monitoring systems now allow for predictive maintenance, optimizing motor performance and extending operational lifespans. This not only reduces waste but also ensures more efficient energy utilization throughout the motor's life cycle.

Looking towards the future, research is ongoing in areas such as superconducting materials and advanced magnetic designs, which promise to push the boundaries of induction motor efficiency even further. These innovations, coupled with continued improvements in manufacturing processes and materials science, are set to cement the induction motor's role in driving society towards a more sustainable future.

In the early stages of development, induction motors were primarily used in industrial applications, powering machinery and equipment in factories. As the technology matured, their use expanded to include transportation, household appliances, and power generation. This widespread adoption was driven by the motor's simple design, robust construction, and relatively low maintenance requirements.

The mid-20th century saw a surge in research and development focused on enhancing the efficiency of induction motors. This period marked the introduction of advanced materials, such as high-grade silicon steel for motor cores and copper alloys for windings, which significantly reduced energy losses. Improved insulation materials also allowed for higher operating temperatures, leading to more compact and powerful motor designs.

The advent of power electronics in the latter half of the 20th century revolutionized induction motor control. Variable frequency drives (VFDs) enabled precise speed control and energy optimization, dramatically improving the motor's efficiency across a wide range of operating conditions. This development was particularly crucial for applications in renewable energy systems, such as wind turbines and hydroelectric generators.

In recent decades, the focus has shifted towards creating more environmentally friendly induction motors. Manufacturers have been developing motors with higher efficiency ratings, such as IE4 and IE5 classifications, which significantly reduce energy consumption and carbon emissions. The use of recycled materials in motor construction and the implementation of life cycle assessment practices have further enhanced the sustainability profile of induction motors.

The integration of smart technologies and the Internet of Things (IoT) has ushered in a new era for induction motors. Advanced sensors and monitoring systems now allow for predictive maintenance, optimizing motor performance and extending operational lifespans. This not only reduces waste but also ensures more efficient energy utilization throughout the motor's life cycle.

Looking towards the future, research is ongoing in areas such as superconducting materials and advanced magnetic designs, which promise to push the boundaries of induction motor efficiency even further. These innovations, coupled with continued improvements in manufacturing processes and materials science, are set to cement the induction motor's role in driving society towards a more sustainable future.

Sustainable Energy Demand

The global energy landscape is undergoing a significant transformation, driven by the urgent need for sustainable solutions to combat climate change and reduce environmental impact. This shift towards sustainability has created a growing demand for energy-efficient technologies, with induction motors playing a crucial role in this transition.

Induction motors, known for their reliability and efficiency, are increasingly being adopted across various industries as a means to reduce energy consumption and carbon emissions. The industrial sector, which accounts for a substantial portion of global energy use, has seen a surge in demand for high-efficiency induction motors. These motors are being integrated into manufacturing processes, HVAC systems, and other industrial applications to optimize energy utilization and reduce operational costs.

In the transportation sector, the rise of electric vehicles has led to a significant increase in the demand for induction motors. As governments worldwide implement stricter emissions regulations and offer incentives for electric vehicle adoption, automakers are turning to induction motors as a key component in their electric powertrains. This trend is expected to continue, with the global electric vehicle market projected to grow exponentially in the coming years.

The renewable energy sector has also contributed to the rising demand for induction motors. Wind turbines, which rely on induction generators, have become an increasingly important source of clean energy. As countries strive to meet their renewable energy targets, the demand for wind power installations continues to grow, driving the need for efficient and reliable induction motors.

Furthermore, the building and construction industry has recognized the potential of induction motors in creating more energy-efficient structures. From elevators and escalators to water pumps and ventilation systems, induction motors are being integrated into smart building designs to reduce energy consumption and improve overall sustainability.

The agricultural sector, too, has seen an increased adoption of induction motors in irrigation systems and other farming equipment. As water scarcity becomes a pressing issue in many regions, farmers are turning to energy-efficient pumping solutions to optimize water usage and reduce their environmental footprint.

As the world moves towards a more sustainable future, the demand for induction motors is expected to continue its upward trajectory. Governments and organizations are implementing stricter energy efficiency standards, further driving the adoption of high-efficiency induction motors across various applications. This growing demand not only contributes to energy conservation efforts but also stimulates innovation in motor design and manufacturing, leading to even more efficient and sustainable solutions in the future.

Induction motors, known for their reliability and efficiency, are increasingly being adopted across various industries as a means to reduce energy consumption and carbon emissions. The industrial sector, which accounts for a substantial portion of global energy use, has seen a surge in demand for high-efficiency induction motors. These motors are being integrated into manufacturing processes, HVAC systems, and other industrial applications to optimize energy utilization and reduce operational costs.

In the transportation sector, the rise of electric vehicles has led to a significant increase in the demand for induction motors. As governments worldwide implement stricter emissions regulations and offer incentives for electric vehicle adoption, automakers are turning to induction motors as a key component in their electric powertrains. This trend is expected to continue, with the global electric vehicle market projected to grow exponentially in the coming years.

The renewable energy sector has also contributed to the rising demand for induction motors. Wind turbines, which rely on induction generators, have become an increasingly important source of clean energy. As countries strive to meet their renewable energy targets, the demand for wind power installations continues to grow, driving the need for efficient and reliable induction motors.

Furthermore, the building and construction industry has recognized the potential of induction motors in creating more energy-efficient structures. From elevators and escalators to water pumps and ventilation systems, induction motors are being integrated into smart building designs to reduce energy consumption and improve overall sustainability.

The agricultural sector, too, has seen an increased adoption of induction motors in irrigation systems and other farming equipment. As water scarcity becomes a pressing issue in many regions, farmers are turning to energy-efficient pumping solutions to optimize water usage and reduce their environmental footprint.

As the world moves towards a more sustainable future, the demand for induction motors is expected to continue its upward trajectory. Governments and organizations are implementing stricter energy efficiency standards, further driving the adoption of high-efficiency induction motors across various applications. This growing demand not only contributes to energy conservation efforts but also stimulates innovation in motor design and manufacturing, leading to even more efficient and sustainable solutions in the future.

Technical Challenges

Induction motors, while widely adopted and efficient, face several technical challenges in their quest to drive society towards a more sustainable future. One of the primary issues is the optimization of energy efficiency across various operating conditions. While induction motors are generally efficient at full load, their performance can degrade significantly at partial loads, which is common in many industrial applications.

The development of advanced control strategies presents another significant challenge. Variable frequency drives (VFDs) have improved motor control, but there is still room for enhancement in areas such as sensorless control techniques and adaptive control algorithms. These advancements are crucial for maximizing efficiency and reducing energy consumption across diverse operating scenarios.

Material limitations pose a considerable hurdle in improving motor performance. The search for better magnetic materials with lower losses and higher saturation flux densities continues to be an active area of research. Similarly, advancements in insulation materials are needed to withstand higher temperatures, allowing for more compact and efficient motor designs.

Thermal management remains a critical challenge, particularly as motors are pushed to higher power densities. Improved cooling techniques and thermal modeling are essential for maintaining motor reliability and efficiency, especially in harsh operating environments or high-performance applications.

The integration of induction motors with renewable energy sources and smart grid systems presents unique technical difficulties. Developing robust control systems that can handle the variability of renewable power sources while maintaining motor performance is a complex task that requires innovative solutions.

Noise and vibration reduction is another area of concern, particularly in urban environments and sensitive applications. Developing quieter motors without compromising on performance or efficiency is a delicate balance that engineers must strike.

Lastly, the challenge of motor diagnostics and predictive maintenance cannot be overlooked. As industries move towards more sustainable practices, the ability to accurately predict and prevent motor failures becomes crucial. Developing advanced sensor technologies and data analytics algorithms for real-time monitoring and fault prediction is an ongoing challenge that requires interdisciplinary expertise.

Addressing these technical challenges is vital for induction motors to continue driving society towards a more sustainable future. It requires a concerted effort from researchers, engineers, and industry stakeholders to innovate and implement solutions that enhance motor performance, efficiency, and reliability across a wide range of applications.

The development of advanced control strategies presents another significant challenge. Variable frequency drives (VFDs) have improved motor control, but there is still room for enhancement in areas such as sensorless control techniques and adaptive control algorithms. These advancements are crucial for maximizing efficiency and reducing energy consumption across diverse operating scenarios.

Material limitations pose a considerable hurdle in improving motor performance. The search for better magnetic materials with lower losses and higher saturation flux densities continues to be an active area of research. Similarly, advancements in insulation materials are needed to withstand higher temperatures, allowing for more compact and efficient motor designs.

Thermal management remains a critical challenge, particularly as motors are pushed to higher power densities. Improved cooling techniques and thermal modeling are essential for maintaining motor reliability and efficiency, especially in harsh operating environments or high-performance applications.

The integration of induction motors with renewable energy sources and smart grid systems presents unique technical difficulties. Developing robust control systems that can handle the variability of renewable power sources while maintaining motor performance is a complex task that requires innovative solutions.

Noise and vibration reduction is another area of concern, particularly in urban environments and sensitive applications. Developing quieter motors without compromising on performance or efficiency is a delicate balance that engineers must strike.

Lastly, the challenge of motor diagnostics and predictive maintenance cannot be overlooked. As industries move towards more sustainable practices, the ability to accurately predict and prevent motor failures becomes crucial. Developing advanced sensor technologies and data analytics algorithms for real-time monitoring and fault prediction is an ongoing challenge that requires interdisciplinary expertise.

Addressing these technical challenges is vital for induction motors to continue driving society towards a more sustainable future. It requires a concerted effort from researchers, engineers, and industry stakeholders to innovate and implement solutions that enhance motor performance, efficiency, and reliability across a wide range of applications.

Current Motor Solutions

01 Energy efficiency improvements in induction motors

Advancements in induction motor design and control strategies to enhance energy efficiency, reducing power consumption and operational costs. This includes optimizing motor components, implementing advanced control algorithms, and utilizing high-efficiency materials to minimize energy losses during operation.- Energy efficiency improvements in induction motors: Advancements in induction motor design and control strategies to enhance energy efficiency, reducing power consumption and improving overall sustainability. This includes optimizing motor components, implementing advanced control algorithms, and utilizing high-efficiency materials to minimize losses and maximize performance.

- Sustainable manufacturing and materials for induction motors: Development of eco-friendly manufacturing processes and sustainable materials for induction motor production. This involves using recycled or renewable materials, implementing cleaner production techniques, and designing motors for easier disassembly and recycling at the end of their lifecycle.

- Integration of induction motors in renewable energy systems: Incorporation of induction motors in renewable energy applications, such as wind turbines and hydroelectric systems. This includes adapting motor designs for variable speed operation, improving grid integration, and enhancing reliability in renewable energy generation to promote sustainable power production.

- Predictive maintenance and condition monitoring for sustainability: Implementation of advanced monitoring and predictive maintenance techniques to extend the lifespan of induction motors and optimize their performance. This involves using sensors, data analytics, and AI-driven algorithms to detect potential issues early, reduce downtime, and minimize energy waste due to inefficiencies.

- Sustainable control and automation systems for induction motors: Development of intelligent control and automation systems that optimize the operation of induction motors in various applications. This includes implementing energy management strategies, load-adaptive control, and integration with smart grid technologies to enhance overall system sustainability and reduce environmental impact.

02 Sustainable manufacturing processes for induction motors

Development of eco-friendly manufacturing techniques for induction motors, focusing on reducing environmental impact throughout the production lifecycle. This involves using recycled materials, implementing cleaner production methods, and optimizing resource utilization in motor manufacturing.Expand Specific Solutions03 Integration of induction motors in renewable energy systems

Incorporation of induction motors in sustainable energy generation and storage systems, such as wind turbines and hydroelectric plants. This includes adapting motor designs for variable speed operation and improving their compatibility with renewable energy sources to enhance overall system efficiency.Expand Specific Solutions04 Predictive maintenance and condition monitoring for sustainability

Implementation of advanced monitoring and diagnostic techniques to predict and prevent motor failures, extending the operational lifespan of induction motors. This involves using sensors, data analytics, and machine learning algorithms to optimize maintenance schedules and reduce unnecessary replacements.Expand Specific Solutions05 Recycling and end-of-life management of induction motors

Development of strategies for efficient recycling and proper disposal of induction motors at the end of their operational life. This includes designing motors for easy disassembly, recovering valuable materials, and establishing circular economy practices to minimize waste and environmental impact.Expand Specific Solutions

Key Industry Players

The induction motor industry is in a mature stage, with established players and widespread adoption across various sectors. However, the market is experiencing renewed growth due to increasing demand for energy-efficient solutions and sustainable technologies. The global market size for induction motors is substantial, estimated to be in the billions of dollars, with steady growth projected in the coming years. Technologically, induction motors are well-developed, but ongoing innovations focus on improving efficiency, reducing environmental impact, and integrating smart features. Companies like LG Electronics, Hyundai Motor, and Kia Corp are investing in advanced motor technologies, while academic institutions such as Xi'an Jiaotong University and Chongqing University contribute to research and development in this field.

LG Electronics, Inc.

Technical Solution: LG Electronics has developed induction motor technology for various applications, including home appliances and electric vehicle components, with a focus on energy efficiency and sustainability. Their induction motor design for washing machines incorporates a variable frequency drive, allowing for precise control and up to 40% energy savings compared to conventional motors [10]. For industrial applications, LG has created high-efficiency induction motors that meet IE4 super-premium efficiency standards, reducing energy consumption and operating costs in manufacturing settings [11]. The company has also invested in smart motor technology, integrating IoT capabilities for predictive maintenance and optimized performance, potentially extending motor life by up to 25% [12].

Strengths: Wide range of applications, high energy efficiency, and smart technology integration. Weaknesses: Less focused on high-power applications like electric vehicles compared to some competitors.

Visteon Global Technologies, Inc.

Technical Solution: Visteon, as a leading automotive technology company, has developed induction motor control systems that contribute to more sustainable transportation. Their motor control units (MCUs) for electric vehicles feature advanced algorithms for torque control and efficiency optimization, improving overall vehicle performance and range [13]. Visteon's induction motor systems incorporate silicon carbide (SiC) power modules, which reduce switching losses and allow for higher operating temperatures, potentially increasing power density by up to 30% [14]. The company has also developed integrated thermal management solutions that optimize the performance of both the motor and the power electronics, leading to improved efficiency across various driving conditions [15].

Strengths: Advanced control algorithms, high-performance power electronics, and integrated thermal management. Weaknesses: Primarily focused on control systems rather than motor manufacturing, potentially limiting full system optimization.

Innovative Technologies

Motor drive system and control method of same

PatentPendingUS20240116366A1

Innovation

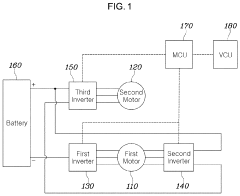

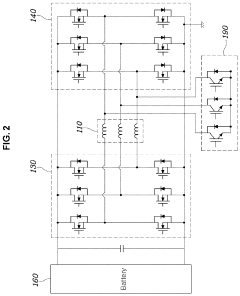

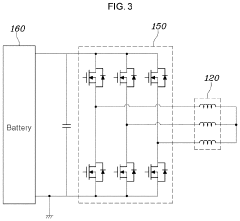

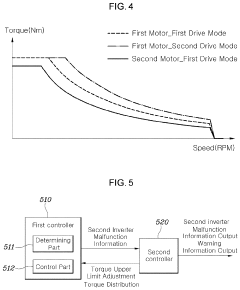

- A motor drive system and control method that dynamically adjust the drive mode from open end winding to closed end winding when a second inverter malfunctions, allowing the first motor to be driven by a single inverter, and relax output limits by increasing torque limits and maintaining them for a predetermined time, ensuring driver-desired torque is met.

Ultra fast lithium-ion battery charging for electric vehicle using hybrid power source

PatentPendingIN202241023199A

Innovation

- The implementation of ultra-fast wireless charging systems using resonant coupling methods and magnetic fields, allowing for efficient energy transfer through coils, enabling charging anywhere, including at home or in garages, with high power transmission and uniform field distribution.

Environmental Impact

Induction motors play a crucial role in driving society towards a more sustainable future by significantly reducing environmental impact across various sectors. These motors, known for their efficiency and reliability, contribute to sustainability through multiple avenues.

Firstly, induction motors offer superior energy efficiency compared to many alternative motor types. This efficiency translates directly into reduced energy consumption, which in turn lowers greenhouse gas emissions associated with power generation. As industries and households increasingly adopt induction motors, the cumulative effect on energy savings becomes substantial, contributing to global efforts to mitigate climate change.

In the transportation sector, induction motors are revolutionizing electric vehicles (EVs). By providing a more efficient and durable propulsion system, these motors extend the range of EVs while reducing the overall environmental footprint of the automotive industry. The shift towards electric mobility, powered by induction motors, is a key factor in reducing urban air pollution and dependence on fossil fuels.

Moreover, induction motors are instrumental in improving the efficiency of renewable energy systems. In wind turbines, for instance, these motors enable more effective energy capture and conversion, enhancing the viability and attractiveness of wind power as a clean energy source. This synergy between induction motors and renewable energy technologies accelerates the transition to a low-carbon energy landscape.

The industrial sector, a major contributor to global emissions, benefits greatly from the widespread adoption of induction motors. These motors optimize manufacturing processes, reducing energy waste and improving overall operational efficiency. This not only cuts down on industrial emissions but also promotes more sustainable production practices across various industries.

Additionally, the longevity and low maintenance requirements of induction motors contribute to sustainability by reducing the need for frequent replacements and repairs. This durability translates into less waste generation and reduced consumption of raw materials over time, aligning with circular economy principles.

In the agricultural sector, induction motors power irrigation systems and other farm equipment more efficiently, leading to reduced water and energy consumption. This is particularly crucial in regions facing water scarcity and environmental stress due to intensive farming practices.

As smart grid technologies advance, induction motors are becoming integral to demand-response systems. Their ability to adjust power consumption based on grid conditions helps balance energy supply and demand, facilitating the integration of intermittent renewable energy sources and improving overall grid stability and efficiency.

Firstly, induction motors offer superior energy efficiency compared to many alternative motor types. This efficiency translates directly into reduced energy consumption, which in turn lowers greenhouse gas emissions associated with power generation. As industries and households increasingly adopt induction motors, the cumulative effect on energy savings becomes substantial, contributing to global efforts to mitigate climate change.

In the transportation sector, induction motors are revolutionizing electric vehicles (EVs). By providing a more efficient and durable propulsion system, these motors extend the range of EVs while reducing the overall environmental footprint of the automotive industry. The shift towards electric mobility, powered by induction motors, is a key factor in reducing urban air pollution and dependence on fossil fuels.

Moreover, induction motors are instrumental in improving the efficiency of renewable energy systems. In wind turbines, for instance, these motors enable more effective energy capture and conversion, enhancing the viability and attractiveness of wind power as a clean energy source. This synergy between induction motors and renewable energy technologies accelerates the transition to a low-carbon energy landscape.

The industrial sector, a major contributor to global emissions, benefits greatly from the widespread adoption of induction motors. These motors optimize manufacturing processes, reducing energy waste and improving overall operational efficiency. This not only cuts down on industrial emissions but also promotes more sustainable production practices across various industries.

Additionally, the longevity and low maintenance requirements of induction motors contribute to sustainability by reducing the need for frequent replacements and repairs. This durability translates into less waste generation and reduced consumption of raw materials over time, aligning with circular economy principles.

In the agricultural sector, induction motors power irrigation systems and other farm equipment more efficiently, leading to reduced water and energy consumption. This is particularly crucial in regions facing water scarcity and environmental stress due to intensive farming practices.

As smart grid technologies advance, induction motors are becoming integral to demand-response systems. Their ability to adjust power consumption based on grid conditions helps balance energy supply and demand, facilitating the integration of intermittent renewable energy sources and improving overall grid stability and efficiency.

Economic Implications

The adoption of induction motors in various industries has significant economic implications, driving society towards a more sustainable future. These motors, known for their efficiency and reliability, contribute to substantial energy savings across multiple sectors. In industrial applications, the widespread use of induction motors leads to reduced operational costs, as they consume less electricity compared to traditional motor types. This efficiency translates into lower energy bills for businesses, improving their bottom line and competitiveness in the global market.

The manufacturing sector, in particular, benefits from the implementation of induction motors. As energy costs often represent a significant portion of production expenses, the adoption of these motors helps manufacturers optimize their energy consumption and reduce overall production costs. This cost reduction can potentially lead to more competitive pricing for consumers, stimulating economic growth and increasing market demand for products.

In the transportation sector, the integration of induction motors in electric vehicles (EVs) is revolutionizing the automotive industry. The shift towards EVs powered by induction motors is creating new job opportunities in manufacturing, research and development, and maintenance. This transition is also fostering innovation in related fields such as battery technology and charging infrastructure, further stimulating economic growth and job creation.

The increased adoption of induction motors also has positive implications for the renewable energy sector. As these motors are highly compatible with variable speed drives, they can be efficiently integrated into wind turbines and other renewable energy systems. This synergy between induction motors and renewable energy sources contributes to the growth of the green energy market, attracting investments and creating jobs in the sustainable energy sector.

From a macroeconomic perspective, the widespread use of induction motors contributes to energy security by reducing dependence on fossil fuels. This shift towards more sustainable energy consumption patterns can lead to reduced energy imports for many countries, positively impacting their trade balances and overall economic stability.

The economic benefits of induction motors extend to the service sector as well. Commercial buildings and facilities equipped with these motors in their HVAC systems, elevators, and other applications experience lower operating costs and improved energy efficiency. This reduction in energy expenses can lead to increased profitability for businesses in the service industry, potentially resulting in job creation and economic growth.

The manufacturing sector, in particular, benefits from the implementation of induction motors. As energy costs often represent a significant portion of production expenses, the adoption of these motors helps manufacturers optimize their energy consumption and reduce overall production costs. This cost reduction can potentially lead to more competitive pricing for consumers, stimulating economic growth and increasing market demand for products.

In the transportation sector, the integration of induction motors in electric vehicles (EVs) is revolutionizing the automotive industry. The shift towards EVs powered by induction motors is creating new job opportunities in manufacturing, research and development, and maintenance. This transition is also fostering innovation in related fields such as battery technology and charging infrastructure, further stimulating economic growth and job creation.

The increased adoption of induction motors also has positive implications for the renewable energy sector. As these motors are highly compatible with variable speed drives, they can be efficiently integrated into wind turbines and other renewable energy systems. This synergy between induction motors and renewable energy sources contributes to the growth of the green energy market, attracting investments and creating jobs in the sustainable energy sector.

From a macroeconomic perspective, the widespread use of induction motors contributes to energy security by reducing dependence on fossil fuels. This shift towards more sustainable energy consumption patterns can lead to reduced energy imports for many countries, positively impacting their trade balances and overall economic stability.

The economic benefits of induction motors extend to the service sector as well. Commercial buildings and facilities equipped with these motors in their HVAC systems, elevators, and other applications experience lower operating costs and improved energy efficiency. This reduction in energy expenses can lead to increased profitability for businesses in the service industry, potentially resulting in job creation and economic growth.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!