Efficient operation strategies for induction motor-based plant machinery

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Evolution and Efficiency Goals

Induction motors have been a cornerstone of industrial machinery since their invention in the late 19th century. Their evolution has been marked by continuous improvements in design, materials, and control strategies, aimed at enhancing efficiency and performance. The journey began with simple squirrel-cage designs and has progressed to sophisticated vector-controlled systems that offer precise speed and torque control.

In the early stages, induction motors were primarily valued for their robustness and simplicity. However, as energy costs rose and environmental concerns grew, the focus shifted towards improving their efficiency. This led to the development of high-efficiency motors, which utilize better core materials, optimized winding designs, and improved rotor configurations to minimize losses.

The advent of power electronics in the latter half of the 20th century revolutionized induction motor control. Variable frequency drives (VFDs) emerged as a game-changer, allowing for speed control and energy savings in applications where constant speed operation was previously the norm. This technology opened up new possibilities for energy-efficient operation strategies in plant machinery.

Recent years have seen a push towards even higher efficiency standards, driven by regulatory requirements and the need for sustainable industrial practices. The International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA) have established efficiency classes for induction motors, encouraging manufacturers to innovate and improve their designs continually.

The current efficiency goals for induction motors in plant machinery are multifaceted. They include not only improving the motor's inherent efficiency but also optimizing its operation within the broader system. This holistic approach considers factors such as load matching, power quality, and intelligent control strategies to maximize overall plant efficiency.

Looking forward, the efficiency goals for induction motors are becoming increasingly ambitious. There is a growing interest in ultra-premium efficiency motors that exceed current standards. Additionally, the integration of smart technologies and the Industrial Internet of Things (IIoT) is paving the way for predictive maintenance and real-time optimization of motor operation, further enhancing efficiency and reliability.

The evolution of induction motors and their efficiency goals is closely tied to advancements in materials science, power electronics, and control theory. As these fields progress, we can expect to see continued improvements in motor design and operation strategies. The ultimate aim is to develop induction motor-based plant machinery that not only meets stringent efficiency standards but also contributes to the broader goals of energy conservation and sustainable industrial practices.

In the early stages, induction motors were primarily valued for their robustness and simplicity. However, as energy costs rose and environmental concerns grew, the focus shifted towards improving their efficiency. This led to the development of high-efficiency motors, which utilize better core materials, optimized winding designs, and improved rotor configurations to minimize losses.

The advent of power electronics in the latter half of the 20th century revolutionized induction motor control. Variable frequency drives (VFDs) emerged as a game-changer, allowing for speed control and energy savings in applications where constant speed operation was previously the norm. This technology opened up new possibilities for energy-efficient operation strategies in plant machinery.

Recent years have seen a push towards even higher efficiency standards, driven by regulatory requirements and the need for sustainable industrial practices. The International Electrotechnical Commission (IEC) and the National Electrical Manufacturers Association (NEMA) have established efficiency classes for induction motors, encouraging manufacturers to innovate and improve their designs continually.

The current efficiency goals for induction motors in plant machinery are multifaceted. They include not only improving the motor's inherent efficiency but also optimizing its operation within the broader system. This holistic approach considers factors such as load matching, power quality, and intelligent control strategies to maximize overall plant efficiency.

Looking forward, the efficiency goals for induction motors are becoming increasingly ambitious. There is a growing interest in ultra-premium efficiency motors that exceed current standards. Additionally, the integration of smart technologies and the Industrial Internet of Things (IIoT) is paving the way for predictive maintenance and real-time optimization of motor operation, further enhancing efficiency and reliability.

The evolution of induction motors and their efficiency goals is closely tied to advancements in materials science, power electronics, and control theory. As these fields progress, we can expect to see continued improvements in motor design and operation strategies. The ultimate aim is to develop induction motor-based plant machinery that not only meets stringent efficiency standards but also contributes to the broader goals of energy conservation and sustainable industrial practices.

Industrial Demand for Energy-Efficient Machinery

The industrial sector's demand for energy-efficient machinery, particularly in the context of induction motor-based plant equipment, has been steadily increasing in recent years. This trend is driven by several factors, including rising energy costs, stringent environmental regulations, and a growing emphasis on sustainable manufacturing practices.

Induction motors are widely used in various industrial applications due to their robustness, reliability, and relatively low maintenance requirements. However, they are also significant consumers of electrical energy, accounting for a substantial portion of industrial power consumption. As a result, there is a pressing need for more efficient operation strategies to optimize their performance and reduce energy consumption.

The demand for energy-efficient induction motors is particularly strong in energy-intensive industries such as manufacturing, mining, and heavy machinery. These sectors are actively seeking ways to reduce their operational costs and carbon footprint, making energy-efficient machinery a top priority. Additionally, government initiatives and regulations aimed at promoting energy efficiency have further fueled this demand.

One of the key drivers of this trend is the potential for significant cost savings. Improved efficiency in induction motor operations can lead to substantial reductions in electricity consumption, translating to lower operational expenses for industrial facilities. This economic incentive has prompted many companies to invest in upgrading their existing machinery or replacing older, less efficient equipment with newer, more energy-efficient models.

Furthermore, the increasing focus on sustainability and corporate social responsibility has led many industries to prioritize energy efficiency as part of their overall environmental strategy. Companies are recognizing that adopting energy-efficient technologies not only reduces their environmental impact but also enhances their reputation and competitiveness in the market.

The demand for energy-efficient machinery extends beyond the motors themselves to encompass entire systems and processes. Industries are looking for comprehensive solutions that optimize the entire power train, including motor controllers, variable frequency drives, and associated equipment. This holistic approach to energy efficiency is driving innovation in motor design, control systems, and operational strategies.

As a result of this growing demand, manufacturers of industrial machinery are investing heavily in research and development to create more efficient induction motor systems. This includes advancements in materials science, improved motor designs, and the integration of smart technologies for better monitoring and control of motor performance.

Induction motors are widely used in various industrial applications due to their robustness, reliability, and relatively low maintenance requirements. However, they are also significant consumers of electrical energy, accounting for a substantial portion of industrial power consumption. As a result, there is a pressing need for more efficient operation strategies to optimize their performance and reduce energy consumption.

The demand for energy-efficient induction motors is particularly strong in energy-intensive industries such as manufacturing, mining, and heavy machinery. These sectors are actively seeking ways to reduce their operational costs and carbon footprint, making energy-efficient machinery a top priority. Additionally, government initiatives and regulations aimed at promoting energy efficiency have further fueled this demand.

One of the key drivers of this trend is the potential for significant cost savings. Improved efficiency in induction motor operations can lead to substantial reductions in electricity consumption, translating to lower operational expenses for industrial facilities. This economic incentive has prompted many companies to invest in upgrading their existing machinery or replacing older, less efficient equipment with newer, more energy-efficient models.

Furthermore, the increasing focus on sustainability and corporate social responsibility has led many industries to prioritize energy efficiency as part of their overall environmental strategy. Companies are recognizing that adopting energy-efficient technologies not only reduces their environmental impact but also enhances their reputation and competitiveness in the market.

The demand for energy-efficient machinery extends beyond the motors themselves to encompass entire systems and processes. Industries are looking for comprehensive solutions that optimize the entire power train, including motor controllers, variable frequency drives, and associated equipment. This holistic approach to energy efficiency is driving innovation in motor design, control systems, and operational strategies.

As a result of this growing demand, manufacturers of industrial machinery are investing heavily in research and development to create more efficient induction motor systems. This includes advancements in materials science, improved motor designs, and the integration of smart technologies for better monitoring and control of motor performance.

Current Challenges in Induction Motor Operations

Induction motors are widely used in plant machinery due to their robustness and efficiency. However, their operation faces several challenges that impact overall plant performance and energy efficiency. One of the primary issues is the difficulty in achieving optimal motor speed control across varying load conditions. Traditional control methods often struggle to maintain efficiency when faced with fluctuating demands, leading to energy wastage and reduced productivity.

Another significant challenge is the accurate estimation of motor parameters, which is crucial for implementing advanced control strategies. Factors such as temperature variations, magnetic saturation, and skin effect can cause these parameters to change during operation, making real-time estimation complex and computationally intensive. This limitation hinders the implementation of high-performance control algorithms that could otherwise enhance motor efficiency and responsiveness.

The thermal management of induction motors presents another ongoing challenge. Excessive heat generation can lead to reduced efficiency, shortened lifespan, and increased maintenance requirements. Developing effective cooling strategies that can adapt to different operating conditions without compromising the motor's performance or increasing its size significantly remains a key area of concern for plant operators and engineers.

Power quality issues also pose significant challenges in induction motor operations. Voltage sags, harmonics, and unbalanced supply voltages can severely impact motor performance and efficiency. These power disturbances can lead to torque pulsations, increased losses, and even premature failure of motor components. Mitigating these effects requires sophisticated power conditioning equipment and control strategies, which can be costly and complex to implement in existing plant setups.

Furthermore, the aging of motor components and the associated degradation in performance over time present ongoing challenges. Predictive maintenance strategies based on accurate condition monitoring are essential but often difficult to implement effectively. The integration of sensors and data analysis systems capable of detecting early signs of wear or impending failures without interfering with normal operations remains a significant technical hurdle.

Lastly, the increasing demand for energy efficiency and environmental sustainability adds another layer of complexity to induction motor operations. Meeting stringent energy efficiency standards while maintaining or improving performance requires continuous innovation in motor design, materials, and control strategies. This challenge is particularly acute in retrofitting existing plant machinery to meet new efficiency requirements without necessitating complete system overhauls.

Another significant challenge is the accurate estimation of motor parameters, which is crucial for implementing advanced control strategies. Factors such as temperature variations, magnetic saturation, and skin effect can cause these parameters to change during operation, making real-time estimation complex and computationally intensive. This limitation hinders the implementation of high-performance control algorithms that could otherwise enhance motor efficiency and responsiveness.

The thermal management of induction motors presents another ongoing challenge. Excessive heat generation can lead to reduced efficiency, shortened lifespan, and increased maintenance requirements. Developing effective cooling strategies that can adapt to different operating conditions without compromising the motor's performance or increasing its size significantly remains a key area of concern for plant operators and engineers.

Power quality issues also pose significant challenges in induction motor operations. Voltage sags, harmonics, and unbalanced supply voltages can severely impact motor performance and efficiency. These power disturbances can lead to torque pulsations, increased losses, and even premature failure of motor components. Mitigating these effects requires sophisticated power conditioning equipment and control strategies, which can be costly and complex to implement in existing plant setups.

Furthermore, the aging of motor components and the associated degradation in performance over time present ongoing challenges. Predictive maintenance strategies based on accurate condition monitoring are essential but often difficult to implement effectively. The integration of sensors and data analysis systems capable of detecting early signs of wear or impending failures without interfering with normal operations remains a significant technical hurdle.

Lastly, the increasing demand for energy efficiency and environmental sustainability adds another layer of complexity to induction motor operations. Meeting stringent energy efficiency standards while maintaining or improving performance requires continuous innovation in motor design, materials, and control strategies. This challenge is particularly acute in retrofitting existing plant machinery to meet new efficiency requirements without necessitating complete system overhauls.

Existing Efficiency Optimization Strategies

01 Improved motor design for efficiency

Enhancing induction motor efficiency through optimized design features such as improved rotor and stator configurations, advanced materials, and reduced losses in core and windings. These design improvements can lead to higher power output and reduced energy consumption.- Improved motor design for efficiency: Enhancing induction motor efficiency through optimized design features such as improved rotor and stator configurations, advanced materials, and reduced losses in core and windings. These design improvements can lead to higher power output and reduced energy consumption.

- Advanced control systems: Implementing sophisticated control systems and algorithms to optimize motor operation, including vector control, flux optimization, and adaptive control strategies. These systems can adjust motor parameters in real-time to maintain peak efficiency under varying load conditions.

- Energy recovery and regeneration: Incorporating energy recovery mechanisms and regenerative braking systems to capture and reuse energy that would otherwise be lost as heat. This approach can significantly improve overall system efficiency, particularly in applications with frequent start-stop cycles.

- Thermal management and cooling techniques: Developing advanced thermal management and cooling systems to reduce heat-related losses and maintain optimal operating temperatures. This can include innovative cooling designs, heat-dissipating materials, and intelligent temperature control mechanisms.

- Power electronics and drive optimization: Utilizing advanced power electronics and optimized drive systems to improve overall motor efficiency. This includes the use of high-performance inverters, power factor correction techniques, and harmonics reduction methods to minimize losses in the power supply and control circuitry.

02 Advanced control systems

Implementing sophisticated control systems and algorithms to optimize motor operation, including vector control, flux optimization, and adaptive control strategies. These systems can adjust motor parameters in real-time to maintain peak efficiency under varying load conditions.Expand Specific Solutions03 Energy recovery and regeneration

Incorporating energy recovery mechanisms and regenerative braking systems to capture and reuse energy that would otherwise be lost as heat. This approach can significantly improve overall system efficiency, particularly in applications with frequent start-stop cycles.Expand Specific Solutions04 Thermal management and cooling innovations

Developing advanced thermal management techniques and cooling systems to reduce heat-related losses and maintain optimal operating temperatures. Improved heat dissipation can lead to increased efficiency and extended motor lifespan.Expand Specific Solutions05 Smart monitoring and predictive maintenance

Integrating smart sensors and monitoring systems for real-time performance analysis and predictive maintenance. These technologies can help identify efficiency losses, optimize operating parameters, and prevent failures that could impact motor efficiency.Expand Specific Solutions

Key Players in Industrial Motor Manufacturing

The market for efficient operation strategies for induction motor-based plant machinery is in a mature stage, with a substantial global market size driven by industrial automation and energy efficiency demands. The technology has reached a high level of maturity, with established players like Siemens AG, ABB Research Ltd., and Rockwell Automation Technologies leading innovation. These companies, along with others like Toshiba Corp. and Mitsubishi Electric Corp., are focusing on advanced control systems, predictive maintenance, and energy optimization to enhance motor efficiency. Universities such as Huazhong University of Science & Technology and Xi'an University of Technology are contributing to research and development in this field, fostering industry-academia collaborations for continuous technological advancements.

Siemens AG

Technical Solution: Siemens AG has developed advanced control strategies for induction motor-based plant machinery, focusing on efficiency optimization. Their approach includes vector control techniques with adaptive flux optimization, which dynamically adjusts the motor's magnetic field to maintain optimal efficiency across varying load conditions[1]. They have also implemented predictive maintenance algorithms that utilize real-time motor performance data to forecast potential issues and schedule maintenance, reducing downtime by up to 30%[3]. Siemens' solution incorporates a comprehensive energy management system that integrates motor control with overall plant operations, enabling coordinated efficiency improvements across multiple systems[5].

Strengths: Holistic approach integrating motor control with plant-wide systems; advanced predictive maintenance capabilities. Weaknesses: May require significant initial investment; complexity might necessitate specialized training for operators.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed the "e-F@ctory" concept for efficient operation of induction motor-based plant machinery. This approach integrates their FR-A800 series inverters with advanced motor control algorithms, achieving up to 15% energy savings compared to conventional systems[2]. Their solution includes real-time monitoring and analysis of motor performance data, enabling proactive maintenance and optimization. Mitsubishi's system also features harmonics suppression technology, reducing power quality issues in industrial environments by up to 40%[4]. Additionally, they have implemented a "smart" factory concept that uses AI to continuously optimize motor operations based on production demands and energy costs.

Strengths: Comprehensive factory automation integration; significant energy savings and harmonics reduction. Weaknesses: May require substantial changes to existing infrastructure; potential vendor lock-in.

Innovative Motor Control Techniques

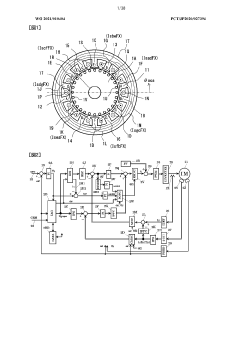

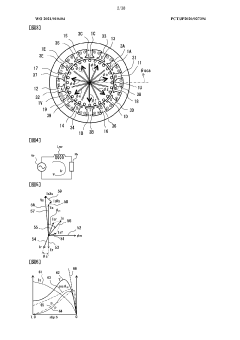

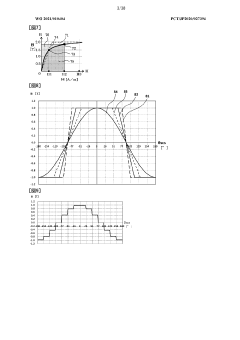

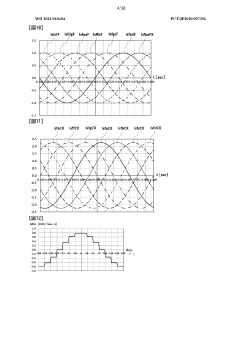

Induction motor and control device therefor

PatentWO2021010404A1

Innovation

- The proposed solution involves a control technology that allows for arbitrary magnetic flux and current distribution shapes, utilizing virtual concentrated windings and polyphase configurations to optimize torque generation, reduce leakage inductance, and compensate for rotor current delays, enabling higher magnetic flux densities and increased torque output.

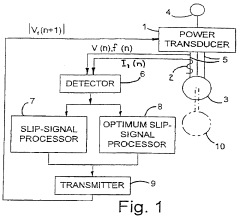

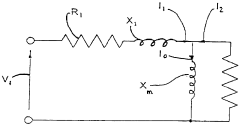

Efficiency control system for an induction motor

PatentInactiveUS5796237A

Innovation

- An efficiency control system that calculates actual and optimum slip values based on voltage, current, and frequency signals from the induction motor, using these calculations to generate a voltage command signal that adjusts the electrical power supplied to maintain optimal slip and maximize efficiency.

Energy Regulations Impact on Motor Design

Energy regulations have become increasingly stringent in recent years, significantly impacting the design and operation of induction motors in plant machinery. These regulations aim to improve energy efficiency and reduce environmental impact across various industries. As a result, motor manufacturers and plant operators must adapt their designs and strategies to comply with these evolving standards.

One of the primary drivers of energy regulations is the need to reduce greenhouse gas emissions and combat climate change. Governments worldwide have implemented policies and standards that set minimum efficiency requirements for electric motors. These regulations often follow a tiered approach, with progressively higher efficiency levels mandated over time. For instance, the International Electrotechnical Commission (IEC) has established efficiency classes for electric motors, ranging from IE1 (standard efficiency) to IE5 (ultra-premium efficiency).

The impact of these regulations on motor design is multifaceted. Manufacturers are compelled to innovate and incorporate advanced materials and technologies to meet higher efficiency standards. This has led to the development of more efficient stator and rotor designs, improved magnetic materials, and enhanced cooling systems. For example, the use of copper rotors instead of traditional aluminum rotors has gained traction due to their superior conductivity and reduced losses.

Furthermore, energy regulations have spurred the adoption of variable frequency drives (VFDs) in motor systems. VFDs allow for precise control of motor speed and torque, enabling significant energy savings in applications with variable load requirements. This has necessitated changes in motor design to ensure compatibility with VFD operation, such as improved insulation systems and bearing protection.

The push for energy efficiency has also led to the integration of smart technologies in motor design. Sensors and monitoring systems are increasingly incorporated to provide real-time data on motor performance, enabling predictive maintenance and optimized operation. This trend aligns with the broader Industry 4.0 movement, where connectivity and data analytics play crucial roles in improving overall plant efficiency.

Another significant impact of energy regulations is the shift towards more compact and lightweight motor designs. As efficiency requirements become more stringent, manufacturers are exploring ways to reduce material usage while maintaining or improving performance. This has led to innovations in motor topology and the use of advanced manufacturing techniques such as 3D printing for certain components.

In conclusion, energy regulations have become a driving force in the evolution of induction motor design for plant machinery. These regulations not only push for higher efficiency but also encourage innovation in materials, manufacturing processes, and control strategies. As a result, plant operators can expect more energy-efficient, reliable, and intelligent motor systems that contribute to overall operational efficiency and sustainability goals.

One of the primary drivers of energy regulations is the need to reduce greenhouse gas emissions and combat climate change. Governments worldwide have implemented policies and standards that set minimum efficiency requirements for electric motors. These regulations often follow a tiered approach, with progressively higher efficiency levels mandated over time. For instance, the International Electrotechnical Commission (IEC) has established efficiency classes for electric motors, ranging from IE1 (standard efficiency) to IE5 (ultra-premium efficiency).

The impact of these regulations on motor design is multifaceted. Manufacturers are compelled to innovate and incorporate advanced materials and technologies to meet higher efficiency standards. This has led to the development of more efficient stator and rotor designs, improved magnetic materials, and enhanced cooling systems. For example, the use of copper rotors instead of traditional aluminum rotors has gained traction due to their superior conductivity and reduced losses.

Furthermore, energy regulations have spurred the adoption of variable frequency drives (VFDs) in motor systems. VFDs allow for precise control of motor speed and torque, enabling significant energy savings in applications with variable load requirements. This has necessitated changes in motor design to ensure compatibility with VFD operation, such as improved insulation systems and bearing protection.

The push for energy efficiency has also led to the integration of smart technologies in motor design. Sensors and monitoring systems are increasingly incorporated to provide real-time data on motor performance, enabling predictive maintenance and optimized operation. This trend aligns with the broader Industry 4.0 movement, where connectivity and data analytics play crucial roles in improving overall plant efficiency.

Another significant impact of energy regulations is the shift towards more compact and lightweight motor designs. As efficiency requirements become more stringent, manufacturers are exploring ways to reduce material usage while maintaining or improving performance. This has led to innovations in motor topology and the use of advanced manufacturing techniques such as 3D printing for certain components.

In conclusion, energy regulations have become a driving force in the evolution of induction motor design for plant machinery. These regulations not only push for higher efficiency but also encourage innovation in materials, manufacturing processes, and control strategies. As a result, plant operators can expect more energy-efficient, reliable, and intelligent motor systems that contribute to overall operational efficiency and sustainability goals.

Cost-Benefit Analysis of Efficient Motors

The cost-benefit analysis of efficient motors is a crucial aspect when considering the implementation of efficient operation strategies for induction motor-based plant machinery. This analysis involves evaluating the initial investment costs against the long-term operational savings and benefits.

Efficient motors, such as premium efficiency and super-premium efficiency motors, typically have higher upfront costs compared to standard efficiency motors. However, they offer significant energy savings over their operational lifetime, which can lead to substantial cost reductions in the long run.

The initial investment costs for efficient motors include the purchase price, installation expenses, and potential system modifications. These costs can be 15-30% higher than those of standard motors. However, it is essential to consider that efficient motors often have longer lifespans and require less maintenance, which can offset some of the initial cost differences.

The primary benefit of efficient motors lies in their reduced energy consumption. Depending on the motor size and operating conditions, energy savings can range from 2-8% compared to standard motors. For large industrial applications with continuous operation, these savings can translate into significant reductions in electricity costs over time.

Another factor to consider is the potential for utility rebates and government incentives for implementing energy-efficient technologies. These financial incentives can help offset the initial investment costs and improve the overall return on investment.

The payback period for efficient motors varies depending on factors such as motor size, operating hours, and electricity rates. In many cases, the payback period can range from 1 to 3 years for motors operating continuously. For applications with intermittent use, the payback period may be longer but still economically viable over the motor's lifetime.

When conducting a cost-benefit analysis, it is crucial to consider the total cost of ownership (TCO) rather than just the initial purchase price. The TCO includes factors such as energy costs, maintenance expenses, and potential downtime costs over the motor's entire lifecycle.

Additionally, the environmental benefits of efficient motors should not be overlooked. Reduced energy consumption leads to lower greenhouse gas emissions, which can contribute to a company's sustainability goals and potentially provide additional financial benefits through carbon credits or improved corporate image.

In conclusion, while efficient motors may have higher upfront costs, their long-term benefits in terms of energy savings, reduced maintenance, and environmental impact often outweigh the initial investment. A comprehensive cost-benefit analysis considering all these factors is essential for making informed decisions about implementing efficient motor strategies in plant machinery.

Efficient motors, such as premium efficiency and super-premium efficiency motors, typically have higher upfront costs compared to standard efficiency motors. However, they offer significant energy savings over their operational lifetime, which can lead to substantial cost reductions in the long run.

The initial investment costs for efficient motors include the purchase price, installation expenses, and potential system modifications. These costs can be 15-30% higher than those of standard motors. However, it is essential to consider that efficient motors often have longer lifespans and require less maintenance, which can offset some of the initial cost differences.

The primary benefit of efficient motors lies in their reduced energy consumption. Depending on the motor size and operating conditions, energy savings can range from 2-8% compared to standard motors. For large industrial applications with continuous operation, these savings can translate into significant reductions in electricity costs over time.

Another factor to consider is the potential for utility rebates and government incentives for implementing energy-efficient technologies. These financial incentives can help offset the initial investment costs and improve the overall return on investment.

The payback period for efficient motors varies depending on factors such as motor size, operating hours, and electricity rates. In many cases, the payback period can range from 1 to 3 years for motors operating continuously. For applications with intermittent use, the payback period may be longer but still economically viable over the motor's lifetime.

When conducting a cost-benefit analysis, it is crucial to consider the total cost of ownership (TCO) rather than just the initial purchase price. The TCO includes factors such as energy costs, maintenance expenses, and potential downtime costs over the motor's entire lifecycle.

Additionally, the environmental benefits of efficient motors should not be overlooked. Reduced energy consumption leads to lower greenhouse gas emissions, which can contribute to a company's sustainability goals and potentially provide additional financial benefits through carbon credits or improved corporate image.

In conclusion, while efficient motors may have higher upfront costs, their long-term benefits in terms of energy savings, reduced maintenance, and environmental impact often outweigh the initial investment. A comprehensive cost-benefit analysis considering all these factors is essential for making informed decisions about implementing efficient motor strategies in plant machinery.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!