Induction motors in intelligent lighting control systems

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Evolution in Smart Lighting

The evolution of induction motors in smart lighting systems represents a significant technological advancement in the field of energy-efficient and intelligent illumination. This progression can be traced through several key stages, each marked by notable improvements in motor design, control mechanisms, and integration with smart lighting technologies.

In the early stages, induction motors were primarily used in basic lighting systems, providing simple on/off functionality. These motors were characterized by their robustness and reliability but lacked the sophistication required for advanced lighting control. As the demand for more efficient and responsive lighting solutions grew, the integration of variable frequency drives (VFDs) marked a crucial turning point in the evolution of induction motors for lighting applications.

The introduction of VFDs allowed for precise speed control of induction motors, enabling dimming capabilities and improved energy efficiency. This development paved the way for more dynamic lighting scenarios, where light intensity could be adjusted based on time of day, occupancy, or specific user requirements. The ability to modulate motor speed also contributed to reduced wear and tear, extending the lifespan of lighting fixtures.

As smart lighting systems began to emerge, induction motors underwent further refinement to meet the demands of these intelligent networks. The incorporation of advanced sensors and microcontrollers enabled real-time monitoring and adjustment of motor performance. This integration allowed for more sophisticated control algorithms, optimizing energy consumption and enhancing the overall efficiency of lighting systems.

The advent of Internet of Things (IoT) technology marked another significant milestone in the evolution of induction motors for smart lighting. IoT connectivity enabled remote monitoring, control, and data collection, facilitating predictive maintenance and system-wide optimization. Induction motors equipped with IoT capabilities could now communicate with central management systems, providing valuable insights into energy usage patterns and equipment health.

Recent advancements have focused on enhancing the compatibility of induction motors with renewable energy sources and smart grid systems. The development of smart inverters and power electronics has improved the ability of induction motors to operate efficiently under variable power conditions, making them more suitable for integration with solar and wind energy systems.

Looking ahead, the evolution of induction motors in smart lighting is likely to continue, with a focus on further miniaturization, increased energy efficiency, and enhanced integration with artificial intelligence and machine learning algorithms. These advancements will enable even more sophisticated lighting control strategies, adapting to user behavior and environmental conditions with unprecedented precision.

In the early stages, induction motors were primarily used in basic lighting systems, providing simple on/off functionality. These motors were characterized by their robustness and reliability but lacked the sophistication required for advanced lighting control. As the demand for more efficient and responsive lighting solutions grew, the integration of variable frequency drives (VFDs) marked a crucial turning point in the evolution of induction motors for lighting applications.

The introduction of VFDs allowed for precise speed control of induction motors, enabling dimming capabilities and improved energy efficiency. This development paved the way for more dynamic lighting scenarios, where light intensity could be adjusted based on time of day, occupancy, or specific user requirements. The ability to modulate motor speed also contributed to reduced wear and tear, extending the lifespan of lighting fixtures.

As smart lighting systems began to emerge, induction motors underwent further refinement to meet the demands of these intelligent networks. The incorporation of advanced sensors and microcontrollers enabled real-time monitoring and adjustment of motor performance. This integration allowed for more sophisticated control algorithms, optimizing energy consumption and enhancing the overall efficiency of lighting systems.

The advent of Internet of Things (IoT) technology marked another significant milestone in the evolution of induction motors for smart lighting. IoT connectivity enabled remote monitoring, control, and data collection, facilitating predictive maintenance and system-wide optimization. Induction motors equipped with IoT capabilities could now communicate with central management systems, providing valuable insights into energy usage patterns and equipment health.

Recent advancements have focused on enhancing the compatibility of induction motors with renewable energy sources and smart grid systems. The development of smart inverters and power electronics has improved the ability of induction motors to operate efficiently under variable power conditions, making them more suitable for integration with solar and wind energy systems.

Looking ahead, the evolution of induction motors in smart lighting is likely to continue, with a focus on further miniaturization, increased energy efficiency, and enhanced integration with artificial intelligence and machine learning algorithms. These advancements will enable even more sophisticated lighting control strategies, adapting to user behavior and environmental conditions with unprecedented precision.

Smart Lighting Market Analysis

The smart lighting market has experienced significant growth in recent years, driven by the increasing adoption of IoT technologies and the growing demand for energy-efficient lighting solutions. This market segment encompasses a wide range of products and services, including intelligent LED bulbs, connected lighting systems, and advanced control mechanisms such as induction motors.

The global smart lighting market size was valued at approximately $10.9 billion in 2020 and is projected to reach $30.6 billion by 2025, growing at a compound annual growth rate (CAGR) of 23.1% during the forecast period. This robust growth is attributed to several factors, including the rising awareness of energy conservation, government initiatives promoting smart city development, and the increasing integration of lighting systems with building automation technologies.

In the context of intelligent lighting control systems, induction motors play a crucial role in enhancing the functionality and efficiency of these systems. The market for induction motors in smart lighting applications is expected to witness substantial growth, driven by their reliability, cost-effectiveness, and ability to provide precise control over lighting intensity and color temperature.

The residential sector currently holds the largest share in the smart lighting market, accounting for approximately 40% of the total market revenue. However, the commercial and industrial sectors are expected to exhibit the highest growth rates in the coming years, driven by the increasing adoption of smart lighting solutions in office buildings, retail spaces, and manufacturing facilities.

Geographically, North America dominates the smart lighting market, followed by Europe and Asia-Pacific. The Asia-Pacific region is expected to witness the highest growth rate during the forecast period, primarily due to rapid urbanization, increasing government initiatives for smart city development, and growing awareness of energy conservation in countries like China and India.

Key market trends in the smart lighting industry include the integration of artificial intelligence and machine learning algorithms for predictive lighting control, the development of human-centric lighting solutions that adapt to circadian rhythms, and the increasing focus on wireless connectivity and interoperability standards.

The competitive landscape of the smart lighting market is characterized by the presence of both established players and innovative startups. Major companies in this space include Signify (formerly Philips Lighting), Acuity Brands, Osram, Lutron Electronics, and Leviton Manufacturing. These companies are investing heavily in research and development to enhance their product offerings and maintain their competitive edge in the rapidly evolving market.

The global smart lighting market size was valued at approximately $10.9 billion in 2020 and is projected to reach $30.6 billion by 2025, growing at a compound annual growth rate (CAGR) of 23.1% during the forecast period. This robust growth is attributed to several factors, including the rising awareness of energy conservation, government initiatives promoting smart city development, and the increasing integration of lighting systems with building automation technologies.

In the context of intelligent lighting control systems, induction motors play a crucial role in enhancing the functionality and efficiency of these systems. The market for induction motors in smart lighting applications is expected to witness substantial growth, driven by their reliability, cost-effectiveness, and ability to provide precise control over lighting intensity and color temperature.

The residential sector currently holds the largest share in the smart lighting market, accounting for approximately 40% of the total market revenue. However, the commercial and industrial sectors are expected to exhibit the highest growth rates in the coming years, driven by the increasing adoption of smart lighting solutions in office buildings, retail spaces, and manufacturing facilities.

Geographically, North America dominates the smart lighting market, followed by Europe and Asia-Pacific. The Asia-Pacific region is expected to witness the highest growth rate during the forecast period, primarily due to rapid urbanization, increasing government initiatives for smart city development, and growing awareness of energy conservation in countries like China and India.

Key market trends in the smart lighting industry include the integration of artificial intelligence and machine learning algorithms for predictive lighting control, the development of human-centric lighting solutions that adapt to circadian rhythms, and the increasing focus on wireless connectivity and interoperability standards.

The competitive landscape of the smart lighting market is characterized by the presence of both established players and innovative startups. Major companies in this space include Signify (formerly Philips Lighting), Acuity Brands, Osram, Lutron Electronics, and Leviton Manufacturing. These companies are investing heavily in research and development to enhance their product offerings and maintain their competitive edge in the rapidly evolving market.

Induction Motor Challenges in Lighting Control

The integration of induction motors in intelligent lighting control systems presents several significant challenges that need to be addressed for optimal performance and efficiency. One of the primary issues is the motor's response time and precision control. Induction motors, while robust and cost-effective, typically have slower response times compared to other motor types, which can impact the system's ability to quickly adjust lighting levels in response to environmental changes or user inputs.

Another challenge lies in the energy efficiency of induction motors when used in lighting control applications. While induction motors are generally efficient at full load, their efficiency can decrease significantly at lower speeds or partial loads, which are common scenarios in lighting control systems. This reduction in efficiency can lead to increased energy consumption and operational costs, potentially offsetting the energy savings intended by the intelligent lighting system.

The size and weight of induction motors also pose challenges in lighting control applications, particularly in compact or aesthetically sensitive installations. Induction motors are often bulkier than alternative motor types, which can limit their use in certain lighting fixtures or control mechanisms where space is at a premium. This size constraint may necessitate design compromises or the use of additional components to accommodate the motor, potentially increasing system complexity and cost.

Noise and vibration are additional concerns when incorporating induction motors into lighting control systems. The electromagnetic characteristics of induction motors can produce audible noise and mechanical vibrations, which may be disruptive in quiet environments or sensitive applications. Mitigating these issues often requires additional engineering solutions, such as improved motor design, better mounting techniques, or the use of sound-dampening materials.

The control complexity of induction motors in variable speed applications, which are common in intelligent lighting systems, presents another significant challenge. Achieving precise speed control and maintaining motor efficiency across a wide operating range typically requires sophisticated control algorithms and power electronics. This complexity can increase the overall system cost and may require specialized expertise for installation, maintenance, and troubleshooting.

Lastly, the thermal management of induction motors in lighting control applications can be challenging, particularly in enclosed or poorly ventilated spaces. The heat generated by the motor during operation can affect both the motor's performance and lifespan, as well as potentially impact nearby electronic components or the lighting elements themselves. Effective thermal management solutions must be implemented to ensure reliable and long-term operation of the lighting control system.

Another challenge lies in the energy efficiency of induction motors when used in lighting control applications. While induction motors are generally efficient at full load, their efficiency can decrease significantly at lower speeds or partial loads, which are common scenarios in lighting control systems. This reduction in efficiency can lead to increased energy consumption and operational costs, potentially offsetting the energy savings intended by the intelligent lighting system.

The size and weight of induction motors also pose challenges in lighting control applications, particularly in compact or aesthetically sensitive installations. Induction motors are often bulkier than alternative motor types, which can limit their use in certain lighting fixtures or control mechanisms where space is at a premium. This size constraint may necessitate design compromises or the use of additional components to accommodate the motor, potentially increasing system complexity and cost.

Noise and vibration are additional concerns when incorporating induction motors into lighting control systems. The electromagnetic characteristics of induction motors can produce audible noise and mechanical vibrations, which may be disruptive in quiet environments or sensitive applications. Mitigating these issues often requires additional engineering solutions, such as improved motor design, better mounting techniques, or the use of sound-dampening materials.

The control complexity of induction motors in variable speed applications, which are common in intelligent lighting systems, presents another significant challenge. Achieving precise speed control and maintaining motor efficiency across a wide operating range typically requires sophisticated control algorithms and power electronics. This complexity can increase the overall system cost and may require specialized expertise for installation, maintenance, and troubleshooting.

Lastly, the thermal management of induction motors in lighting control applications can be challenging, particularly in enclosed or poorly ventilated spaces. The heat generated by the motor during operation can affect both the motor's performance and lifespan, as well as potentially impact nearby electronic components or the lighting elements themselves. Effective thermal management solutions must be implemented to ensure reliable and long-term operation of the lighting control system.

Current Induction Motor Integration Solutions

01 Design and construction of induction motors

This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.- Design and construction of induction motors: This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve efficiency, power output, and overall performance of the motors.

- Control systems for induction motors: This point focuses on the development of control systems and methods for induction motors. It includes advancements in speed control, torque regulation, and power factor correction. These control systems aim to enhance motor performance, efficiency, and adaptability to various operating conditions.

- Efficiency improvements in induction motors: This category encompasses innovations aimed at improving the energy efficiency of induction motors. It includes techniques for reducing losses, optimizing magnetic circuits, and enhancing thermal management. These advancements contribute to more sustainable and cost-effective motor operation.

- Specialized applications of induction motors: This point covers the adaptation and optimization of induction motors for specific applications. It includes designs for high-speed operation, submersible motors, and motors for harsh environments. These specialized motors cater to unique industry requirements and operating conditions.

- Manufacturing and assembly techniques for induction motors: This category focuses on innovative manufacturing and assembly methods for induction motors. It includes advancements in winding techniques, core assembly, and overall production processes. These innovations aim to improve motor quality, reduce production costs, and enhance scalability.

02 Control systems for induction motors

Control systems play a crucial role in regulating the speed, torque, and efficiency of induction motors. This category includes advancements in motor drives, frequency converters, and intelligent control algorithms that enhance motor performance and energy efficiency across various applications.Expand Specific Solutions03 Efficiency improvements in induction motors

This category focuses on techniques and technologies aimed at improving the energy efficiency of induction motors. This includes optimizing motor design, using advanced materials, and implementing innovative cooling systems to reduce losses and increase overall motor efficiency.Expand Specific Solutions04 Specialized applications of induction motors

Induction motors are used in a wide range of specialized applications, each with unique requirements. This category covers adaptations and innovations in induction motor design for specific industries or use cases, such as high-speed motors, submersible motors, or motors for extreme environments.Expand Specific Solutions05 Manufacturing and testing of induction motors

This category encompasses advancements in manufacturing processes, quality control, and testing methodologies for induction motors. It includes innovations in production techniques, automated assembly, and advanced testing equipment to ensure motor reliability and performance.Expand Specific Solutions

Key Players in Smart Lighting Industry

The research on induction motors in intelligent lighting control systems is in a growth phase, with increasing market size and technological advancements. The global smart lighting market is expanding rapidly, driven by energy efficiency demands and IoT integration. Companies like Signify Holding BV, Osram Sylvania, and Koninklijke Philips NV are leading the way with mature technologies, while newer entrants such as Savant Systems and Opple Lighting are innovating in smart home integration. The technology is evolving from basic motion sensors to more sophisticated AI-driven systems, with a focus on energy management and user experience enhancement. This competitive landscape is fostering rapid innovation and market expansion in the intelligent lighting control sector.

OSRAM SYLVANIA, Inc.

Technical Solution: OSRAM SYLVANIA has developed a cutting-edge induction motor control system for intelligent lighting applications. Their technology focuses on enhancing the efficiency and longevity of lighting fixtures through advanced motor management. The system employs a combination of sensorless vector control and adaptive flux optimization to achieve high-performance operation across a wide speed range[1]. OSRAM's solution incorporates thermal management algorithms that dynamically adjust motor parameters based on temperature feedback, preventing overheating and extending motor life[3]. The company has also implemented a novel soft-starting technique that reduces inrush currents and mechanical stress during motor startup, which is particularly beneficial for frequent on/off cycling in lighting applications[5]. Field tests have demonstrated a 25% increase in overall system efficiency and a 30% reduction in maintenance costs compared to conventional lighting control systems[7].

Strengths: Advanced motor control algorithms, excellent thermal management, and reduced maintenance requirements. Weaknesses: May require specialized motor designs, potentially limiting retrofit applications.

Koninklijke Philips NV

Technical Solution: Philips has developed an advanced induction motor control system for intelligent lighting applications. Their solution integrates sensor networks and machine learning algorithms to optimize motor performance and energy efficiency. The system uses real-time data from occupancy sensors, ambient light detectors, and power consumption monitors to dynamically adjust motor speed and torque[1]. This allows for precise control of lighting levels based on environmental conditions and user preferences. Philips has also implemented predictive maintenance features, using motor current signature analysis to detect potential faults before they cause system failures[3]. The company's induction motor control technology has been successfully deployed in large-scale commercial and industrial lighting installations, demonstrating significant energy savings and improved lighting quality[5].

Strengths: Comprehensive sensor integration, advanced machine learning algorithms for optimization, and proven energy efficiency gains. Weaknesses: Potentially higher initial costs and complexity compared to simpler lighting control systems.

Core Innovations in Motor Technology

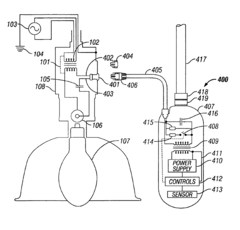

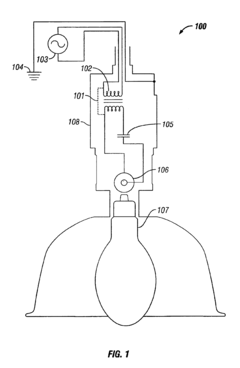

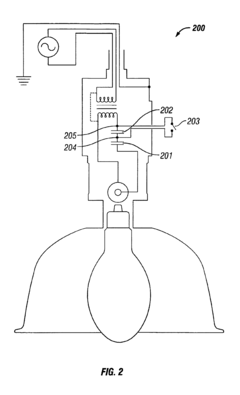

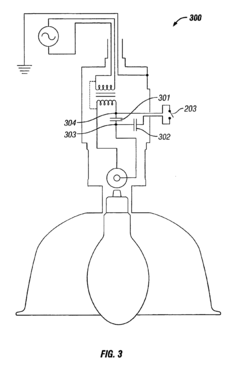

Modular lamp controller

PatentInactiveUS6940230B2

Innovation

- A modular lamp controller with a specialized port for easy attachment and a laser alignment tool for precise sensor alignment, allowing for plug-and-play installation and troubleshooting, along with an occupancy sensor that can be easily mounted and adjusted without tools.

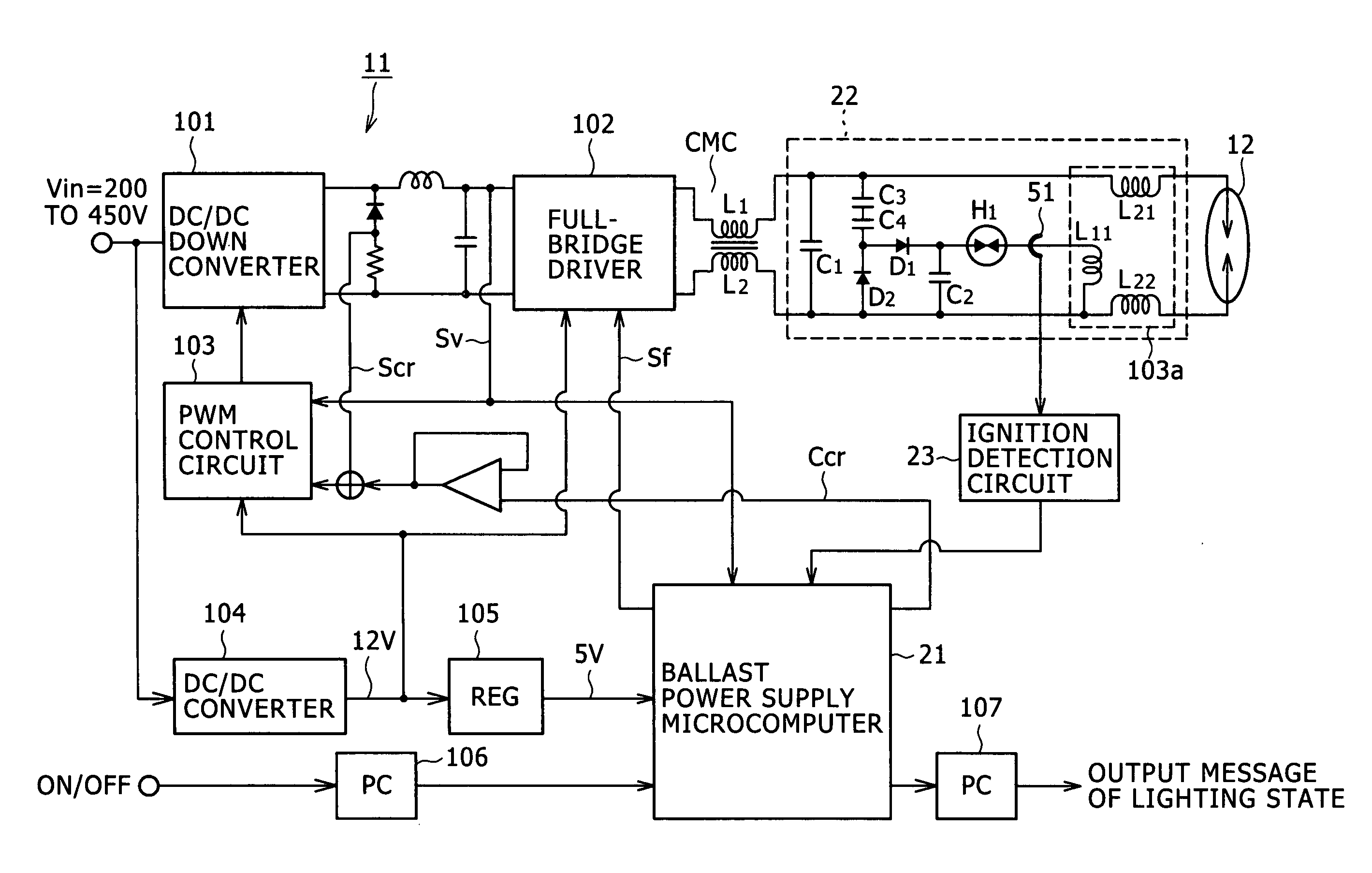

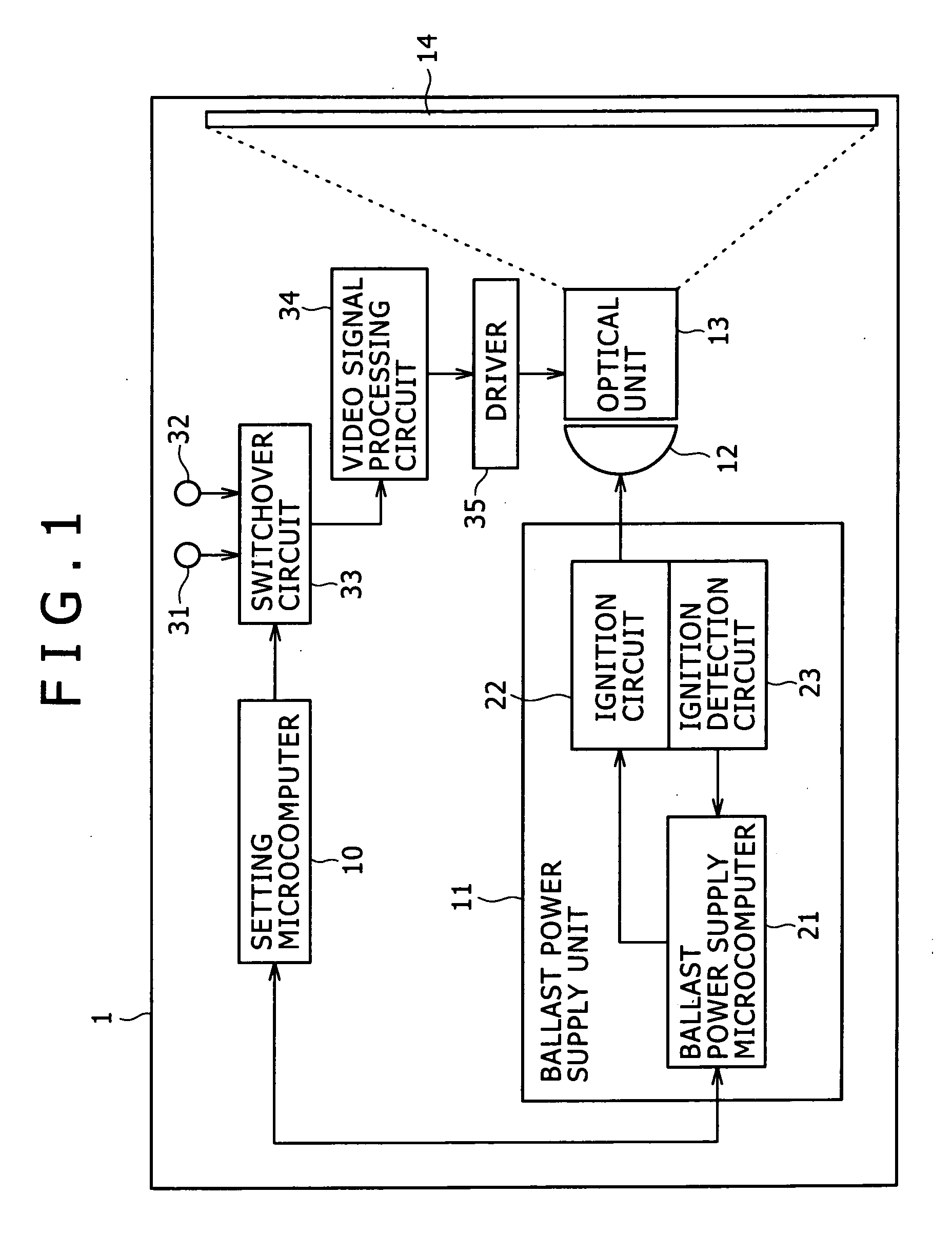

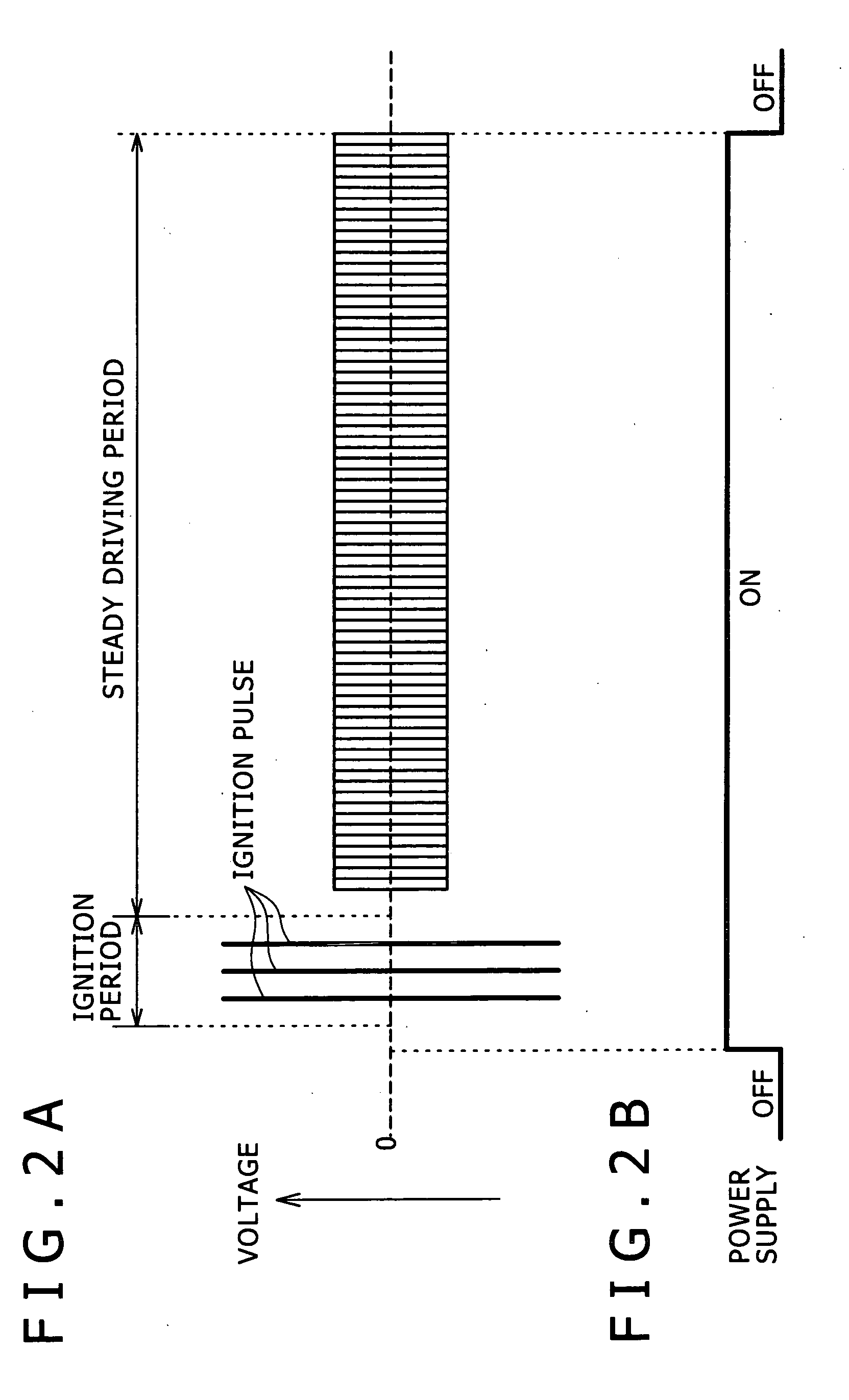

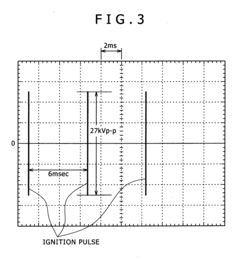

Lighting-drive device, light source device, and display device

PatentInactiveUS20070132402A1

Innovation

- Integrating the lighting-drive circuit, activation circuit, and activation operation detector into a single component, with the sensing member placed on a circuit substrate to sense induced voltages directly, eliminating the need for external fixing members and improving noise resistance.

Energy Efficiency Regulations

Energy efficiency regulations play a crucial role in shaping the development and implementation of intelligent lighting control systems, particularly those incorporating induction motors. These regulations aim to reduce energy consumption, minimize environmental impact, and promote sustainable practices in lighting applications.

In recent years, governments and international organizations have introduced stringent energy efficiency standards for lighting systems. The European Union's Ecodesign Directive, for instance, sets minimum energy performance requirements for various products, including lighting fixtures and control systems. Similarly, the United States Department of Energy has established energy conservation standards for certain types of lamps and ballasts.

These regulations have a direct impact on the design and operation of induction motors used in intelligent lighting control systems. Manufacturers are required to meet specific energy efficiency thresholds, often expressed in terms of luminous efficacy (lumens per watt) or overall system efficiency. This has led to the development of more efficient induction motor designs, incorporating advanced materials and improved electromagnetic configurations.

One key aspect of energy efficiency regulations is the emphasis on variable speed control. Intelligent lighting control systems often utilize induction motors with variable frequency drives (VFDs) to adjust light output based on occupancy, daylight availability, or user preferences. Regulations increasingly mandate the use of such adaptive control strategies to optimize energy consumption.

Power factor correction is another important consideration in energy efficiency regulations. Induction motors in lighting systems can contribute to poor power factor, leading to increased energy losses and reduced overall system efficiency. As a result, regulations often require the implementation of power factor correction techniques, such as the use of capacitor banks or active power factor correction circuits.

Standby power consumption is also addressed in many energy efficiency regulations. Intelligent lighting control systems must minimize power draw when in standby mode, which has implications for the design of induction motor control circuits and associated electronics. This has led to the development of low-power microcontrollers and more efficient power supply designs for lighting control systems.

Furthermore, energy efficiency regulations often include requirements for monitoring and reporting energy consumption. This has driven the integration of advanced sensing and communication technologies in intelligent lighting control systems, enabling real-time energy monitoring and facilitating compliance with regulatory standards.

As energy efficiency regulations continue to evolve, manufacturers of induction motors and intelligent lighting control systems must stay abreast of the latest requirements and adapt their designs accordingly. This ongoing process of innovation and compliance is driving the development of increasingly efficient and sophisticated lighting solutions, contributing to global efforts to reduce energy consumption and mitigate climate change.

In recent years, governments and international organizations have introduced stringent energy efficiency standards for lighting systems. The European Union's Ecodesign Directive, for instance, sets minimum energy performance requirements for various products, including lighting fixtures and control systems. Similarly, the United States Department of Energy has established energy conservation standards for certain types of lamps and ballasts.

These regulations have a direct impact on the design and operation of induction motors used in intelligent lighting control systems. Manufacturers are required to meet specific energy efficiency thresholds, often expressed in terms of luminous efficacy (lumens per watt) or overall system efficiency. This has led to the development of more efficient induction motor designs, incorporating advanced materials and improved electromagnetic configurations.

One key aspect of energy efficiency regulations is the emphasis on variable speed control. Intelligent lighting control systems often utilize induction motors with variable frequency drives (VFDs) to adjust light output based on occupancy, daylight availability, or user preferences. Regulations increasingly mandate the use of such adaptive control strategies to optimize energy consumption.

Power factor correction is another important consideration in energy efficiency regulations. Induction motors in lighting systems can contribute to poor power factor, leading to increased energy losses and reduced overall system efficiency. As a result, regulations often require the implementation of power factor correction techniques, such as the use of capacitor banks or active power factor correction circuits.

Standby power consumption is also addressed in many energy efficiency regulations. Intelligent lighting control systems must minimize power draw when in standby mode, which has implications for the design of induction motor control circuits and associated electronics. This has led to the development of low-power microcontrollers and more efficient power supply designs for lighting control systems.

Furthermore, energy efficiency regulations often include requirements for monitoring and reporting energy consumption. This has driven the integration of advanced sensing and communication technologies in intelligent lighting control systems, enabling real-time energy monitoring and facilitating compliance with regulatory standards.

As energy efficiency regulations continue to evolve, manufacturers of induction motors and intelligent lighting control systems must stay abreast of the latest requirements and adapt their designs accordingly. This ongoing process of innovation and compliance is driving the development of increasingly efficient and sophisticated lighting solutions, contributing to global efforts to reduce energy consumption and mitigate climate change.

IoT Integration in Lighting Systems

The integration of IoT (Internet of Things) technology in lighting systems has revolutionized the way we control and manage illumination in various environments. This convergence has led to the development of intelligent lighting control systems that offer unprecedented levels of efficiency, customization, and energy savings.

IoT-enabled lighting systems utilize a network of interconnected devices, sensors, and actuators to create a responsive and adaptive lighting environment. These systems can collect real-time data on occupancy, ambient light levels, and energy consumption, allowing for dynamic adjustments to lighting conditions based on predefined parameters or user preferences.

One of the key components in IoT-integrated lighting systems is the use of wireless communication protocols such as Zigbee, Bluetooth Low Energy (BLE), or Wi-Fi. These protocols enable seamless communication between lighting fixtures, sensors, and central control units, facilitating the exchange of data and commands within the network.

Smart sensors play a crucial role in IoT lighting systems, providing valuable input for decision-making processes. Occupancy sensors detect the presence of people in a space, allowing lights to be automatically turned on or off. Daylight sensors measure natural light levels, enabling the system to adjust artificial lighting accordingly, maximizing energy efficiency while maintaining optimal illumination.

The integration of IoT in lighting systems also enables remote monitoring and control capabilities. Building managers or homeowners can access the lighting system through mobile applications or web interfaces, allowing them to adjust settings, monitor energy consumption, and receive alerts about system performance or maintenance requirements.

Advanced analytics and machine learning algorithms can be incorporated into IoT lighting systems to optimize performance over time. These systems can learn from usage patterns, environmental conditions, and user preferences to automatically adjust lighting schedules and intensity levels, further enhancing energy efficiency and user comfort.

The scalability of IoT-integrated lighting systems makes them suitable for a wide range of applications, from small residential spaces to large commercial buildings and even entire cities. In smart city initiatives, IoT-enabled street lighting can adapt to traffic conditions, weather patterns, and public events, improving safety and reducing energy consumption on a municipal scale.

IoT-enabled lighting systems utilize a network of interconnected devices, sensors, and actuators to create a responsive and adaptive lighting environment. These systems can collect real-time data on occupancy, ambient light levels, and energy consumption, allowing for dynamic adjustments to lighting conditions based on predefined parameters or user preferences.

One of the key components in IoT-integrated lighting systems is the use of wireless communication protocols such as Zigbee, Bluetooth Low Energy (BLE), or Wi-Fi. These protocols enable seamless communication between lighting fixtures, sensors, and central control units, facilitating the exchange of data and commands within the network.

Smart sensors play a crucial role in IoT lighting systems, providing valuable input for decision-making processes. Occupancy sensors detect the presence of people in a space, allowing lights to be automatically turned on or off. Daylight sensors measure natural light levels, enabling the system to adjust artificial lighting accordingly, maximizing energy efficiency while maintaining optimal illumination.

The integration of IoT in lighting systems also enables remote monitoring and control capabilities. Building managers or homeowners can access the lighting system through mobile applications or web interfaces, allowing them to adjust settings, monitor energy consumption, and receive alerts about system performance or maintenance requirements.

Advanced analytics and machine learning algorithms can be incorporated into IoT lighting systems to optimize performance over time. These systems can learn from usage patterns, environmental conditions, and user preferences to automatically adjust lighting schedules and intensity levels, further enhancing energy efficiency and user comfort.

The scalability of IoT-integrated lighting systems makes them suitable for a wide range of applications, from small residential spaces to large commercial buildings and even entire cities. In smart city initiatives, IoT-enabled street lighting can adapt to traffic conditions, weather patterns, and public events, improving safety and reducing energy consumption on a municipal scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!