Innovations in cooling techniques for induction motor heat management

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor Cooling Evolution and Objectives

Induction motors have been a cornerstone of industrial applications for over a century, with their cooling techniques evolving significantly to meet the increasing demands for efficiency and performance. The journey of induction motor cooling began with simple natural convection methods, where heat dissipation relied solely on the motor's surface area and ambient air circulation. As power densities increased, forced air cooling systems were introduced, utilizing external fans to enhance heat removal.

The advent of totally enclosed fan-cooled (TEFC) motors marked a significant milestone in cooling technology. These motors featured an internal fan mounted on the rotor shaft, circulating air within the enclosure to improve heat transfer. This design not only enhanced cooling efficiency but also protected the motor from environmental contaminants, making it suitable for harsh industrial environments.

As industrial processes became more demanding, water-cooled systems emerged as a superior solution for high-power applications. Water jackets surrounding the motor frame allowed for more effective heat dissipation, enabling motors to operate at higher power densities without overheating. This technology paved the way for larger and more powerful induction motors in heavy industries.

Recent years have seen a surge in innovative cooling techniques aimed at further improving motor efficiency and reliability. Advanced materials with superior thermal conductivity are being incorporated into motor designs, enhancing heat dissipation from the core components. Heat pipe technology, originally developed for aerospace applications, is now being adapted for motor cooling, offering a passive and highly efficient method of heat transfer.

The objectives of modern induction motor cooling techniques are multifaceted. Primarily, they aim to maintain optimal operating temperatures to prevent insulation breakdown and extend motor lifespan. Improved cooling also allows for higher power densities, enabling more compact and powerful motor designs. Additionally, efficient cooling contributes to overall motor efficiency by reducing electrical losses associated with high temperatures.

Another key objective is to develop cooling solutions that are energy-efficient themselves, minimizing the parasitic power consumption of cooling systems. This aligns with the broader industry trend towards energy conservation and sustainability. Furthermore, there is a growing focus on developing cooling techniques that are adaptable to various operating conditions and environments, ensuring consistent performance across diverse applications.

As we look to the future, the evolution of induction motor cooling techniques is likely to continue, driven by the need for even higher efficiency, reliability, and power density. Emerging technologies such as phase-change materials and microfluidic cooling systems hold promise for revolutionizing heat management in electric motors, potentially leading to breakthroughs in motor design and performance.

The advent of totally enclosed fan-cooled (TEFC) motors marked a significant milestone in cooling technology. These motors featured an internal fan mounted on the rotor shaft, circulating air within the enclosure to improve heat transfer. This design not only enhanced cooling efficiency but also protected the motor from environmental contaminants, making it suitable for harsh industrial environments.

As industrial processes became more demanding, water-cooled systems emerged as a superior solution for high-power applications. Water jackets surrounding the motor frame allowed for more effective heat dissipation, enabling motors to operate at higher power densities without overheating. This technology paved the way for larger and more powerful induction motors in heavy industries.

Recent years have seen a surge in innovative cooling techniques aimed at further improving motor efficiency and reliability. Advanced materials with superior thermal conductivity are being incorporated into motor designs, enhancing heat dissipation from the core components. Heat pipe technology, originally developed for aerospace applications, is now being adapted for motor cooling, offering a passive and highly efficient method of heat transfer.

The objectives of modern induction motor cooling techniques are multifaceted. Primarily, they aim to maintain optimal operating temperatures to prevent insulation breakdown and extend motor lifespan. Improved cooling also allows for higher power densities, enabling more compact and powerful motor designs. Additionally, efficient cooling contributes to overall motor efficiency by reducing electrical losses associated with high temperatures.

Another key objective is to develop cooling solutions that are energy-efficient themselves, minimizing the parasitic power consumption of cooling systems. This aligns with the broader industry trend towards energy conservation and sustainability. Furthermore, there is a growing focus on developing cooling techniques that are adaptable to various operating conditions and environments, ensuring consistent performance across diverse applications.

As we look to the future, the evolution of induction motor cooling techniques is likely to continue, driven by the need for even higher efficiency, reliability, and power density. Emerging technologies such as phase-change materials and microfluidic cooling systems hold promise for revolutionizing heat management in electric motors, potentially leading to breakthroughs in motor design and performance.

Market Demand for Efficient Motor Cooling Solutions

The market demand for efficient motor cooling solutions has been steadily increasing in recent years, driven by several key factors. Industrial sectors, particularly manufacturing and energy production, are experiencing a growing need for more powerful and compact induction motors. This trend has led to increased heat generation within motors, necessitating advanced cooling techniques to maintain optimal performance and longevity.

Energy efficiency regulations and sustainability initiatives have also played a significant role in shaping market demand. Governments worldwide are implementing stricter energy efficiency standards, compelling industries to adopt more efficient motor systems. This regulatory pressure has created a substantial market for cooling solutions that can help motors operate at higher efficiencies while managing heat effectively.

The automotive industry, especially with the rise of electric vehicles, has emerged as a major driver for innovative motor cooling technologies. As electric vehicles become more mainstream, the demand for high-performance, compact motors with efficient cooling systems has surged. This sector alone is expected to contribute significantly to the growth of the motor cooling solutions market in the coming years.

In the HVAC industry, there's an increasing focus on energy-efficient systems, which has led to a higher demand for well-cooled, high-efficiency motors. This trend is particularly pronounced in commercial and residential building sectors, where energy consumption and operational costs are critical considerations.

The data center industry, with its ever-growing need for cooling solutions, has also become a significant market for motor cooling technologies. As data centers expand and become more power-intensive, the demand for efficient cooling systems for their numerous motors and pumps has increased substantially.

Market research indicates that the global market for motor cooling solutions is experiencing robust growth. This growth is not only in terms of market size but also in the diversity of solutions being sought. There's a clear trend towards more sophisticated, intelligent cooling systems that can adapt to varying operational conditions and integrate with smart industrial systems.

Geographically, while developed economies in North America and Europe continue to be significant markets, rapid industrialization in emerging economies, particularly in Asia-Pacific, is creating new growth opportunities. Countries like China and India are seeing a surge in demand for efficient motor cooling solutions across various industries.

Energy efficiency regulations and sustainability initiatives have also played a significant role in shaping market demand. Governments worldwide are implementing stricter energy efficiency standards, compelling industries to adopt more efficient motor systems. This regulatory pressure has created a substantial market for cooling solutions that can help motors operate at higher efficiencies while managing heat effectively.

The automotive industry, especially with the rise of electric vehicles, has emerged as a major driver for innovative motor cooling technologies. As electric vehicles become more mainstream, the demand for high-performance, compact motors with efficient cooling systems has surged. This sector alone is expected to contribute significantly to the growth of the motor cooling solutions market in the coming years.

In the HVAC industry, there's an increasing focus on energy-efficient systems, which has led to a higher demand for well-cooled, high-efficiency motors. This trend is particularly pronounced in commercial and residential building sectors, where energy consumption and operational costs are critical considerations.

The data center industry, with its ever-growing need for cooling solutions, has also become a significant market for motor cooling technologies. As data centers expand and become more power-intensive, the demand for efficient cooling systems for their numerous motors and pumps has increased substantially.

Market research indicates that the global market for motor cooling solutions is experiencing robust growth. This growth is not only in terms of market size but also in the diversity of solutions being sought. There's a clear trend towards more sophisticated, intelligent cooling systems that can adapt to varying operational conditions and integrate with smart industrial systems.

Geographically, while developed economies in North America and Europe continue to be significant markets, rapid industrialization in emerging economies, particularly in Asia-Pacific, is creating new growth opportunities. Countries like China and India are seeing a surge in demand for efficient motor cooling solutions across various industries.

Current Challenges in Induction Motor Heat Management

Induction motors, widely used in industrial applications, face significant challenges in heat management. The primary issue stems from the inherent inefficiencies in energy conversion, where a portion of electrical energy is converted into heat rather than mechanical energy. This heat generation, if not properly managed, can lead to reduced motor efficiency, shortened lifespan, and potential failure.

One of the main challenges is the limited space available for cooling systems within the motor structure. As industries demand more compact and powerful motors, the heat density increases, making it difficult to implement traditional cooling methods effectively. This spatial constraint necessitates innovative approaches to heat dissipation that can operate within confined areas without compromising motor performance.

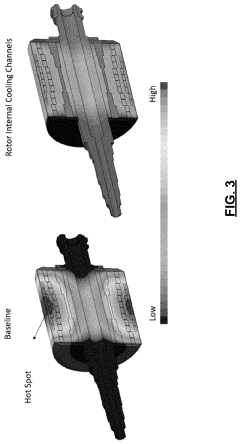

Another significant challenge is the uneven distribution of heat within the motor. Hot spots can develop in areas such as the stator windings, rotor bars, and bearings, leading to localized thermal stress. These temperature gradients not only reduce overall efficiency but also accelerate wear and tear on specific components, potentially leading to premature failure.

The variability in operating conditions presents another hurdle in heat management. Induction motors often operate under fluctuating loads and in diverse environmental conditions, from extreme cold to high ambient temperatures. Designing a cooling system that can adapt to these varying conditions while maintaining optimal performance is a complex task that requires advanced thermal management strategies.

Energy efficiency is a growing concern in industrial applications, and cooling systems for induction motors must balance effective heat dissipation with minimal energy consumption. Traditional cooling methods, such as forced air cooling, can be energy-intensive, potentially offsetting the efficiency gains of the motor itself. This creates a need for more energy-efficient cooling solutions that do not significantly increase the overall power consumption of the system.

Maintenance and reliability issues also pose challenges in heat management. Cooling systems must be designed for longevity and ease of maintenance to ensure consistent performance over the motor's lifetime. However, integrating robust cooling solutions while maintaining the motor's reliability and serviceability can be challenging, especially in harsh industrial environments.

Lastly, the increasing focus on environmental sustainability adds another layer of complexity to induction motor cooling. Traditional cooling methods may rely on materials or processes that have negative environmental impacts. Developing eco-friendly cooling solutions that meet performance requirements while minimizing environmental footprint is becoming increasingly important in the industry.

One of the main challenges is the limited space available for cooling systems within the motor structure. As industries demand more compact and powerful motors, the heat density increases, making it difficult to implement traditional cooling methods effectively. This spatial constraint necessitates innovative approaches to heat dissipation that can operate within confined areas without compromising motor performance.

Another significant challenge is the uneven distribution of heat within the motor. Hot spots can develop in areas such as the stator windings, rotor bars, and bearings, leading to localized thermal stress. These temperature gradients not only reduce overall efficiency but also accelerate wear and tear on specific components, potentially leading to premature failure.

The variability in operating conditions presents another hurdle in heat management. Induction motors often operate under fluctuating loads and in diverse environmental conditions, from extreme cold to high ambient temperatures. Designing a cooling system that can adapt to these varying conditions while maintaining optimal performance is a complex task that requires advanced thermal management strategies.

Energy efficiency is a growing concern in industrial applications, and cooling systems for induction motors must balance effective heat dissipation with minimal energy consumption. Traditional cooling methods, such as forced air cooling, can be energy-intensive, potentially offsetting the efficiency gains of the motor itself. This creates a need for more energy-efficient cooling solutions that do not significantly increase the overall power consumption of the system.

Maintenance and reliability issues also pose challenges in heat management. Cooling systems must be designed for longevity and ease of maintenance to ensure consistent performance over the motor's lifetime. However, integrating robust cooling solutions while maintaining the motor's reliability and serviceability can be challenging, especially in harsh industrial environments.

Lastly, the increasing focus on environmental sustainability adds another layer of complexity to induction motor cooling. Traditional cooling methods may rely on materials or processes that have negative environmental impacts. Developing eco-friendly cooling solutions that meet performance requirements while minimizing environmental footprint is becoming increasingly important in the industry.

Existing Induction Motor Cooling Techniques

01 Cooling systems for induction motors

Various cooling systems are employed to manage heat in induction motors. These may include liquid cooling systems, air cooling systems, or a combination of both. Effective cooling helps maintain optimal motor performance and extends the lifespan of the motor components.- Cooling systems for induction motors: Various cooling systems are employed to manage heat in induction motors. These may include liquid cooling, forced air cooling, or heat pipe systems. Such cooling mechanisms help dissipate heat generated during motor operation, improving efficiency and prolonging motor life.

- Heat-resistant materials and coatings: The use of heat-resistant materials and coatings in induction motor construction helps to manage thermal stress. These materials can include specialized insulations, high-temperature lubricants, and thermal barrier coatings, which enhance the motor's ability to withstand and dissipate heat.

- Thermal management in motor windings: Effective thermal management in motor windings is crucial for preventing overheating. This can involve innovative winding designs, the use of thermally conductive materials, and strategic placement of temperature sensors to monitor and control heat buildup in the windings.

- Heat dissipation through motor design: Motor design plays a significant role in heat dissipation. This includes optimizing the rotor and stator geometry, incorporating heat sinks, and designing efficient ventilation paths within the motor structure to facilitate natural cooling and heat removal.

- Smart thermal management systems: Advanced thermal management systems incorporate smart technologies for real-time monitoring and control of motor temperature. These systems may use sensors, microcontrollers, and adaptive cooling strategies to optimize heat management based on operating conditions and load variations.

02 Heat dissipation through motor design

Innovative motor designs incorporate features to enhance heat dissipation. This may include optimized rotor and stator configurations, use of heat-conductive materials, and improved ventilation channels within the motor structure.Expand Specific Solutions03 Thermal management in industrial applications

Industrial applications of induction motors often require specialized thermal management solutions. These may include external cooling systems, temperature monitoring devices, and adaptive control systems that adjust motor operation based on thermal conditions.Expand Specific Solutions04 Heat-resistant materials and coatings

The use of heat-resistant materials and coatings in motor construction can significantly improve heat tolerance. This includes advanced insulation materials, thermally conductive coatings, and high-temperature lubricants for bearings and other moving parts.Expand Specific Solutions05 Smart thermal management systems

Integration of smart thermal management systems in induction motors allows for real-time monitoring and control of heat generation. These systems may use sensors, predictive algorithms, and adaptive cooling mechanisms to optimize motor performance and prevent overheating.Expand Specific Solutions

Key Players in Motor Cooling Industry

The cooling techniques for induction motor heat management market is in a growth phase, driven by increasing demand for energy-efficient motors across industries. The global market size is projected to expand significantly in the coming years, fueled by technological advancements and stricter energy regulations. While the technology is relatively mature, ongoing innovations are pushing its boundaries. Key players like Hyundai Motor, Kia, BorgWarner, and Caterpillar are investing heavily in R&D to develop more efficient cooling solutions. Emerging technologies from companies such as Hanon Systems and Robert Bosch are focusing on advanced thermal management systems, integrating smart sensors and AI-driven controls to optimize motor cooling performance and energy efficiency.

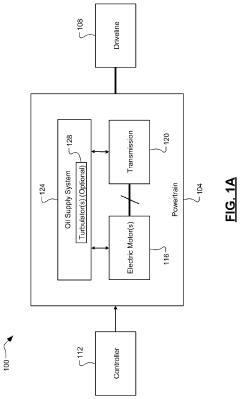

Robert Bosch GmbH

Technical Solution: Bosch has developed an innovative cooling technique for induction motors using a direct oil cooling system. This system involves circulating oil directly through the motor's stator and rotor, allowing for more efficient heat dissipation. The oil is then cooled externally and recirculated. This method has shown to improve cooling efficiency by up to 65% compared to traditional air-cooled systems [1]. Additionally, Bosch has implemented advanced thermal management software that optimizes the cooling process based on real-time temperature data and motor load, further enhancing the system's efficiency [3].

Strengths: Highly efficient cooling, improved motor performance, and extended motor life. Weaknesses: Increased system complexity and potential for oil leaks.

BorgWarner, Inc.

Technical Solution: BorgWarner has pioneered a dual-coolant approach for induction motor heat management. This system utilizes a combination of oil and water-glycol coolants, each targeting specific components of the motor. The stator is cooled by a water-glycol mixture circulating through a cooling jacket, while the rotor and bearings are cooled by oil spray. This dual approach allows for targeted cooling of different motor components, optimizing overall thermal management. BorgWarner's system has demonstrated a 20% improvement in power density and a 15% reduction in motor size due to enhanced cooling efficiency [2][5].

Strengths: Targeted cooling for different motor components, improved power density. Weaknesses: Increased system complexity and higher initial cost.

Innovative Heat Dissipation Methods Analysis

Thermal management techniques for electric motors

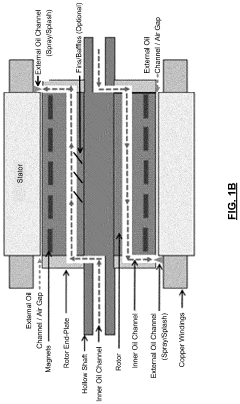

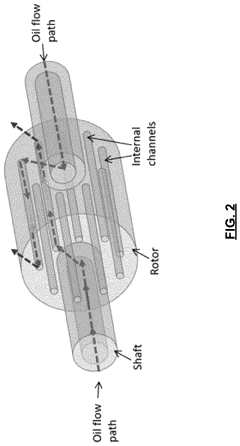

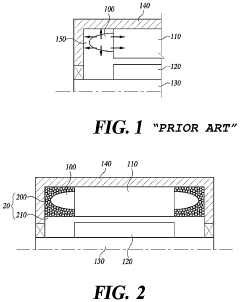

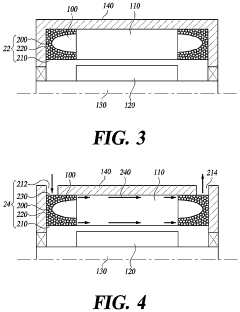

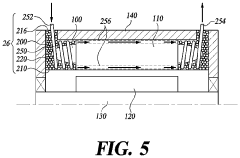

PatentActiveUS11973407B2

Innovation

- A thermal management system that utilizes internal oil channels within the rotor and external oil channels defined by end plates to cool the rotor and stator, enhancing heat transfer through fins, baffles, and turbulators, while controlling oil flow to optimize cooling performance.

End coil cooling structure for an induction motor

PatentActiveUS11848598B2

Innovation

- An end coil cooling structure featuring a shielding member and heat conducting particles that form an enclosed space around the end coil, with optional non-moving or moving refrigerant and a refrigerant flow pipe to enhance heat transfer and maintainability.

Energy Efficiency Regulations Impact

Energy efficiency regulations have a significant impact on the development and implementation of cooling techniques for induction motor heat management. As governments worldwide strive to reduce energy consumption and greenhouse gas emissions, stringent regulations are being introduced to improve the efficiency of electrical systems, including induction motors.

These regulations, such as the International Electrotechnical Commission (IEC) 60034-30-1 standard and the U.S. Department of Energy's (DOE) Electric Motors Energy Conservation Standards, set minimum efficiency levels for various types of electric motors. As a result, manufacturers are compelled to innovate and develop more efficient cooling solutions to meet these requirements.

The impact of these regulations extends beyond mere compliance. They drive research and development efforts towards advanced cooling techniques, such as improved thermal management systems, novel materials for heat dissipation, and more efficient cooling designs. This regulatory pressure has led to the emergence of innovative solutions like phase-change materials, nanofluid coolants, and advanced heat pipe technologies for induction motor cooling.

Furthermore, energy efficiency regulations have influenced the market dynamics of induction motors and their cooling systems. Manufacturers are increasingly focusing on producing high-efficiency motors with integrated cooling solutions to meet both regulatory requirements and customer demands for energy-efficient products. This shift has created new opportunities for companies specializing in thermal management technologies and has fostered collaborations between motor manufacturers and cooling system providers.

The regulations have also prompted a reevaluation of traditional cooling methods. Air-cooled systems, while still prevalent, are being optimized or replaced with more efficient liquid cooling systems in applications where higher performance is required. This trend is particularly evident in industries such as electric vehicles and renewable energy, where motor efficiency is crucial for overall system performance.

Additionally, these regulations have spurred the development of advanced monitoring and control systems for motor cooling. Intelligent thermal management systems that can adapt to varying load conditions and environmental factors are becoming increasingly common, further enhancing energy efficiency and motor longevity.

In conclusion, energy efficiency regulations have been a key driver in the evolution of cooling techniques for induction motor heat management. They have not only set new standards for motor efficiency but have also catalyzed innovation in cooling technologies, reshaped market dynamics, and promoted the adoption of more sophisticated thermal management solutions across various industries.

These regulations, such as the International Electrotechnical Commission (IEC) 60034-30-1 standard and the U.S. Department of Energy's (DOE) Electric Motors Energy Conservation Standards, set minimum efficiency levels for various types of electric motors. As a result, manufacturers are compelled to innovate and develop more efficient cooling solutions to meet these requirements.

The impact of these regulations extends beyond mere compliance. They drive research and development efforts towards advanced cooling techniques, such as improved thermal management systems, novel materials for heat dissipation, and more efficient cooling designs. This regulatory pressure has led to the emergence of innovative solutions like phase-change materials, nanofluid coolants, and advanced heat pipe technologies for induction motor cooling.

Furthermore, energy efficiency regulations have influenced the market dynamics of induction motors and their cooling systems. Manufacturers are increasingly focusing on producing high-efficiency motors with integrated cooling solutions to meet both regulatory requirements and customer demands for energy-efficient products. This shift has created new opportunities for companies specializing in thermal management technologies and has fostered collaborations between motor manufacturers and cooling system providers.

The regulations have also prompted a reevaluation of traditional cooling methods. Air-cooled systems, while still prevalent, are being optimized or replaced with more efficient liquid cooling systems in applications where higher performance is required. This trend is particularly evident in industries such as electric vehicles and renewable energy, where motor efficiency is crucial for overall system performance.

Additionally, these regulations have spurred the development of advanced monitoring and control systems for motor cooling. Intelligent thermal management systems that can adapt to varying load conditions and environmental factors are becoming increasingly common, further enhancing energy efficiency and motor longevity.

In conclusion, energy efficiency regulations have been a key driver in the evolution of cooling techniques for induction motor heat management. They have not only set new standards for motor efficiency but have also catalyzed innovation in cooling technologies, reshaped market dynamics, and promoted the adoption of more sophisticated thermal management solutions across various industries.

Environmental Considerations in Cooling Design

Environmental considerations have become increasingly important in the design of cooling systems for induction motors. As industries strive to reduce their carbon footprint and meet stringent environmental regulations, innovative cooling techniques must align with sustainability goals. One key aspect is the selection of environmentally friendly refrigerants. Traditional cooling systems often relied on hydrofluorocarbons (HFCs), which have high global warming potential. However, new alternatives such as hydrofluoroolefins (HFOs) and natural refrigerants like CO2 are gaining traction due to their lower environmental impact.

Energy efficiency is another critical factor in environmentally conscious cooling design. Advanced heat exchangers and optimized airflow patterns can significantly reduce the energy consumption of cooling systems. Variable speed drives for cooling fans and pumps allow for dynamic adjustment of cooling capacity, further enhancing energy efficiency. Additionally, the integration of waste heat recovery systems can repurpose thermal energy for other industrial processes or space heating, improving overall system efficiency.

The use of sustainable materials in cooling system components is also gaining attention. Manufacturers are exploring biodegradable or recyclable materials for insulation, piping, and heat exchange surfaces. This approach not only reduces the environmental impact during the operational life of the motor but also addresses end-of-life considerations and promotes a circular economy.

Water conservation is becoming increasingly important, especially in water-scarce regions. Closed-loop cooling systems and air-cooled designs are being developed to minimize water consumption. In cases where water cooling is necessary, advanced filtration and treatment systems are being implemented to allow for water recycling and reuse, reducing the overall water footprint of the cooling system.

Noise pollution is another environmental concern addressed in modern cooling designs. Acoustic engineering principles are being applied to reduce the noise generated by cooling fans and other components. This includes the use of low-noise fan blades, vibration dampening materials, and strategic placement of cooling equipment to minimize sound propagation.

Lifecycle assessment (LCA) is becoming an integral part of cooling system design. This holistic approach considers the environmental impact of the cooling system from raw material extraction through manufacturing, use, and disposal. By conducting comprehensive LCAs, designers can identify and mitigate environmental hotspots throughout the entire lifecycle of the cooling system, leading to more sustainable solutions.

Energy efficiency is another critical factor in environmentally conscious cooling design. Advanced heat exchangers and optimized airflow patterns can significantly reduce the energy consumption of cooling systems. Variable speed drives for cooling fans and pumps allow for dynamic adjustment of cooling capacity, further enhancing energy efficiency. Additionally, the integration of waste heat recovery systems can repurpose thermal energy for other industrial processes or space heating, improving overall system efficiency.

The use of sustainable materials in cooling system components is also gaining attention. Manufacturers are exploring biodegradable or recyclable materials for insulation, piping, and heat exchange surfaces. This approach not only reduces the environmental impact during the operational life of the motor but also addresses end-of-life considerations and promotes a circular economy.

Water conservation is becoming increasingly important, especially in water-scarce regions. Closed-loop cooling systems and air-cooled designs are being developed to minimize water consumption. In cases where water cooling is necessary, advanced filtration and treatment systems are being implemented to allow for water recycling and reuse, reducing the overall water footprint of the cooling system.

Noise pollution is another environmental concern addressed in modern cooling designs. Acoustic engineering principles are being applied to reduce the noise generated by cooling fans and other components. This includes the use of low-noise fan blades, vibration dampening materials, and strategic placement of cooling equipment to minimize sound propagation.

Lifecycle assessment (LCA) is becoming an integral part of cooling system design. This holistic approach considers the environmental impact of the cooling system from raw material extraction through manufacturing, use, and disposal. By conducting comprehensive LCAs, designers can identify and mitigate environmental hotspots throughout the entire lifecycle of the cooling system, leading to more sustainable solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!