How induction motors interact with wireless energy transfer systems

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Induction Motor WET Interaction Background

The interaction between induction motors and wireless energy transfer (WET) systems represents a fascinating intersection of two fundamental technologies in electrical engineering. Induction motors, first invented by Nikola Tesla in the late 19th century, have become the workhorses of industrial applications due to their robustness, efficiency, and low maintenance requirements. On the other hand, wireless energy transfer, while conceptualized around the same time, has only recently gained significant traction in practical applications.

The evolution of these technologies has been driven by different needs and constraints. Induction motors have seen incremental improvements in efficiency and power density over the decades, while WET systems have undergone more radical transformations as new methods of energy transfer have been developed. The convergence of these technologies is primarily motivated by the increasing demand for flexible and efficient power delivery in industrial and automotive applications.

One of the key challenges in this interaction lies in the fundamental operating principles of induction motors. These motors rely on electromagnetic induction to create motion, which inherently involves the generation of magnetic fields. When placed in proximity to a WET system, these fields can potentially interfere with the energy transfer process, leading to reduced efficiency or even system malfunction.

Conversely, the strong electromagnetic fields generated by WET systems can induce unwanted currents in the motor windings, potentially affecting motor performance or causing damage. This mutual interference presents a significant technical hurdle that researchers and engineers must overcome to enable seamless integration of these technologies.

The potential benefits of successfully combining induction motors with WET systems are substantial. In industrial settings, it could lead to more flexible manufacturing layouts, eliminating the need for fixed power connections to motor-driven equipment. In electric vehicles, it could enable dynamic charging while in motion, significantly extending range and reducing charging times.

Recent advancements in shielding technologies, adaptive power control algorithms, and novel materials have begun to address some of the challenges in this interaction. Researchers are exploring techniques such as frequency tuning, spatial field shaping, and active cancellation to mitigate interference and optimize energy transfer efficiency.

As we delve deeper into this topic, it becomes clear that understanding and optimizing the interaction between induction motors and WET systems is not just an academic exercise, but a crucial step towards more efficient and flexible electromechanical systems. The successful integration of these technologies could pave the way for innovative applications across various industries, from manufacturing and transportation to consumer electronics.

The evolution of these technologies has been driven by different needs and constraints. Induction motors have seen incremental improvements in efficiency and power density over the decades, while WET systems have undergone more radical transformations as new methods of energy transfer have been developed. The convergence of these technologies is primarily motivated by the increasing demand for flexible and efficient power delivery in industrial and automotive applications.

One of the key challenges in this interaction lies in the fundamental operating principles of induction motors. These motors rely on electromagnetic induction to create motion, which inherently involves the generation of magnetic fields. When placed in proximity to a WET system, these fields can potentially interfere with the energy transfer process, leading to reduced efficiency or even system malfunction.

Conversely, the strong electromagnetic fields generated by WET systems can induce unwanted currents in the motor windings, potentially affecting motor performance or causing damage. This mutual interference presents a significant technical hurdle that researchers and engineers must overcome to enable seamless integration of these technologies.

The potential benefits of successfully combining induction motors with WET systems are substantial. In industrial settings, it could lead to more flexible manufacturing layouts, eliminating the need for fixed power connections to motor-driven equipment. In electric vehicles, it could enable dynamic charging while in motion, significantly extending range and reducing charging times.

Recent advancements in shielding technologies, adaptive power control algorithms, and novel materials have begun to address some of the challenges in this interaction. Researchers are exploring techniques such as frequency tuning, spatial field shaping, and active cancellation to mitigate interference and optimize energy transfer efficiency.

As we delve deeper into this topic, it becomes clear that understanding and optimizing the interaction between induction motors and WET systems is not just an academic exercise, but a crucial step towards more efficient and flexible electromechanical systems. The successful integration of these technologies could pave the way for innovative applications across various industries, from manufacturing and transportation to consumer electronics.

Market Demand Analysis

The market demand for wireless energy transfer systems in conjunction with induction motors is experiencing significant growth, driven by the increasing need for efficient and flexible power solutions across various industries. This technology combination offers numerous advantages, including reduced maintenance costs, improved safety, and enhanced operational flexibility, which are particularly attractive in industrial and manufacturing settings.

In the automotive sector, the integration of wireless energy transfer systems with induction motors is gaining traction, especially in electric vehicle (EV) charging applications. The convenience of wireless charging for EVs is expected to drive adoption, with the global wireless EV charging market projected to grow substantially in the coming years. This growth is further supported by government initiatives promoting electric mobility and the development of smart cities.

The industrial automation sector represents another significant market for this technology combination. Wireless power transfer systems can eliminate the need for complex wiring in factory environments, reducing downtime and improving overall efficiency. Induction motors, being the workhorses of many industrial processes, stand to benefit greatly from this integration, leading to increased demand from manufacturing facilities looking to modernize their operations.

In the renewable energy sector, particularly in wind power generation, the interaction between induction motors and wireless energy transfer systems shows promise. This technology could potentially improve the efficiency of wind turbines by enabling better power management and reducing maintenance requirements for the motor systems in nacelles.

The healthcare industry is also showing interest in this technology combination, particularly for medical devices and equipment. Wireless charging of medical devices powered by induction motors could enhance sterilization processes and improve device mobility within healthcare facilities.

Consumer electronics represent another growing market segment, with potential applications in household appliances and portable devices. The convenience of wireless charging coupled with the reliability of induction motors could lead to innovative product designs and improved user experiences.

However, the market faces challenges such as the need for standardization, concerns about electromagnetic interference, and the initial cost of implementation. These factors may temporarily slow adoption rates in some sectors.

Despite these challenges, the overall market trajectory remains positive. As research and development efforts continue to address technical limitations and improve efficiency, the interaction between induction motors and wireless energy transfer systems is expected to unlock new applications and market opportunities across multiple industries.

In the automotive sector, the integration of wireless energy transfer systems with induction motors is gaining traction, especially in electric vehicle (EV) charging applications. The convenience of wireless charging for EVs is expected to drive adoption, with the global wireless EV charging market projected to grow substantially in the coming years. This growth is further supported by government initiatives promoting electric mobility and the development of smart cities.

The industrial automation sector represents another significant market for this technology combination. Wireless power transfer systems can eliminate the need for complex wiring in factory environments, reducing downtime and improving overall efficiency. Induction motors, being the workhorses of many industrial processes, stand to benefit greatly from this integration, leading to increased demand from manufacturing facilities looking to modernize their operations.

In the renewable energy sector, particularly in wind power generation, the interaction between induction motors and wireless energy transfer systems shows promise. This technology could potentially improve the efficiency of wind turbines by enabling better power management and reducing maintenance requirements for the motor systems in nacelles.

The healthcare industry is also showing interest in this technology combination, particularly for medical devices and equipment. Wireless charging of medical devices powered by induction motors could enhance sterilization processes and improve device mobility within healthcare facilities.

Consumer electronics represent another growing market segment, with potential applications in household appliances and portable devices. The convenience of wireless charging coupled with the reliability of induction motors could lead to innovative product designs and improved user experiences.

However, the market faces challenges such as the need for standardization, concerns about electromagnetic interference, and the initial cost of implementation. These factors may temporarily slow adoption rates in some sectors.

Despite these challenges, the overall market trajectory remains positive. As research and development efforts continue to address technical limitations and improve efficiency, the interaction between induction motors and wireless energy transfer systems is expected to unlock new applications and market opportunities across multiple industries.

Technical Challenges

The interaction between induction motors and wireless energy transfer systems presents several significant technical challenges that need to be addressed for effective implementation. One of the primary issues is the electromagnetic interference (EMI) generated by both systems. Induction motors, by their nature, produce strong electromagnetic fields during operation, which can potentially disrupt the delicate resonant coupling mechanisms used in wireless energy transfer systems.

Conversely, the high-frequency electromagnetic fields generated by wireless power transfer systems can induce unwanted currents in the motor windings, potentially leading to performance degradation, increased heating, and reduced efficiency of the motor. This bidirectional interference necessitates careful shielding and design considerations to ensure the coexistence of both systems without compromising their respective functionalities.

Another challenge lies in the power transfer efficiency when integrating induction motors with wireless energy systems. Wireless power transfer typically operates at high frequencies to achieve efficient transmission, while induction motors generally operate at lower frequencies. This frequency mismatch can lead to significant power losses and reduced overall system efficiency. Developing effective power conversion and management strategies to bridge this gap is crucial for practical applications.

The dynamic nature of induction motor loads also poses a challenge for wireless energy transfer systems. As motor loads vary during operation, the power demand fluctuates, requiring the wireless power system to adapt quickly to these changes. This necessitates the development of advanced control algorithms and real-time power management systems capable of responding to rapid load variations while maintaining stable and efficient power transfer.

Thermal management is another critical issue when combining these technologies. Both induction motors and wireless power transfer components generate heat during operation. The proximity of these systems can lead to thermal coupling, potentially exacerbating heating issues and reducing the overall system reliability. Innovative cooling solutions and thermal design strategies are essential to maintain optimal operating temperatures and ensure long-term system stability.

Furthermore, the physical integration of wireless power transfer components with induction motors presents design challenges. Incorporating the necessary coils and electronics for wireless power reception into the motor assembly without significantly altering its form factor or performance characteristics requires careful engineering and potentially new manufacturing techniques. This integration must also consider factors such as weight, size, and cost to ensure the resulting system remains commercially viable.

Lastly, standardization and regulatory compliance pose significant hurdles. As the integration of wireless power transfer with induction motors is a relatively new field, there is a lack of established standards and regulations governing their combined use. Developing comprehensive standards that address safety, electromagnetic compatibility, and performance metrics is crucial for widespread adoption and interoperability of these integrated systems across different applications and industries.

Conversely, the high-frequency electromagnetic fields generated by wireless power transfer systems can induce unwanted currents in the motor windings, potentially leading to performance degradation, increased heating, and reduced efficiency of the motor. This bidirectional interference necessitates careful shielding and design considerations to ensure the coexistence of both systems without compromising their respective functionalities.

Another challenge lies in the power transfer efficiency when integrating induction motors with wireless energy systems. Wireless power transfer typically operates at high frequencies to achieve efficient transmission, while induction motors generally operate at lower frequencies. This frequency mismatch can lead to significant power losses and reduced overall system efficiency. Developing effective power conversion and management strategies to bridge this gap is crucial for practical applications.

The dynamic nature of induction motor loads also poses a challenge for wireless energy transfer systems. As motor loads vary during operation, the power demand fluctuates, requiring the wireless power system to adapt quickly to these changes. This necessitates the development of advanced control algorithms and real-time power management systems capable of responding to rapid load variations while maintaining stable and efficient power transfer.

Thermal management is another critical issue when combining these technologies. Both induction motors and wireless power transfer components generate heat during operation. The proximity of these systems can lead to thermal coupling, potentially exacerbating heating issues and reducing the overall system reliability. Innovative cooling solutions and thermal design strategies are essential to maintain optimal operating temperatures and ensure long-term system stability.

Furthermore, the physical integration of wireless power transfer components with induction motors presents design challenges. Incorporating the necessary coils and electronics for wireless power reception into the motor assembly without significantly altering its form factor or performance characteristics requires careful engineering and potentially new manufacturing techniques. This integration must also consider factors such as weight, size, and cost to ensure the resulting system remains commercially viable.

Lastly, standardization and regulatory compliance pose significant hurdles. As the integration of wireless power transfer with induction motors is a relatively new field, there is a lack of established standards and regulations governing their combined use. Developing comprehensive standards that address safety, electromagnetic compatibility, and performance metrics is crucial for widespread adoption and interoperability of these integrated systems across different applications and industries.

Current Integration Solutions

01 Design and construction of induction motors

This category covers the fundamental design and construction aspects of induction motors, including rotor and stator configurations, winding arrangements, and core materials. Innovations in these areas aim to improve motor efficiency, power output, and overall performance.- Design and construction of induction motors: This category covers various aspects of induction motor design and construction, including improvements in rotor and stator configurations, winding arrangements, and overall motor structure. These advancements aim to enhance motor efficiency, power output, and reliability.

- Control systems for induction motors: This point focuses on the development of control systems and methods for induction motors. It includes innovations in speed control, torque regulation, and overall motor performance optimization through advanced control algorithms and electronic systems.

- Efficiency improvements in induction motors: This category encompasses various techniques and technologies aimed at improving the energy efficiency of induction motors. It includes advancements in materials, design optimizations, and innovative cooling systems to reduce energy losses and increase overall motor efficiency.

- Specialized applications of induction motors: This point covers the adaptation and optimization of induction motors for specific industrial applications. It includes designs tailored for high-power applications, variable speed operations, and motors suited for harsh or specialized environments.

- Manufacturing and assembly techniques for induction motors: This category focuses on innovative manufacturing processes and assembly techniques for induction motors. It includes advancements in production methods, quality control, and assembly automation to improve motor reliability and reduce manufacturing costs.

02 Control systems for induction motors

This point focuses on the development of control systems and methods for induction motors. It includes advancements in speed control, torque regulation, and power factor correction. These control systems aim to enhance motor performance, efficiency, and adaptability to various operating conditions.Expand Specific Solutions03 Efficiency improvements in induction motors

This category encompasses innovations aimed at improving the energy efficiency of induction motors. It includes techniques for reducing losses, optimizing magnetic circuits, and enhancing thermal management. These advancements contribute to reduced energy consumption and improved motor performance.Expand Specific Solutions04 Specialized applications of induction motors

This point covers the adaptation and optimization of induction motors for specific applications. It includes designs for high-speed operations, heavy-duty industrial use, and integration with renewable energy systems. These specialized motors are tailored to meet the unique requirements of various industries and operating environments.Expand Specific Solutions05 Manufacturing and assembly techniques for induction motors

This category focuses on innovative manufacturing and assembly methods for induction motors. It includes advancements in production processes, materials, and quality control techniques. These innovations aim to improve motor reliability, reduce production costs, and enhance overall manufacturing efficiency.Expand Specific Solutions

Key Industry Players

The interaction between induction motors and wireless energy transfer systems is an emerging field in the early stages of development, with a growing market driven by increasing demand for efficient and flexible power solutions. The technology is still evolving, with varying levels of maturity across different applications. Key players like Samsung Electronics, Texas Instruments, and Intel are investing in research and development to advance this technology. Companies such as Solace Power and Koninklijke Philips are focusing on innovative solutions for wireless power transfer, while automotive giants like Toyota and Renault are exploring its potential in electric vehicle applications. The market is characterized by a mix of established electronics manufacturers and specialized startups, indicating a competitive and dynamic landscape.

Solace Power, Inc.

Technical Solution: Solace Power has developed a proprietary Resonant Capacitive Coupling (RC²) technology for wireless power transfer. This technology utilizes electric fields for power transfer, which is particularly suitable for integration with induction motors. The RC² system can transfer power through various materials, including metal, which is crucial for motor applications. Solace's approach minimizes electromagnetic interference, a common concern when dealing with induction motors[1]. The company has demonstrated power transfer capabilities of up to 250W over distances of several centimeters, which is sufficient for many motor applications[2].

Strengths: High efficiency power transfer through various materials, including metal; low electromagnetic interference. Weaknesses: Limited power transfer distance compared to some other wireless technologies; may require precise alignment for optimal performance.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed a wireless power transfer system that utilizes magnetic resonance technology, which can be effectively integrated with induction motors. Their system employs a dual-mode operation that can switch between tightly coupled and loosely coupled modes, allowing for efficient power transfer at various distances[3]. This adaptability is particularly useful when dealing with the dynamic environment of induction motors. Samsung's technology also incorporates advanced foreign object detection and removal systems, which are crucial for maintaining safety and efficiency when used in conjunction with induction motors[4]. The company has demonstrated power transfer of up to 2.2 kW for electric vehicle applications, showcasing its potential for high-power motor systems[5].

Strengths: Dual-mode operation for flexible power transfer; advanced safety features; high power transfer capability. Weaknesses: May require complex control systems; potential for increased cost due to advanced features.

Core Technologies Analysis

system FOR WIRELESS ENERGY TRANSMISSION

PatentInactiveAT515624A1

Innovation

- The primary coils of the transmitter are arranged flat in one plane, allowing for a more compact and efficient design.

- The receiver with secondary coils is arranged movably along a secondary plane parallel to the plane of the primary coils, enabling flexible positioning and continuous power supply to moving devices.

- The system is particularly suitable for supplying power to and actuating movable electrical consumers such as light-emitting elements or personal computers, expanding the application scope of wireless energy transmission.

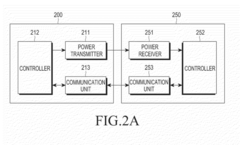

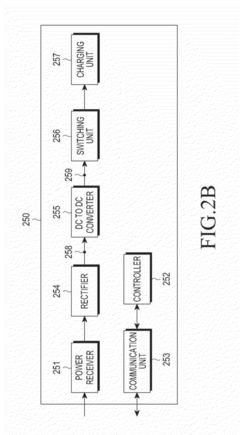

Wireless power transmitter and method of controlling the same

PatentActiveUS20160118844A1

Innovation

- A wireless power transmitter equipped with an overcurrent protection circuit and a controller that monitors the current value of the output terminal, connecting the overcurrent protection circuit to adjust impedance when the current exceeds a predetermined threshold, preventing excessive power transmission.

Electromagnetic Compatibility

Electromagnetic compatibility (EMC) is a critical consideration when integrating induction motors with wireless energy transfer systems. The interaction between these two technologies can lead to various electromagnetic interference (EMI) issues that need to be addressed to ensure optimal performance and safety.

Induction motors, by their nature, generate electromagnetic fields during operation. These fields can potentially interfere with the wireless energy transfer system, causing disruptions in power transmission efficiency and overall system performance. Conversely, the high-frequency electromagnetic fields produced by wireless energy transfer systems may induce unwanted currents in the motor windings, leading to increased losses, heating, and potential damage to the motor.

To mitigate these EMC challenges, several strategies can be employed. Proper shielding of both the induction motor and the wireless energy transfer components is essential. This can involve the use of conductive enclosures, ferrite materials, or specialized EMI-absorbing materials to contain and redirect electromagnetic fields. Additionally, careful placement and orientation of components can help minimize mutual interference.

Frequency selection for the wireless energy transfer system is another crucial factor. By choosing operating frequencies that are sufficiently different from the motor's electrical characteristics, the risk of interference can be reduced. This may involve using higher frequencies for wireless power transfer, which are less likely to interact with the motor's lower frequency operations.

Filtering techniques play a vital role in maintaining electromagnetic compatibility. Low-pass filters can be implemented to prevent high-frequency noise from the wireless system from affecting the motor, while high-pass filters can be used to block lower frequency interference from the motor reaching the wireless transfer components. Active filtering methods, such as adaptive noise cancellation, may also be employed for more sophisticated EMC management.

Grounding and bonding practices are essential for creating low-impedance paths for unwanted currents and reducing common-mode noise. Proper grounding of both the motor and wireless transfer system components helps to minimize potential differences and reduce EMI propagation.

Compliance with relevant EMC standards and regulations is crucial when integrating induction motors with wireless energy transfer systems. Standards such as IEC 61000 series for electromagnetic compatibility provide guidelines for emission limits and immunity requirements that must be adhered to in industrial and consumer applications.

Regular EMC testing and monitoring should be conducted throughout the development and implementation phases to ensure ongoing compatibility. This may involve near-field and far-field measurements, conducted emissions testing, and immunity testing under various operating conditions.

Induction motors, by their nature, generate electromagnetic fields during operation. These fields can potentially interfere with the wireless energy transfer system, causing disruptions in power transmission efficiency and overall system performance. Conversely, the high-frequency electromagnetic fields produced by wireless energy transfer systems may induce unwanted currents in the motor windings, leading to increased losses, heating, and potential damage to the motor.

To mitigate these EMC challenges, several strategies can be employed. Proper shielding of both the induction motor and the wireless energy transfer components is essential. This can involve the use of conductive enclosures, ferrite materials, or specialized EMI-absorbing materials to contain and redirect electromagnetic fields. Additionally, careful placement and orientation of components can help minimize mutual interference.

Frequency selection for the wireless energy transfer system is another crucial factor. By choosing operating frequencies that are sufficiently different from the motor's electrical characteristics, the risk of interference can be reduced. This may involve using higher frequencies for wireless power transfer, which are less likely to interact with the motor's lower frequency operations.

Filtering techniques play a vital role in maintaining electromagnetic compatibility. Low-pass filters can be implemented to prevent high-frequency noise from the wireless system from affecting the motor, while high-pass filters can be used to block lower frequency interference from the motor reaching the wireless transfer components. Active filtering methods, such as adaptive noise cancellation, may also be employed for more sophisticated EMC management.

Grounding and bonding practices are essential for creating low-impedance paths for unwanted currents and reducing common-mode noise. Proper grounding of both the motor and wireless transfer system components helps to minimize potential differences and reduce EMI propagation.

Compliance with relevant EMC standards and regulations is crucial when integrating induction motors with wireless energy transfer systems. Standards such as IEC 61000 series for electromagnetic compatibility provide guidelines for emission limits and immunity requirements that must be adhered to in industrial and consumer applications.

Regular EMC testing and monitoring should be conducted throughout the development and implementation phases to ensure ongoing compatibility. This may involve near-field and far-field measurements, conducted emissions testing, and immunity testing under various operating conditions.

Energy Efficiency Considerations

Energy efficiency is a critical consideration in the interaction between induction motors and wireless energy transfer systems. The overall efficiency of such a system is determined by the combined efficiencies of the wireless power transmission and the induction motor's operation. Wireless power transfer systems typically operate at high frequencies to maximize transmission efficiency, but this can lead to increased losses in the induction motor due to eddy currents and hysteresis in the motor's core.

To address this challenge, advanced materials and designs are being developed to minimize these losses. For instance, the use of high-frequency, low-loss magnetic materials in the motor's core can significantly reduce eddy current losses. Additionally, optimizing the motor's winding design and geometry can help to better match the motor's impedance with the wireless power system, improving overall energy transfer efficiency.

The efficiency of the wireless power transfer system itself is also a crucial factor. Resonant inductive coupling techniques have shown promise in achieving high efficiency over longer distances. By carefully tuning the resonant frequencies of the transmitter and receiver coils, power transfer efficiency can be maximized while minimizing electromagnetic interference.

Another important aspect is the power management and control systems used in these setups. Adaptive frequency tracking and impedance matching techniques can dynamically adjust the system parameters to maintain optimal efficiency under varying load conditions. This is particularly important for induction motors, which may experience significant changes in load during operation.

The integration of smart power electronics and advanced control algorithms can further enhance energy efficiency. For example, implementing variable frequency drives (VFDs) in conjunction with wireless power systems can allow for precise control of the motor's speed and torque, reducing energy consumption during partial load operations.

Thermal management is another critical consideration in energy efficiency. Both the wireless power transfer system and the induction motor generate heat, which can lead to increased losses if not properly managed. Innovative cooling solutions, such as the use of phase-change materials or advanced heat sink designs, can help maintain optimal operating temperatures and improve overall system efficiency.

As research in this field progresses, we can expect to see further improvements in energy efficiency through the development of novel materials, advanced control strategies, and optimized system designs. These advancements will be crucial in making wireless-powered induction motor systems a viable and energy-efficient solution for various industrial and consumer applications.

To address this challenge, advanced materials and designs are being developed to minimize these losses. For instance, the use of high-frequency, low-loss magnetic materials in the motor's core can significantly reduce eddy current losses. Additionally, optimizing the motor's winding design and geometry can help to better match the motor's impedance with the wireless power system, improving overall energy transfer efficiency.

The efficiency of the wireless power transfer system itself is also a crucial factor. Resonant inductive coupling techniques have shown promise in achieving high efficiency over longer distances. By carefully tuning the resonant frequencies of the transmitter and receiver coils, power transfer efficiency can be maximized while minimizing electromagnetic interference.

Another important aspect is the power management and control systems used in these setups. Adaptive frequency tracking and impedance matching techniques can dynamically adjust the system parameters to maintain optimal efficiency under varying load conditions. This is particularly important for induction motors, which may experience significant changes in load during operation.

The integration of smart power electronics and advanced control algorithms can further enhance energy efficiency. For example, implementing variable frequency drives (VFDs) in conjunction with wireless power systems can allow for precise control of the motor's speed and torque, reducing energy consumption during partial load operations.

Thermal management is another critical consideration in energy efficiency. Both the wireless power transfer system and the induction motor generate heat, which can lead to increased losses if not properly managed. Innovative cooling solutions, such as the use of phase-change materials or advanced heat sink designs, can help maintain optimal operating temperatures and improve overall system efficiency.

As research in this field progresses, we can expect to see further improvements in energy efficiency through the development of novel materials, advanced control strategies, and optimized system designs. These advancements will be crucial in making wireless-powered induction motor systems a viable and energy-efficient solution for various industrial and consumer applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!