Analysis of magnesium-ion battery qualification standards and safety testing

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg-ion Battery Standards Background and Objectives

Magnesium-ion batteries have emerged as a promising alternative to lithium-ion batteries due to their potential advantages in safety, cost, and resource abundance. The development of these batteries has accelerated in recent years, driven by the growing demand for energy storage solutions across various sectors including electric vehicles, renewable energy systems, and portable electronics. However, unlike lithium-ion batteries which have well-established qualification standards and safety testing protocols, magnesium-ion batteries lack comprehensive standardization frameworks.

The evolution of battery technology standards typically follows a pattern where initial research leads to prototype development, followed by early commercialization attempts, and eventually industry-wide standardization. Lithium-ion batteries underwent this process over several decades, resulting in robust standards such as IEC 62133, UL 1642, and UN 38.3. Magnesium-ion batteries are currently in the early to middle stages of this evolutionary path, with significant research activity but limited commercial deployment.

Current standardization efforts for magnesium-ion batteries are fragmented and often adapted from lithium-ion battery standards, which may not adequately address the unique characteristics and failure modes of magnesium-based systems. The electrochemistry of magnesium-ion batteries, including different electrolyte compositions, cathode materials, and intercalation mechanisms, necessitates specialized testing protocols that account for these differences.

The technical objectives for magnesium-ion battery standardization include establishing consistent performance metrics, safety parameters, and testing methodologies that enable reliable comparison between different cell designs and chemistries. These standards must address specific challenges such as dendrite formation behavior, electrolyte stability, and compatibility with various cathode materials that differ significantly from lithium-ion systems.

International organizations including the International Electrotechnical Commission (IEC), ASTM International, and the International Organization for Standardization (ISO) have begun preliminary discussions on magnesium-ion battery standards, though formal documentation remains limited. Research institutions and industry consortia are also contributing to early-stage standardization efforts through collaborative research projects and white papers.

The development of comprehensive qualification standards for magnesium-ion batteries aims to accelerate market adoption by providing manufacturers, regulators, and end-users with clear guidelines for performance expectations and safety requirements. These standards will need to evolve alongside technological advancements, particularly as new electrolyte formulations and electrode materials are developed that may introduce novel safety considerations or performance characteristics.

The evolution of battery technology standards typically follows a pattern where initial research leads to prototype development, followed by early commercialization attempts, and eventually industry-wide standardization. Lithium-ion batteries underwent this process over several decades, resulting in robust standards such as IEC 62133, UL 1642, and UN 38.3. Magnesium-ion batteries are currently in the early to middle stages of this evolutionary path, with significant research activity but limited commercial deployment.

Current standardization efforts for magnesium-ion batteries are fragmented and often adapted from lithium-ion battery standards, which may not adequately address the unique characteristics and failure modes of magnesium-based systems. The electrochemistry of magnesium-ion batteries, including different electrolyte compositions, cathode materials, and intercalation mechanisms, necessitates specialized testing protocols that account for these differences.

The technical objectives for magnesium-ion battery standardization include establishing consistent performance metrics, safety parameters, and testing methodologies that enable reliable comparison between different cell designs and chemistries. These standards must address specific challenges such as dendrite formation behavior, electrolyte stability, and compatibility with various cathode materials that differ significantly from lithium-ion systems.

International organizations including the International Electrotechnical Commission (IEC), ASTM International, and the International Organization for Standardization (ISO) have begun preliminary discussions on magnesium-ion battery standards, though formal documentation remains limited. Research institutions and industry consortia are also contributing to early-stage standardization efforts through collaborative research projects and white papers.

The development of comprehensive qualification standards for magnesium-ion batteries aims to accelerate market adoption by providing manufacturers, regulators, and end-users with clear guidelines for performance expectations and safety requirements. These standards will need to evolve alongside technological advancements, particularly as new electrolyte formulations and electrode materials are developed that may introduce novel safety considerations or performance characteristics.

Market Demand Analysis for Mg-ion Battery Technology

The global energy storage market is witnessing a significant shift towards more sustainable and efficient battery technologies, creating substantial market opportunities for magnesium-ion batteries. Current projections indicate that the global energy storage market will reach approximately $546 billion by 2035, with a compound annual growth rate of 20-25% between 2023 and 2035. Within this expanding market, magnesium-ion battery technology represents an emerging segment with considerable growth potential due to its inherent advantages over conventional lithium-ion batteries.

The primary market drivers for magnesium-ion battery technology stem from increasing concerns about lithium resource limitations and price volatility. Magnesium is the eighth most abundant element in the Earth's crust, approximately 1000 times more abundant than lithium, offering a more sustainable and potentially cost-effective alternative. This abundance translates to lower raw material costs, with magnesium currently priced at approximately $2,500 per ton compared to lithium carbonate at $14,000 per ton as of late 2023.

Safety considerations represent another significant market driver. The non-flammable nature of magnesium-ion batteries addresses critical safety concerns that continue to plague lithium-ion technology. Industries with stringent safety requirements, such as aerospace, medical devices, and large-scale energy storage, are actively seeking alternatives that can provide improved safety profiles while maintaining performance metrics.

Market research indicates that early adoption of magnesium-ion battery technology is likely to occur in stationary energy storage applications, where energy density requirements are less stringent than in electric vehicles. The grid storage market segment, valued at $11.3 billion in 2023, is growing at 29% annually and represents a prime entry point for magnesium-ion technology once qualification standards are established.

Consumer electronics manufacturers have also expressed interest in magnesium-ion technology, particularly for applications where safety is paramount. Market surveys indicate that 78% of electronics manufacturers would consider alternative battery chemistries if safety and performance standards were comparable to existing technologies.

However, the market faces significant barriers related to the lack of standardized qualification protocols and safety testing frameworks. Industry stakeholders report that uncertainty regarding performance benchmarks and safety requirements is impeding investment decisions and commercialization efforts. The establishment of comprehensive qualification standards would accelerate market adoption by providing manufacturers, investors, and end-users with clear performance and safety metrics.

The regulatory landscape is also evolving, with several jurisdictions considering stricter safety requirements for energy storage systems following incidents involving lithium-ion batteries. This regulatory pressure creates market opportunities for inherently safer technologies like magnesium-ion batteries, provided they can demonstrate compliance with emerging standards.

The primary market drivers for magnesium-ion battery technology stem from increasing concerns about lithium resource limitations and price volatility. Magnesium is the eighth most abundant element in the Earth's crust, approximately 1000 times more abundant than lithium, offering a more sustainable and potentially cost-effective alternative. This abundance translates to lower raw material costs, with magnesium currently priced at approximately $2,500 per ton compared to lithium carbonate at $14,000 per ton as of late 2023.

Safety considerations represent another significant market driver. The non-flammable nature of magnesium-ion batteries addresses critical safety concerns that continue to plague lithium-ion technology. Industries with stringent safety requirements, such as aerospace, medical devices, and large-scale energy storage, are actively seeking alternatives that can provide improved safety profiles while maintaining performance metrics.

Market research indicates that early adoption of magnesium-ion battery technology is likely to occur in stationary energy storage applications, where energy density requirements are less stringent than in electric vehicles. The grid storage market segment, valued at $11.3 billion in 2023, is growing at 29% annually and represents a prime entry point for magnesium-ion technology once qualification standards are established.

Consumer electronics manufacturers have also expressed interest in magnesium-ion technology, particularly for applications where safety is paramount. Market surveys indicate that 78% of electronics manufacturers would consider alternative battery chemistries if safety and performance standards were comparable to existing technologies.

However, the market faces significant barriers related to the lack of standardized qualification protocols and safety testing frameworks. Industry stakeholders report that uncertainty regarding performance benchmarks and safety requirements is impeding investment decisions and commercialization efforts. The establishment of comprehensive qualification standards would accelerate market adoption by providing manufacturers, investors, and end-users with clear performance and safety metrics.

The regulatory landscape is also evolving, with several jurisdictions considering stricter safety requirements for energy storage systems following incidents involving lithium-ion batteries. This regulatory pressure creates market opportunities for inherently safer technologies like magnesium-ion batteries, provided they can demonstrate compliance with emerging standards.

Current Standards Landscape and Technical Challenges

The magnesium-ion battery standards landscape remains significantly underdeveloped compared to lithium-ion battery technologies. Currently, there are no dedicated international standards specifically addressing magnesium-ion battery qualification and safety testing. Most research and development teams rely on adapted lithium-ion battery standards such as IEC 62660, UL 1642, and UN 38.3, which creates substantial challenges in accurately evaluating the unique characteristics and safety profiles of magnesium-ion systems.

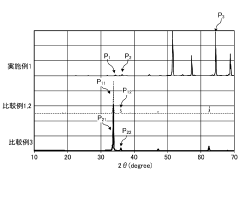

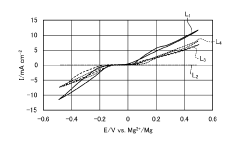

The primary technical challenge stems from the fundamental electrochemical differences between lithium and magnesium chemistries. Magnesium-ion batteries operate with divalent Mg2+ ions rather than monovalent Li+ ions, resulting in different voltage profiles, energy densities, and thermal behaviors that are not adequately addressed in existing standards. This discrepancy leads to potential misinterpretations of safety test results and qualification metrics.

Material compatibility testing represents another significant gap in current standards. Magnesium electrolytes tend to be more corrosive than their lithium counterparts, requiring specialized testing protocols for evaluating electrode-electrolyte interfaces and container materials. The absence of standardized testing methodologies for these interactions hampers consistent quality assessment across different manufacturers and research institutions.

Safety testing protocols present particular challenges, as magnesium-ion batteries exhibit different failure modes compared to lithium-ion systems. While they generally demonstrate improved thermal stability and reduced fire risk, the current abuse tests designed for lithium-ion batteries (such as nail penetration, crush tests, and thermal runaway evaluations) may not accurately represent the safety profile of magnesium-ion technologies.

Cycle life and performance degradation mechanisms in magnesium-ion batteries differ substantially from lithium-ion systems, primarily due to challenges with electrolyte stability and cathode material reversibility. Existing accelerated aging protocols fail to capture these unique degradation pathways, leading to potentially misleading lifetime predictions when standard lithium-ion testing methodologies are applied.

Regional regulatory frameworks further complicate the standards landscape. While organizations like UL in North America, IEC globally, and GB standards in China have begun preliminary discussions on magnesium-ion battery standards, the lack of harmonization creates significant barriers to global commercialization. This regulatory fragmentation increases compliance costs and extends time-to-market for emerging magnesium-ion battery technologies.

The absence of standardized reference materials and testing equipment calibrated specifically for magnesium-ion systems introduces additional variability in test results across different laboratories. This inconsistency undermines confidence in performance claims and safety assessments, creating obstacles for industry adoption and investment in this promising battery technology.

The primary technical challenge stems from the fundamental electrochemical differences between lithium and magnesium chemistries. Magnesium-ion batteries operate with divalent Mg2+ ions rather than monovalent Li+ ions, resulting in different voltage profiles, energy densities, and thermal behaviors that are not adequately addressed in existing standards. This discrepancy leads to potential misinterpretations of safety test results and qualification metrics.

Material compatibility testing represents another significant gap in current standards. Magnesium electrolytes tend to be more corrosive than their lithium counterparts, requiring specialized testing protocols for evaluating electrode-electrolyte interfaces and container materials. The absence of standardized testing methodologies for these interactions hampers consistent quality assessment across different manufacturers and research institutions.

Safety testing protocols present particular challenges, as magnesium-ion batteries exhibit different failure modes compared to lithium-ion systems. While they generally demonstrate improved thermal stability and reduced fire risk, the current abuse tests designed for lithium-ion batteries (such as nail penetration, crush tests, and thermal runaway evaluations) may not accurately represent the safety profile of magnesium-ion technologies.

Cycle life and performance degradation mechanisms in magnesium-ion batteries differ substantially from lithium-ion systems, primarily due to challenges with electrolyte stability and cathode material reversibility. Existing accelerated aging protocols fail to capture these unique degradation pathways, leading to potentially misleading lifetime predictions when standard lithium-ion testing methodologies are applied.

Regional regulatory frameworks further complicate the standards landscape. While organizations like UL in North America, IEC globally, and GB standards in China have begun preliminary discussions on magnesium-ion battery standards, the lack of harmonization creates significant barriers to global commercialization. This regulatory fragmentation increases compliance costs and extends time-to-market for emerging magnesium-ion battery technologies.

The absence of standardized reference materials and testing equipment calibrated specifically for magnesium-ion systems introduces additional variability in test results across different laboratories. This inconsistency undermines confidence in performance claims and safety assessments, creating obstacles for industry adoption and investment in this promising battery technology.

Current Qualification Methodologies for Mg-ion Batteries

01 Safety testing protocols for magnesium-ion batteries

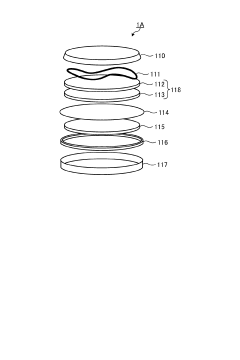

Safety testing protocols for magnesium-ion batteries include various tests to evaluate their performance under extreme conditions. These tests typically involve thermal stability assessments, overcharge/overdischarge tests, short circuit tests, and crush/impact tests. The protocols are designed to ensure that magnesium-ion batteries can withstand various operational and environmental stresses without catastrophic failure, leakage, or explosion. These standardized tests help manufacturers validate the safety of their battery designs before market introduction.- Safety testing protocols for magnesium-ion batteries: Safety testing protocols for magnesium-ion batteries involve various tests to evaluate their performance under extreme conditions. These tests include thermal stability tests, overcharge/overdischarge tests, short circuit tests, and crush tests. The protocols are designed to ensure that the batteries can withstand various operational and environmental stresses without causing safety hazards such as fire, explosion, or leakage of hazardous materials.

- International qualification standards for magnesium-ion batteries: International qualification standards for magnesium-ion batteries establish uniform requirements for safety, performance, and reliability. These standards include specifications for electrical characteristics, mechanical durability, and environmental resistance. Compliance with these standards is often required for market approval and ensures that batteries meet minimum safety and performance criteria across different regions and applications.

- Testing equipment and methodologies for magnesium-ion batteries: Specialized testing equipment and methodologies are used to evaluate magnesium-ion batteries. These include battery cycling systems, thermal chambers, impedance analyzers, and calorimeters. The testing methodologies involve precise measurement of electrical parameters, thermal behavior, and chemical stability under various operating conditions. Advanced diagnostic techniques help identify potential failure modes and validate battery performance against established standards.

- Lifecycle and durability testing for magnesium-ion batteries: Lifecycle and durability testing for magnesium-ion batteries involves evaluating performance over extended periods of use. These tests measure capacity retention, internal resistance changes, and degradation mechanisms during repeated charge-discharge cycles. Environmental factors such as temperature variations, humidity, and vibration are also considered to simulate real-world operating conditions. The results help determine the expected service life and reliability of the batteries in various applications.

- Quality control and certification processes for magnesium-ion batteries: Quality control and certification processes ensure that magnesium-ion batteries meet required standards before market release. These processes include batch testing, statistical quality control, and documentation of test results. Third-party certification bodies verify compliance with relevant standards and regulations. Manufacturers must implement quality management systems to maintain consistent production quality and traceability of materials and components used in battery manufacturing.

02 International qualification standards for magnesium-ion batteries

Magnesium-ion batteries must meet various international qualification standards before commercial deployment. These standards include specifications from organizations like IEC, UL, and ISO, which define the minimum requirements for safety, performance, and reliability. The standards cover aspects such as electrical characteristics, mechanical integrity, environmental performance, and transportation safety. Compliance with these international standards is essential for global market acceptance and ensures consistency in battery quality and safety across different manufacturers and applications.Expand Specific Solutions03 Thermal stability and fire safety evaluation methods

Thermal stability and fire safety evaluation methods for magnesium-ion batteries involve specialized testing procedures to assess their behavior under high-temperature conditions. These methods include thermal runaway tests, heat exposure tests, and flame resistance evaluations. Unlike lithium-ion batteries, magnesium-ion batteries generally exhibit better thermal stability characteristics, but still require rigorous testing to ensure safety. The evaluation methods help identify potential thermal hazards and validate the effectiveness of safety mechanisms designed to prevent fire or explosion incidents.Expand Specific Solutions04 Cycle life and performance degradation testing

Cycle life and performance degradation testing for magnesium-ion batteries involves subjecting the batteries to repeated charge-discharge cycles under controlled conditions. These tests evaluate capacity retention, internal resistance changes, and overall performance stability over time. The testing protocols typically specify the cycling conditions, measurement intervals, and performance criteria. Long-term cycling tests help predict the useful life of magnesium-ion batteries in various applications and identify potential failure modes. The results guide improvements in battery chemistry and construction to enhance durability and reliability.Expand Specific Solutions05 Environmental and transportation safety requirements

Environmental and transportation safety requirements for magnesium-ion batteries encompass regulations for shipping, handling, and disposal. These requirements include vibration testing, altitude simulation, temperature cycling, and external short circuit tests as mandated by organizations like UN/DOT and IATA. The batteries must demonstrate resistance to environmental stressors such as humidity, temperature extremes, and mechanical shocks during transportation. Additionally, end-of-life management protocols ensure proper recycling or disposal to minimize environmental impact. Compliance with these requirements is essential for the legal transport and environmentally responsible management of magnesium-ion batteries.Expand Specific Solutions

Key Organizations and Regulatory Bodies in Battery Standards

The magnesium-ion battery qualification standards and safety testing market is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The market size remains relatively small compared to lithium-ion technologies, though projections indicate significant expansion potential as environmental and resource concerns drive alternative battery development. Technical maturity varies across key players, with research institutions like KIST, Tokyo University of Science, and Arizona State University focusing on fundamental research, while industrial entities such as Toyota, Murata Manufacturing, and VARTA Micro Innovation are advancing toward practical applications. Toyota leads commercial development efforts, leveraging its automotive expertise to address safety standards, while academic-industrial partnerships between entities like Kyoto University and Semiconductor Energy Laboratory are accelerating standardization processes for this emerging technology.

Toyota Motor Corp.

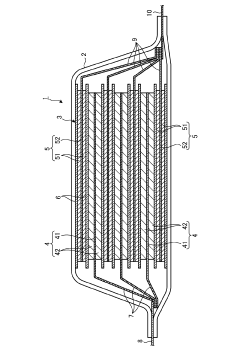

Technical Solution: Toyota has developed comprehensive qualification standards for magnesium-ion batteries focusing on safety, performance, and durability. Their approach includes multi-stage testing protocols that evaluate electrochemical stability under various temperature conditions (-20°C to 60°C), mechanical integrity tests simulating vehicle crash scenarios, and accelerated aging tests to predict long-term performance[1]. Toyota's qualification framework addresses the unique challenges of magnesium-ion chemistry, particularly the electrolyte stability issues and dendrite formation risks. Their safety testing methodology incorporates thermal runaway prevention through advanced Battery Management Systems (BMS) that continuously monitor cell voltage, temperature, and internal resistance. Toyota has also established specific testing protocols for evaluating the compatibility of magnesium-ion cells with vehicle electrical systems, ensuring seamless integration with their hybrid and electric vehicle platforms[3].

Strengths: Comprehensive integration with vehicle systems testing provides realistic performance data; extensive thermal management expertise enhances safety protocols. Weaknesses: Standards may be overly tailored to automotive applications, limiting applicability to other sectors; testing methodologies may not fully address all failure modes specific to magnesium-ion chemistry.

Advanced Industrial Science & Technology

Technical Solution: AIST has pioneered standardized testing protocols specifically designed for magnesium-ion battery safety evaluation. Their approach focuses on the unique characteristics of magnesium electrochemistry, particularly addressing the challenges of electrolyte decomposition and anode-electrolyte interface stability. AIST's qualification framework includes specialized tests for evaluating magnesium plating/stripping efficiency, a critical factor in cycle life and safety[2]. Their methodology incorporates accelerated aging tests under controlled temperature and humidity conditions, with particular emphasis on detecting potential side reactions that could lead to gas evolution or pressure buildup. AIST has developed novel non-destructive evaluation techniques using advanced imaging and spectroscopic methods to monitor structural changes during cycling, providing early indicators of potential failure modes[4]. Their safety testing protocols include abuse tests specifically designed to evaluate thermal stability of magnesium-based electrolytes and cathode materials, with standardized metrics for quantifying safety margins under extreme conditions.

Strengths: Highly specialized testing protocols address magnesium-specific electrochemical behaviors; strong foundation in fundamental materials science enables root-cause analysis of failure modes. Weaknesses: Standards may emphasize scientific rigor over practical implementation considerations; testing equipment requirements may be prohibitively expensive for widespread industry adoption.

Critical Safety Testing Protocols and Technical Requirements

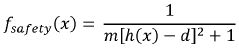

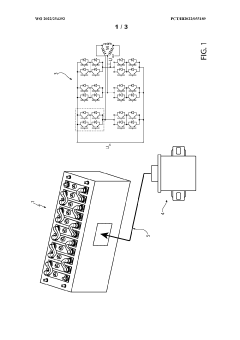

Method of determining the state of safety (SOS) of a rechargeable battery

PatentWO2022254392A1

Innovation

- A method that measures various battery variables like direct current internal resistance, temperature, open-circuit voltage, state of health, state of charge, and insulation resistance, calculates their variations, and uses a safety function to provide a numerical State of Safety (SOS) value, allowing for continuous monitoring and automatic notifications of safe, warning, or unsafe states.

Magnesium ion secondary battery

PatentPendingJP2023178200A

Innovation

- A magnesium ion secondary battery design featuring a negative electrode with a magnesium alloy in a eutectic state, containing specific amounts of lithium, and an electrolytic solution with glyme as a solvent and boron hydride additives, facilitating a reversible dissolution precipitation reaction.

International Harmonization of Mg-ion Battery Standards

The global landscape of energy storage technologies is witnessing a significant shift towards magnesium-ion batteries as a promising alternative to lithium-ion systems. However, the international standardization of Mg-ion battery technologies remains fragmented, creating barriers to global market adoption and technological advancement.

Currently, major standardization bodies such as the International Electrotechnical Commission (IEC), International Organization for Standardization (ISO), and regional entities like UL in North America, CEN in Europe, and GB standards in China operate with different testing protocols and safety requirements for emerging battery technologies. This lack of harmonization creates significant challenges for manufacturers seeking global market access.

The harmonization process requires addressing several critical dimensions of Mg-ion battery standards. Performance metrics need standardization across regions, including capacity retention, cycle life, temperature performance, and self-discharge rates specific to magnesium chemistry. Safety testing protocols must be adapted to account for the unique characteristics of magnesium-ion systems, particularly regarding thermal stability and electrolyte behavior.

Environmental considerations present another area requiring harmonization, with varying regional approaches to recyclability requirements, material restrictions, and end-of-life management. Transportation regulations also differ significantly across jurisdictions, creating logistical complexities for global supply chains.

Recent international efforts have begun addressing these challenges. The Battery Standards Harmonization Initiative, launched in 2022, brings together key stakeholders from North America, Europe, and Asia to develop unified testing methodologies for next-generation battery technologies, including Mg-ion systems. Technical working groups have been established to address specific aspects of standardization, from performance metrics to safety protocols.

Bilateral agreements between standards organizations represent another pathway toward harmonization. The IEC-UL Memorandum of Understanding signed in 2023 specifically addresses emerging battery technologies, creating a framework for mutual recognition of test results and certification processes.

Industry consortia are also playing a crucial role in driving standardization efforts. The Global Battery Alliance and the International Battery Materials Association have established dedicated working groups focused on magnesium-ion technologies, bringing together industry leaders, research institutions, and regulatory bodies to develop consensus-based approaches to qualification standards.

The path toward fully harmonized international standards for Mg-ion batteries will require continued collaboration between regulatory bodies, industry stakeholders, and research institutions. Establishing mutual recognition agreements, developing standardized testing protocols that account for Mg-ion chemistry's unique characteristics, and creating flexible frameworks that can accommodate technological evolution will be essential to supporting the global adoption of this promising energy storage technology.

Currently, major standardization bodies such as the International Electrotechnical Commission (IEC), International Organization for Standardization (ISO), and regional entities like UL in North America, CEN in Europe, and GB standards in China operate with different testing protocols and safety requirements for emerging battery technologies. This lack of harmonization creates significant challenges for manufacturers seeking global market access.

The harmonization process requires addressing several critical dimensions of Mg-ion battery standards. Performance metrics need standardization across regions, including capacity retention, cycle life, temperature performance, and self-discharge rates specific to magnesium chemistry. Safety testing protocols must be adapted to account for the unique characteristics of magnesium-ion systems, particularly regarding thermal stability and electrolyte behavior.

Environmental considerations present another area requiring harmonization, with varying regional approaches to recyclability requirements, material restrictions, and end-of-life management. Transportation regulations also differ significantly across jurisdictions, creating logistical complexities for global supply chains.

Recent international efforts have begun addressing these challenges. The Battery Standards Harmonization Initiative, launched in 2022, brings together key stakeholders from North America, Europe, and Asia to develop unified testing methodologies for next-generation battery technologies, including Mg-ion systems. Technical working groups have been established to address specific aspects of standardization, from performance metrics to safety protocols.

Bilateral agreements between standards organizations represent another pathway toward harmonization. The IEC-UL Memorandum of Understanding signed in 2023 specifically addresses emerging battery technologies, creating a framework for mutual recognition of test results and certification processes.

Industry consortia are also playing a crucial role in driving standardization efforts. The Global Battery Alliance and the International Battery Materials Association have established dedicated working groups focused on magnesium-ion technologies, bringing together industry leaders, research institutions, and regulatory bodies to develop consensus-based approaches to qualification standards.

The path toward fully harmonized international standards for Mg-ion batteries will require continued collaboration between regulatory bodies, industry stakeholders, and research institutions. Establishing mutual recognition agreements, developing standardized testing protocols that account for Mg-ion chemistry's unique characteristics, and creating flexible frameworks that can accommodate technological evolution will be essential to supporting the global adoption of this promising energy storage technology.

Environmental and Sustainability Considerations in Testing

The environmental impact of battery testing procedures has become increasingly important as the magnesium-ion battery industry expands. Current qualification standards must evolve to incorporate sustainability metrics that assess the ecological footprint of both the testing processes and the batteries themselves. Testing laboratories are now implementing waste reduction protocols, with particular emphasis on proper disposal of electrolytes containing magnesium salts, which can have significant environmental implications if improperly managed.

Life cycle assessment (LCA) methodologies are being integrated into magnesium-ion battery testing frameworks to evaluate environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal. These assessments help quantify carbon emissions, resource depletion, and potential toxicity associated with battery production and testing. Notably, magnesium-ion batteries offer potential environmental advantages over lithium-ion alternatives due to the greater abundance and lower extraction impact of magnesium resources.

Energy consumption during testing represents another critical environmental consideration. Extended cycling tests and thermal stability evaluations consume substantial electricity, contributing to the carbon footprint of battery qualification processes. Progressive testing facilities are implementing renewable energy sources and energy-efficient equipment to mitigate these impacts. Some certification bodies are beginning to require energy consumption reporting as part of their qualification protocols.

Water usage in testing procedures presents additional environmental challenges. Cooling systems for abuse testing and cleaning processes can consume significant water resources. Advanced facilities are implementing closed-loop water recycling systems and dry testing alternatives where feasible to reduce consumption. These water conservation measures are increasingly becoming standard requirements in comprehensive battery qualification frameworks.

The recyclability assessment of magnesium-ion batteries is emerging as a key component of environmental testing standards. Evaluations now often include disassembly tests to determine the ease of material recovery and separation. The unique chemistry of magnesium-ion batteries presents both challenges and opportunities for recycling processes, with testing protocols being developed to specifically address the recoverability of magnesium compounds from spent batteries.

Regulatory frameworks worldwide are evolving to incorporate these environmental considerations into mandatory testing requirements. The European Union's Battery Directive is being updated to include specific provisions for magnesium-ion technologies, while similar regulatory developments are occurring in North America and Asia. These emerging standards emphasize reduced environmental impact throughout the battery lifecycle, including during qualification testing phases.

Life cycle assessment (LCA) methodologies are being integrated into magnesium-ion battery testing frameworks to evaluate environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal. These assessments help quantify carbon emissions, resource depletion, and potential toxicity associated with battery production and testing. Notably, magnesium-ion batteries offer potential environmental advantages over lithium-ion alternatives due to the greater abundance and lower extraction impact of magnesium resources.

Energy consumption during testing represents another critical environmental consideration. Extended cycling tests and thermal stability evaluations consume substantial electricity, contributing to the carbon footprint of battery qualification processes. Progressive testing facilities are implementing renewable energy sources and energy-efficient equipment to mitigate these impacts. Some certification bodies are beginning to require energy consumption reporting as part of their qualification protocols.

Water usage in testing procedures presents additional environmental challenges. Cooling systems for abuse testing and cleaning processes can consume significant water resources. Advanced facilities are implementing closed-loop water recycling systems and dry testing alternatives where feasible to reduce consumption. These water conservation measures are increasingly becoming standard requirements in comprehensive battery qualification frameworks.

The recyclability assessment of magnesium-ion batteries is emerging as a key component of environmental testing standards. Evaluations now often include disassembly tests to determine the ease of material recovery and separation. The unique chemistry of magnesium-ion batteries presents both challenges and opportunities for recycling processes, with testing protocols being developed to specifically address the recoverability of magnesium compounds from spent batteries.

Regulatory frameworks worldwide are evolving to incorporate these environmental considerations into mandatory testing requirements. The European Union's Battery Directive is being updated to include specific provisions for magnesium-ion technologies, while similar regulatory developments are occurring in North America and Asia. These emerging standards emphasize reduced environmental impact throughout the battery lifecycle, including during qualification testing phases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!