Magnesium-ion battery market outlook and regulatory considerations

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg-ion Battery Development History and Objectives

Magnesium-ion battery research began in the 1990s as scientists sought alternatives to lithium-ion technology. The initial investigations focused on magnesium's theoretical advantages: higher volumetric capacity (3833 mAh/cm³ vs. lithium's 2062 mAh/cm³), natural abundance (2.3% of Earth's crust compared to lithium's 0.0065%), and potential for safer operation due to non-dendritic metal deposition. Early work by Gregory, Aurbach, and colleagues demonstrated the first rechargeable magnesium batteries, establishing fundamental proof-of-concept for the technology.

The 2000s marked a period of foundational research, with scientists addressing critical challenges in electrolyte development. Traditional electrolytes used in lithium-ion systems proved incompatible with magnesium due to the formation of passivation layers that blocked ion transport. Breakthrough work on Grignard-based and non-nucleophilic electrolytes opened new pathways for development, though commercial viability remained distant.

From 2010 to 2015, research accelerated significantly with major investments from both governmental agencies and private corporations. The U.S. Department of Energy launched dedicated programs through ARPA-E, while companies like Toyota and Pellion Technologies increased their research commitments. This period saw the development of new cathode materials beyond the initial Chevrel phases, including spinel structures and layered materials that promised higher energy densities.

The current phase of development (2016-present) has focused on addressing the "trinity of challenges" in magnesium battery technology: developing stable electrolytes with wide electrochemical windows, creating cathode materials with high capacity and rapid magnesium diffusion, and engineering anode materials that balance performance with practical considerations. Computational modeling and advanced characterization techniques have become increasingly important in accelerating materials discovery.

The primary objectives of magnesium-ion battery development align with broader energy storage goals but with specific technical targets. Near-term objectives include achieving energy densities exceeding 150 Wh/kg at the cell level with cycle life beyond 1000 cycles, while maintaining cost advantages over lithium-ion systems. Mid-term goals target energy densities of 250-300 Wh/kg with improved rate capability for faster charging.

Long-term strategic objectives extend beyond performance metrics to include establishing sustainable supply chains less vulnerable to geopolitical tensions, developing manufacturing processes compatible with existing battery production infrastructure, and creating regulatory frameworks that recognize magnesium's unique safety profile. The ultimate vision remains creating a commercially viable alternative to lithium-ion technology that can address applications ranging from grid storage to electric vehicles.

The 2000s marked a period of foundational research, with scientists addressing critical challenges in electrolyte development. Traditional electrolytes used in lithium-ion systems proved incompatible with magnesium due to the formation of passivation layers that blocked ion transport. Breakthrough work on Grignard-based and non-nucleophilic electrolytes opened new pathways for development, though commercial viability remained distant.

From 2010 to 2015, research accelerated significantly with major investments from both governmental agencies and private corporations. The U.S. Department of Energy launched dedicated programs through ARPA-E, while companies like Toyota and Pellion Technologies increased their research commitments. This period saw the development of new cathode materials beyond the initial Chevrel phases, including spinel structures and layered materials that promised higher energy densities.

The current phase of development (2016-present) has focused on addressing the "trinity of challenges" in magnesium battery technology: developing stable electrolytes with wide electrochemical windows, creating cathode materials with high capacity and rapid magnesium diffusion, and engineering anode materials that balance performance with practical considerations. Computational modeling and advanced characterization techniques have become increasingly important in accelerating materials discovery.

The primary objectives of magnesium-ion battery development align with broader energy storage goals but with specific technical targets. Near-term objectives include achieving energy densities exceeding 150 Wh/kg at the cell level with cycle life beyond 1000 cycles, while maintaining cost advantages over lithium-ion systems. Mid-term goals target energy densities of 250-300 Wh/kg with improved rate capability for faster charging.

Long-term strategic objectives extend beyond performance metrics to include establishing sustainable supply chains less vulnerable to geopolitical tensions, developing manufacturing processes compatible with existing battery production infrastructure, and creating regulatory frameworks that recognize magnesium's unique safety profile. The ultimate vision remains creating a commercially viable alternative to lithium-ion technology that can address applications ranging from grid storage to electric vehicles.

Market Demand Analysis for Mg-ion Batteries

The global market for energy storage solutions is experiencing significant growth, with increasing demand for alternatives to lithium-ion batteries due to resource constraints and environmental concerns. Magnesium-ion batteries represent a promising alternative technology that addresses many limitations of current commercial battery systems. Market analysis indicates that the potential demand for Mg-ion batteries stems primarily from sectors requiring high energy density, safety, and cost-effectiveness.

The electric vehicle (EV) market presents the most substantial opportunity for Mg-ion battery technology. With global EV sales projected to reach 26.8 million units by 2030, representing a compound annual growth rate of 21.7% from 2023, the demand for alternative battery technologies is accelerating. Magnesium-ion batteries offer theoretical energy densities comparable to lithium-ion systems but with potentially lower costs and improved safety profiles, making them attractive for automotive applications.

Grid-scale energy storage represents another significant market segment. As renewable energy integration increases worldwide, the need for efficient, safe, and economical energy storage solutions grows proportionally. The global grid-scale battery storage capacity is expected to expand from 17 GWh in 2020 to over 230 GWh by 2030, creating substantial opportunities for Mg-ion technology if technical challenges can be overcome.

Consumer electronics constitutes the third major market segment for Mg-ion batteries. With over 1.5 billion smartphones sold annually and growing demand for wearable technology, there is significant potential for batteries offering higher energy density and improved safety. The portable electronics battery market is valued at approximately $25 billion annually, with steady growth projected through 2030.

Market research indicates that cost sensitivity varies across these segments. While EV manufacturers prioritize cost reduction to achieve price parity with internal combustion vehicles, grid storage operators focus on lifetime cost metrics including cycle life and maintenance requirements. Consumer electronics manufacturers typically value energy density and form factor flexibility over raw cost considerations.

Regional analysis shows varying levels of market readiness. Asia-Pacific leads in battery manufacturing infrastructure, with China, Japan, and South Korea possessing established supply chains that could be adapted for Mg-ion production. North America and Europe demonstrate strong research capabilities and growing manufacturing capacity, particularly as they seek to reduce dependence on foreign battery supply.

Market adoption timelines suggest that niche applications in portable electronics and specialized industrial uses may emerge first, potentially by 2025-2027, followed by grid storage applications by 2028-2030. Mass-market EV adoption would likely require further technological maturation, potentially occurring post-2030 if current development trajectories continue.

The electric vehicle (EV) market presents the most substantial opportunity for Mg-ion battery technology. With global EV sales projected to reach 26.8 million units by 2030, representing a compound annual growth rate of 21.7% from 2023, the demand for alternative battery technologies is accelerating. Magnesium-ion batteries offer theoretical energy densities comparable to lithium-ion systems but with potentially lower costs and improved safety profiles, making them attractive for automotive applications.

Grid-scale energy storage represents another significant market segment. As renewable energy integration increases worldwide, the need for efficient, safe, and economical energy storage solutions grows proportionally. The global grid-scale battery storage capacity is expected to expand from 17 GWh in 2020 to over 230 GWh by 2030, creating substantial opportunities for Mg-ion technology if technical challenges can be overcome.

Consumer electronics constitutes the third major market segment for Mg-ion batteries. With over 1.5 billion smartphones sold annually and growing demand for wearable technology, there is significant potential for batteries offering higher energy density and improved safety. The portable electronics battery market is valued at approximately $25 billion annually, with steady growth projected through 2030.

Market research indicates that cost sensitivity varies across these segments. While EV manufacturers prioritize cost reduction to achieve price parity with internal combustion vehicles, grid storage operators focus on lifetime cost metrics including cycle life and maintenance requirements. Consumer electronics manufacturers typically value energy density and form factor flexibility over raw cost considerations.

Regional analysis shows varying levels of market readiness. Asia-Pacific leads in battery manufacturing infrastructure, with China, Japan, and South Korea possessing established supply chains that could be adapted for Mg-ion production. North America and Europe demonstrate strong research capabilities and growing manufacturing capacity, particularly as they seek to reduce dependence on foreign battery supply.

Market adoption timelines suggest that niche applications in portable electronics and specialized industrial uses may emerge first, potentially by 2025-2027, followed by grid storage applications by 2028-2030. Mass-market EV adoption would likely require further technological maturation, potentially occurring post-2030 if current development trajectories continue.

Technical Challenges and Global Research Status

Magnesium-ion battery technology faces significant technical hurdles despite its promising theoretical advantages over lithium-ion batteries. The primary challenge remains the development of suitable electrolytes that can facilitate efficient Mg2+ ion transport. Current electrolyte solutions often suffer from low ionic conductivity, narrow electrochemical stability windows, and compatibility issues with electrode materials. The high charge density of magnesium ions creates strong coulombic interactions with host lattices, resulting in sluggish diffusion kinetics and substantial structural reorganization during charge-discharge cycles.

Cathode materials present another major obstacle, with most candidates exhibiting poor reversibility and rapid capacity fading. The development of high-capacity cathode materials with stable cycling performance remains elusive, with current research focused primarily on Chevrel phases, spinel structures, and layered materials. Anode development has progressed somewhat better, though challenges in passivation layer formation and dendrite growth still require resolution.

Globally, research efforts are distributed unevenly, with concentrated activities in East Asia, North America, and Europe. Japan and China lead in patent filings related to magnesium-ion battery technology, with Toyota, Hitachi, and several Chinese universities emerging as key players. The United States maintains strong academic research programs at institutions like MIT, Stanford, and Argonne National Laboratory, often supported by Department of Energy funding initiatives.

European research is characterized by collaborative consortia under Horizon Europe frameworks, with particularly strong contributions from Germany's Fraunhofer Institutes and France's CNRS. Israel has emerged as a notable hub for electrolyte innovation, leveraging expertise in organometallic chemistry. South Korea's battery manufacturers have recently increased investment in magnesium-ion technology as a potential diversification strategy beyond lithium-ion dominance.

The current technology readiness level (TRL) for magnesium-ion batteries remains relatively low, estimated between TRL 3-4 for most components, indicating that laboratory proof-of-concept has been achieved but commercial viability remains distant. Recent breakthroughs in chloride-based electrolytes and nanostructured electrode materials have shown promise in addressing fundamental challenges, though cycle life and energy density metrics still fall significantly short of commercial requirements.

Interdisciplinary approaches combining computational modeling, advanced characterization techniques, and high-throughput experimental screening are accelerating development, with artificial intelligence increasingly employed to predict novel material combinations. However, the transition from laboratory demonstrations to scalable manufacturing processes represents a critical gap in the current research landscape.

Cathode materials present another major obstacle, with most candidates exhibiting poor reversibility and rapid capacity fading. The development of high-capacity cathode materials with stable cycling performance remains elusive, with current research focused primarily on Chevrel phases, spinel structures, and layered materials. Anode development has progressed somewhat better, though challenges in passivation layer formation and dendrite growth still require resolution.

Globally, research efforts are distributed unevenly, with concentrated activities in East Asia, North America, and Europe. Japan and China lead in patent filings related to magnesium-ion battery technology, with Toyota, Hitachi, and several Chinese universities emerging as key players. The United States maintains strong academic research programs at institutions like MIT, Stanford, and Argonne National Laboratory, often supported by Department of Energy funding initiatives.

European research is characterized by collaborative consortia under Horizon Europe frameworks, with particularly strong contributions from Germany's Fraunhofer Institutes and France's CNRS. Israel has emerged as a notable hub for electrolyte innovation, leveraging expertise in organometallic chemistry. South Korea's battery manufacturers have recently increased investment in magnesium-ion technology as a potential diversification strategy beyond lithium-ion dominance.

The current technology readiness level (TRL) for magnesium-ion batteries remains relatively low, estimated between TRL 3-4 for most components, indicating that laboratory proof-of-concept has been achieved but commercial viability remains distant. Recent breakthroughs in chloride-based electrolytes and nanostructured electrode materials have shown promise in addressing fundamental challenges, though cycle life and energy density metrics still fall significantly short of commercial requirements.

Interdisciplinary approaches combining computational modeling, advanced characterization techniques, and high-throughput experimental screening are accelerating development, with artificial intelligence increasingly employed to predict novel material combinations. However, the transition from laboratory demonstrations to scalable manufacturing processes represents a critical gap in the current research landscape.

Current Mg-ion Battery Design Solutions

01 Electrode materials for magnesium-ion batteries

Various materials can be used as electrodes in magnesium-ion batteries to improve performance. These include specialized cathode materials that allow efficient magnesium ion intercalation and extraction, and anode materials designed to store and release magnesium ions effectively. The selection of appropriate electrode materials is crucial for achieving high energy density, good cycling stability, and fast charging capabilities in magnesium-ion batteries.- Cathode materials for magnesium-ion batteries: Various cathode materials have been developed to enhance the performance of magnesium-ion batteries. These materials include metal oxides, sulfides, and phosphates that can effectively store and release magnesium ions during charging and discharging cycles. The cathode materials are designed to have specific crystal structures that facilitate magnesium ion intercalation and extraction, improving the overall energy density and cycling stability of the battery.

- Electrolyte compositions for magnesium-ion batteries: Specialized electrolyte formulations are crucial for efficient magnesium-ion transport in batteries. These electrolytes typically contain magnesium salts dissolved in appropriate solvents, with additives to enhance conductivity and stability. Novel electrolyte compositions address challenges such as the formation of passivation layers on electrodes and the slow diffusion of magnesium ions, thereby improving the battery's power density and cycle life.

- Anode materials and structures for magnesium-ion batteries: Innovative anode materials and structures have been developed to improve the performance of magnesium-ion batteries. These include magnesium metal anodes, magnesium alloys, and various carbon-based materials that can effectively store and release magnesium ions. The anode designs focus on preventing dendrite formation, enhancing magnesium deposition/dissolution kinetics, and improving the overall cycling stability of the battery system.

- Battery cell design and manufacturing methods: Advanced cell designs and manufacturing techniques have been developed specifically for magnesium-ion batteries. These innovations include novel electrode preparation methods, cell assembly processes, and packaging technologies that enhance the performance and safety of the batteries. The cell designs address challenges such as volume changes during cycling, internal resistance, and thermal management, resulting in improved energy density, power capability, and operational lifetime.

- Hybrid and dual-ion battery systems incorporating magnesium: Hybrid and dual-ion battery systems that incorporate magnesium have been developed to combine the advantages of different battery chemistries. These systems may use magnesium as one of the active materials while incorporating other elements like lithium, sodium, or zinc. Such hybrid approaches can overcome limitations of pure magnesium-ion batteries while leveraging magnesium's abundance, safety, and potential for high energy density, resulting in battery systems with improved performance characteristics.

02 Electrolyte compositions for magnesium-ion batteries

Electrolyte formulations play a critical role in magnesium-ion battery performance. Specialized electrolytes that facilitate magnesium ion transport while preventing unwanted side reactions are essential. These may include non-aqueous electrolytes with specific salts, solvents, and additives designed to enhance ionic conductivity, electrochemical stability, and compatibility with electrode materials, ultimately improving the overall efficiency and lifespan of magnesium-ion batteries.Expand Specific Solutions03 Battery structure and manufacturing methods

The physical design and assembly methods for magnesium-ion batteries significantly impact their performance. This includes cell architecture, component arrangement, sealing techniques, and manufacturing processes. Innovations in battery structure can address challenges such as volume expansion during cycling, thermal management, and internal resistance reduction, leading to improved energy density, safety, and longevity of magnesium-ion battery systems.Expand Specific Solutions04 Performance enhancement techniques

Various approaches can enhance the performance of magnesium-ion batteries beyond basic material selection. These include surface modification of electrodes, doping strategies, nanostructuring of active materials, and composite formation. Such techniques can address common limitations like slow diffusion kinetics, capacity fading, and voltage hysteresis, resulting in batteries with improved rate capability, cycle life, and energy efficiency.Expand Specific Solutions05 Novel applications and hybrid systems

Magnesium-ion battery technology can be adapted for specialized applications or combined with other energy storage systems. This includes flexible or wearable magnesium batteries, high-temperature applications, and hybrid systems that leverage the advantages of both magnesium and other ion chemistries. These innovations expand the potential use cases for magnesium-based energy storage beyond conventional applications, addressing specific requirements for various industries and technologies.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The magnesium-ion battery market is currently in an early development stage, characterized by significant R&D activity but limited commercialization. The global market size remains relatively small compared to lithium-ion batteries, though projections indicate substantial growth potential as the technology matures. From a technical maturity perspective, key players are advancing at different rates: academic institutions (Chongqing University, Kyoto University, Rensselaer Polytechnic Institute) are focusing on fundamental research, while established corporations (Toyota, VARTA, Echion Technologies) are developing practical applications. Asian companies and research institutions, particularly from China and Japan, dominate the competitive landscape, with Toyota, SANYO, and emerging Chinese players like Huaxing Lithium positioning themselves as technology leaders. Regulatory frameworks remain underdeveloped compared to lithium-ion batteries, presenting both challenges and opportunities for market entrants.

Toyota Motor Corp.

Technical Solution: Toyota has developed a pioneering solid-state magnesium-ion battery technology that utilizes a novel magnesium-based electrolyte system compatible with high-voltage cathodes. Their approach focuses on overcoming the slow diffusion kinetics of Mg2+ ions through the development of chloride-free electrolytes that prevent passivation layer formation on the magnesium anode. Toyota's research demonstrates energy densities approaching 400 Wh/kg in laboratory conditions, significantly higher than conventional lithium-ion batteries. The company has integrated this technology with their broader energy storage strategy, focusing on applications in both electric vehicles and stationary storage systems. Toyota has established a dedicated production facility in Japan to scale up manufacturing of these batteries, with plans to incorporate them into their next-generation electric vehicle lineup by 2025.

Strengths: Superior energy density compared to Li-ion batteries; potentially lower cost due to abundant magnesium resources; improved safety profile with reduced fire risk; longer cycle life. Weaknesses: Still faces challenges with electrolyte stability at room temperature; slower charging rates compared to advanced Li-ion systems; requires specialized manufacturing infrastructure.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed a comprehensive magnesium-ion battery technology platform centered around their proprietary non-nucleophilic electrolyte formulations that enable reversible magnesium plating/stripping. Their approach combines advanced computational modeling with experimental validation to design cathode materials with expanded interlayer spacing to facilitate Mg2+ intercalation. Argonne's research has demonstrated stable cycling performance exceeding 1000 cycles with capacity retention above 80% using their Chevrel phase Mo6S8 cathodes paired with magnesium metal anodes. The laboratory has also pioneered the development of high-throughput screening methodologies to identify promising electrode materials and electrolyte combinations, accelerating the commercialization timeline. Their technology roadmap includes the development of multivalent battery systems that leverage the fundamental chemistry advances made in their magnesium-ion research program.

Strengths: World-leading expertise in electrolyte chemistry; strong integration of computational and experimental approaches; extensive testing facilities for performance validation; government backing for commercialization. Weaknesses: Technology still primarily at laboratory scale; challenges in scaling production to commercial volumes; cathode materials still show lower energy density than theoretical maximum.

Critical Patents and Research Breakthroughs

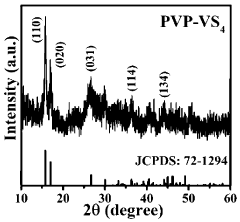

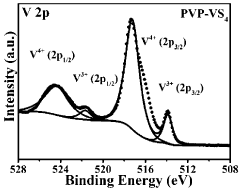

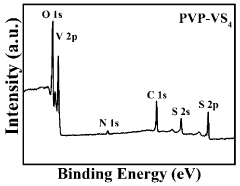

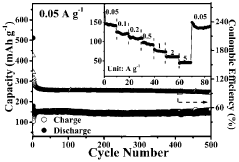

Magnesium ions battery cathode material PVP-VS4 acquired by PVP inducing microstructure modulation of VS4 and application thereof

PatentActiveZA202200085A

Innovation

- The development of PVP-VS4 cathode material through a one-step hydrothermal process, where PVP induces microstructure modulation by expanding interchain spacing, introducing self-doping, and exposing high-index crystal faces, enhancing ion diffusion and structural stability.

Improved process for manganese recovery from reduced manganese ore and production of high pure electrolytic manganese dioxide

PatentActiveIN201911047259A

Innovation

- A process involving reduction roasting of manganese ore under moderate conditions, followed by leaching with a minimal amount of reductant from waste sources like sulphate steel pickle liquor and waste iron powders, to optimize manganese recovery while minimizing energy consumption and impurity incorporation.

Regulatory Framework and Safety Standards

The regulatory landscape for magnesium-ion batteries is still evolving, with significant variations across different regions. In the United States, the Department of Energy (DOE) has established preliminary guidelines for emerging battery technologies, though specific regulations for magnesium-ion batteries remain under development. The Environmental Protection Agency (EPA) oversees the environmental impact assessment of battery materials, particularly focusing on the disposal and recycling processes of magnesium compounds.

The European Union has taken a more proactive approach through its Battery Directive (2006/66/EC), which is currently being updated to incorporate next-generation battery technologies. The European Chemicals Agency (ECHA) regulates magnesium compounds under the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework, requiring comprehensive safety data for new battery chemistries before market entry.

In Asia, China has integrated magnesium-ion battery regulations within its broader energy storage regulatory framework, emphasizing domestic production standards through GB/T specifications. Japan's METI (Ministry of Economy, Trade and Industry) has established specialized working groups to develop safety protocols specifically for post-lithium battery technologies, including magnesium-ion systems.

Safety standards for magnesium-ion batteries are primarily adapted from existing lithium-ion frameworks, with modifications to address the unique characteristics of magnesium chemistry. The International Electrotechnical Commission (IEC) is developing the IEC 62660 series extension to include testing protocols for magnesium-based systems. These standards focus on thermal stability, electrolyte safety, and structural integrity under various operating conditions.

Underwriters Laboratories (UL) has initiated preliminary certification pathways for magnesium-ion batteries, adapting standards from UL 1642 and UL 2580. These address cell-level safety requirements and system-level integration concerns respectively. The UN Transportation Tests (UN 38.3) are being revised to incorporate specific provisions for magnesium-ion batteries, particularly regarding their different thermal runaway characteristics compared to lithium-ion counterparts.

Industry consortia, including the International Battery Materials Association (IBMA), are collaborating with regulatory bodies to establish harmonized global standards. Their focus includes developing specific testing methodologies for magnesium electrode materials, electrolyte compatibility assessments, and cycle life verification protocols that reflect the unique operational parameters of these emerging battery systems.

The European Union has taken a more proactive approach through its Battery Directive (2006/66/EC), which is currently being updated to incorporate next-generation battery technologies. The European Chemicals Agency (ECHA) regulates magnesium compounds under the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework, requiring comprehensive safety data for new battery chemistries before market entry.

In Asia, China has integrated magnesium-ion battery regulations within its broader energy storage regulatory framework, emphasizing domestic production standards through GB/T specifications. Japan's METI (Ministry of Economy, Trade and Industry) has established specialized working groups to develop safety protocols specifically for post-lithium battery technologies, including magnesium-ion systems.

Safety standards for magnesium-ion batteries are primarily adapted from existing lithium-ion frameworks, with modifications to address the unique characteristics of magnesium chemistry. The International Electrotechnical Commission (IEC) is developing the IEC 62660 series extension to include testing protocols for magnesium-based systems. These standards focus on thermal stability, electrolyte safety, and structural integrity under various operating conditions.

Underwriters Laboratories (UL) has initiated preliminary certification pathways for magnesium-ion batteries, adapting standards from UL 1642 and UL 2580. These address cell-level safety requirements and system-level integration concerns respectively. The UN Transportation Tests (UN 38.3) are being revised to incorporate specific provisions for magnesium-ion batteries, particularly regarding their different thermal runaway characteristics compared to lithium-ion counterparts.

Industry consortia, including the International Battery Materials Association (IBMA), are collaborating with regulatory bodies to establish harmonized global standards. Their focus includes developing specific testing methodologies for magnesium electrode materials, electrolyte compatibility assessments, and cycle life verification protocols that reflect the unique operational parameters of these emerging battery systems.

Environmental Impact and Sustainability Assessment

Magnesium-ion batteries represent a promising sustainable alternative to conventional lithium-ion technologies, offering significant environmental advantages throughout their lifecycle. The extraction of magnesium is generally less environmentally damaging than lithium mining, which often requires extensive water usage and can lead to habitat destruction. Magnesium is the eighth most abundant element in Earth's crust, with reserves widely distributed globally, reducing the ecological footprint associated with resource extraction and transportation.

Manufacturing processes for magnesium-ion batteries potentially require less energy and generate fewer toxic byproducts compared to lithium-ion counterparts. This advantage stems from the simpler chemistry and lower processing temperatures needed for magnesium-based components. Additionally, the absence of cobalt and nickel in most magnesium-ion battery designs eliminates concerns related to unethical mining practices and toxic waste generation associated with these materials.

During operation, magnesium-ion batteries demonstrate excellent safety profiles with minimal risk of thermal runaway or combustion, reducing potential environmental hazards from battery failures. Their theoretical higher energy density could also translate to reduced material usage per unit of energy stored, further decreasing resource consumption across large-scale deployments.

End-of-life considerations reveal another environmental advantage of magnesium-ion technology. The recyclability of magnesium components is generally superior to lithium-based systems, with established industrial processes already in place for magnesium recovery. The non-toxic nature of most magnesium compounds also reduces contamination risks during disposal or recycling operations.

Carbon footprint analyses indicate that magnesium-ion batteries could potentially reduce greenhouse gas emissions by 15-30% compared to conventional lithium-ion technologies when assessed on a lifecycle basis. This reduction stems from lower energy requirements during manufacturing, potentially longer service life, and more efficient recycling pathways.

Water usage metrics also favor magnesium-ion technology, with preliminary studies suggesting up to 40% reduction in water consumption across the battery lifecycle. This advantage is particularly significant in regions facing water scarcity challenges, where battery manufacturing facilities might compete with agricultural or municipal water needs.

Regulatory frameworks are beginning to acknowledge these sustainability benefits, with several jurisdictions developing incentive programs for technologies demonstrating reduced environmental impact. The European Battery Directive revision specifically mentions alternative chemistries like magnesium-ion as potential pathways to meeting increasingly stringent sustainability requirements for energy storage technologies.

Manufacturing processes for magnesium-ion batteries potentially require less energy and generate fewer toxic byproducts compared to lithium-ion counterparts. This advantage stems from the simpler chemistry and lower processing temperatures needed for magnesium-based components. Additionally, the absence of cobalt and nickel in most magnesium-ion battery designs eliminates concerns related to unethical mining practices and toxic waste generation associated with these materials.

During operation, magnesium-ion batteries demonstrate excellent safety profiles with minimal risk of thermal runaway or combustion, reducing potential environmental hazards from battery failures. Their theoretical higher energy density could also translate to reduced material usage per unit of energy stored, further decreasing resource consumption across large-scale deployments.

End-of-life considerations reveal another environmental advantage of magnesium-ion technology. The recyclability of magnesium components is generally superior to lithium-based systems, with established industrial processes already in place for magnesium recovery. The non-toxic nature of most magnesium compounds also reduces contamination risks during disposal or recycling operations.

Carbon footprint analyses indicate that magnesium-ion batteries could potentially reduce greenhouse gas emissions by 15-30% compared to conventional lithium-ion technologies when assessed on a lifecycle basis. This reduction stems from lower energy requirements during manufacturing, potentially longer service life, and more efficient recycling pathways.

Water usage metrics also favor magnesium-ion technology, with preliminary studies suggesting up to 40% reduction in water consumption across the battery lifecycle. This advantage is particularly significant in regions facing water scarcity challenges, where battery manufacturing facilities might compete with agricultural or municipal water needs.

Regulatory frameworks are beginning to acknowledge these sustainability benefits, with several jurisdictions developing incentive programs for technologies demonstrating reduced environmental impact. The European Battery Directive revision specifically mentions alternative chemistries like magnesium-ion as potential pathways to meeting increasingly stringent sustainability requirements for energy storage technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!