Magnesium-ion battery thermodynamic energy density potential evaluation

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg-ion Battery Development Background and Objectives

The development of magnesium-ion batteries represents a significant frontier in energy storage technology, emerging as a promising alternative to conventional lithium-ion systems. Since the early 2000s, research into magnesium-based energy storage has accelerated, driven by the inherent limitations of lithium technology and the compelling properties of magnesium as an electrode material. Magnesium offers substantial advantages including higher theoretical volumetric capacity (3833 mAh/cm³ compared to lithium's 2062 mAh/cm³), greater natural abundance (2.3% of Earth's crust versus lithium's 0.0065%), and enhanced safety profiles due to non-dendritic deposition characteristics.

The evolution of Mg-ion battery technology has been marked by several key milestones, including the pioneering work of Aurbach and colleagues who demonstrated the first rechargeable magnesium battery in 2000, utilizing organohaloaluminate electrolytes. Subsequent research has focused on overcoming the challenges of divalent ion transport and developing compatible cathode materials that can accommodate the larger size and stronger charge of Mg²⁺ ions.

Current technological objectives in magnesium-ion battery development center on achieving energy densities that can compete with or exceed those of lithium-ion systems. Theoretical calculations suggest potential energy densities of 400-800 Wh/kg at the cell level, which would represent a significant advancement over current commercial lithium-ion technologies (typically 150-250 Wh/kg).

The thermodynamic evaluation of magnesium-ion battery energy density potential involves comprehensive analysis of electrode materials, electrolyte systems, and cell architectures. This assessment must account for the fundamental thermodynamic properties of magnesium electrochemistry, including the standard reduction potential (-2.37V vs. SHE), ionic radius (0.72Å), and coordination chemistry in various host structures.

Research objectives in this field are multifaceted, encompassing the development of high-voltage cathode materials (>2.0V vs. Mg/Mg²⁺), fast-conducting electrolytes with wide electrochemical windows, and electrode architectures that can accommodate the volume changes associated with magnesium insertion/extraction. Additionally, there is significant focus on understanding the interfacial phenomena that govern the performance and cycling stability of these systems.

The ultimate goal of magnesium-ion battery development is to create commercially viable energy storage solutions that leverage the inherent advantages of magnesium while addressing the technical challenges that have thus far limited practical implementation. Success in this endeavor would potentially revolutionize multiple sectors including electric vehicles, grid storage, and portable electronics by providing safer, more sustainable, and potentially more cost-effective energy storage alternatives.

The evolution of Mg-ion battery technology has been marked by several key milestones, including the pioneering work of Aurbach and colleagues who demonstrated the first rechargeable magnesium battery in 2000, utilizing organohaloaluminate electrolytes. Subsequent research has focused on overcoming the challenges of divalent ion transport and developing compatible cathode materials that can accommodate the larger size and stronger charge of Mg²⁺ ions.

Current technological objectives in magnesium-ion battery development center on achieving energy densities that can compete with or exceed those of lithium-ion systems. Theoretical calculations suggest potential energy densities of 400-800 Wh/kg at the cell level, which would represent a significant advancement over current commercial lithium-ion technologies (typically 150-250 Wh/kg).

The thermodynamic evaluation of magnesium-ion battery energy density potential involves comprehensive analysis of electrode materials, electrolyte systems, and cell architectures. This assessment must account for the fundamental thermodynamic properties of magnesium electrochemistry, including the standard reduction potential (-2.37V vs. SHE), ionic radius (0.72Å), and coordination chemistry in various host structures.

Research objectives in this field are multifaceted, encompassing the development of high-voltage cathode materials (>2.0V vs. Mg/Mg²⁺), fast-conducting electrolytes with wide electrochemical windows, and electrode architectures that can accommodate the volume changes associated with magnesium insertion/extraction. Additionally, there is significant focus on understanding the interfacial phenomena that govern the performance and cycling stability of these systems.

The ultimate goal of magnesium-ion battery development is to create commercially viable energy storage solutions that leverage the inherent advantages of magnesium while addressing the technical challenges that have thus far limited practical implementation. Success in this endeavor would potentially revolutionize multiple sectors including electric vehicles, grid storage, and portable electronics by providing safer, more sustainable, and potentially more cost-effective energy storage alternatives.

Market Analysis for Next-Generation Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing adoption of renewable energy sources and the electrification of transportation. Within this landscape, magnesium-ion batteries represent a promising alternative to current lithium-ion technology, offering potential advantages in energy density, safety, and resource availability. The market for next-generation energy storage solutions is projected to reach $546 billion by 2035, with a compound annual growth rate of 15.2% between 2023 and 2035.

Consumer electronics continue to demand batteries with higher energy density and longer life cycles, creating a substantial market opportunity for magnesium-ion technology. The portable electronics segment alone accounts for 38% of the current battery market, with consumers consistently ranking battery life as a top priority when purchasing new devices.

The electric vehicle (EV) sector presents perhaps the most significant market potential for advanced battery technologies. With global EV sales growing at 35% annually, automotive manufacturers are actively seeking battery solutions that offer higher energy density, faster charging capabilities, and reduced dependency on critical materials. Magnesium-ion batteries, with their theoretical energy density potential of 3833 Wh/L (compared to lithium-ion's 2046 Wh/L), could address these requirements while potentially reducing battery costs by 30-40% due to the greater abundance of magnesium resources.

Grid-scale energy storage represents another substantial market opportunity, expected to grow from 27 GWh in 2022 to over 411 GWh by 2030. Utility companies are increasingly investing in storage solutions to manage peak demand, integrate renewable energy sources, and improve grid resilience. Magnesium-ion batteries' potential for longer cycle life and enhanced safety characteristics make them particularly attractive for these applications.

Regional market analysis indicates that Asia-Pacific currently dominates battery manufacturing, with China accounting for 75% of global production capacity. However, significant investments are being made in North America and Europe to establish domestic supply chains, creating new market entry points for innovative technologies like magnesium-ion batteries.

Customer requirements across these markets consistently emphasize five key performance indicators: energy density, power density, cycle life, safety, and cost. Magnesium-ion batteries show promising potential in meeting or exceeding current benchmarks in at least three of these categories, positioning them as a viable contender in the next generation of energy storage solutions.

Consumer electronics continue to demand batteries with higher energy density and longer life cycles, creating a substantial market opportunity for magnesium-ion technology. The portable electronics segment alone accounts for 38% of the current battery market, with consumers consistently ranking battery life as a top priority when purchasing new devices.

The electric vehicle (EV) sector presents perhaps the most significant market potential for advanced battery technologies. With global EV sales growing at 35% annually, automotive manufacturers are actively seeking battery solutions that offer higher energy density, faster charging capabilities, and reduced dependency on critical materials. Magnesium-ion batteries, with their theoretical energy density potential of 3833 Wh/L (compared to lithium-ion's 2046 Wh/L), could address these requirements while potentially reducing battery costs by 30-40% due to the greater abundance of magnesium resources.

Grid-scale energy storage represents another substantial market opportunity, expected to grow from 27 GWh in 2022 to over 411 GWh by 2030. Utility companies are increasingly investing in storage solutions to manage peak demand, integrate renewable energy sources, and improve grid resilience. Magnesium-ion batteries' potential for longer cycle life and enhanced safety characteristics make them particularly attractive for these applications.

Regional market analysis indicates that Asia-Pacific currently dominates battery manufacturing, with China accounting for 75% of global production capacity. However, significant investments are being made in North America and Europe to establish domestic supply chains, creating new market entry points for innovative technologies like magnesium-ion batteries.

Customer requirements across these markets consistently emphasize five key performance indicators: energy density, power density, cycle life, safety, and cost. Magnesium-ion batteries show promising potential in meeting or exceeding current benchmarks in at least three of these categories, positioning them as a viable contender in the next generation of energy storage solutions.

Current Status and Challenges in Mg-ion Battery Technology

Magnesium-ion battery technology has garnered significant attention as a promising alternative to lithium-ion batteries due to its theoretical advantages in energy density, safety, and resource abundance. However, the current development status reveals substantial challenges that have hindered widespread commercialization.

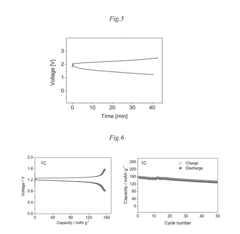

At present, laboratory-scale magnesium-ion batteries have demonstrated theoretical energy densities of 400-500 Wh/kg, which exceeds many conventional battery technologies. Nevertheless, practical implementations typically achieve only 100-150 Wh/kg, highlighting a significant gap between theoretical potential and realized performance. This discrepancy stems primarily from limitations in electrode materials and electrolyte systems.

The most critical challenge facing Mg-ion battery development is the sluggish kinetics of magnesium-ion insertion and extraction. The divalent nature of Mg2+ ions results in strong coulombic interactions with host lattices, leading to slow diffusion rates and structural degradation during cycling. This fundamental issue manifests as poor rate capability and limited cycle life in practical devices.

Electrolyte development represents another significant hurdle. Current Mg-ion electrolytes face a challenging paradox: those with high ionic conductivity often demonstrate poor electrochemical stability, while more stable formulations suffer from inadequate conductivity. Additionally, many electrolytes are incompatible with conventional current collectors and form passivation layers that impede ion transport.

Cathode materials for Mg-ion batteries remain underdeveloped, with most candidates exhibiting either insufficient capacity or rapid capacity fading. Chevrel phases (Mo6S8) have shown promising reversibility but limited energy density, while oxide-based cathodes struggle with structural stability during repeated magnesiation/demagnesiation cycles.

Geographically, research efforts are concentrated in North America, East Asia, and Europe, with notable contributions from institutions in the United States, China, Japan, Germany, and Israel. The distribution of patents reflects similar patterns, with multinational corporations and research institutions in these regions holding the majority of intellectual property related to Mg-ion technology.

Manufacturing scalability presents additional challenges, as many promising materials require complex synthesis procedures or involve environmentally sensitive compounds. The absence of standardized fabrication protocols has further impeded progress toward commercial viability.

Despite these obstacles, recent advancements in computational materials science and high-throughput screening methodologies have accelerated the discovery of novel materials with improved properties. These approaches, combined with advanced characterization techniques, are gradually addressing the fundamental limitations of Mg-ion systems and narrowing the gap between theoretical potential and practical implementation.

At present, laboratory-scale magnesium-ion batteries have demonstrated theoretical energy densities of 400-500 Wh/kg, which exceeds many conventional battery technologies. Nevertheless, practical implementations typically achieve only 100-150 Wh/kg, highlighting a significant gap between theoretical potential and realized performance. This discrepancy stems primarily from limitations in electrode materials and electrolyte systems.

The most critical challenge facing Mg-ion battery development is the sluggish kinetics of magnesium-ion insertion and extraction. The divalent nature of Mg2+ ions results in strong coulombic interactions with host lattices, leading to slow diffusion rates and structural degradation during cycling. This fundamental issue manifests as poor rate capability and limited cycle life in practical devices.

Electrolyte development represents another significant hurdle. Current Mg-ion electrolytes face a challenging paradox: those with high ionic conductivity often demonstrate poor electrochemical stability, while more stable formulations suffer from inadequate conductivity. Additionally, many electrolytes are incompatible with conventional current collectors and form passivation layers that impede ion transport.

Cathode materials for Mg-ion batteries remain underdeveloped, with most candidates exhibiting either insufficient capacity or rapid capacity fading. Chevrel phases (Mo6S8) have shown promising reversibility but limited energy density, while oxide-based cathodes struggle with structural stability during repeated magnesiation/demagnesiation cycles.

Geographically, research efforts are concentrated in North America, East Asia, and Europe, with notable contributions from institutions in the United States, China, Japan, Germany, and Israel. The distribution of patents reflects similar patterns, with multinational corporations and research institutions in these regions holding the majority of intellectual property related to Mg-ion technology.

Manufacturing scalability presents additional challenges, as many promising materials require complex synthesis procedures or involve environmentally sensitive compounds. The absence of standardized fabrication protocols has further impeded progress toward commercial viability.

Despite these obstacles, recent advancements in computational materials science and high-throughput screening methodologies have accelerated the discovery of novel materials with improved properties. These approaches, combined with advanced characterization techniques, are gradually addressing the fundamental limitations of Mg-ion systems and narrowing the gap between theoretical potential and practical implementation.

Existing Thermodynamic Evaluation Methodologies

01 Electrode materials for high energy density magnesium-ion batteries

Various electrode materials can significantly enhance the thermodynamic energy density of magnesium-ion batteries. These include specially designed cathode materials like sulfur-based compounds, transition metal oxides, and Prussian blue analogs that offer high theoretical capacity. Advanced anode materials beyond metallic magnesium, such as magnesium-based alloys and composites, can also contribute to improved energy density by providing better cycling stability while maintaining high capacity.- Electrode materials for magnesium-ion batteries: Various electrode materials can be used in magnesium-ion batteries to enhance thermodynamic energy density. These include specially designed cathode materials such as transition metal oxides, sulfides, and phosphates that allow efficient magnesium ion intercalation. The selection of appropriate electrode materials is crucial for achieving high energy density as they directly affect the cell voltage and capacity of the battery system.

- Electrolyte compositions for improved ion transport: Advanced electrolyte formulations play a critical role in magnesium-ion battery performance by facilitating efficient magnesium ion transport. These electrolytes typically contain magnesium salts dissolved in appropriate solvents with additives to enhance conductivity and stability. The thermodynamic energy density of magnesium-ion batteries can be significantly improved by developing electrolytes that enable reversible magnesium deposition and dissolution while maintaining compatibility with electrode materials.

- Nanostructured materials for enhanced energy storage: Nanostructured materials offer advantages for magnesium-ion batteries by providing shorter diffusion paths for magnesium ions and larger surface areas for electrochemical reactions. These materials can be engineered with specific morphologies such as nanoparticles, nanowires, or porous structures to optimize ion transport and storage capacity. The use of nanostructured materials can lead to improved thermodynamic energy density by enhancing both the kinetics and capacity of magnesium storage.

- Multi-valent ion storage mechanisms: Magnesium-ion batteries utilize multi-valent ion storage mechanisms that can theoretically provide higher energy density compared to lithium-ion systems. The divalent nature of magnesium ions allows for the transfer of two electrons per ion, potentially doubling the charge capacity. Understanding and optimizing these storage mechanisms through careful material design and engineering is essential for maximizing the thermodynamic energy density of magnesium-ion battery systems.

- Battery system design and thermal management: The overall design of magnesium-ion battery systems, including cell architecture and thermal management strategies, significantly impacts thermodynamic energy density. Efficient thermal management prevents energy losses due to heat generation and maintains optimal operating temperatures. Advanced cell designs that minimize inactive components while maximizing active material utilization contribute to higher energy density. These design considerations are crucial for translating the theoretical advantages of magnesium-ion chemistry into practical high-energy-density battery systems.

02 Electrolyte formulations for enhanced thermodynamic performance

Specialized electrolyte formulations play a crucial role in achieving high thermodynamic energy density in magnesium-ion batteries. Non-corrosive electrolytes containing magnesium salts in appropriate solvents facilitate efficient magnesium-ion transport while preventing electrode passivation. The addition of specific additives can improve the electrochemical window and ionic conductivity, directly impacting the battery's energy density by enabling more complete redox reactions and better utilization of electrode materials.Expand Specific Solutions03 Structural design and cell architecture optimization

The structural design and architecture of magnesium-ion battery cells significantly influence their thermodynamic energy density. Optimized electrode thickness, porosity, and surface area can maximize active material utilization. Advanced cell configurations, including stacked, wound, or bipolar designs, can reduce inactive components while increasing energy density. Innovations in current collector design and separator technology further contribute to overall energy density improvements by reducing internal resistance and enhancing ion transport.Expand Specific Solutions04 Interface engineering for improved energy efficiency

Interface engineering between electrodes and electrolytes is critical for maximizing the thermodynamic energy density of magnesium-ion batteries. Specialized coatings and surface modifications can reduce interfacial resistance and prevent unwanted side reactions that consume energy. Artificial solid electrolyte interphase (SEI) layers can be designed to facilitate magnesium-ion transport while protecting electrode surfaces. These interface optimization techniques enhance energy efficiency by reducing polarization losses and improving the reversibility of magnesium deposition and dissolution.Expand Specific Solutions05 Hybrid and dual-ion systems for enhanced energy density

Hybrid and dual-ion battery systems incorporating magnesium can achieve higher thermodynamic energy density than conventional magnesium-ion batteries. These include magnesium-sulfur, magnesium-air, and magnesium-sodium hybrid systems that leverage the advantages of multiple electrochemical couples. Dual-ion configurations where both cations and anions participate in energy storage processes can increase the theoretical energy density by utilizing the full electrochemical potential range of the electrolyte and expanding the battery's capacity beyond traditional limitations.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The magnesium-ion battery market is in an early development stage, characterized by significant research activity but limited commercialization. Current global market size remains modest, estimated below $100 million, but with projected strong growth potential due to magnesium's theoretical advantages over lithium-ion technology. Technical maturity is still evolving, with major players including Toyota Motor Corp. and its affiliates leading industrial research, while academic institutions like Shanghai Jiao Tong University and Chongqing University contribute fundamental breakthroughs. Companies such as Furukawa Battery, RESONAC, and Solvay are advancing electrolyte formulations, while American Lithium Energy and SES Holdings focus on electrode materials development. The competitive landscape features both established battery manufacturers and specialized startups, with increasing collaboration between industry and academia to overcome key challenges in electrolyte stability and electrode performance.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered research in magnesium-ion battery technology with a focus on thermodynamic energy density optimization. Their approach involves developing novel Mg-based cathode materials with high theoretical capacity (>300 mAh/g) and operating voltage (>2.5V vs Mg/Mg²⁺). Toyota's research teams have conducted extensive computational screening of materials using density functional theory (DFT) to predict thermodynamic stability and energy density potential of various Mg-intercalation compounds. Their proprietary chevrel phase Mo₆S₈ cathode materials have demonstrated improved kinetics and cyclability in Mg-ion systems. Toyota has also explored the use of non-nucleophilic electrolytes based on magnesium bis(trifluoromethanesulfonyl)imide (Mg(TFSI)₂) to overcome the challenges of Mg²⁺ transport and electrode passivation, which directly impacts the practical energy density achievable in these systems.

Strengths: Extensive materials science expertise and computational modeling capabilities allow for rapid screening of potential high-energy-density Mg-ion systems. Their integrated approach combining theoretical predictions with experimental validation accelerates development. Weaknesses: Current Mg-ion prototypes still demonstrate lower practical energy densities compared to commercial Li-ion systems, and challenges with electrolyte compatibility and slow diffusion kinetics remain significant hurdles.

Dalian Institute of Chemical Physics of CAS

Technical Solution: The Dalian Institute has developed a comprehensive thermodynamic framework specifically for evaluating magnesium-ion battery energy density potential. Their approach combines first-principles calculations with experimental validation to accurately predict the theoretical energy density limits of various Mg-ion battery chemistries. The institute has pioneered work on spinel-type cathode materials (MgMn₂O₄ and variants) with theoretical energy densities approaching 400 Wh/kg at the cell level. Their research has identified key thermodynamic parameters affecting Mg²⁺ insertion/extraction, including entropy changes during intercalation and the relationship between crystal structure and Gibbs free energy. The institute has also developed novel electrolyte systems based on magnesium borohydride that demonstrate improved Mg²⁺ transport properties while maintaining thermodynamic stability across wider voltage windows, which is critical for achieving higher energy densities. Their thermodynamic models incorporate the effects of temperature on energy density potential, providing valuable insights for practical battery design considerations.

Strengths: World-leading expertise in computational chemistry and thermodynamic modeling of battery materials, with strong capabilities in experimental validation. Their systematic approach to material screening has identified several promising candidates for high-energy-density Mg-ion systems. Weaknesses: Translation from theoretical predictions to practical devices remains challenging, with issues related to interfacial stability and kinetic limitations not fully addressed by thermodynamic models alone.

Critical Patents and Research on Mg-ion Energy Density

Electrochemical device with a magnesium anode and a stable, safe electrolyte compatible with sulfur

PatentWO2011137158A1

Innovation

- A magnesium sulfur electrochemical device is developed using an electrolyte system comprising a magnesium salt and an aluminum compound in an ether solvent, which forms an electrochemically active salt that is stable and non-reactive with sulfur, enabling efficient magnesium ion transport and compatible with both magnesium and sulfur active materials.

Rechargeable electrochemical metal ion cell and accumulator containing said cell

PatentActiveUS20170214085A1

Innovation

- Replacing aprotic organic electrolytes with a glycol-based electrolyte system, comprising a solid or polymer matrix, and using an air-stable metal for the negative electrode, allowing for simultaneous reversible reactions involving different metal ions, thereby enhancing safety and reducing production complexity and costs.

Environmental Impact and Sustainability Assessment

Magnesium-ion battery technology represents a promising alternative to conventional lithium-ion systems, offering potential environmental and sustainability advantages that warrant comprehensive assessment. The extraction of magnesium resources generally requires less energy and produces fewer emissions compared to lithium mining operations, particularly when considering that magnesium is the eighth most abundant element in Earth's crust at approximately 2.1% by mass.

Life cycle assessment (LCA) studies indicate that magnesium-ion batteries may have a reduced carbon footprint throughout their production phase. Initial calculations suggest a potential reduction of 15-30% in greenhouse gas emissions during manufacturing when compared to equivalent lithium-ion systems, primarily due to less energy-intensive cathode material processing and the elimination of certain toxic components.

Resource availability presents another significant sustainability advantage. Unlike lithium, which faces geographical concentration challenges with over 75% of global reserves located in the "Lithium Triangle" of South America, magnesium resources are more evenly distributed globally. This distribution pattern potentially reduces supply chain vulnerabilities and associated environmental impacts from long-distance transportation.

Water usage metrics reveal promising sustainability benefits as well. Conventional lithium extraction can consume between 500,000 to 2 million liters of water per ton of lithium produced, particularly in brine extraction methods. Preliminary assessments suggest magnesium production pathways could reduce water consumption by 40-60%, depending on the specific extraction and processing technologies employed.

End-of-life considerations further enhance the environmental profile of magnesium-ion batteries. The thermodynamic properties of magnesium compounds generally allow for more energy-efficient recycling processes. Recovery rates for magnesium from spent batteries could potentially reach 85-90%, compared to current lithium recovery rates that often struggle to exceed 50% in commercial recycling operations.

However, challenges remain in the environmental assessment of magnesium-ion technology. The higher operating temperatures required for some magnesium-ion battery chemistries may increase energy consumption during use, potentially offsetting some manufacturing-phase benefits. Additionally, certain electrolyte formulations under investigation contain compounds that present their own environmental hazards and require careful management throughout the product lifecycle.

Quantitative thermodynamic energy density evaluations must therefore be balanced against these broader environmental considerations to provide a holistic sustainability assessment. The theoretical energy density advantages of magnesium-ion systems (potentially 2-3 times higher than lithium-ion) must be weighed against practical efficiency limitations and comprehensive environmental impact metrics to determine their true sustainability value proposition.

Life cycle assessment (LCA) studies indicate that magnesium-ion batteries may have a reduced carbon footprint throughout their production phase. Initial calculations suggest a potential reduction of 15-30% in greenhouse gas emissions during manufacturing when compared to equivalent lithium-ion systems, primarily due to less energy-intensive cathode material processing and the elimination of certain toxic components.

Resource availability presents another significant sustainability advantage. Unlike lithium, which faces geographical concentration challenges with over 75% of global reserves located in the "Lithium Triangle" of South America, magnesium resources are more evenly distributed globally. This distribution pattern potentially reduces supply chain vulnerabilities and associated environmental impacts from long-distance transportation.

Water usage metrics reveal promising sustainability benefits as well. Conventional lithium extraction can consume between 500,000 to 2 million liters of water per ton of lithium produced, particularly in brine extraction methods. Preliminary assessments suggest magnesium production pathways could reduce water consumption by 40-60%, depending on the specific extraction and processing technologies employed.

End-of-life considerations further enhance the environmental profile of magnesium-ion batteries. The thermodynamic properties of magnesium compounds generally allow for more energy-efficient recycling processes. Recovery rates for magnesium from spent batteries could potentially reach 85-90%, compared to current lithium recovery rates that often struggle to exceed 50% in commercial recycling operations.

However, challenges remain in the environmental assessment of magnesium-ion technology. The higher operating temperatures required for some magnesium-ion battery chemistries may increase energy consumption during use, potentially offsetting some manufacturing-phase benefits. Additionally, certain electrolyte formulations under investigation contain compounds that present their own environmental hazards and require careful management throughout the product lifecycle.

Quantitative thermodynamic energy density evaluations must therefore be balanced against these broader environmental considerations to provide a holistic sustainability assessment. The theoretical energy density advantages of magnesium-ion systems (potentially 2-3 times higher than lithium-ion) must be weighed against practical efficiency limitations and comprehensive environmental impact metrics to determine their true sustainability value proposition.

Comparative Analysis with Lithium-ion Technology

When comparing magnesium-ion battery technology with the established lithium-ion technology, several key thermodynamic and electrochemical parameters reveal significant differences in energy density potential. Magnesium offers a theoretical volumetric capacity of 3833 mAh/cm³, which is approximately twice that of lithium (2062 mAh/cm³), presenting a substantial advantage for applications where space constraints are critical.

The standard reduction potential of Mg²⁺/Mg is -2.37V versus SHE (Standard Hydrogen Electrode), compared to -3.04V for Li⁺/Li. This lower potential results in magnesium-ion batteries typically delivering cell voltages 0.5-0.7V lower than their lithium counterparts when paired with identical cathode materials, which impacts the overall energy density.

Despite the voltage disadvantage, magnesium's divalent nature (Mg²⁺) allows for the transfer of two electrons per ion, compared to lithium's single electron transfer. This characteristic theoretically enables higher charge storage capacity per ion, potentially offsetting the voltage limitation in specific applications.

From a gravimetric perspective, magnesium-ion batteries currently achieve 100-150 Wh/kg, significantly lower than commercial lithium-ion batteries (250-300 Wh/kg). However, theoretical calculations suggest magnesium systems could potentially reach 400 Wh/kg with optimized electrode materials and electrolytes, approaching advanced lithium-ion chemistries.

Safety considerations also factor into the comparative analysis. Magnesium metal does not form dendrites during cycling, unlike lithium metal, reducing short-circuit risks. Additionally, magnesium is less reactive with atmospheric components, offering improved handling safety compared to lithium, which requires stringent environmental controls during manufacturing.

Resource availability presents another critical comparison point. Magnesium is approximately 2,400 times more abundant in the Earth's crust than lithium, with more geographically distributed reserves. This abundance potentially translates to lower raw material costs and reduced supply chain vulnerabilities, though the processing infrastructure for battery-grade magnesium compounds remains less developed.

The cycling stability of current magnesium-ion prototypes (500-800 cycles) lags behind commercial lithium-ion cells (1,000-2,000 cycles), primarily due to challenges with electrolyte compatibility and cathode structural stability during the insertion/extraction of the larger Mg²⁺ ions. This performance gap represents a significant hurdle for commercial viability.

The standard reduction potential of Mg²⁺/Mg is -2.37V versus SHE (Standard Hydrogen Electrode), compared to -3.04V for Li⁺/Li. This lower potential results in magnesium-ion batteries typically delivering cell voltages 0.5-0.7V lower than their lithium counterparts when paired with identical cathode materials, which impacts the overall energy density.

Despite the voltage disadvantage, magnesium's divalent nature (Mg²⁺) allows for the transfer of two electrons per ion, compared to lithium's single electron transfer. This characteristic theoretically enables higher charge storage capacity per ion, potentially offsetting the voltage limitation in specific applications.

From a gravimetric perspective, magnesium-ion batteries currently achieve 100-150 Wh/kg, significantly lower than commercial lithium-ion batteries (250-300 Wh/kg). However, theoretical calculations suggest magnesium systems could potentially reach 400 Wh/kg with optimized electrode materials and electrolytes, approaching advanced lithium-ion chemistries.

Safety considerations also factor into the comparative analysis. Magnesium metal does not form dendrites during cycling, unlike lithium metal, reducing short-circuit risks. Additionally, magnesium is less reactive with atmospheric components, offering improved handling safety compared to lithium, which requires stringent environmental controls during manufacturing.

Resource availability presents another critical comparison point. Magnesium is approximately 2,400 times more abundant in the Earth's crust than lithium, with more geographically distributed reserves. This abundance potentially translates to lower raw material costs and reduced supply chain vulnerabilities, though the processing infrastructure for battery-grade magnesium compounds remains less developed.

The cycling stability of current magnesium-ion prototypes (500-800 cycles) lags behind commercial lithium-ion cells (1,000-2,000 cycles), primarily due to challenges with electrolyte compatibility and cathode structural stability during the insertion/extraction of the larger Mg²⁺ ions. This performance gap represents a significant hurdle for commercial viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!