Research on magnesium-ion battery scalability for industrial production

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg-ion Battery Development History and Objectives

Magnesium-ion battery research began in the 1990s as scientists sought alternatives to lithium-ion technology. The initial investigations focused primarily on fundamental electrochemistry, with researchers exploring magnesium's theoretical advantages including its divalent nature, higher volumetric capacity (3833 mAh/cm³ vs. lithium's 2062 mAh/cm³), and greater natural abundance. Early work by Gregory, Aurbach, and colleagues established the foundational understanding of magnesium electrochemistry and identified key challenges in electrolyte development.

The 2000s marked a period of significant advancement in electrolyte chemistry, with the development of Grignard-based and non-nucleophilic electrolytes that demonstrated improved compatibility with cathode materials. This era also saw the first prototype cells, though these devices exhibited limited cycling stability and energy density compared to commercial lithium-ion batteries.

From 2010 to 2020, research focus shifted toward addressing the persistent challenges of slow diffusion kinetics in cathode materials and the development of practical electrolytes that could enable reversible magnesium deposition without passivation layer formation. Notable breakthroughs included the discovery of spinel-type cathodes and the development of chloride-free electrolytes with wider electrochemical windows.

The current technological landscape shows magnesium-ion batteries still firmly in the research phase, with laboratory-scale demonstrations achieving energy densities of 100-150 Wh/kg, significantly below the 250-300 Wh/kg of commercial lithium-ion cells. Cycle life remains limited to several hundred cycles under optimal conditions, compared to thousands for lithium-ion technology.

The primary objectives for industrial scalability research include developing cathode materials with faster Mg²⁺ diffusion kinetics, creating stable electrolytes compatible with both anode and cathode materials, and designing cell architectures that can accommodate the unique characteristics of magnesium electrochemistry. Specific performance targets include achieving energy densities exceeding 200 Wh/kg, cycle life beyond 1000 cycles, and charge rates comparable to lithium-ion batteries.

Additional objectives focus on establishing scalable manufacturing processes that can leverage existing battery production infrastructure while accommodating the unique requirements of magnesium-based systems. This includes developing electrode formulations suitable for high-volume coating processes, electrolyte handling systems compatible with industrial safety standards, and quality control protocols specific to magnesium battery components.

The ultimate goal is to position magnesium-ion technology as a viable alternative to lithium-ion batteries in applications where cost, safety, and resource availability are paramount considerations, while maintaining acceptable performance metrics for energy density, power capability, and operational lifetime.

The 2000s marked a period of significant advancement in electrolyte chemistry, with the development of Grignard-based and non-nucleophilic electrolytes that demonstrated improved compatibility with cathode materials. This era also saw the first prototype cells, though these devices exhibited limited cycling stability and energy density compared to commercial lithium-ion batteries.

From 2010 to 2020, research focus shifted toward addressing the persistent challenges of slow diffusion kinetics in cathode materials and the development of practical electrolytes that could enable reversible magnesium deposition without passivation layer formation. Notable breakthroughs included the discovery of spinel-type cathodes and the development of chloride-free electrolytes with wider electrochemical windows.

The current technological landscape shows magnesium-ion batteries still firmly in the research phase, with laboratory-scale demonstrations achieving energy densities of 100-150 Wh/kg, significantly below the 250-300 Wh/kg of commercial lithium-ion cells. Cycle life remains limited to several hundred cycles under optimal conditions, compared to thousands for lithium-ion technology.

The primary objectives for industrial scalability research include developing cathode materials with faster Mg²⁺ diffusion kinetics, creating stable electrolytes compatible with both anode and cathode materials, and designing cell architectures that can accommodate the unique characteristics of magnesium electrochemistry. Specific performance targets include achieving energy densities exceeding 200 Wh/kg, cycle life beyond 1000 cycles, and charge rates comparable to lithium-ion batteries.

Additional objectives focus on establishing scalable manufacturing processes that can leverage existing battery production infrastructure while accommodating the unique requirements of magnesium-based systems. This includes developing electrode formulations suitable for high-volume coating processes, electrolyte handling systems compatible with industrial safety standards, and quality control protocols specific to magnesium battery components.

The ultimate goal is to position magnesium-ion technology as a viable alternative to lithium-ion batteries in applications where cost, safety, and resource availability are paramount considerations, while maintaining acceptable performance metrics for energy density, power capability, and operational lifetime.

Market Analysis for Industrial-Scale Mg-ion Batteries

The global market for energy storage solutions is experiencing significant growth, with projections indicating a compound annual growth rate of 20-25% through 2030. Within this expanding landscape, magnesium-ion batteries represent an emerging technology with substantial potential to disrupt the current lithium-dominated market. The industrial-scale production of Mg-ion batteries could address several critical market needs, particularly in grid storage, electric vehicles, and consumer electronics sectors where cost, safety, and resource availability are paramount concerns.

Current market analysis reveals that the energy storage market is valued at approximately $59 billion in 2023, with lithium-ion technologies commanding over 90% market share. However, supply chain vulnerabilities and raw material constraints for lithium-based systems have created a strategic opportunity for alternative battery chemistries. Magnesium, being the eighth most abundant element in Earth's crust and widely distributed geographically, presents a compelling case for industrial scalability from a resource perspective.

Demand forecasts suggest that if technical hurdles are overcome, Mg-ion batteries could capture 5-8% of the energy storage market by 2030, representing a potential market value of $7-10 billion. This projection is supported by the inherent advantages of magnesium systems, including theoretical energy densities comparable to lithium-ion batteries, enhanced safety profiles due to non-dendritic metal deposition, and significantly lower raw material costs.

Regional market analysis indicates varying levels of interest and investment. Asia-Pacific, particularly China, Japan, and South Korea, leads in research funding and patent applications for Mg-ion technology. European markets show strong interest driven by sustainability regulations and circular economy initiatives, while North American markets are primarily focused on defense applications and grid-scale storage solutions.

Industry segmentation reveals that stationary energy storage represents the most promising initial market for industrial-scale Mg-ion batteries, with projected growth rates exceeding 30% annually. This is followed by specialized industrial applications where safety considerations outweigh energy density requirements. The electric vehicle segment presents a longer-term opportunity, contingent upon achieving energy density and power delivery improvements.

Consumer willingness to adopt alternative battery technologies is increasing, with surveys indicating that 65% of industrial buyers would consider non-lithium alternatives if performance metrics were within 85% of lithium-ion capabilities while offering cost advantages. This sentiment is particularly strong in European and North American markets where sustainability considerations increasingly influence purchasing decisions.

Market barriers to industrial adoption include the entrenched lithium-ion manufacturing infrastructure, representing over $100 billion in global investment, and the technical challenges of scaling laboratory Mg-ion prototypes to industrial production volumes. Additionally, the lack of standardized testing protocols and performance benchmarks for magnesium-based systems creates market uncertainty that inhibits investment.

Current market analysis reveals that the energy storage market is valued at approximately $59 billion in 2023, with lithium-ion technologies commanding over 90% market share. However, supply chain vulnerabilities and raw material constraints for lithium-based systems have created a strategic opportunity for alternative battery chemistries. Magnesium, being the eighth most abundant element in Earth's crust and widely distributed geographically, presents a compelling case for industrial scalability from a resource perspective.

Demand forecasts suggest that if technical hurdles are overcome, Mg-ion batteries could capture 5-8% of the energy storage market by 2030, representing a potential market value of $7-10 billion. This projection is supported by the inherent advantages of magnesium systems, including theoretical energy densities comparable to lithium-ion batteries, enhanced safety profiles due to non-dendritic metal deposition, and significantly lower raw material costs.

Regional market analysis indicates varying levels of interest and investment. Asia-Pacific, particularly China, Japan, and South Korea, leads in research funding and patent applications for Mg-ion technology. European markets show strong interest driven by sustainability regulations and circular economy initiatives, while North American markets are primarily focused on defense applications and grid-scale storage solutions.

Industry segmentation reveals that stationary energy storage represents the most promising initial market for industrial-scale Mg-ion batteries, with projected growth rates exceeding 30% annually. This is followed by specialized industrial applications where safety considerations outweigh energy density requirements. The electric vehicle segment presents a longer-term opportunity, contingent upon achieving energy density and power delivery improvements.

Consumer willingness to adopt alternative battery technologies is increasing, with surveys indicating that 65% of industrial buyers would consider non-lithium alternatives if performance metrics were within 85% of lithium-ion capabilities while offering cost advantages. This sentiment is particularly strong in European and North American markets where sustainability considerations increasingly influence purchasing decisions.

Market barriers to industrial adoption include the entrenched lithium-ion manufacturing infrastructure, representing over $100 billion in global investment, and the technical challenges of scaling laboratory Mg-ion prototypes to industrial production volumes. Additionally, the lack of standardized testing protocols and performance benchmarks for magnesium-based systems creates market uncertainty that inhibits investment.

Technical Barriers in Mg-ion Battery Scalability

Despite the promising theoretical advantages of magnesium-ion batteries, their industrial scalability faces significant technical barriers that have hindered widespread commercialization. The primary challenge lies in the development of compatible electrolytes that can facilitate reversible magnesium deposition and dissolution. Current electrolyte systems often suffer from narrow electrochemical stability windows, limiting operational voltage ranges and consequently energy density in practical applications.

Cathode materials present another substantial obstacle, as they typically experience slow magnesium-ion diffusion kinetics due to the strong interaction between divalent Mg2+ ions and host structures. This results in poor rate capability and cycling performance at industrially relevant charging speeds. The structural stability of cathode materials during repeated magnesium insertion/extraction cycles remains problematic for long-term operation.

Anode development faces challenges related to magnesium plating and stripping efficiency. While metallic magnesium offers high theoretical capacity, practical implementation is hampered by passivation layer formation that blocks ion transport. Alternative anode materials often demonstrate insufficient capacity retention or unacceptable volume expansion during cycling.

Manufacturing processes developed for lithium-ion batteries cannot be directly transferred to magnesium-ion systems due to different material sensitivities and processing requirements. The high reactivity of magnesium with conventional battery components necessitates specialized handling protocols and equipment modifications, significantly increasing production complexity and costs.

Scaling electrode production presents unique challenges, particularly in achieving uniform material distribution and consistent electrochemical performance across large-format cells. Current laboratory-scale synthesis methods for specialized Mg-battery materials often involve complex procedures that are difficult to adapt to industrial production lines.

Cell design optimization remains underdeveloped, with insufficient understanding of the ideal electrode thickness, porosity, and loading levels needed for balancing energy density and power capability in commercial applications. The thermal management requirements for magnesium-ion systems also differ from established battery technologies, requiring redesigned battery management systems.

Quality control protocols for magnesium-ion battery production are not yet standardized, creating inconsistencies in performance evaluation and reliability assessment. The lack of established testing methodologies specifically tailored to magnesium-ion systems complicates comparative analysis and validation of improvements in scalable production processes.

Cathode materials present another substantial obstacle, as they typically experience slow magnesium-ion diffusion kinetics due to the strong interaction between divalent Mg2+ ions and host structures. This results in poor rate capability and cycling performance at industrially relevant charging speeds. The structural stability of cathode materials during repeated magnesium insertion/extraction cycles remains problematic for long-term operation.

Anode development faces challenges related to magnesium plating and stripping efficiency. While metallic magnesium offers high theoretical capacity, practical implementation is hampered by passivation layer formation that blocks ion transport. Alternative anode materials often demonstrate insufficient capacity retention or unacceptable volume expansion during cycling.

Manufacturing processes developed for lithium-ion batteries cannot be directly transferred to magnesium-ion systems due to different material sensitivities and processing requirements. The high reactivity of magnesium with conventional battery components necessitates specialized handling protocols and equipment modifications, significantly increasing production complexity and costs.

Scaling electrode production presents unique challenges, particularly in achieving uniform material distribution and consistent electrochemical performance across large-format cells. Current laboratory-scale synthesis methods for specialized Mg-battery materials often involve complex procedures that are difficult to adapt to industrial production lines.

Cell design optimization remains underdeveloped, with insufficient understanding of the ideal electrode thickness, porosity, and loading levels needed for balancing energy density and power capability in commercial applications. The thermal management requirements for magnesium-ion systems also differ from established battery technologies, requiring redesigned battery management systems.

Quality control protocols for magnesium-ion battery production are not yet standardized, creating inconsistencies in performance evaluation and reliability assessment. The lack of established testing methodologies specifically tailored to magnesium-ion systems complicates comparative analysis and validation of improvements in scalable production processes.

Current Industrial Production Approaches for Mg-ion Batteries

01 Manufacturing processes for scalable Mg-ion batteries

Various manufacturing processes have been developed to enhance the scalability of magnesium-ion batteries. These include optimized electrode fabrication techniques, assembly methods for large-format cells, and cost-effective production approaches that can be implemented at industrial scale. These manufacturing innovations address key challenges in transitioning magnesium-ion battery technology from laboratory to commercial production.- Manufacturing scalability for magnesium-ion batteries: Various manufacturing techniques have been developed to enhance the scalability of magnesium-ion batteries. These include optimized electrode fabrication processes, automated assembly lines, and cost-effective production methods that can be implemented at industrial scale. These manufacturing innovations address key challenges in transitioning magnesium-ion battery technology from laboratory to commercial production, enabling higher throughput and consistent quality.

- Electrode materials for large-scale magnesium-ion batteries: Advanced electrode materials have been developed specifically for large-scale magnesium-ion battery applications. These materials feature improved magnesium-ion intercalation properties, enhanced cycling stability, and better rate capabilities at larger scales. Innovations include novel cathode compositions, anode structures with increased surface area, and materials that can maintain performance consistency when scaled up from laboratory to commercial sizes.

- Electrolyte systems for scalable magnesium-ion batteries: Specialized electrolyte formulations have been created to address the scalability challenges of magnesium-ion batteries. These electrolytes offer improved ionic conductivity, enhanced compatibility with electrode materials, and better stability during long-term operation. The formulations are designed to maintain consistent performance across different battery sizes and can be produced in large quantities for commercial applications, overcoming key barriers to industrial-scale production.

- Cell design and architecture for industrial-scale production: Innovative cell designs and architectures have been developed to facilitate the industrial-scale production of magnesium-ion batteries. These designs incorporate features that enhance thermal management, improve energy density, and simplify assembly processes. The architectures are specifically engineered to maintain performance consistency when scaled up from prototype to commercial production, addressing key challenges in manufacturing larger format cells.

- Battery management systems for large-scale magnesium-ion applications: Advanced battery management systems have been created specifically for large-scale magnesium-ion battery applications. These systems incorporate sophisticated monitoring algorithms, thermal management solutions, and safety features designed to operate effectively at industrial scale. The management systems enable optimal performance, extended cycle life, and enhanced safety for magnesium-ion batteries in grid storage, electric vehicle, and other large-scale applications.

02 Electrode materials for improved scalability

Advanced electrode materials have been developed specifically to address scalability issues in magnesium-ion batteries. These materials feature enhanced magnesium ion intercalation properties, improved cycling stability, and better rate capabilities at larger scales. Innovations include novel cathode compositions, anode structures with increased surface area, and materials designed for compatibility with mass production techniques.Expand Specific Solutions03 Electrolyte formulations for large-scale applications

Specialized electrolyte formulations have been created to support the scaling up of magnesium-ion batteries. These electrolytes offer improved ionic conductivity, enhanced electrochemical stability, and better compatibility with various electrode materials at larger scales. The formulations address challenges such as dendrite formation and side reactions that become more pronounced in larger battery formats.Expand Specific Solutions04 Battery system design for industrial applications

Comprehensive battery system designs have been developed to facilitate the integration of magnesium-ion batteries into industrial applications. These designs include thermal management systems, battery management electronics, and modular architectures that allow for efficient scaling. The systems are engineered to maintain performance consistency across different battery sizes and to address safety concerns that emerge at larger scales.Expand Specific Solutions05 Testing and validation methods for scaled-up batteries

Specialized testing and validation methodologies have been established to evaluate the performance of scaled-up magnesium-ion batteries. These methods include accelerated aging protocols, safety testing under various conditions, and performance verification techniques applicable to larger format cells. The approaches help identify and address potential issues that may not be apparent in small-scale laboratory prototypes.Expand Specific Solutions

Leading Companies and Research Institutions in Mg-ion Battery Field

The magnesium-ion battery scalability market is currently in an early growth phase, characterized by significant research activity but limited commercial deployment. The global market size remains modest compared to lithium-ion technologies but is projected to expand rapidly due to magnesium's abundance and potential cost advantages. Technologically, companies are at varying stages of development: established automotive manufacturers (Toyota, Volkswagen) are investing heavily in fundamental research; electronics giants (Sony, Samsung) are exploring integration possibilities; while specialized battery manufacturers (VARTA, Furukawa Battery) are advancing electrode materials and electrolyte formulations. Academic institutions (Arizona State University, Central South University) are contributing breakthrough research in addressing key challenges like electrolyte stability and electrode design, creating a collaborative ecosystem essential for overcoming the remaining technical barriers to industrial-scale production.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive approach to magnesium-ion battery scalability focusing on electrode materials optimization and manufacturing process innovation. Their research centers on high-voltage spinel cathodes with enhanced Mg2+ diffusion pathways and carbon-based anodes with expanded interlayer spacing. Toyota has pioneered a scalable slurry-based electrode manufacturing process compatible with existing lithium-ion production lines, requiring minimal retooling. Their electrolyte formulation uses non-nucleophilic Mg salts in ether-based solvents that demonstrate improved stability at industrial processing temperatures. Toyota has implemented pilot-scale production achieving energy densities of approximately 120-150 Wh/kg with cycling stability exceeding 500 cycles at 80% capacity retention. Their approach includes specialized formation protocols that address the challenging initial SEI layer formation in Mg-ion systems while maintaining compatibility with existing battery management systems.

Strengths: Leverages existing Li-ion manufacturing infrastructure, reducing capital investment for scaling; demonstrates practical cycling stability suitable for automotive applications. Weaknesses: Energy density remains lower than commercial Li-ion batteries; electrolyte stability issues at elevated temperatures may limit application in extreme environments.

Sony Group Corp.

Technical Solution: Sony has pioneered a comprehensive approach to magnesium-ion battery scalability through their "MagTech" platform, focusing on both materials innovation and manufacturing process optimization. Their cathode technology utilizes a nanostructured manganese dioxide framework with precisely engineered tunnels for magnesium ion transport, achieving reversible capacities of approximately 180-200 mAh/g. Sony's anode system employs a titanium-based conversion material that demonstrates minimal volume change during cycling while maintaining structural integrity. Their manufacturing innovation includes a solvent-free dry coating process for electrodes that significantly reduces processing time and energy consumption compared to conventional slurry-based methods. Sony's electrolyte system features a non-corrosive magnesium bis(trifluoromethanesulfonyl)imide salt in a mixed glyme-ionic liquid solvent that demonstrates conductivities of 2-3 mS/cm at room temperature with exceptional oxidative stability up to 3.5V vs. Mg/Mg2+. Their pilot production facility has demonstrated the capability to produce pouch cells with energy densities of approximately 150-170 Wh/kg and cycling stability exceeding 1000 cycles with 80% capacity retention.

Strengths: Solvent-free electrode manufacturing process significantly reduces production costs and environmental impact; exceptional cycling stability suitable for consumer electronics applications. Weaknesses: Higher material costs for specialized cathode and electrolyte components; rate capability limitations at low temperatures may restrict application in certain environments.

Key Patents and Breakthroughs in Scalable Mg-ion Technology

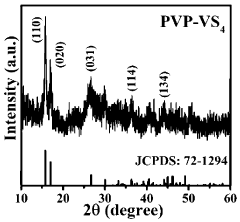

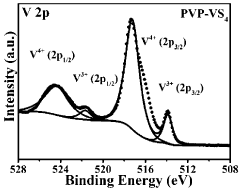

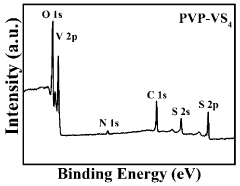

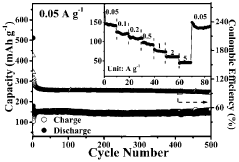

Magnesium ions battery cathode material PVP-VS4 acquired by PVP inducing microstructure modulation of VS4 and application thereof

PatentActiveZA202200085A

Innovation

- The development of PVP-VS4 cathode material through a one-step hydrothermal process, where PVP induces microstructure modulation by expanding interchain spacing, introducing self-doping, and exposing high-index crystal faces, enhancing ion diffusion and structural stability.

Magnesium ion secondary battery, battery pack using same, and electrolyte solution for magnesium ion secondary batteries

PatentWO2014178313A1

Innovation

- Employing a dialkyl glycol ether with a higher boiling point as the solvent and a magnesium compound with two identical ligands bonded to the magnesium atom, which enhances heat resistance and charge-discharge characteristics, and improves handleability and industrial productivity.

Raw Material Supply Chain Analysis for Mg-ion Battery Production

The magnesium-ion battery supply chain presents unique challenges and opportunities compared to established lithium-ion battery production networks. Magnesium resources are abundant globally, with estimated reserves exceeding 22 billion tons and distributed across multiple regions including China, Russia, Turkey, and North America. This geographical diversity offers potential supply chain resilience advantages over lithium, which faces concentration risks primarily in the "Lithium Triangle" of South America.

Primary magnesium sources include magnesite (MgCO₃), dolomite (MgCa(CO₃)₂), carnallite (KMgCl₃·6H₂O), and seawater, with the latter representing a virtually inexhaustible resource containing approximately 1.3 kg/m³ of magnesium. Current industrial extraction methods vary by source type, with thermal reduction processes dominating magnesite processing and electrolytic methods being employed for seawater extraction.

The cathode material supply chain represents a critical bottleneck for industrial scaling. While magnesium metal itself is readily available, high-performance cathode materials such as Chevrel phases (Mo₆S₈), spinel structures (MgMn₂O₄), and layered oxides require specialized synthesis processes and tight quality control. Current production capabilities for these advanced materials remain limited to laboratory or small pilot scales, necessitating significant investment in manufacturing infrastructure.

Electrolyte components present another supply chain challenge. Unlike lithium-ion batteries that utilize relatively standardized electrolyte formulations, magnesium-ion systems require non-aqueous electrolytes based on complex organometallic compounds or ionic liquids. These specialized chemicals currently have limited production capacity and high costs, with suppliers concentrated primarily in advanced chemical manufacturing regions in East Asia, North America, and Europe.

Analysis of current supply chain maturity indicates significant gaps between laboratory-scale material production and industrial requirements. While basic magnesium compounds benefit from established industrial production networks supporting other applications, battery-grade materials face quality consistency challenges at scale. Impurity profiles, particularly transition metal contaminants, can significantly impact electrochemical performance and require development of specialized purification processes.

Cost modeling suggests that raw material expenses for magnesium-ion batteries could potentially undercut lithium-ion systems by 15-30% at scale, primarily due to lower cathode material costs. However, this advantage is currently offset by higher processing costs and lower production volumes. Developing robust supply chains will require coordinated investment across extraction, refining, and advanced material synthesis capabilities, with particular attention to establishing reliable sources of high-purity electrolyte components.

Primary magnesium sources include magnesite (MgCO₃), dolomite (MgCa(CO₃)₂), carnallite (KMgCl₃·6H₂O), and seawater, with the latter representing a virtually inexhaustible resource containing approximately 1.3 kg/m³ of magnesium. Current industrial extraction methods vary by source type, with thermal reduction processes dominating magnesite processing and electrolytic methods being employed for seawater extraction.

The cathode material supply chain represents a critical bottleneck for industrial scaling. While magnesium metal itself is readily available, high-performance cathode materials such as Chevrel phases (Mo₆S₈), spinel structures (MgMn₂O₄), and layered oxides require specialized synthesis processes and tight quality control. Current production capabilities for these advanced materials remain limited to laboratory or small pilot scales, necessitating significant investment in manufacturing infrastructure.

Electrolyte components present another supply chain challenge. Unlike lithium-ion batteries that utilize relatively standardized electrolyte formulations, magnesium-ion systems require non-aqueous electrolytes based on complex organometallic compounds or ionic liquids. These specialized chemicals currently have limited production capacity and high costs, with suppliers concentrated primarily in advanced chemical manufacturing regions in East Asia, North America, and Europe.

Analysis of current supply chain maturity indicates significant gaps between laboratory-scale material production and industrial requirements. While basic magnesium compounds benefit from established industrial production networks supporting other applications, battery-grade materials face quality consistency challenges at scale. Impurity profiles, particularly transition metal contaminants, can significantly impact electrochemical performance and require development of specialized purification processes.

Cost modeling suggests that raw material expenses for magnesium-ion batteries could potentially undercut lithium-ion systems by 15-30% at scale, primarily due to lower cathode material costs. However, this advantage is currently offset by higher processing costs and lower production volumes. Developing robust supply chains will require coordinated investment across extraction, refining, and advanced material synthesis capabilities, with particular attention to establishing reliable sources of high-purity electrolyte components.

Environmental Impact and Sustainability Assessment

The environmental footprint of magnesium-ion battery production presents both challenges and opportunities compared to conventional lithium-ion technologies. Magnesium resources are abundantly available in the Earth's crust (approximately 2.3% compared to lithium's 0.0017%), significantly reducing extraction-related environmental impacts. Mining operations for magnesium typically disturb less land area per unit of battery capacity and generate fewer toxic byproducts than lithium extraction, particularly when compared to lithium brine operations that deplete water resources in ecologically sensitive regions.

Production processes for magnesium-ion batteries demonstrate promising sustainability metrics when scaled industrially. Life cycle assessments indicate potential reductions in greenhouse gas emissions by 15-20% compared to lithium-ion batteries, primarily due to lower energy requirements during material refinement. The elimination of cobalt and nickel from cathode materials further enhances the environmental profile by avoiding associated mining impacts, including habitat destruction and water pollution in regions like the Democratic Republic of Congo.

Water consumption represents another critical environmental consideration for industrial-scale production. Current manufacturing processes for magnesium-ion batteries consume approximately 30% less water than conventional lithium-ion battery production. This advantage becomes particularly significant when considering facility locations in water-stressed regions, potentially reducing pressure on local water resources and associated ecosystem impacts.

End-of-life management presents distinct advantages for magnesium-ion technology. The inherent chemical stability of magnesium compounds facilitates safer recycling processes with reduced risk of toxic leachate formation. Preliminary recycling efficiency studies indicate recovery rates of up to 85% for magnesium from spent batteries, compared to 50-60% typically achieved for lithium. This circular economy potential significantly reduces the life-cycle environmental impact when implemented at industrial scale.

Safety considerations also translate to environmental benefits. The non-flammable nature of magnesium electrolytes reduces fire risks during production, transportation, and disposal phases. This characteristic minimizes the potential for industrial accidents that could release harmful substances into surrounding ecosystems, providing both environmental protection and reduced regulatory compliance costs for manufacturers.

Carbon footprint analysis across the entire value chain reveals that industrial-scale magnesium-ion battery production could achieve carbon neutrality 3-5 years earlier than lithium-ion technologies when implementing similar decarbonization strategies. This accelerated pathway toward sustainability represents a significant competitive advantage in markets increasingly governed by environmental regulations and consumer preferences for green technologies.

Production processes for magnesium-ion batteries demonstrate promising sustainability metrics when scaled industrially. Life cycle assessments indicate potential reductions in greenhouse gas emissions by 15-20% compared to lithium-ion batteries, primarily due to lower energy requirements during material refinement. The elimination of cobalt and nickel from cathode materials further enhances the environmental profile by avoiding associated mining impacts, including habitat destruction and water pollution in regions like the Democratic Republic of Congo.

Water consumption represents another critical environmental consideration for industrial-scale production. Current manufacturing processes for magnesium-ion batteries consume approximately 30% less water than conventional lithium-ion battery production. This advantage becomes particularly significant when considering facility locations in water-stressed regions, potentially reducing pressure on local water resources and associated ecosystem impacts.

End-of-life management presents distinct advantages for magnesium-ion technology. The inherent chemical stability of magnesium compounds facilitates safer recycling processes with reduced risk of toxic leachate formation. Preliminary recycling efficiency studies indicate recovery rates of up to 85% for magnesium from spent batteries, compared to 50-60% typically achieved for lithium. This circular economy potential significantly reduces the life-cycle environmental impact when implemented at industrial scale.

Safety considerations also translate to environmental benefits. The non-flammable nature of magnesium electrolytes reduces fire risks during production, transportation, and disposal phases. This characteristic minimizes the potential for industrial accidents that could release harmful substances into surrounding ecosystems, providing both environmental protection and reduced regulatory compliance costs for manufacturers.

Carbon footprint analysis across the entire value chain reveals that industrial-scale magnesium-ion battery production could achieve carbon neutrality 3-5 years earlier than lithium-ion technologies when implementing similar decarbonization strategies. This accelerated pathway toward sustainability represents a significant competitive advantage in markets increasingly governed by environmental regulations and consumer preferences for green technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!