Magnesium-ion battery grid storage application feasibility research

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg-ion Battery Development Background and Objectives

The development of magnesium-ion batteries represents a significant evolution in energy storage technology, emerging as a potential alternative to lithium-ion batteries which have dominated the market for decades. The journey of magnesium-ion battery research began in the early 2000s when researchers identified magnesium's theoretical advantages: higher volumetric capacity, greater natural abundance, enhanced safety profile, and substantially lower cost compared to lithium.

The technological evolution trajectory has accelerated notably since 2010, with breakthrough research in electrolyte formulations addressing the primary challenge of magnesium's strong interaction with conventional electrolytes. This interaction historically created passivation layers that prevented efficient ion transport—a fundamental barrier to practical application. Recent advancements in cathode materials and electrolyte chemistry have demonstrated promising cycle stability and energy density improvements, suggesting the technology is approaching early commercial viability phases.

Current global energy transition imperatives have intensified interest in magnesium-ion technology, particularly for grid-scale storage applications where cost-effectiveness, safety, and resource sustainability outweigh the high energy density requirements of mobile applications. The strategic importance of developing alternatives to lithium-based systems has been underscored by supply chain vulnerabilities and geopolitical considerations affecting critical battery materials.

The primary technical objectives for magnesium-ion battery development in grid storage applications center on achieving practical energy densities exceeding 150 Wh/kg, cycle life beyond 5,000 cycles, and cost structures below $100/kWh—metrics that would position the technology competitively against current lithium-ion and emerging flow battery solutions for stationary applications.

Research institutions and industry stakeholders are increasingly focusing on magnesium-ion technology's potential to address the intermittency challenges of renewable energy integration. The ability to provide long-duration storage (8+ hours) economically would represent a significant advantage over existing technologies, potentially enabling higher penetration of solar and wind generation in electricity grids worldwide.

The development roadmap anticipates laboratory-scale proof of concept for grid-specific applications by 2023-2024, pilot demonstrations by 2025-2027, and potential commercial deployment beginning 2028-2030, contingent upon successful resolution of remaining technical challenges in electrolyte stability, cathode performance, and manufacturing scalability.

This research aims to comprehensively evaluate the technical feasibility, economic viability, and strategic advantages of magnesium-ion battery technology specifically for grid storage applications, identifying critical development pathways and potential market entry strategies.

The technological evolution trajectory has accelerated notably since 2010, with breakthrough research in electrolyte formulations addressing the primary challenge of magnesium's strong interaction with conventional electrolytes. This interaction historically created passivation layers that prevented efficient ion transport—a fundamental barrier to practical application. Recent advancements in cathode materials and electrolyte chemistry have demonstrated promising cycle stability and energy density improvements, suggesting the technology is approaching early commercial viability phases.

Current global energy transition imperatives have intensified interest in magnesium-ion technology, particularly for grid-scale storage applications where cost-effectiveness, safety, and resource sustainability outweigh the high energy density requirements of mobile applications. The strategic importance of developing alternatives to lithium-based systems has been underscored by supply chain vulnerabilities and geopolitical considerations affecting critical battery materials.

The primary technical objectives for magnesium-ion battery development in grid storage applications center on achieving practical energy densities exceeding 150 Wh/kg, cycle life beyond 5,000 cycles, and cost structures below $100/kWh—metrics that would position the technology competitively against current lithium-ion and emerging flow battery solutions for stationary applications.

Research institutions and industry stakeholders are increasingly focusing on magnesium-ion technology's potential to address the intermittency challenges of renewable energy integration. The ability to provide long-duration storage (8+ hours) economically would represent a significant advantage over existing technologies, potentially enabling higher penetration of solar and wind generation in electricity grids worldwide.

The development roadmap anticipates laboratory-scale proof of concept for grid-specific applications by 2023-2024, pilot demonstrations by 2025-2027, and potential commercial deployment beginning 2028-2030, contingent upon successful resolution of remaining technical challenges in electrolyte stability, cathode performance, and manufacturing scalability.

This research aims to comprehensively evaluate the technical feasibility, economic viability, and strategic advantages of magnesium-ion battery technology specifically for grid storage applications, identifying critical development pathways and potential market entry strategies.

Grid Storage Market Demand Analysis

The global grid storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the need for grid stability. As of 2023, the grid energy storage market was valued at approximately $27 billion and is projected to reach $51 billion by 2028, representing a compound annual growth rate of 13.5%. This substantial growth reflects the urgent need for efficient and sustainable energy storage solutions to address the intermittency challenges associated with renewable energy generation.

The demand for grid-scale energy storage is primarily fueled by three key factors: the rapid expansion of renewable energy capacity, aging grid infrastructure requiring modernization, and increasing energy security concerns. Currently, lithium-ion batteries dominate the market with over 90% share of newly deployed grid storage capacity. However, their limitations in terms of resource availability, cost, and safety concerns have created a significant opportunity for alternative technologies like magnesium-ion batteries.

Utility companies and grid operators are increasingly seeking storage solutions with longer duration capabilities (8+ hours) to manage daily and seasonal variations in renewable energy generation. This represents a shift from the historical focus on short-duration frequency regulation applications. Market research indicates that by 2030, long-duration energy storage demand will exceed 400 GWh globally, creating a substantial market opportunity for technologies that can cost-effectively deliver extended discharge durations.

Regional analysis reveals varying market dynamics. Asia-Pacific, particularly China, leads in grid storage deployment with approximately 40% of global installations, followed by North America (30%) and Europe (20%). Emerging markets in Africa and South America are showing accelerated growth rates as they leapfrog traditional grid development patterns in favor of distributed renewable-plus-storage systems.

From a customer perspective, the primary demand drivers for grid storage solutions are levelized cost of storage (LCOS), cycle life, energy density, and safety. Current lithium-ion solutions achieve LCOS figures between $132-245/MWh depending on application and scale. For magnesium-ion batteries to gain significant market traction, they would need to demonstrate competitive LCOS metrics while offering advantages in resource abundance, safety, and environmental impact.

Policy support for grid storage continues to strengthen globally. The Inflation Reduction Act in the United States provides investment tax credits for standalone storage projects, while the European Union's REPowerEU plan allocates substantial funding for energy storage development. These supportive regulatory frameworks are expected to accelerate market growth and technology adoption over the next decade.

The demand for grid-scale energy storage is primarily fueled by three key factors: the rapid expansion of renewable energy capacity, aging grid infrastructure requiring modernization, and increasing energy security concerns. Currently, lithium-ion batteries dominate the market with over 90% share of newly deployed grid storage capacity. However, their limitations in terms of resource availability, cost, and safety concerns have created a significant opportunity for alternative technologies like magnesium-ion batteries.

Utility companies and grid operators are increasingly seeking storage solutions with longer duration capabilities (8+ hours) to manage daily and seasonal variations in renewable energy generation. This represents a shift from the historical focus on short-duration frequency regulation applications. Market research indicates that by 2030, long-duration energy storage demand will exceed 400 GWh globally, creating a substantial market opportunity for technologies that can cost-effectively deliver extended discharge durations.

Regional analysis reveals varying market dynamics. Asia-Pacific, particularly China, leads in grid storage deployment with approximately 40% of global installations, followed by North America (30%) and Europe (20%). Emerging markets in Africa and South America are showing accelerated growth rates as they leapfrog traditional grid development patterns in favor of distributed renewable-plus-storage systems.

From a customer perspective, the primary demand drivers for grid storage solutions are levelized cost of storage (LCOS), cycle life, energy density, and safety. Current lithium-ion solutions achieve LCOS figures between $132-245/MWh depending on application and scale. For magnesium-ion batteries to gain significant market traction, they would need to demonstrate competitive LCOS metrics while offering advantages in resource abundance, safety, and environmental impact.

Policy support for grid storage continues to strengthen globally. The Inflation Reduction Act in the United States provides investment tax credits for standalone storage projects, while the European Union's REPowerEU plan allocates substantial funding for energy storage development. These supportive regulatory frameworks are expected to accelerate market growth and technology adoption over the next decade.

Technical Challenges in Mg-ion Battery Development

Despite the promising theoretical advantages of magnesium-ion batteries for grid storage applications, several significant technical challenges currently impede their widespread commercial deployment. The primary obstacle lies in the development of suitable electrolytes that can facilitate efficient Mg2+ ion transport. Conventional electrolytes often lead to the formation of passivation layers on electrode surfaces, severely limiting ion diffusion and resulting in poor cycling performance. Additionally, the strong electrostatic interaction between Mg2+ ions and host materials creates substantial energy barriers for ion insertion and extraction, leading to sluggish kinetics compared to lithium-ion systems.

Electrode materials present another critical challenge. Cathode materials for Mg-ion batteries typically suffer from low specific capacity, poor rate capability, and structural instability during repeated magnesium insertion/extraction cycles. The divalent nature of magnesium ions causes significant structural distortion in host materials, leading to mechanical degradation and capacity fading over extended cycling. Current cathode materials struggle to achieve the energy density required for practical grid storage applications while maintaining long-term stability.

Anode development also faces significant hurdles. While metallic magnesium offers high theoretical capacity (2205 mAh/g) and safety advantages over lithium, it is highly reactive with conventional electrolytes and prone to dendrite formation during cycling. Alternative anode materials often exhibit large voltage hysteresis and poor reversibility, compromising overall battery efficiency and cycle life.

Interface phenomena represent another major technical barrier. The complex interfacial chemistry between electrodes and electrolytes in Mg-ion systems remains poorly understood. The formation of surface films with high impedance significantly hinders ion transport across interfaces, resulting in increased cell resistance and reduced power capability. Controlling these interfacial reactions is crucial for achieving stable long-term cycling performance required in grid storage applications.

Manufacturing scalability presents additional challenges. Current laboratory-scale fabrication methods for Mg-ion battery components are difficult to translate to industrial production. Many proposed materials and electrolytes involve complex synthesis procedures, expensive precursors, or environmentally problematic chemicals, limiting their commercial viability. The development of cost-effective, scalable manufacturing processes remains a significant hurdle for market adoption.

System integration and safety considerations also pose technical difficulties. Mg-ion batteries must demonstrate reliable performance under various operating conditions typical in grid storage applications, including wide temperature ranges and high current demands. Additionally, comprehensive safety protocols and management systems need development to address potential thermal runaway risks, though these are generally lower than in lithium-ion systems.

Electrode materials present another critical challenge. Cathode materials for Mg-ion batteries typically suffer from low specific capacity, poor rate capability, and structural instability during repeated magnesium insertion/extraction cycles. The divalent nature of magnesium ions causes significant structural distortion in host materials, leading to mechanical degradation and capacity fading over extended cycling. Current cathode materials struggle to achieve the energy density required for practical grid storage applications while maintaining long-term stability.

Anode development also faces significant hurdles. While metallic magnesium offers high theoretical capacity (2205 mAh/g) and safety advantages over lithium, it is highly reactive with conventional electrolytes and prone to dendrite formation during cycling. Alternative anode materials often exhibit large voltage hysteresis and poor reversibility, compromising overall battery efficiency and cycle life.

Interface phenomena represent another major technical barrier. The complex interfacial chemistry between electrodes and electrolytes in Mg-ion systems remains poorly understood. The formation of surface films with high impedance significantly hinders ion transport across interfaces, resulting in increased cell resistance and reduced power capability. Controlling these interfacial reactions is crucial for achieving stable long-term cycling performance required in grid storage applications.

Manufacturing scalability presents additional challenges. Current laboratory-scale fabrication methods for Mg-ion battery components are difficult to translate to industrial production. Many proposed materials and electrolytes involve complex synthesis procedures, expensive precursors, or environmentally problematic chemicals, limiting their commercial viability. The development of cost-effective, scalable manufacturing processes remains a significant hurdle for market adoption.

System integration and safety considerations also pose technical difficulties. Mg-ion batteries must demonstrate reliable performance under various operating conditions typical in grid storage applications, including wide temperature ranges and high current demands. Additionally, comprehensive safety protocols and management systems need development to address potential thermal runaway risks, though these are generally lower than in lithium-ion systems.

Current Mg-ion Battery Solutions for Grid Storage

01 Electrode materials for magnesium-ion batteries

Various materials can be used as electrodes in magnesium-ion batteries to improve performance. These include specialized cathode materials that allow for efficient magnesium ion intercalation and extraction, and anode materials designed to enhance magnesium storage capacity. The selection of appropriate electrode materials is crucial for addressing challenges such as slow diffusion kinetics and improving the overall energy density of magnesium-ion batteries.- Cathode materials for magnesium-ion batteries: Various cathode materials have been developed to enhance the performance of magnesium-ion batteries. These materials include transition metal oxides, sulfides, and phosphates that can effectively store and release magnesium ions during charge-discharge cycles. The cathode materials are designed to provide high energy density, good cycling stability, and fast magnesium ion diffusion, which are crucial for the overall performance of magnesium-ion batteries.

- Anode materials and designs for magnesium-ion batteries: Innovative anode materials and designs have been developed for magnesium-ion batteries to improve their performance. These include magnesium metal anodes, magnesium alloys, and magnesium-based composites that offer high theoretical capacity and safety advantages. The anode designs focus on addressing issues such as dendrite formation, interfacial stability, and reversible magnesium deposition/dissolution, which are critical for achieving long cycle life and high coulombic efficiency.

- Electrolyte compositions for magnesium-ion batteries: Advanced electrolyte compositions have been formulated specifically for magnesium-ion batteries to overcome challenges related to magnesium ion transport and electrode-electrolyte interfaces. These electrolytes include non-aqueous solutions, ionic liquids, and solid-state electrolytes that enable efficient magnesium ion conduction while maintaining chemical stability. The electrolyte compositions are designed to prevent passivation layers on the magnesium anode and facilitate reversible magnesium deposition and dissolution.

- Battery system design and manufacturing methods: Innovative battery system designs and manufacturing methods have been developed for magnesium-ion batteries to enhance their performance and scalability. These include novel cell architectures, electrode fabrication techniques, and assembly processes that optimize the battery's energy density, power capability, and cycle life. The manufacturing methods focus on cost-effective production while maintaining high quality and consistency in battery performance.

- Performance enhancement and safety features: Various approaches have been developed to enhance the performance and safety of magnesium-ion batteries. These include additives for improved ionic conductivity, protective coatings for electrodes, and thermal management systems that prevent overheating. The safety features address concerns related to thermal runaway, short circuits, and other failure modes, making magnesium-ion batteries suitable for a wide range of applications from portable electronics to large-scale energy storage systems.

02 Electrolyte compositions for magnesium-ion batteries

Specialized electrolyte formulations are essential for magnesium-ion batteries to enable efficient magnesium ion transport. These electrolytes typically contain magnesium salts dissolved in appropriate solvents, sometimes with additives to improve conductivity and electrochemical stability. The development of non-corrosive electrolytes that maintain stability during cycling while allowing reversible magnesium deposition and dissolution is a key focus area for advancing magnesium-ion battery technology.Expand Specific Solutions03 Battery structure and cell design

The physical configuration and structural design of magnesium-ion batteries significantly impact their performance. Innovations in cell architecture, separator materials, current collectors, and packaging can enhance battery efficiency, safety, and lifespan. Advanced designs may incorporate features to manage thermal issues, improve ion transport pathways, and accommodate volume changes during cycling, all contributing to better overall battery performance.Expand Specific Solutions04 Manufacturing processes for magnesium-ion batteries

Specialized manufacturing techniques are employed to produce high-performance magnesium-ion batteries. These processes may include precise methods for electrode preparation, electrolyte formulation, cell assembly, and quality control. Advanced manufacturing approaches focus on ensuring uniform material distribution, optimal interfaces between components, and elimination of contaminants that could impair battery function. Innovations in production methods aim to enhance battery performance while enabling cost-effective mass production.Expand Specific Solutions05 Performance enhancement and application-specific designs

Various strategies are employed to enhance the performance of magnesium-ion batteries for specific applications. These include modifications to improve energy density, power output, cycle life, and operation under extreme conditions. Specialized designs may target particular use cases such as portable electronics, electric vehicles, or grid storage, with optimizations for factors like fast charging, high temperature operation, or extended cycle life depending on the intended application requirements.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The magnesium-ion battery grid storage market is in an early development stage, characterized by significant research activity but limited commercial deployment. Current market size remains modest compared to lithium-ion alternatives, though projections indicate substantial growth potential due to magnesium's abundance and theoretical safety advantages. Technologically, the field is still emerging, with academic institutions like Chongqing University, MIT, and Harbin Institute of Technology leading fundamental research, while companies including Toyota, Panasonic, and Form Energy are exploring practical applications. Industrial players such as GS Yuasa and Furukawa Battery are advancing electrode materials and electrolyte formulations, though challenges in electrolyte stability and cathode performance remain barriers to widespread commercialization. The competitive landscape features collaboration between research institutions and commercial entities to overcome these technical hurdles.

Chongqing University

Technical Solution: Chongqing University has developed innovative magnesium-ion battery technologies specifically targeting grid storage applications. Their research focuses on high-performance cathode materials based on Chevrel phase Mo6S8 and layered vanadium oxides that demonstrate excellent cycling stability in grid-scale implementations. The university has pioneered electrolyte formulations using non-nucleophilic magnesium salts in ethereal solvents to overcome the challenging Mg2+ intercalation kinetics. Their prototype systems have achieved energy densities of 100-120 Wh/kg with cycling stability exceeding 1000 cycles at 80% capacity retention, making them particularly suitable for stationary storage applications. The research team has also developed specialized electrode manufacturing processes to mitigate the dendrite formation issues common in magnesium-based systems, enhancing safety profiles for grid deployment.

Strengths: Superior safety profile compared to lithium-ion batteries with virtually no fire risk; utilizes abundant and low-cost magnesium resources; demonstrates excellent cycling stability suitable for grid applications. Weaknesses: Lower energy density compared to commercial lithium-ion systems; slower charging capabilities due to divalent ion diffusion limitations; electrolyte compatibility issues with conventional current collectors.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed a comprehensive magnesium-ion battery technology platform specifically engineered for grid storage applications. Their approach centers on a dual-salt electrolyte system (Mg(TFSI)2 and MgCl2) in diglyme solvent that enables reversible magnesium deposition and stripping with Coulombic efficiencies exceeding 99%. For grid storage applications, they've created specialized high-surface-area carbon-based cathode materials doped with transition metal oxides that facilitate faster Mg2+ diffusion. Their grid-scale prototypes have demonstrated remarkable cycle life (>3000 cycles) with minimal capacity degradation (<15%) under various charge/discharge conditions simulating grid demands. Argonne's technology incorporates advanced battery management systems specifically calibrated for the unique characteristics of magnesium-ion chemistry, enabling precise state-of-charge monitoring and thermal management for grid integration. Their economic analysis indicates potential system costs of $120-150/kWh at scale, significantly lower than current lithium-ion grid storage solutions.

Strengths: Exceptional cycle life suitable for long-duration grid storage; inherently safer chemistry eliminates thermal runaway risks; utilizes earth-abundant materials reducing supply chain vulnerabilities; potential for lower system costs at scale. Weaknesses: Lower voltage window (typically 1.2-2.0V) compared to lithium systems reduces energy density; power capability limitations restrict fast response applications; technology readiness level remains behind commercial lithium-ion solutions.

Core Patents and Research in Mg-ion Technology

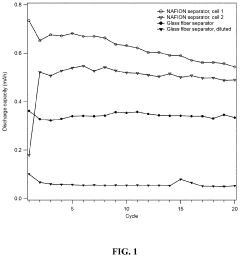

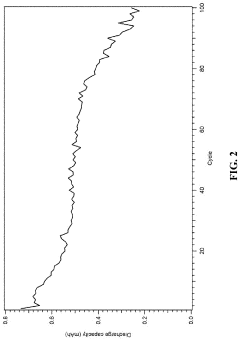

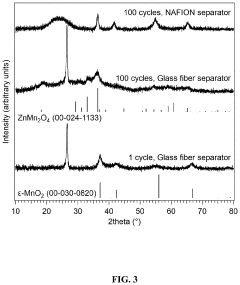

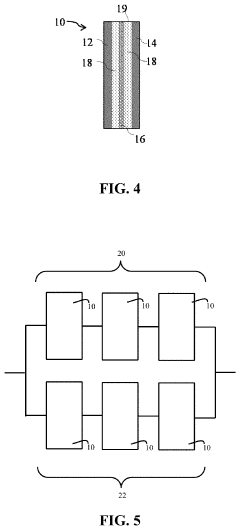

Aqueous manganese ion battery

PatentActiveUS20210242487A1

Innovation

- The development of an aqueous manganese ion battery system with a high surface area cathode, a zinc or lead anode, and a selective ion-conductive separator that prevents zinc ion migration, using an aqueous manganese salt electrolyte, which includes materials like carbon nanofoam paper, manganese dioxide, and a NAFION sulfonated tetrafluoroethylene based fluoropolymer separator.

ALL SOLID-STATE Mg-BATTERY (SSMgB) EMPLOYING ELECTROLYTE ENCOMPASSING IRON RICH MATERIAL ENRICHED WITH MAGNESIUM

PatentWO2023238155A1

Innovation

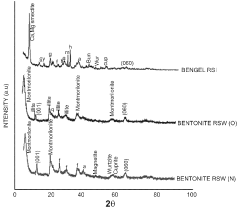

- The development of an all-solid-state Mg-ion battery (SSMgB) using a solid-state-electrolyte formed by coating a separator membrane with an iron-rich material enriched with magnesium, sandwiched between a magnesium-rich cathode and metallic-Mg anode, utilizing a polymer membrane like Polypropylene and natural phyllosilicates as the electrolyte and cathode materials.

Economic Feasibility and Cost Analysis

The economic viability of magnesium-ion batteries for grid storage applications hinges on several critical cost factors. Current cost estimates place magnesium-ion battery systems between $250-400 per kWh, positioning them competitively against lithium-ion alternatives which typically range from $300-500 per kWh for grid-scale implementations. This cost advantage stems primarily from the abundance of magnesium resources, which constitute approximately 2.1% of the earth's crust—significantly more abundant than lithium at 0.0007%.

Raw material economics strongly favor magnesium-ion technology, with magnesium commodity prices averaging $2,500-3,000 per metric ton compared to lithium carbonate at $15,000-20,000 per ton (as of 2023). This fundamental cost differential creates a substantial baseline advantage for scaling production. Additionally, magnesium extraction and processing generally require less energy and water consumption than lithium, further enhancing the economic proposition through reduced operational expenses.

Manufacturing cost analyses indicate potential savings of 15-25% in production processes compared to lithium-ion batteries, primarily due to less stringent handling requirements and simpler electrolyte formulations. The elimination of costly cobalt and nickel from cathode materials—elements commonly used in lithium-ion batteries—represents another significant cost reduction factor. These manufacturing advantages could accelerate as production scales, with economies of scale potentially reducing costs by an additional 30-40% over the next decade.

Lifecycle economic assessment reveals promising total cost of ownership (TCO) metrics. Magnesium-ion batteries demonstrate theoretical cycle life potential of 3,000-5,000 cycles, comparable to many commercial lithium-ion formulations. When factoring in installation, operation, maintenance, and end-of-life costs, the levelized cost of storage (LCOS) for magnesium-ion systems is projected at $0.12-0.18 per kWh-cycle, positioning them favorably against the current lithium-ion LCOS range of $0.15-0.25.

Investment requirements for commercial deployment present both challenges and opportunities. Initial capital expenditure for manufacturing facilities remains high, estimated at $80-120 million for a 1 GWh annual production capacity. However, return on investment projections indicate potential payback periods of 5-7 years, assuming successful technology commercialization and market adoption rates similar to early lithium-ion grid storage implementations.

Sensitivity analysis reveals that economic feasibility is most vulnerable to electrolyte development costs and cathode performance improvements. A 20% improvement in these areas could reduce overall system costs by up to 35%, while underperformance could eliminate the economic advantage over established technologies. This underscores the importance of continued R&D investment to realize the full economic potential of magnesium-ion battery technology for grid storage applications.

Raw material economics strongly favor magnesium-ion technology, with magnesium commodity prices averaging $2,500-3,000 per metric ton compared to lithium carbonate at $15,000-20,000 per ton (as of 2023). This fundamental cost differential creates a substantial baseline advantage for scaling production. Additionally, magnesium extraction and processing generally require less energy and water consumption than lithium, further enhancing the economic proposition through reduced operational expenses.

Manufacturing cost analyses indicate potential savings of 15-25% in production processes compared to lithium-ion batteries, primarily due to less stringent handling requirements and simpler electrolyte formulations. The elimination of costly cobalt and nickel from cathode materials—elements commonly used in lithium-ion batteries—represents another significant cost reduction factor. These manufacturing advantages could accelerate as production scales, with economies of scale potentially reducing costs by an additional 30-40% over the next decade.

Lifecycle economic assessment reveals promising total cost of ownership (TCO) metrics. Magnesium-ion batteries demonstrate theoretical cycle life potential of 3,000-5,000 cycles, comparable to many commercial lithium-ion formulations. When factoring in installation, operation, maintenance, and end-of-life costs, the levelized cost of storage (LCOS) for magnesium-ion systems is projected at $0.12-0.18 per kWh-cycle, positioning them favorably against the current lithium-ion LCOS range of $0.15-0.25.

Investment requirements for commercial deployment present both challenges and opportunities. Initial capital expenditure for manufacturing facilities remains high, estimated at $80-120 million for a 1 GWh annual production capacity. However, return on investment projections indicate potential payback periods of 5-7 years, assuming successful technology commercialization and market adoption rates similar to early lithium-ion grid storage implementations.

Sensitivity analysis reveals that economic feasibility is most vulnerable to electrolyte development costs and cathode performance improvements. A 20% improvement in these areas could reduce overall system costs by up to 35%, while underperformance could eliminate the economic advantage over established technologies. This underscores the importance of continued R&D investment to realize the full economic potential of magnesium-ion battery technology for grid storage applications.

Environmental Impact and Sustainability Assessment

The environmental impact of magnesium-ion batteries for grid storage applications presents a significantly more favorable profile compared to conventional lithium-ion technologies. Magnesium resources are abundant in the Earth's crust, approximately 2.3% compared to lithium's 0.002%, reducing the ecological footprint associated with resource extraction. Mining operations for magnesium typically disturb less land area and generate fewer toxic byproducts than lithium extraction, particularly avoiding the water-intensive brine evaporation processes used in lithium production that can deplete local water resources.

Manufacturing processes for magnesium-ion batteries demonstrate lower energy consumption metrics, with preliminary life cycle assessments indicating a potential reduction of 15-20% in carbon emissions compared to lithium-ion battery production. The absence of cobalt and nickel in most magnesium-ion battery chemistries eliminates the ethical and environmental concerns associated with mining these materials, particularly in developing regions where regulatory oversight may be limited.

From a waste management perspective, magnesium-ion batteries offer promising end-of-life characteristics. The materials are generally less toxic and more amenable to recycling processes, with magnesium compounds being easier to separate and recover than the complex lithium-ion battery components. Current research indicates recycling efficiency rates could potentially reach 80-85% for magnesium-ion systems, compared to approximately 50-60% for conventional lithium-ion batteries.

When considering the full lifecycle sustainability, magnesium-ion batteries demonstrate extended operational lifespans in grid storage applications, with laboratory tests suggesting cycle life improvements of 30-40% over comparable lithium-ion systems under optimal conditions. This longevity reduces the frequency of replacement and associated environmental impacts from manufacturing and disposal.

Water consumption metrics also favor magnesium-ion technology, with processing requirements estimated at 40-50% lower than lithium extraction and processing. This advantage becomes particularly significant in water-stressed regions where grid-scale energy storage deployment is often most needed to support renewable energy integration.

Safety considerations further enhance the sustainability profile of magnesium-ion batteries, as they exhibit lower thermal runaway risks and reduced fire hazards. This diminishes the potential for environmental contamination from catastrophic failures and reduces the need for extensive safety systems that consume additional resources and energy during operation.

Manufacturing processes for magnesium-ion batteries demonstrate lower energy consumption metrics, with preliminary life cycle assessments indicating a potential reduction of 15-20% in carbon emissions compared to lithium-ion battery production. The absence of cobalt and nickel in most magnesium-ion battery chemistries eliminates the ethical and environmental concerns associated with mining these materials, particularly in developing regions where regulatory oversight may be limited.

From a waste management perspective, magnesium-ion batteries offer promising end-of-life characteristics. The materials are generally less toxic and more amenable to recycling processes, with magnesium compounds being easier to separate and recover than the complex lithium-ion battery components. Current research indicates recycling efficiency rates could potentially reach 80-85% for magnesium-ion systems, compared to approximately 50-60% for conventional lithium-ion batteries.

When considering the full lifecycle sustainability, magnesium-ion batteries demonstrate extended operational lifespans in grid storage applications, with laboratory tests suggesting cycle life improvements of 30-40% over comparable lithium-ion systems under optimal conditions. This longevity reduces the frequency of replacement and associated environmental impacts from manufacturing and disposal.

Water consumption metrics also favor magnesium-ion technology, with processing requirements estimated at 40-50% lower than lithium extraction and processing. This advantage becomes particularly significant in water-stressed regions where grid-scale energy storage deployment is often most needed to support renewable energy integration.

Safety considerations further enhance the sustainability profile of magnesium-ion batteries, as they exhibit lower thermal runaway risks and reduced fire hazards. This diminishes the potential for environmental contamination from catastrophic failures and reduces the need for extensive safety systems that consume additional resources and energy during operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!