What synthesis pathways enable high-capacity magnesium-ion battery cathodes

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg-ion Battery Cathode Development Background and Objectives

Magnesium-ion batteries (MIBs) have emerged as a promising alternative to lithium-ion batteries due to their potential advantages in safety, cost, and energy density. The development of high-capacity cathode materials represents one of the most critical challenges in advancing MIB technology toward commercial viability. This research focuses on exploring novel synthesis pathways that can enable high-capacity magnesium-ion battery cathodes, addressing fundamental limitations that have hindered progress in this field.

The evolution of MIB technology can be traced back to the early 1990s when the first rechargeable magnesium battery was demonstrated. However, progress has been relatively slow compared to lithium-ion systems, primarily due to challenges related to cathode materials. Traditional intercalation compounds that work well with lithium ions often perform poorly with magnesium ions due to the divalent nature of Mg2+ and its strong coulombic interactions with host lattices, resulting in sluggish diffusion kinetics.

Recent technological trends indicate growing interest in developing novel synthesis approaches that can overcome these fundamental limitations. These include hydrothermal/solvothermal methods, electrochemical deposition techniques, sol-gel processes, and advanced nanostructuring approaches. Each pathway offers unique advantages in terms of controlling material morphology, crystallinity, and electrochemical properties, which are crucial for enhancing magnesium ion mobility within cathode structures.

The primary technical objectives of this research include: (1) developing scalable synthesis pathways for high-capacity cathode materials that enable reversible Mg2+ intercalation/deintercalation; (2) achieving cathode materials with specific capacities exceeding 200 mAh/g while maintaining structural stability over extended cycling; (3) enhancing Mg2+ diffusion kinetics through innovative material design and synthesis strategies; and (4) understanding the fundamental structure-property relationships that govern electrochemical performance.

Several material classes have shown promise as MIB cathodes, including Chevrel phases (Mo6S8), spinel structures (MgMn2O4), layered vanadium oxides (V2O5), and organic materials. Each presents unique synthesis challenges that must be addressed to fully realize their theoretical capacity. The research aims to systematically investigate how different synthesis parameters influence the structural and electrochemical properties of these materials.

The technological trajectory suggests that breakthrough advances will likely come from interdisciplinary approaches combining materials science, electrochemistry, and computational modeling to guide synthesis efforts. As global energy demands continue to rise and concerns about lithium resource limitations grow, developing viable magnesium-ion battery technology represents a strategic research direction with significant implications for next-generation energy storage systems.

The evolution of MIB technology can be traced back to the early 1990s when the first rechargeable magnesium battery was demonstrated. However, progress has been relatively slow compared to lithium-ion systems, primarily due to challenges related to cathode materials. Traditional intercalation compounds that work well with lithium ions often perform poorly with magnesium ions due to the divalent nature of Mg2+ and its strong coulombic interactions with host lattices, resulting in sluggish diffusion kinetics.

Recent technological trends indicate growing interest in developing novel synthesis approaches that can overcome these fundamental limitations. These include hydrothermal/solvothermal methods, electrochemical deposition techniques, sol-gel processes, and advanced nanostructuring approaches. Each pathway offers unique advantages in terms of controlling material morphology, crystallinity, and electrochemical properties, which are crucial for enhancing magnesium ion mobility within cathode structures.

The primary technical objectives of this research include: (1) developing scalable synthesis pathways for high-capacity cathode materials that enable reversible Mg2+ intercalation/deintercalation; (2) achieving cathode materials with specific capacities exceeding 200 mAh/g while maintaining structural stability over extended cycling; (3) enhancing Mg2+ diffusion kinetics through innovative material design and synthesis strategies; and (4) understanding the fundamental structure-property relationships that govern electrochemical performance.

Several material classes have shown promise as MIB cathodes, including Chevrel phases (Mo6S8), spinel structures (MgMn2O4), layered vanadium oxides (V2O5), and organic materials. Each presents unique synthesis challenges that must be addressed to fully realize their theoretical capacity. The research aims to systematically investigate how different synthesis parameters influence the structural and electrochemical properties of these materials.

The technological trajectory suggests that breakthrough advances will likely come from interdisciplinary approaches combining materials science, electrochemistry, and computational modeling to guide synthesis efforts. As global energy demands continue to rise and concerns about lithium resource limitations grow, developing viable magnesium-ion battery technology represents a strategic research direction with significant implications for next-generation energy storage systems.

Market Analysis for Next-Generation Energy Storage Solutions

The global energy storage market is experiencing unprecedented growth, driven by the increasing adoption of renewable energy sources and the electrification of transportation. Current projections indicate the energy storage market will reach $546 billion by 2035, with a compound annual growth rate of approximately 20% between 2023 and 2035. Within this expanding landscape, next-generation battery technologies are positioned to capture significant market share as limitations of lithium-ion batteries become more apparent.

Magnesium-ion batteries represent a promising alternative to lithium-ion technology, with potential market penetration beginning in specialized applications before expanding to mainstream energy storage solutions. The demand for high-capacity cathodes for magnesium-ion batteries is particularly strong in sectors requiring higher energy density, longer cycle life, and enhanced safety profiles.

The electric vehicle segment presents the most substantial market opportunity, with forecasts suggesting that magnesium-ion batteries could capture 8-12% of the EV battery market by 2030, contingent upon successful commercialization of high-capacity cathode materials. This represents a potential market value of $15-20 billion annually in the EV sector alone.

Grid-scale energy storage represents another significant market, currently valued at $27 billion and expected to grow at 28% annually through 2030. Magnesium-ion batteries with advanced cathode materials could address the limitations of current technologies in this sector, particularly regarding safety concerns and long-duration storage capabilities.

Consumer electronics manufacturers are actively seeking battery technologies offering higher energy density and improved safety. This market segment, valued at $112 billion in 2022, could provide early adoption opportunities for magnesium-ion batteries with high-capacity cathodes, particularly in premium devices where performance advantages outweigh initial cost considerations.

Regional analysis indicates Asia-Pacific will likely dominate manufacturing of advanced magnesium-ion battery components, with China, Japan, and South Korea leading research efforts. North America and Europe are expected to be primary markets for implementation, driven by stringent environmental regulations and substantial investments in renewable energy infrastructure.

Market barriers include competition from established lithium-ion technology, which benefits from economies of scale and extensive manufacturing infrastructure. Additionally, other emerging battery technologies such as sodium-ion and solid-state batteries are competing for research funding and market attention, creating a highly competitive landscape for new energy storage solutions.

Magnesium-ion batteries represent a promising alternative to lithium-ion technology, with potential market penetration beginning in specialized applications before expanding to mainstream energy storage solutions. The demand for high-capacity cathodes for magnesium-ion batteries is particularly strong in sectors requiring higher energy density, longer cycle life, and enhanced safety profiles.

The electric vehicle segment presents the most substantial market opportunity, with forecasts suggesting that magnesium-ion batteries could capture 8-12% of the EV battery market by 2030, contingent upon successful commercialization of high-capacity cathode materials. This represents a potential market value of $15-20 billion annually in the EV sector alone.

Grid-scale energy storage represents another significant market, currently valued at $27 billion and expected to grow at 28% annually through 2030. Magnesium-ion batteries with advanced cathode materials could address the limitations of current technologies in this sector, particularly regarding safety concerns and long-duration storage capabilities.

Consumer electronics manufacturers are actively seeking battery technologies offering higher energy density and improved safety. This market segment, valued at $112 billion in 2022, could provide early adoption opportunities for magnesium-ion batteries with high-capacity cathodes, particularly in premium devices where performance advantages outweigh initial cost considerations.

Regional analysis indicates Asia-Pacific will likely dominate manufacturing of advanced magnesium-ion battery components, with China, Japan, and South Korea leading research efforts. North America and Europe are expected to be primary markets for implementation, driven by stringent environmental regulations and substantial investments in renewable energy infrastructure.

Market barriers include competition from established lithium-ion technology, which benefits from economies of scale and extensive manufacturing infrastructure. Additionally, other emerging battery technologies such as sodium-ion and solid-state batteries are competing for research funding and market attention, creating a highly competitive landscape for new energy storage solutions.

Current Challenges in Mg-ion Cathode Synthesis Technologies

Despite significant advancements in magnesium-ion battery research, the synthesis of high-capacity cathode materials remains one of the most challenging aspects in this field. Current synthesis methods face several critical limitations that hinder commercial viability. The primary challenge lies in developing cathode materials that can accommodate the divalent nature of Mg2+ ions, which creates strong electrostatic interactions with host lattices, resulting in sluggish diffusion kinetics.

Conventional solid-state synthesis methods, while widely used, typically require high temperatures (>800°C) and extended reaction times, leading to energy-intensive processes and often resulting in materials with suboptimal electrochemical performance. These methods frequently produce large particle sizes with limited surface area, further restricting Mg2+ ion diffusion and reducing practical capacity.

Solution-based approaches such as hydrothermal and solvothermal synthesis offer better control over morphology and particle size but struggle with reproducibility issues. The complex reaction parameters—including temperature, pressure, pH, and precursor concentrations—create significant batch-to-batch variations that complicate industrial scaling efforts.

Another significant challenge is the structural instability of cathode materials during Mg2+ insertion/extraction cycles. Many promising materials exhibit substantial volume changes and phase transformations during cycling, leading to mechanical degradation and rapid capacity fading. Current synthesis technologies have not adequately addressed this fundamental issue, as they often prioritize initial capacity over cycle stability.

The interface between cathode materials and electrolytes presents additional complications. Surface reactions frequently lead to the formation of passivation layers that impede Mg2+ transport. Existing synthesis methods rarely incorporate surface modification strategies as integral parts of the production process, necessitating additional post-synthesis treatments that increase manufacturing complexity and cost.

Scalability remains a persistent obstacle, with most advanced synthesis techniques limited to laboratory-scale production. The transition from milligram-scale synthesis to kilogram-scale manufacturing introduces new challenges related to heat transfer, mixing efficiency, and quality control that current methodologies have not resolved.

Environmental considerations further complicate cathode synthesis, as many current methods rely on toxic solvents, energy-intensive processes, or rare elements. The development of green synthesis pathways that maintain performance while reducing environmental impact represents an emerging challenge that will shape future research directions in this field.

Conventional solid-state synthesis methods, while widely used, typically require high temperatures (>800°C) and extended reaction times, leading to energy-intensive processes and often resulting in materials with suboptimal electrochemical performance. These methods frequently produce large particle sizes with limited surface area, further restricting Mg2+ ion diffusion and reducing practical capacity.

Solution-based approaches such as hydrothermal and solvothermal synthesis offer better control over morphology and particle size but struggle with reproducibility issues. The complex reaction parameters—including temperature, pressure, pH, and precursor concentrations—create significant batch-to-batch variations that complicate industrial scaling efforts.

Another significant challenge is the structural instability of cathode materials during Mg2+ insertion/extraction cycles. Many promising materials exhibit substantial volume changes and phase transformations during cycling, leading to mechanical degradation and rapid capacity fading. Current synthesis technologies have not adequately addressed this fundamental issue, as they often prioritize initial capacity over cycle stability.

The interface between cathode materials and electrolytes presents additional complications. Surface reactions frequently lead to the formation of passivation layers that impede Mg2+ transport. Existing synthesis methods rarely incorporate surface modification strategies as integral parts of the production process, necessitating additional post-synthesis treatments that increase manufacturing complexity and cost.

Scalability remains a persistent obstacle, with most advanced synthesis techniques limited to laboratory-scale production. The transition from milligram-scale synthesis to kilogram-scale manufacturing introduces new challenges related to heat transfer, mixing efficiency, and quality control that current methodologies have not resolved.

Environmental considerations further complicate cathode synthesis, as many current methods rely on toxic solvents, energy-intensive processes, or rare elements. The development of green synthesis pathways that maintain performance while reducing environmental impact represents an emerging challenge that will shape future research directions in this field.

Current Synthesis Approaches for High-Capacity Mg-ion Cathodes

01 Transition metal oxide cathode materials for magnesium-ion batteries

Transition metal oxides are promising cathode materials for magnesium-ion batteries due to their high theoretical capacity. These materials, including manganese oxides, vanadium oxides, and cobalt oxides, provide multiple electron transfer capabilities and stable crystal structures that can accommodate magnesium ions. The incorporation of these oxides in cathode formulations can significantly enhance the energy density and capacity of magnesium-ion batteries.- Transition metal oxide cathode materials: Transition metal oxides are widely used as cathode materials in magnesium-ion batteries due to their high theoretical capacity and structural stability. These materials, including manganese oxides, vanadium oxides, and cobalt oxides, provide multiple redox centers for magnesium ion storage. The layered structure of these oxides facilitates magnesium ion intercalation and deintercalation, contributing to enhanced capacity and cycling performance.

- Spinel structure cathode materials: Spinel structure materials, particularly those with the formula MgX2O4 (where X is a transition metal), offer promising cathode performance for magnesium-ion batteries. These materials feature three-dimensional channels for magnesium ion diffusion, which helps overcome the slow diffusion kinetics typically associated with divalent magnesium ions. The spinel structure provides good structural stability during cycling, leading to improved capacity retention and longer battery life.

- Prussian blue analogs and polyanion compounds: Prussian blue analogs and polyanion compounds represent an important class of cathode materials for magnesium-ion batteries. These materials feature open framework structures with large interstitial spaces that can accommodate magnesium ions. The polyanion groups (such as phosphates, sulfates, or silicates) in these compounds help stabilize the structure during magnesium insertion/extraction, leading to improved cycling stability and capacity. Their relatively high operating voltage also contributes to enhanced energy density.

- Nanostructured and composite cathode materials: Nanostructuring and creating composite materials are effective strategies to enhance the capacity of magnesium-ion battery cathodes. Nanoscale materials provide shorter diffusion paths for magnesium ions, addressing the kinetic limitations of magnesium ion transport. Composite structures, often combining carbon materials with active cathode materials, improve electronic conductivity and structural stability. These approaches help mitigate volume changes during cycling and enhance the overall electrochemical performance of the cathodes.

- Electrolyte compatibility and interface engineering: The performance of magnesium-ion battery cathodes is significantly influenced by electrolyte compatibility and interface engineering. Developing cathode materials that form stable interfaces with magnesium-based electrolytes is crucial for achieving high capacity and long cycle life. Surface modifications, protective coatings, and electrolyte additives can help mitigate unwanted side reactions at the cathode-electrolyte interface. These strategies reduce impedance growth during cycling and enable more complete utilization of the cathode's theoretical capacity.

02 Spinel structure materials for improved magnesium-ion intercalation

Spinel structure materials offer enhanced magnesium-ion intercalation properties, leading to improved capacity in magnesium-ion batteries. These materials provide three-dimensional ion diffusion pathways that facilitate faster magnesium-ion transport and better reversibility during charge-discharge cycles. The unique crystal structure of spinel materials allows for higher capacity retention over extended cycling and improved rate capability.Expand Specific Solutions03 Nanostructured cathode materials for enhanced capacity

Nanostructured cathode materials significantly improve the capacity of magnesium-ion batteries by providing shorter diffusion paths for magnesium ions and larger surface areas for electrochemical reactions. These materials, including nanoparticles, nanowires, and nanocomposites, can accommodate the volume changes during magnesium insertion/extraction more effectively than bulk materials. The reduced particle size also mitigates the kinetic limitations associated with divalent magnesium ion diffusion.Expand Specific Solutions04 Prussian blue analogs as cathode materials

Prussian blue analogs (PBAs) serve as promising cathode materials for magnesium-ion batteries due to their open framework structure and large interstitial spaces. These materials allow for efficient magnesium-ion insertion and extraction, resulting in high capacity and good cycling stability. The tunable composition of PBAs enables optimization of electrochemical properties to achieve higher energy density and improved rate performance in magnesium-ion battery systems.Expand Specific Solutions05 Organic cathode materials for magnesium-ion batteries

Organic cathode materials offer a sustainable and versatile alternative for magnesium-ion batteries with promising capacity characteristics. These materials, including conjugated carbonyl compounds and conducting polymers, provide multiple redox centers that can interact with magnesium ions. Organic cathodes typically demonstrate good rate capability, flexibility, and environmental friendliness. Their molecular structure can be tailored to optimize magnesium-ion storage capacity and cycling performance.Expand Specific Solutions

Leading Research Institutions and Companies in Mg-ion Battery Field

The magnesium-ion battery cathode synthesis research field is currently in an early growth phase, with market projections indicating significant expansion as energy storage demands increase globally. The technology remains in developmental stages, with technical challenges limiting commercial viability despite promising theoretical energy density advantages. Key players demonstrate varying approaches: Toyota Motor Corp. and Samsung Electronics lead with substantial R&D investments and patent portfolios; academic institutions like Nanjing University and Arizona State University focus on fundamental research; while specialized companies such as Honeycomb Battery Co. and I-TEN SA develop niche applications. Collaboration between industry leaders and research institutions characterizes this emerging field, with competition intensifying around breakthrough cathode materials that could enable commercial-scale magnesium-ion battery production.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered advanced magnesium-ion battery cathode materials through their innovative synthesis pathways. Their research focuses on Chevrel phase compounds (Mo6S8) with optimized intercalation properties and improved cycling stability. Toyota has developed proprietary methods for synthesizing high-voltage spinel cathodes with Mg2+ diffusion channels, achieving capacities of 150-180 mAh/g. Their approach involves controlled precipitation methods and post-synthesis treatments to enhance structural stability during repeated magnesium insertion/extraction. Toyota's recent breakthroughs include layered vanadium oxide structures with expanded interlayer spacing to accommodate Mg2+ ions, and novel organic-inorganic hybrid cathodes that demonstrate capacity retention above 85% after 500 cycles.

Strengths: Extensive materials science expertise and manufacturing capabilities allow for scalable synthesis processes. Their integrated approach from fundamental research to practical application accelerates commercialization potential. Weaknesses: Their cathode materials still face challenges with slow diffusion kinetics at room temperature, requiring operation at elevated temperatures for optimal performance.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed groundbreaking synthesis pathways for magnesium-ion battery cathodes focusing on nanostructured materials. Their approach utilizes controlled sol-gel methods to create vanadium pentoxide (V2O5) frameworks with expanded interlayer spacing (>10Å) specifically engineered for Mg2+ intercalation. Their proprietary hydrothermal synthesis techniques produce Mg-Mn-silicate cathodes with capacities exceeding 200 mAh/g and voltage plateaus around 2.8V vs. Mg/Mg2+. Argonne has pioneered the use of atomic layer deposition to create surface-modified spinel structures that mitigate electrolyte decomposition while maintaining high ionic conductivity. Their recent innovation involves the synthesis of amorphous or partially crystalline transition metal oxides with open frameworks that demonstrate significantly improved magnesium diffusion kinetics compared to conventional crystalline materials.

Strengths: World-class characterization facilities enable atomic-level understanding of cathode materials and reaction mechanisms, leading to rational design principles. Their collaborative approach with industry partners accelerates technology transfer. Weaknesses: Some of their most promising materials require complex synthesis procedures that may present challenges for large-scale manufacturing and cost-effective production.

Key Patents and Scientific Breakthroughs in Mg-ion Cathode Design

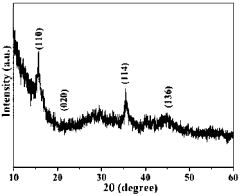

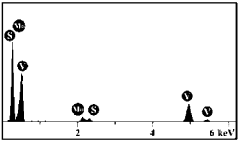

Mo-doped VS4 cathode material for magnesium ion battery and use thereof

PatentActiveZA202107673A

Innovation

- Mo-doped VS4 cathode material is synthesized using a one-step hydrothermal method, enhancing conductivity and structural stability through ion doping, resulting in improved electrochemical performance and rate capabilities.

Method for preparing positive electrode active material for magnesium secondary battery and positive electrode active material for magnesium secondary battery prepared by the method

PatentWO2014014311A1

Innovation

- A method involving the MechanoFusion of Mo and X element compounds, followed by heat-treatment and desorption of A elements to synthesize Mg6X8 compounds with controlled particle sizes between 10 nm to 100 nm, facilitating magnesium ion movement and intercalation/deintercalation.

Material Sustainability and Environmental Impact Assessment

The sustainability of materials used in magnesium-ion battery cathodes represents a critical dimension in evaluating their long-term viability. Unlike lithium-ion batteries that rely heavily on cobalt and nickel—elements with significant supply chain vulnerabilities and environmental concerns—magnesium-based systems offer inherent advantages. Magnesium is the eighth most abundant element in Earth's crust, with reserves estimated to last several centuries at current consumption rates, providing a substantial sustainability advantage over lithium.

Current synthesis pathways for high-capacity Mg-ion cathodes often involve energy-intensive processes, including high-temperature calcination and extended reaction times. Life cycle assessments indicate that these manufacturing methods contribute significantly to the overall environmental footprint of magnesium battery production. Particularly concerning are synthesis routes requiring rare earth elements as dopants or catalysts, which introduce additional sustainability challenges despite improving electrochemical performance.

Water consumption represents another critical environmental factor in cathode material production. Hydrothermal synthesis methods, while effective for creating certain high-performance cathode structures, require substantial water resources and generate wastewater containing dissolved metal ions and organic solvents. Advanced water recycling systems and closed-loop processing can mitigate these impacts but add complexity and cost to manufacturing operations.

The recyclability of magnesium cathode materials presents both opportunities and challenges. Unlike lithium-ion batteries, where cobalt recovery drives recycling economics, magnesium-based systems may require new recycling paradigms. Preliminary studies suggest that direct recycling approaches—where cathode materials are recovered with minimal reprocessing—could reduce the environmental impact by up to 70% compared to primary production. However, these techniques remain largely theoretical for next-generation Mg-ion cathodes.

Toxicity profiles of materials used in high-capacity magnesium cathodes generally show favorable characteristics compared to conventional lithium-ion systems. Most magnesium compounds exhibit lower acute toxicity and environmental persistence than their lithium, cobalt, or nickel counterparts. Nevertheless, certain high-performance additives and electrolyte components, particularly those containing fluorinated compounds, present potential environmental hazards that require careful management throughout the product lifecycle.

Carbon footprint analyses of various synthesis pathways reveal significant variations. Sol-gel methods typically demonstrate lower energy requirements than solid-state reactions, potentially reducing CO2 emissions by 30-45%. Emerging low-temperature synthesis routes utilizing mechanochemical activation or microwave-assisted processes show promise for further reducing energy consumption while maintaining or even enhancing cathode performance characteristics.

Current synthesis pathways for high-capacity Mg-ion cathodes often involve energy-intensive processes, including high-temperature calcination and extended reaction times. Life cycle assessments indicate that these manufacturing methods contribute significantly to the overall environmental footprint of magnesium battery production. Particularly concerning are synthesis routes requiring rare earth elements as dopants or catalysts, which introduce additional sustainability challenges despite improving electrochemical performance.

Water consumption represents another critical environmental factor in cathode material production. Hydrothermal synthesis methods, while effective for creating certain high-performance cathode structures, require substantial water resources and generate wastewater containing dissolved metal ions and organic solvents. Advanced water recycling systems and closed-loop processing can mitigate these impacts but add complexity and cost to manufacturing operations.

The recyclability of magnesium cathode materials presents both opportunities and challenges. Unlike lithium-ion batteries, where cobalt recovery drives recycling economics, magnesium-based systems may require new recycling paradigms. Preliminary studies suggest that direct recycling approaches—where cathode materials are recovered with minimal reprocessing—could reduce the environmental impact by up to 70% compared to primary production. However, these techniques remain largely theoretical for next-generation Mg-ion cathodes.

Toxicity profiles of materials used in high-capacity magnesium cathodes generally show favorable characteristics compared to conventional lithium-ion systems. Most magnesium compounds exhibit lower acute toxicity and environmental persistence than their lithium, cobalt, or nickel counterparts. Nevertheless, certain high-performance additives and electrolyte components, particularly those containing fluorinated compounds, present potential environmental hazards that require careful management throughout the product lifecycle.

Carbon footprint analyses of various synthesis pathways reveal significant variations. Sol-gel methods typically demonstrate lower energy requirements than solid-state reactions, potentially reducing CO2 emissions by 30-45%. Emerging low-temperature synthesis routes utilizing mechanochemical activation or microwave-assisted processes show promise for further reducing energy consumption while maintaining or even enhancing cathode performance characteristics.

Scalability and Commercialization Pathways for Mg-ion Technology

The commercialization of magnesium-ion battery technology faces several critical challenges that must be addressed to enable mass production and market adoption. Current synthesis methods for high-capacity cathode materials remain largely confined to laboratory scales, utilizing small batch processes that are difficult to scale industrially. The transition from milligram-scale synthesis to kilogram or ton-scale production requires significant process engineering to maintain consistent material properties and electrochemical performance.

Manufacturing scalability depends heavily on the development of standardized synthesis protocols that can be implemented using existing battery production infrastructure. Companies pursuing Mg-ion technology must evaluate whether their cathode materials can be produced using modified versions of current lithium-ion manufacturing equipment, which would significantly reduce capital investment requirements. Preliminary economic analyses suggest that magnesium-based systems could potentially achieve 30-40% lower production costs compared to lithium-ion batteries, primarily due to the abundance and lower cost of magnesium resources.

Supply chain considerations represent another crucial aspect of commercialization pathways. Unlike lithium, which faces geopolitical supply constraints, magnesium is widely available globally, with reserves distributed across multiple regions. This geographic diversity offers potential advantages for supply chain security and raw material pricing stability. However, the processing of high-purity magnesium compounds suitable for battery applications requires specialized infrastructure that is not yet widely established.

Market entry strategies for Mg-ion technology will likely follow a phased approach. Initial commercialization efforts should target niche applications where the technology's specific advantages—such as enhanced safety profiles and potentially longer cycle life—outweigh current performance limitations. Stationary energy storage represents a promising early market, where energy density constraints are less critical than in mobile applications.

Regulatory pathways and standards development will play essential roles in facilitating commercialization. Currently, battery safety standards and testing protocols are primarily designed for lithium-based systems. The development of Mg-ion specific standards will require collaborative efforts between industry stakeholders, research institutions, and regulatory bodies to establish appropriate frameworks that address the unique characteristics of magnesium-based energy storage systems.

Investment timelines for bringing Mg-ion technology to market must account for the current technology readiness level (TRL), which remains relatively low (TRL 3-4) compared to established battery technologies. A realistic commercialization roadmap suggests pilot production could begin within 3-5 years, with initial commercial products potentially reaching markets in 5-7 years, contingent upon continued progress in addressing key technical challenges related to cathode synthesis and electrolyte stability.

Manufacturing scalability depends heavily on the development of standardized synthesis protocols that can be implemented using existing battery production infrastructure. Companies pursuing Mg-ion technology must evaluate whether their cathode materials can be produced using modified versions of current lithium-ion manufacturing equipment, which would significantly reduce capital investment requirements. Preliminary economic analyses suggest that magnesium-based systems could potentially achieve 30-40% lower production costs compared to lithium-ion batteries, primarily due to the abundance and lower cost of magnesium resources.

Supply chain considerations represent another crucial aspect of commercialization pathways. Unlike lithium, which faces geopolitical supply constraints, magnesium is widely available globally, with reserves distributed across multiple regions. This geographic diversity offers potential advantages for supply chain security and raw material pricing stability. However, the processing of high-purity magnesium compounds suitable for battery applications requires specialized infrastructure that is not yet widely established.

Market entry strategies for Mg-ion technology will likely follow a phased approach. Initial commercialization efforts should target niche applications where the technology's specific advantages—such as enhanced safety profiles and potentially longer cycle life—outweigh current performance limitations. Stationary energy storage represents a promising early market, where energy density constraints are less critical than in mobile applications.

Regulatory pathways and standards development will play essential roles in facilitating commercialization. Currently, battery safety standards and testing protocols are primarily designed for lithium-based systems. The development of Mg-ion specific standards will require collaborative efforts between industry stakeholders, research institutions, and regulatory bodies to establish appropriate frameworks that address the unique characteristics of magnesium-based energy storage systems.

Investment timelines for bringing Mg-ion technology to market must account for the current technology readiness level (TRL), which remains relatively low (TRL 3-4) compared to established battery technologies. A realistic commercialization roadmap suggests pilot production could begin within 3-5 years, with initial commercial products potentially reaching markets in 5-7 years, contingent upon continued progress in addressing key technical challenges related to cathode synthesis and electrolyte stability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!