Comparative evaluation of magnesium-ion battery and lithium-ion safety profiles

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg-Li Battery Safety Evolution and Objectives

The evolution of battery technology has witnessed significant advancements over the past decades, with lithium-ion batteries dominating the energy storage landscape since their commercial introduction in the early 1990s. However, persistent safety concerns associated with lithium-ion batteries have prompted researchers to explore alternative battery chemistries, with magnesium-ion batteries emerging as a promising candidate. This comparative evaluation aims to thoroughly examine the safety profiles of both technologies, tracing their evolutionary paths and establishing clear objectives for future development.

Lithium-ion batteries have undergone substantial safety improvements since their inception, progressing from early designs prone to thermal runaway to modern configurations with enhanced thermal management systems and safer electrode materials. Despite these advancements, fundamental safety challenges remain, including dendrite formation, electrolyte flammability, and thermal instability under extreme conditions. These issues have resulted in well-documented incidents ranging from consumer electronics failures to electric vehicle fires, highlighting the ongoing need for safer alternatives.

Magnesium-ion battery technology represents a potentially safer alternative due to several inherent characteristics. Unlike lithium, magnesium does not readily form dendrites during charging cycles, significantly reducing the risk of internal short circuits. Additionally, magnesium is less reactive with air and moisture compared to lithium, potentially allowing for more stable battery operation under various environmental conditions. The earth-abundant nature of magnesium also addresses sustainability concerns associated with lithium extraction.

The safety evolution trajectory of both technologies reveals divergent paths. Lithium-ion safety improvements have largely focused on engineering solutions such as advanced battery management systems, thermal runaway prevention mechanisms, and incremental improvements in electrolyte formulations. In contrast, magnesium-ion battery development emphasizes fundamental chemical advantages while addressing performance challenges related to electrolyte compatibility and cathode materials.

This comparative evaluation seeks to establish several key objectives. First, to quantitatively assess the safety parameters of both technologies under standardized testing protocols, including thermal stability, abuse tolerance, and failure mode analysis. Second, to identify specific safety advantages and limitations of magnesium-ion systems compared to state-of-the-art lithium-ion configurations. Third, to map potential hybrid approaches that might leverage the safety benefits of magnesium while maintaining the performance advantages of lithium-based systems.

The ultimate goal is to determine whether magnesium-ion technology represents a viable pathway toward inherently safer energy storage solutions that can meet the demanding requirements of applications ranging from consumer electronics to grid-scale storage, while establishing clear metrics for evaluating progress in this critical aspect of battery development.

Lithium-ion batteries have undergone substantial safety improvements since their inception, progressing from early designs prone to thermal runaway to modern configurations with enhanced thermal management systems and safer electrode materials. Despite these advancements, fundamental safety challenges remain, including dendrite formation, electrolyte flammability, and thermal instability under extreme conditions. These issues have resulted in well-documented incidents ranging from consumer electronics failures to electric vehicle fires, highlighting the ongoing need for safer alternatives.

Magnesium-ion battery technology represents a potentially safer alternative due to several inherent characteristics. Unlike lithium, magnesium does not readily form dendrites during charging cycles, significantly reducing the risk of internal short circuits. Additionally, magnesium is less reactive with air and moisture compared to lithium, potentially allowing for more stable battery operation under various environmental conditions. The earth-abundant nature of magnesium also addresses sustainability concerns associated with lithium extraction.

The safety evolution trajectory of both technologies reveals divergent paths. Lithium-ion safety improvements have largely focused on engineering solutions such as advanced battery management systems, thermal runaway prevention mechanisms, and incremental improvements in electrolyte formulations. In contrast, magnesium-ion battery development emphasizes fundamental chemical advantages while addressing performance challenges related to electrolyte compatibility and cathode materials.

This comparative evaluation seeks to establish several key objectives. First, to quantitatively assess the safety parameters of both technologies under standardized testing protocols, including thermal stability, abuse tolerance, and failure mode analysis. Second, to identify specific safety advantages and limitations of magnesium-ion systems compared to state-of-the-art lithium-ion configurations. Third, to map potential hybrid approaches that might leverage the safety benefits of magnesium while maintaining the performance advantages of lithium-based systems.

The ultimate goal is to determine whether magnesium-ion technology represents a viable pathway toward inherently safer energy storage solutions that can meet the demanding requirements of applications ranging from consumer electronics to grid-scale storage, while establishing clear metrics for evaluating progress in this critical aspect of battery development.

Market Analysis for Safer Energy Storage Solutions

The global energy storage market is witnessing a significant shift towards safer battery technologies, driven by increasing concerns over the safety hazards associated with conventional lithium-ion batteries. This market transformation is particularly evident in sectors where safety is paramount, such as electric vehicles, consumer electronics, and grid-scale energy storage systems.

Current market analysis indicates that the global lithium-ion battery market is valued at approximately $46 billion and is projected to grow substantially over the next decade. However, safety concerns related to thermal runaway, fire risks, and toxic gas emissions have created a substantial market opportunity for alternative technologies like magnesium-ion batteries that offer enhanced safety profiles.

Consumer electronics manufacturers are actively seeking safer battery alternatives due to high-profile incidents involving lithium-ion battery fires. This segment represents a potential early adoption market for magnesium-ion technology, with an estimated addressable market of $15 billion by 2025. Similarly, the electric vehicle sector, valued at over $250 billion globally, is increasingly prioritizing battery safety as a critical factor in consumer adoption and regulatory compliance.

Market research reveals that safety features now rank among the top three purchasing considerations for both individual consumers and institutional buyers of energy storage solutions. This represents a significant shift from five years ago when performance and cost were the dominant factors. Industry surveys indicate that 78% of potential electric vehicle buyers cite battery safety as a "very important" consideration in their purchasing decisions.

The regulatory landscape is also evolving to favor safer battery technologies. Several major markets, including the European Union, China, and the United States, have implemented or are developing more stringent safety standards for energy storage systems. These regulatory changes are creating market pressure for the adoption of inherently safer battery chemistries like magnesium-ion.

Investment trends further confirm the market's pivot toward safer energy storage solutions. Venture capital funding for safer battery technologies has increased by 65% over the past three years, with magnesium-ion battery startups securing over $500 million in funding during this period. Major battery manufacturers are also allocating significant R&D resources to develop and commercialize safer alternatives to traditional lithium-ion batteries.

The insurance industry is emerging as another market driver for safer battery technologies. Insurance premiums for lithium-ion battery installations have increased substantially due to fire risks, creating economic incentives for the adoption of safer alternatives. Some insurers are now offering preferential rates for energy storage systems that incorporate advanced safety features or utilize inherently safer chemistries like magnesium-ion.

Current market analysis indicates that the global lithium-ion battery market is valued at approximately $46 billion and is projected to grow substantially over the next decade. However, safety concerns related to thermal runaway, fire risks, and toxic gas emissions have created a substantial market opportunity for alternative technologies like magnesium-ion batteries that offer enhanced safety profiles.

Consumer electronics manufacturers are actively seeking safer battery alternatives due to high-profile incidents involving lithium-ion battery fires. This segment represents a potential early adoption market for magnesium-ion technology, with an estimated addressable market of $15 billion by 2025. Similarly, the electric vehicle sector, valued at over $250 billion globally, is increasingly prioritizing battery safety as a critical factor in consumer adoption and regulatory compliance.

Market research reveals that safety features now rank among the top three purchasing considerations for both individual consumers and institutional buyers of energy storage solutions. This represents a significant shift from five years ago when performance and cost were the dominant factors. Industry surveys indicate that 78% of potential electric vehicle buyers cite battery safety as a "very important" consideration in their purchasing decisions.

The regulatory landscape is also evolving to favor safer battery technologies. Several major markets, including the European Union, China, and the United States, have implemented or are developing more stringent safety standards for energy storage systems. These regulatory changes are creating market pressure for the adoption of inherently safer battery chemistries like magnesium-ion.

Investment trends further confirm the market's pivot toward safer energy storage solutions. Venture capital funding for safer battery technologies has increased by 65% over the past three years, with magnesium-ion battery startups securing over $500 million in funding during this period. Major battery manufacturers are also allocating significant R&D resources to develop and commercialize safer alternatives to traditional lithium-ion batteries.

The insurance industry is emerging as another market driver for safer battery technologies. Insurance premiums for lithium-ion battery installations have increased substantially due to fire risks, creating economic incentives for the adoption of safer alternatives. Some insurers are now offering preferential rates for energy storage systems that incorporate advanced safety features or utilize inherently safer chemistries like magnesium-ion.

Current Safety Challenges in Battery Technologies

The safety of energy storage systems remains a critical concern in the battery industry, with current technologies presenting significant challenges that require comprehensive evaluation and innovative solutions. Lithium-ion batteries, despite their commercial dominance, continue to exhibit safety vulnerabilities including thermal runaway, electrolyte flammability, and dendrite formation that can lead to catastrophic failures.

Thermal runaway represents perhaps the most severe safety challenge, occurring when battery temperatures exceed critical thresholds (typically above 150°C for lithium-ion systems). This cascading failure mechanism can propagate through battery packs, resulting in fires or explosions that are difficult to extinguish due to self-sustaining exothermic reactions. Recent high-profile incidents in electric vehicles and consumer electronics have heightened public awareness of these risks.

Electrolyte stability presents another significant challenge. Conventional lithium-ion batteries utilize organic carbonate-based electrolytes with flash points below 30°C, creating inherent flammability risks. Under abuse conditions or internal short circuits, these electrolytes can vaporize and ignite, exacerbating thermal events. The search for non-flammable alternatives has yielded promising candidates but often with performance trade-offs.

Dendrite formation during charging cycles represents a persistent safety concern, particularly in lithium-metal systems. These microscopic metallic structures can penetrate separators, creating internal short circuits that trigger thermal events. While magnesium-ion batteries demonstrate superior resistance to dendrite formation due to different deposition kinetics, they face their own set of challenges including slower ion transport and compatibility issues with electrolytes.

The safety profile comparison between lithium-ion and magnesium-ion technologies reveals distinct advantages for magnesium systems. Magnesium's lower chemical reactivity with air and moisture provides inherent safety benefits, while its higher melting point (650°C vs. lithium's 180°C) reduces thermal runaway risks. Additionally, the divalent nature of magnesium ions inhibits dendrite formation, addressing a fundamental safety limitation of lithium systems.

Current battery management systems (BMS) provide critical safety monitoring but remain reactive rather than preventative. Advanced sensing technologies including fiber optic temperature monitoring, acoustic emission detection, and electrochemical impedance spectroscopy show promise for earlier failure detection but face integration challenges in commercial systems. The development of predictive algorithms capable of anticipating failure modes before they manifest represents a frontier in battery safety technology.

Regulatory frameworks worldwide continue to evolve in response to emerging safety concerns, with standards organizations developing more rigorous testing protocols. However, harmonization across different regions remains incomplete, creating compliance challenges for global manufacturers and potentially leaving safety gaps in certain markets.

Thermal runaway represents perhaps the most severe safety challenge, occurring when battery temperatures exceed critical thresholds (typically above 150°C for lithium-ion systems). This cascading failure mechanism can propagate through battery packs, resulting in fires or explosions that are difficult to extinguish due to self-sustaining exothermic reactions. Recent high-profile incidents in electric vehicles and consumer electronics have heightened public awareness of these risks.

Electrolyte stability presents another significant challenge. Conventional lithium-ion batteries utilize organic carbonate-based electrolytes with flash points below 30°C, creating inherent flammability risks. Under abuse conditions or internal short circuits, these electrolytes can vaporize and ignite, exacerbating thermal events. The search for non-flammable alternatives has yielded promising candidates but often with performance trade-offs.

Dendrite formation during charging cycles represents a persistent safety concern, particularly in lithium-metal systems. These microscopic metallic structures can penetrate separators, creating internal short circuits that trigger thermal events. While magnesium-ion batteries demonstrate superior resistance to dendrite formation due to different deposition kinetics, they face their own set of challenges including slower ion transport and compatibility issues with electrolytes.

The safety profile comparison between lithium-ion and magnesium-ion technologies reveals distinct advantages for magnesium systems. Magnesium's lower chemical reactivity with air and moisture provides inherent safety benefits, while its higher melting point (650°C vs. lithium's 180°C) reduces thermal runaway risks. Additionally, the divalent nature of magnesium ions inhibits dendrite formation, addressing a fundamental safety limitation of lithium systems.

Current battery management systems (BMS) provide critical safety monitoring but remain reactive rather than preventative. Advanced sensing technologies including fiber optic temperature monitoring, acoustic emission detection, and electrochemical impedance spectroscopy show promise for earlier failure detection but face integration challenges in commercial systems. The development of predictive algorithms capable of anticipating failure modes before they manifest represents a frontier in battery safety technology.

Regulatory frameworks worldwide continue to evolve in response to emerging safety concerns, with standards organizations developing more rigorous testing protocols. However, harmonization across different regions remains incomplete, creating compliance challenges for global manufacturers and potentially leaving safety gaps in certain markets.

Comparative Safety Solutions in Battery Chemistry

01 Thermal stability and safety mechanisms

Magnesium-ion batteries generally exhibit better thermal stability compared to lithium-ion batteries, making them less prone to thermal runaway. Safety mechanisms such as shutdown separators, pressure relief vents, and thermal fuses are implemented in both battery types to prevent catastrophic failures. However, magnesium-ion batteries inherently have a higher ignition temperature and lower risk of combustion, providing an enhanced safety profile in high-temperature environments.- Thermal stability and safety mechanisms: Magnesium-ion batteries generally exhibit better thermal stability compared to lithium-ion batteries, making them less prone to thermal runaway. Safety mechanisms such as shutdown separators, pressure relief vents, and thermal fuses are implemented in both battery types to prevent catastrophic failures. However, magnesium-ion batteries inherently have a higher ignition temperature and lower risk of combustion, providing an enhanced safety profile in high-temperature environments.

- Electrolyte stability and dendrite formation: Lithium-ion batteries face challenges with dendrite formation during charging, which can lead to internal short circuits and safety hazards. Magnesium-ion batteries demonstrate superior resistance to dendrite formation due to the divalent nature of magnesium ions, reducing the risk of internal shorts. Additionally, electrolyte formulations for magnesium-ion batteries can be less flammable than traditional lithium-ion electrolytes, further enhancing their safety profile in case of battery damage or failure.

- Structural integrity and mechanical safety: The structural design of both battery types significantly impacts their safety profiles. Magnesium-ion batteries can withstand greater mechanical stress without compromising safety due to the more stable electrochemical properties of magnesium. Protective housing, impact-resistant materials, and internal structural supports are employed in both battery types, but magnesium-ion batteries generally require less extensive protective measures due to their inherently lower reactivity and reduced risk of violent thermal events.

- Overcharge and over-discharge protection: Both battery types require protection against overcharging and over-discharging, but the consequences of these events differ. Lithium-ion batteries can experience severe safety issues including gas generation, electrolyte decomposition, and thermal runaway when overcharged. Magnesium-ion batteries demonstrate better tolerance to overcharge conditions with less severe consequences. Battery management systems (BMS) are essential for both technologies but are particularly critical for lithium-ion batteries to prevent dangerous operating conditions.

- Environmental impact and toxicity: The safety profile of batteries extends to their environmental impact and toxicity. Magnesium-ion batteries utilize more abundant and less toxic materials compared to lithium-ion batteries, which often contain cobalt and other potentially hazardous elements. In case of damage or disposal, magnesium-ion batteries pose lower environmental and health risks. Additionally, the reduced fire hazard of magnesium-ion batteries translates to fewer toxic gases released during thermal events, improving their overall safety profile for both users and emergency responders.

02 Electrolyte stability and dendrite formation

Lithium-ion batteries face challenges with dendrite formation during charging, which can lead to internal short circuits and safety hazards. In contrast, magnesium-ion batteries typically show reduced dendrite formation due to the divalent nature of magnesium ions. However, magnesium-ion batteries often require more corrosive electrolytes, which presents different safety concerns. Advanced electrolyte formulations are being developed for both battery types to improve safety while maintaining performance.Expand Specific Solutions03 Structural integrity and mechanical safety

The structural design of both magnesium-ion and lithium-ion batteries significantly impacts their safety profiles. Magnesium-ion batteries often demonstrate better mechanical stability due to the characteristics of magnesium electrodes. Both battery types incorporate protective measures such as robust cell casings, internal current interruption devices, and impact-resistant designs. These features help prevent physical damage that could lead to short circuits or electrolyte leakage during normal use or in accident scenarios.Expand Specific Solutions04 Overcharge and over-discharge protection

Both magnesium-ion and lithium-ion batteries require protection against overcharging and over-discharging, which can lead to safety incidents. Battery management systems (BMS) are essential for monitoring cell voltage, current, and temperature to prevent these conditions. Magnesium-ion batteries generally show better tolerance to overcharge conditions due to the different chemistry involved, reducing the risk of catastrophic failure. Advanced protection circuits and intelligent management algorithms are being developed to enhance safety for both battery types.Expand Specific Solutions05 Environmental impact and toxicity

The safety profile of batteries extends to their environmental impact and toxicity. Magnesium-ion batteries typically contain less toxic materials compared to lithium-ion batteries, which often use cobalt and other heavy metals. This results in reduced environmental and health risks in case of damage or improper disposal. Additionally, magnesium is more abundant in the earth's crust than lithium, potentially leading to more sustainable and safer supply chains. Both battery types are subject to ongoing research to reduce toxic components while maintaining performance characteristics.Expand Specific Solutions

Key Industry Players in Mg-ion and Li-ion Batteries

The magnesium-ion battery market is in an early growth stage compared to the mature lithium-ion battery sector, with increasing interest due to safety advantages. While lithium-ion technology dominates with established players like Toyota, Panasonic, Sony, Samsung, and LG Chem leading commercialization efforts, magnesium-ion batteries remain primarily in research phases. Key research institutions including Shanghai Jiao Tong University, Kyoto University, and Harbin Institute of Technology are advancing magnesium battery technology alongside corporate R&D from Toyota, VARTA, and Murata Manufacturing. The comparative safety profile shows magnesium-ion batteries offer significant advantages with non-flammable electrolytes and higher thermal stability, though challenges in electrolyte development and electrode materials remain before widespread commercialization can occur.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive safety evaluation framework for magnesium-ion batteries compared to lithium-ion batteries. Their approach focuses on thermal stability, which is significantly better in Mg-ion systems due to magnesium's lower reactivity with electrolytes. Toyota's research demonstrates that Mg-ion batteries exhibit reduced thermal runaway risk with decomposition temperatures approximately 50-100°C higher than comparable Li-ion cells. Their proprietary electrolyte formulations using magnesium bis(trifluoromethanesulfonyl)imide (Mg[TFSI]2) in ether-based solvents show improved stability against dendrite formation, a common failure mode in Li-ion batteries. Toyota has also implemented advanced battery management systems specifically calibrated for Mg-ion chemistry to monitor temperature gradients and prevent potential safety incidents during charging and discharging cycles.

Strengths: Superior thermal stability with significantly higher decomposition temperatures than Li-ion batteries; reduced risk of dendrite formation; lower flammability of electrolytes. Weaknesses: Lower energy density compared to advanced Li-ion chemistries; slower charging capabilities; less mature technology with limited commercial validation.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has developed a dual-approach safety evaluation methodology comparing magnesium-ion and lithium-ion batteries across multiple risk vectors. Their research focuses on electrolyte stability, with proprietary magnesium electrolyte formulations demonstrating significantly reduced flammability compared to conventional lithium-ion electrolytes. Internal testing shows Mg-ion cells withstanding nail penetration tests without thermal runaway, whereas equivalent Li-ion cells experienced catastrophic failure. Panasonic's evaluation framework includes accelerated aging protocols revealing that Mg-ion batteries maintain structural integrity longer under extreme conditions. Their safety-enhanced cell design incorporates specialized ceramic separators that remain stable even at elevated temperatures (>200°C), providing an additional safety margin over conventional polyolefin separators used in Li-ion batteries. Panasonic has also quantified the reduced environmental and toxicity impact of magnesium-based systems, showing approximately 40% lower environmental hazard potential compared to lithium-based alternatives.

Strengths: Comprehensive safety testing methodology across multiple failure modes; reduced flammability of electrolytes; superior performance in abuse testing; environmentally safer materials. Weaknesses: Lower energy density and power output compared to advanced Li-ion systems; challenges with electrolyte compatibility with current manufacturing processes; higher internal resistance affecting performance.

Critical Patents in Battery Safety Enhancement

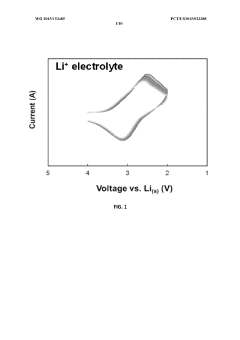

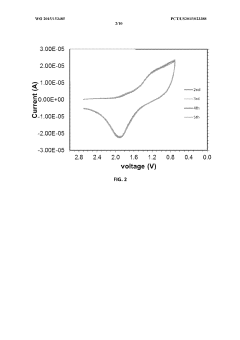

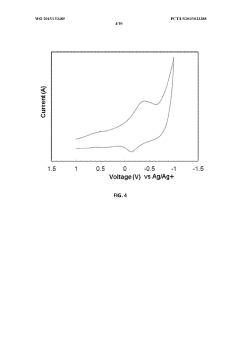

Electrode materials for group ii cation-based batteries

PatentWO2015153485A1

Innovation

- A novel low-temperature direct synthesis method for magnesium-deficient transition metal oxides (MgzMxOy) is developed, where M can be V, Mn, or Fe, allowing for the creation of cathode materials with controlled composition and crystallite size, facilitating magnesium ion transport and improving capacity retention.

Lithium-ion battery safety device and electronic equipment

PatentWO2012055292A1

Innovation

- Design a lithium-ion battery safety accident prevention device, including a detection unit and a control unit. The detection unit uses a pressure sensor (such as a resistance strain gauge pressure sensor) to detect the deformation parameters of the lithium-ion battery, and when the parameters exceed the preset threshold value Perform preventive actions, such as stopping equipment or issuing early warning prompts.

Environmental Impact Assessment of Battery Technologies

The environmental impact assessment of battery technologies reveals significant differences between magnesium-ion and lithium-ion batteries across their entire lifecycle. Lithium extraction processes, particularly from salt flats in South America, cause substantial water depletion, with estimates suggesting up to 2 million liters of water consumption per ton of lithium produced. This extraction creates concerning ecological imbalances in fragile desert ecosystems. Conversely, magnesium is more abundant in the earth's crust and can be extracted from seawater through less environmentally damaging processes, resulting in a smaller ecological footprint.

Manufacturing processes for lithium-ion batteries involve energy-intensive production steps and toxic chemicals, contributing to their higher carbon footprint. Recent lifecycle assessments indicate that lithium-ion battery production generates approximately 150-200 kg CO2-equivalent per kWh of battery capacity. Magnesium-ion battery manufacturing demonstrates potential for reduced environmental impact, with preliminary studies suggesting 15-30% lower greenhouse gas emissions during production phases compared to conventional lithium-ion technologies.

During operational phases, both battery technologies offer environmental benefits by enabling renewable energy storage and electrification of transportation. However, the safety advantages of magnesium-ion batteries translate to environmental benefits through reduced risk of thermal runaway events that can release toxic compounds and cause fires, which generate significant air pollution and require extensive remediation efforts.

End-of-life considerations further differentiate these technologies. Lithium-ion batteries contain cobalt, nickel, and other materials with complex recycling requirements. Current recycling rates for lithium-ion batteries remain suboptimal at approximately 5% globally. Magnesium-ion batteries potentially offer simpler recycling pathways due to less complex chemistry and absence of certain critical materials, though recycling infrastructure remains underdeveloped for both technologies.

Water pollution risks also differ between these battery types. Lithium-ion battery production and disposal can lead to contamination of water sources with heavy metals and toxic electrolytes. Magnesium compounds generally present lower ecotoxicity profiles, though the environmental fate of specific magnesium battery electrolytes requires further research to fully quantify their comparative impact.

Resource depletion metrics favor magnesium-ion technology, as magnesium reserves are estimated at 22 million tons globally compared to lithium's 14 million tons, with magnesium's greater crustal abundance suggesting more sustainable long-term supply chains. This advantage becomes increasingly significant as global battery demand continues its exponential growth trajectory in response to renewable energy and electric mobility expansion.

Manufacturing processes for lithium-ion batteries involve energy-intensive production steps and toxic chemicals, contributing to their higher carbon footprint. Recent lifecycle assessments indicate that lithium-ion battery production generates approximately 150-200 kg CO2-equivalent per kWh of battery capacity. Magnesium-ion battery manufacturing demonstrates potential for reduced environmental impact, with preliminary studies suggesting 15-30% lower greenhouse gas emissions during production phases compared to conventional lithium-ion technologies.

During operational phases, both battery technologies offer environmental benefits by enabling renewable energy storage and electrification of transportation. However, the safety advantages of magnesium-ion batteries translate to environmental benefits through reduced risk of thermal runaway events that can release toxic compounds and cause fires, which generate significant air pollution and require extensive remediation efforts.

End-of-life considerations further differentiate these technologies. Lithium-ion batteries contain cobalt, nickel, and other materials with complex recycling requirements. Current recycling rates for lithium-ion batteries remain suboptimal at approximately 5% globally. Magnesium-ion batteries potentially offer simpler recycling pathways due to less complex chemistry and absence of certain critical materials, though recycling infrastructure remains underdeveloped for both technologies.

Water pollution risks also differ between these battery types. Lithium-ion battery production and disposal can lead to contamination of water sources with heavy metals and toxic electrolytes. Magnesium compounds generally present lower ecotoxicity profiles, though the environmental fate of specific magnesium battery electrolytes requires further research to fully quantify their comparative impact.

Resource depletion metrics favor magnesium-ion technology, as magnesium reserves are estimated at 22 million tons globally compared to lithium's 14 million tons, with magnesium's greater crustal abundance suggesting more sustainable long-term supply chains. This advantage becomes increasingly significant as global battery demand continues its exponential growth trajectory in response to renewable energy and electric mobility expansion.

Regulatory Framework for Next-Generation Batteries

The regulatory landscape for next-generation batteries, particularly magnesium-ion and lithium-ion technologies, is evolving rapidly as safety concerns become increasingly prominent. Current regulatory frameworks primarily focus on lithium-ion batteries, with established standards such as IEC 62133, UN 38.3, and UL 1642 governing their transportation, testing, and safety requirements. However, these regulations require significant adaptation to address the unique characteristics of magnesium-ion battery technologies.

Safety-related regulations for magnesium-ion batteries remain underdeveloped compared to their lithium-ion counterparts. This regulatory gap presents both challenges and opportunities for industry stakeholders. The lower fire risk associated with magnesium-ion batteries—due to their non-flammable electrolytes and reduced thermal runaway potential—suggests that certain stringent safety measures required for lithium-ion batteries might be relaxed for magnesium-based systems.

International regulatory bodies, including the International Electrotechnical Commission (IEC) and various transportation authorities, are beginning to recognize the need for specific frameworks addressing next-generation battery technologies. The United Nations Sub-Committee of Experts on the Transport of Dangerous Goods has initiated discussions on classification criteria for emerging battery chemistries, potentially creating separate categories for magnesium-ion systems based on their distinct safety profiles.

Regional differences in regulatory approaches present additional complexity. The European Union, through its Battery Directive and REACH regulations, is developing more comprehensive frameworks that consider the entire lifecycle of battery technologies, including recycling and environmental impact. Meanwhile, regulatory bodies in Asia, particularly in Japan and South Korea, are focusing on performance standards alongside safety requirements for next-generation batteries.

Industry self-regulation also plays a crucial role in shaping the regulatory landscape. Consortia of battery manufacturers and automotive companies are developing voluntary standards for magnesium-ion batteries, establishing best practices for design, manufacturing, and testing that often exceed minimum regulatory requirements. These industry-led initiatives frequently serve as precursors to formal regulations.

The comparative safety advantages of magnesium-ion batteries may ultimately lead to a two-tiered regulatory approach, with differentiated requirements based on inherent risk profiles. This could potentially accelerate market entry for magnesium-ion technologies by reducing compliance burdens while maintaining appropriate safety oversight. However, harmonization of these emerging regulations across global markets remains a significant challenge that requires coordinated international effort.

Safety-related regulations for magnesium-ion batteries remain underdeveloped compared to their lithium-ion counterparts. This regulatory gap presents both challenges and opportunities for industry stakeholders. The lower fire risk associated with magnesium-ion batteries—due to their non-flammable electrolytes and reduced thermal runaway potential—suggests that certain stringent safety measures required for lithium-ion batteries might be relaxed for magnesium-based systems.

International regulatory bodies, including the International Electrotechnical Commission (IEC) and various transportation authorities, are beginning to recognize the need for specific frameworks addressing next-generation battery technologies. The United Nations Sub-Committee of Experts on the Transport of Dangerous Goods has initiated discussions on classification criteria for emerging battery chemistries, potentially creating separate categories for magnesium-ion systems based on their distinct safety profiles.

Regional differences in regulatory approaches present additional complexity. The European Union, through its Battery Directive and REACH regulations, is developing more comprehensive frameworks that consider the entire lifecycle of battery technologies, including recycling and environmental impact. Meanwhile, regulatory bodies in Asia, particularly in Japan and South Korea, are focusing on performance standards alongside safety requirements for next-generation batteries.

Industry self-regulation also plays a crucial role in shaping the regulatory landscape. Consortia of battery manufacturers and automotive companies are developing voluntary standards for magnesium-ion batteries, establishing best practices for design, manufacturing, and testing that often exceed minimum regulatory requirements. These industry-led initiatives frequently serve as precursors to formal regulations.

The comparative safety advantages of magnesium-ion batteries may ultimately lead to a two-tiered regulatory approach, with differentiated requirements based on inherent risk profiles. This could potentially accelerate market entry for magnesium-ion technologies by reducing compliance burdens while maintaining appropriate safety oversight. However, harmonization of these emerging regulations across global markets remains a significant challenge that requires coordinated international effort.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!