Analysis of Market Trends for SERS Substrates in Hydrophobic Coatings

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Substrate Technology Evolution and Objectives

Surface-Enhanced Raman Spectroscopy (SERS) substrate technology has evolved significantly since its discovery in the 1970s. Initially, SERS was observed on electrochemically roughened silver electrodes, providing enhancement factors of 10^5-10^6. The field remained relatively dormant until the late 1990s when advances in nanofabrication techniques enabled more precise control over metallic nanostructures, leading to the development of the first commercial SERS substrates.

The evolution of SERS substrates has been characterized by three distinct generations. First-generation substrates consisted of randomly roughened metal surfaces with limited reproducibility. Second-generation substrates introduced engineered nanostructures with improved enhancement factors and reproducibility. Current third-generation substrates feature sophisticated designs incorporating multiple materials and structures to achieve enhancement factors exceeding 10^10 while maintaining batch-to-batch consistency.

Hydrophobic coatings represent a critical innovation in SERS substrate technology. Traditional SERS substrates often suffer from poor wettability, limiting their effectiveness for aqueous sample analysis. The integration of hydrophobic coatings began around 2010, addressing this limitation while simultaneously providing protection against environmental degradation and extending shelf life.

Recent technological advancements have focused on developing omniphobic SERS substrates capable of repelling both water and oil-based substances while maintaining high enhancement factors. These innovations have expanded SERS applications into previously challenging areas such as environmental monitoring in complex matrices and point-of-care diagnostics in biological fluids.

The primary objective of current SERS substrate development is to achieve the "perfect substrate" - one that combines ultra-high sensitivity (single-molecule detection), excellent reproducibility (RSD < 5%), long-term stability (>1 year shelf life), and versatility across diverse sample types. Additionally, there is growing emphasis on developing substrates that are environmentally sustainable and cost-effective for mass production.

Future technological trajectories point toward smart SERS substrates with stimuli-responsive hydrophobic properties, allowing dynamic control over surface wettability. This would enable selective concentration of analytes and removal of interferents, significantly improving detection limits in complex matrices. Another emerging objective is the development of flexible and conformable SERS substrates with hydrophobic properties for in-situ environmental monitoring and wearable diagnostic applications.

The convergence of SERS substrate technology with microfluidics represents another important development direction, with hydrophobic patterning enabling precise fluid control and analyte concentration. This integration aims to create complete lab-on-chip systems for point-of-use applications in resource-limited settings, potentially revolutionizing fields from environmental monitoring to personalized medicine.

The evolution of SERS substrates has been characterized by three distinct generations. First-generation substrates consisted of randomly roughened metal surfaces with limited reproducibility. Second-generation substrates introduced engineered nanostructures with improved enhancement factors and reproducibility. Current third-generation substrates feature sophisticated designs incorporating multiple materials and structures to achieve enhancement factors exceeding 10^10 while maintaining batch-to-batch consistency.

Hydrophobic coatings represent a critical innovation in SERS substrate technology. Traditional SERS substrates often suffer from poor wettability, limiting their effectiveness for aqueous sample analysis. The integration of hydrophobic coatings began around 2010, addressing this limitation while simultaneously providing protection against environmental degradation and extending shelf life.

Recent technological advancements have focused on developing omniphobic SERS substrates capable of repelling both water and oil-based substances while maintaining high enhancement factors. These innovations have expanded SERS applications into previously challenging areas such as environmental monitoring in complex matrices and point-of-care diagnostics in biological fluids.

The primary objective of current SERS substrate development is to achieve the "perfect substrate" - one that combines ultra-high sensitivity (single-molecule detection), excellent reproducibility (RSD < 5%), long-term stability (>1 year shelf life), and versatility across diverse sample types. Additionally, there is growing emphasis on developing substrates that are environmentally sustainable and cost-effective for mass production.

Future technological trajectories point toward smart SERS substrates with stimuli-responsive hydrophobic properties, allowing dynamic control over surface wettability. This would enable selective concentration of analytes and removal of interferents, significantly improving detection limits in complex matrices. Another emerging objective is the development of flexible and conformable SERS substrates with hydrophobic properties for in-situ environmental monitoring and wearable diagnostic applications.

The convergence of SERS substrate technology with microfluidics represents another important development direction, with hydrophobic patterning enabling precise fluid control and analyte concentration. This integration aims to create complete lab-on-chip systems for point-of-use applications in resource-limited settings, potentially revolutionizing fields from environmental monitoring to personalized medicine.

Market Demand Analysis for SERS in Hydrophobic Applications

The global market for Surface-Enhanced Raman Spectroscopy (SERS) substrates in hydrophobic coating applications has witnessed significant growth in recent years, driven by increasing demand for advanced analytical techniques in various industries. The market size for SERS technologies was valued at approximately $1.2 billion in 2022, with a projected compound annual growth rate of 10.8% through 2030, according to recent industry analyses.

Hydrophobic coating applications represent a rapidly expanding segment within this market, particularly in sectors requiring water-repellent, self-cleaning, and anti-corrosion properties. The integration of SERS substrates with hydrophobic coatings creates multifunctional surfaces that combine analytical capabilities with protective features, addressing critical needs across multiple industries.

The pharmaceutical and biotechnology sectors demonstrate the highest demand for SERS-enhanced hydrophobic coatings, primarily for drug discovery, biomarker detection, and quality control processes. These industries value the non-destructive, highly sensitive detection capabilities that SERS provides while maintaining sample integrity through hydrophobic protection.

Environmental monitoring applications constitute another significant market segment, with growing implementation in water quality assessment, pollutant detection, and environmental remediation efforts. The ability of SERS-hydrophobic combinations to function effectively in harsh environmental conditions while delivering precise molecular identification has positioned them as valuable tools for field-deployable sensing systems.

The food safety and agriculture sectors have emerged as promising growth areas, with increasing regulatory requirements driving adoption of advanced detection methods for contaminants, pesticides, and foodborne pathogens. SERS substrates incorporated into hydrophobic packaging materials enable continuous monitoring capabilities while maintaining product protection.

Consumer electronics manufacturers have begun incorporating SERS-hydrophobic coatings in high-end devices, providing both analytical functionality and protection against water damage. This trend is expected to accelerate as miniaturization technologies advance and production costs decrease.

Regional market analysis reveals North America currently holds the largest market share at 38%, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding industrial applications and increasing R&D investments in countries like China, Japan, and South Korea.

Key market challenges include relatively high implementation costs, technical complexity requiring specialized expertise, and limited standardization across different applications. Despite these challenges, the convergence of nanotechnology advancements, increasing regulatory requirements for sensitive detection methods, and growing demand for multifunctional materials indicates strong continued market expansion for SERS substrates in hydrophobic coating applications.

Hydrophobic coating applications represent a rapidly expanding segment within this market, particularly in sectors requiring water-repellent, self-cleaning, and anti-corrosion properties. The integration of SERS substrates with hydrophobic coatings creates multifunctional surfaces that combine analytical capabilities with protective features, addressing critical needs across multiple industries.

The pharmaceutical and biotechnology sectors demonstrate the highest demand for SERS-enhanced hydrophobic coatings, primarily for drug discovery, biomarker detection, and quality control processes. These industries value the non-destructive, highly sensitive detection capabilities that SERS provides while maintaining sample integrity through hydrophobic protection.

Environmental monitoring applications constitute another significant market segment, with growing implementation in water quality assessment, pollutant detection, and environmental remediation efforts. The ability of SERS-hydrophobic combinations to function effectively in harsh environmental conditions while delivering precise molecular identification has positioned them as valuable tools for field-deployable sensing systems.

The food safety and agriculture sectors have emerged as promising growth areas, with increasing regulatory requirements driving adoption of advanced detection methods for contaminants, pesticides, and foodborne pathogens. SERS substrates incorporated into hydrophobic packaging materials enable continuous monitoring capabilities while maintaining product protection.

Consumer electronics manufacturers have begun incorporating SERS-hydrophobic coatings in high-end devices, providing both analytical functionality and protection against water damage. This trend is expected to accelerate as miniaturization technologies advance and production costs decrease.

Regional market analysis reveals North America currently holds the largest market share at 38%, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding industrial applications and increasing R&D investments in countries like China, Japan, and South Korea.

Key market challenges include relatively high implementation costs, technical complexity requiring specialized expertise, and limited standardization across different applications. Despite these challenges, the convergence of nanotechnology advancements, increasing regulatory requirements for sensitive detection methods, and growing demand for multifunctional materials indicates strong continued market expansion for SERS substrates in hydrophobic coating applications.

Technical Challenges in SERS Substrate Development

The development of Surface-Enhanced Raman Spectroscopy (SERS) substrates for hydrophobic coating applications faces several significant technical challenges that currently limit their widespread commercial adoption. These challenges span from fundamental material science issues to practical implementation concerns in real-world environments.

Substrate stability represents one of the most critical barriers to overcome. Current SERS substrates often suffer from degradation when exposed to environmental factors such as oxidation, humidity, and UV radiation. This instability significantly reduces their effective lifespan and reliability in hydrophobic coating applications, where long-term performance is essential for market acceptance.

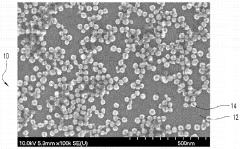

Reproducibility in manufacturing presents another major hurdle. The enhancement effect in SERS substrates is highly dependent on nanoscale features, making consistent production at scale extremely difficult. Variations in hot spot density and distribution lead to inconsistent signal enhancement, which compromises analytical reliability and quantitative applications in hydrophobic coating quality control and monitoring.

The integration of SERS substrates with hydrophobic coating matrices poses complex compatibility issues. The hydrophobic nature of the coatings can interfere with analyte access to SERS-active sites, reducing detection sensitivity. Additionally, the incorporation process must preserve both the SERS enhancement properties and the hydrophobic performance of the coating, creating a delicate balance that is technically challenging to achieve.

Cost-effectiveness remains a significant barrier to market penetration. Current high-performance SERS substrates often rely on precious metals like gold and silver, with complex nanofabrication techniques that drive up production costs. This economic factor limits scalability and widespread adoption in price-sensitive coating markets, particularly in industrial applications where large surface areas need treatment.

Signal specificity and selectivity challenges also persist. In complex chemical environments typical of hydrophobic coating applications, multiple compounds can generate overlapping Raman signals. Developing SERS substrates with molecular recognition capabilities or selective enhancement properties remains technically challenging but essential for practical implementation in quality control and monitoring systems.

Standardization issues further complicate the field. The lack of universally accepted performance metrics and testing protocols for SERS substrates in hydrophobic coating applications makes it difficult to compare different solutions and establish industry benchmarks. This absence of standardization impedes regulatory approval processes and slows market adoption.

Addressing these technical challenges requires interdisciplinary approaches combining nanotechnology, materials science, analytical chemistry, and manufacturing engineering. Recent research has begun exploring alternative materials such as graphene-based substrates, plasmonic alloys, and self-assembled nanostructures to overcome some of these limitations, but significant technical barriers remain before SERS substrates can achieve their full potential in hydrophobic coating applications.

Substrate stability represents one of the most critical barriers to overcome. Current SERS substrates often suffer from degradation when exposed to environmental factors such as oxidation, humidity, and UV radiation. This instability significantly reduces their effective lifespan and reliability in hydrophobic coating applications, where long-term performance is essential for market acceptance.

Reproducibility in manufacturing presents another major hurdle. The enhancement effect in SERS substrates is highly dependent on nanoscale features, making consistent production at scale extremely difficult. Variations in hot spot density and distribution lead to inconsistent signal enhancement, which compromises analytical reliability and quantitative applications in hydrophobic coating quality control and monitoring.

The integration of SERS substrates with hydrophobic coating matrices poses complex compatibility issues. The hydrophobic nature of the coatings can interfere with analyte access to SERS-active sites, reducing detection sensitivity. Additionally, the incorporation process must preserve both the SERS enhancement properties and the hydrophobic performance of the coating, creating a delicate balance that is technically challenging to achieve.

Cost-effectiveness remains a significant barrier to market penetration. Current high-performance SERS substrates often rely on precious metals like gold and silver, with complex nanofabrication techniques that drive up production costs. This economic factor limits scalability and widespread adoption in price-sensitive coating markets, particularly in industrial applications where large surface areas need treatment.

Signal specificity and selectivity challenges also persist. In complex chemical environments typical of hydrophobic coating applications, multiple compounds can generate overlapping Raman signals. Developing SERS substrates with molecular recognition capabilities or selective enhancement properties remains technically challenging but essential for practical implementation in quality control and monitoring systems.

Standardization issues further complicate the field. The lack of universally accepted performance metrics and testing protocols for SERS substrates in hydrophobic coating applications makes it difficult to compare different solutions and establish industry benchmarks. This absence of standardization impedes regulatory approval processes and slows market adoption.

Addressing these technical challenges requires interdisciplinary approaches combining nanotechnology, materials science, analytical chemistry, and manufacturing engineering. Recent research has begun exploring alternative materials such as graphene-based substrates, plasmonic alloys, and self-assembled nanostructures to overcome some of these limitations, but significant technical barriers remain before SERS substrates can achieve their full potential in hydrophobic coating applications.

Current SERS Substrate Solutions for Hydrophobic Surfaces

01 Metallic nanostructures for SERS substrates

Metallic nanostructures are widely used as SERS substrates due to their ability to enhance Raman signals through surface plasmon resonance. These structures can be fabricated using various methods including lithography, deposition, and chemical synthesis. Gold, silver, and copper nanoparticles or nanostructured surfaces are commonly employed for their excellent plasmonic properties. The size, shape, and arrangement of these metallic nanostructures can be optimized to achieve maximum SERS enhancement factors.- Metallic nanostructures for SERS substrates: Metallic nanostructures are widely used as SERS substrates due to their ability to enhance Raman signals through localized surface plasmon resonance. These substrates typically consist of noble metals like gold, silver, or copper arranged in various configurations such as nanoparticles, nanorods, or nanogaps. The size, shape, and spacing of these metallic structures can be optimized to achieve maximum enhancement factors, enabling sensitive detection of analytes at low concentrations.

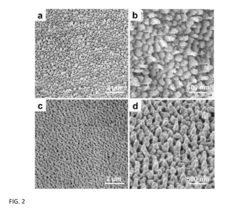

- Fabrication methods for SERS substrates: Various fabrication techniques are employed to create effective SERS substrates with reproducible enhancement factors. These methods include lithographic approaches, self-assembly processes, template-assisted growth, and chemical synthesis routes. Advanced manufacturing techniques allow for precise control over the substrate geometry, which is crucial for optimizing the plasmonic properties and ensuring consistent performance across the substrate surface for reliable analytical applications.

- SERS detection systems and instrumentation: SERS detection systems integrate specialized substrates with appropriate instrumentation for signal acquisition and analysis. These systems typically include laser excitation sources, spectrometers, detectors, and data processing software. Innovations in this area focus on improving sensitivity, portability, and ease of use, enabling applications in point-of-care diagnostics, environmental monitoring, and field-deployable sensing platforms.

- Substrate enhancement mechanisms and optimization: Research on SERS substrate enhancement mechanisms focuses on understanding and optimizing the electromagnetic and chemical enhancement factors. This includes engineering hotspots with intense local electromagnetic fields, controlling the surface chemistry of the substrate, and developing hybrid materials that combine multiple enhancement mechanisms. Computational modeling and experimental validation are used to design substrates with higher sensitivity and broader applicability across different analytes.

- Application-specific SERS substrate designs: SERS substrates are increasingly being tailored for specific applications such as biomedical diagnostics, food safety testing, environmental monitoring, and security screening. These specialized substrates may incorporate selective capture elements, protective coatings, or integrated microfluidics to enhance performance in complex sample matrices. Some designs focus on reusability, stability under harsh conditions, or compatibility with existing analytical workflows to facilitate practical implementation in real-world scenarios.

02 Fabrication methods for SERS substrates

Various fabrication techniques are employed to create effective SERS substrates with controlled morphology and reproducible enhancement factors. These methods include nanolithography, template-assisted growth, self-assembly, electrochemical deposition, and laser ablation. Advanced manufacturing processes allow for precise control over the nanoscale features that are critical for SERS performance. The fabrication methods can be tailored to create substrates with specific characteristics suitable for different analytical applications.Expand Specific Solutions03 Novel materials for SERS enhancement

Beyond traditional noble metals, researchers are exploring novel materials to create more effective SERS substrates. These include hybrid materials, semiconductor-metal composites, graphene-based structures, and metal oxide combinations. These novel materials can provide additional enhancement mechanisms, improved stability, or broader applicability. Some materials are designed to be biocompatible for in vivo applications, while others focus on chemical stability for harsh environmental sensing conditions.Expand Specific Solutions04 Portable and integrated SERS detection systems

Innovations in SERS technology include the development of portable, miniaturized, and integrated detection systems. These systems combine SERS substrates with microfluidics, optical components, and data processing capabilities to create complete analytical platforms. Such integrated approaches enable point-of-care diagnostics, field-deployable environmental monitoring, and rapid on-site chemical analysis. The integration of SERS substrates into practical devices bridges the gap between laboratory research and real-world applications.Expand Specific Solutions05 Application-specific SERS substrate designs

SERS substrates can be specifically designed for particular applications such as biomedical diagnostics, environmental monitoring, food safety, and security screening. These specialized substrates may incorporate molecular recognition elements, selective coatings, or specific geometries optimized for target analytes. Some designs focus on ultra-sensitive detection of specific biomarkers, while others emphasize multiplexed detection capabilities. Application-specific substrates often balance enhancement factors with other practical considerations such as reproducibility, stability, and ease of use.Expand Specific Solutions

Key Industry Players in SERS Substrate Manufacturing

The SERS substrates market in hydrophobic coatings is currently in a growth phase, characterized by increasing adoption across industrial applications. The market size is expanding steadily, projected to reach significant value as demand for advanced surface analysis and sensing technologies rises. From a technological maturity perspective, the field shows varied development levels, with academic institutions like University of British Columbia, Peking University, and The University of Sydney driving fundamental research, while commercial entities including Saint-Gobain, Guardian Glass, and Saudi Aramco focus on practical applications. Research organizations such as A*STAR and CSIR are bridging the gap between theoretical advancements and commercial viability. The competitive landscape reveals a balanced ecosystem of academic innovation and industrial implementation, with increasing collaboration between sectors accelerating technology transfer and market penetration.

University of British Columbia

Technical Solution: The University of British Columbia (UBC) has pioneered a green synthesis approach for SERS substrates with hydrophobic properties, focusing on environmental sustainability and biocompatibility. Their technology utilizes plant-derived reducing agents to create silver and gold nanoparticles with controlled morphology, which are then assembled onto cellulose-based scaffolds. The resulting structures are treated with environmentally friendly hydrophobic coatings derived from modified natural waxes and silicones. UBC's substrates achieve enhancement factors of approximately 10^6, sufficient for detecting pesticides and pharmaceutical compounds at concentrations below regulatory limits. A distinctive feature of their approach is the use of biodegradable materials for both the substrate base and hydrophobic coating, addressing end-of-life concerns associated with conventional nanomaterials[1]. Recent developments include paper-based SERS substrates with patterned hydrophobic regions that enable multiplexed detection without cross-contamination. These substrates maintain their SERS activity even after exposure to various environmental conditions, including UV radiation and temperature fluctuations between -20°C and 60°C[3]. UBC researchers have also demonstrated field applications of these substrates for on-site water quality monitoring in remote locations.

Strengths: Environmentally sustainable production methods; biodegradable components; cost-effective fabrication; suitable for field deployment; minimal toxicity concerns. Weaknesses: Lower enhancement factors compared to lithographically fabricated substrates; batch-to-batch variability; limited shelf-life compared to fully synthetic alternatives; potential for natural material degradation.

Agency for Science, Technology & Research

Technical Solution: The Agency for Science, Technology & Research (A*STAR) has developed advanced SERS substrates incorporating hydrophobic coatings for environmental monitoring and food safety applications. Their technology utilizes nanofabrication techniques to create highly ordered metallic nanostructures (primarily silver and gold) with controlled spacing and geometry, optimized for maximum SERS enhancement. A*STAR's approach involves a two-step process: first creating high-density hotspots through lithographic patterning, then applying fluorinated silane-based hydrophobic coatings that maintain SERS sensitivity while providing protection against environmental degradation. Their substrates demonstrate enhancement factors exceeding 10^7, allowing detection limits in the sub-ppb range for various contaminants[1]. A*STAR has also pioneered reusable SERS platforms with self-cleaning properties through the integration of superhydrophobic coatings that exhibit the "lotus effect," enabling water droplets to remove analytes after measurement, extending substrate lifetime significantly compared to conventional SERS materials[3].

Strengths: Superior sensitivity with high enhancement factors; excellent reproducibility through precise nanofabrication; extended shelf-life due to protective hydrophobic coatings; reusability through self-cleaning properties. Weaknesses: Higher production costs compared to chemical synthesis methods; requires sophisticated manufacturing facilities; potential for reduced sensitivity with thicker hydrophobic layers.

Critical Patents and Innovations in SERS Substrate Technology

SERS substrates

PatentInactiveUS9360429B2

Innovation

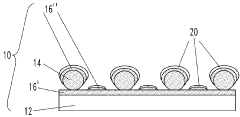

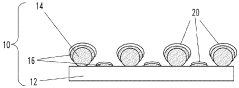

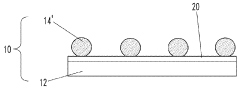

- The development of SERS substrates with a plasma nanocoating layer applied using low-temperature plasma deposition techniques, which allows for precise control of surface tension and contact angles, ensuring consistent chemical absorption and reproducible Raman signals by adjusting plasma chemistry and gas composition.

Surface enhanced raman scattering (SERS) apparatus, methods and applications

PatentActiveUS9001322B2

Innovation

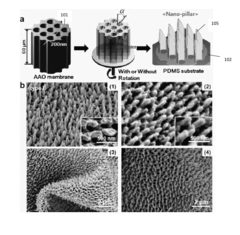

- The development of a shadow mask assisted evaporation (SMAE) method for fabricating SERS-enhanced nanostructured substrates with controlled nanostructures, including arrays of elongate shapes like nano-pillars, nano-nibs, and nano-triangular tips on flexible substrates, allowing for adjustable spacing and integration with functionalized nanoparticles for enhanced sensitivity.

Environmental Impact and Sustainability Considerations

The integration of SERS substrates in hydrophobic coatings presents significant environmental considerations that must be addressed as this technology gains market traction. The manufacturing processes for SERS substrates often involve noble metals like gold and silver, which require resource-intensive mining operations that can lead to habitat destruction, soil erosion, and water pollution. Additionally, chemical reagents used in substrate fabrication may include hazardous substances that pose risks to ecosystems if improperly managed during production or disposal phases.

Hydrophobic coatings enhanced with SERS technology offer potential environmental benefits through extended product lifespans and reduced maintenance requirements. By preventing water damage and microbial growth, these coatings can significantly decrease the frequency of reapplication and replacement, thereby reducing overall material consumption and waste generation. This longevity factor represents a key sustainability advantage that should be quantified in lifecycle assessments.

Concerns regarding nanoparticle leaching from SERS-enhanced hydrophobic coatings into aquatic environments warrant careful examination. Recent studies indicate that silver nanoparticles, commonly used in SERS substrates, can exhibit toxicity to aquatic organisms at certain concentrations. The environmental fate of these materials throughout their lifecycle requires thorough investigation to ensure that innovation in surface enhancement does not come at an ecological cost.

The recyclability of SERS-enhanced coatings presents both challenges and opportunities. Current recovery methods for noble metals from composite materials are limited in efficiency and economic viability. However, emerging technologies for precious metal reclamation from electronic waste show promise for adaptation to coating recovery systems, potentially creating closed-loop material cycles that would significantly improve sustainability profiles.

Regulatory frameworks governing nanomaterials in consumer and industrial products continue to evolve globally, with increasing emphasis on environmental impact assessment. Companies developing SERS substrate technologies for hydrophobic applications must anticipate stricter regulations regarding end-of-life management and environmental release prevention. Proactive adoption of green chemistry principles in substrate design could provide competitive advantages as regulatory requirements intensify.

Energy consumption during SERS substrate production represents another critical environmental consideration. Traditional manufacturing methods often require high-temperature processes and multiple purification steps with substantial energy footprints. Recent innovations in room-temperature synthesis and renewable energy integration in production facilities demonstrate pathways toward reducing the carbon intensity of these advanced materials, aligning with global decarbonization objectives.

Hydrophobic coatings enhanced with SERS technology offer potential environmental benefits through extended product lifespans and reduced maintenance requirements. By preventing water damage and microbial growth, these coatings can significantly decrease the frequency of reapplication and replacement, thereby reducing overall material consumption and waste generation. This longevity factor represents a key sustainability advantage that should be quantified in lifecycle assessments.

Concerns regarding nanoparticle leaching from SERS-enhanced hydrophobic coatings into aquatic environments warrant careful examination. Recent studies indicate that silver nanoparticles, commonly used in SERS substrates, can exhibit toxicity to aquatic organisms at certain concentrations. The environmental fate of these materials throughout their lifecycle requires thorough investigation to ensure that innovation in surface enhancement does not come at an ecological cost.

The recyclability of SERS-enhanced coatings presents both challenges and opportunities. Current recovery methods for noble metals from composite materials are limited in efficiency and economic viability. However, emerging technologies for precious metal reclamation from electronic waste show promise for adaptation to coating recovery systems, potentially creating closed-loop material cycles that would significantly improve sustainability profiles.

Regulatory frameworks governing nanomaterials in consumer and industrial products continue to evolve globally, with increasing emphasis on environmental impact assessment. Companies developing SERS substrate technologies for hydrophobic applications must anticipate stricter regulations regarding end-of-life management and environmental release prevention. Proactive adoption of green chemistry principles in substrate design could provide competitive advantages as regulatory requirements intensify.

Energy consumption during SERS substrate production represents another critical environmental consideration. Traditional manufacturing methods often require high-temperature processes and multiple purification steps with substantial energy footprints. Recent innovations in room-temperature synthesis and renewable energy integration in production facilities demonstrate pathways toward reducing the carbon intensity of these advanced materials, aligning with global decarbonization objectives.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of SERS substrates for hydrophobic coatings presents significant challenges that directly impact market adoption rates. Current production methods predominantly rely on cleanroom-based nanofabrication techniques, including electron beam lithography and focused ion beam milling, which entail substantial capital investments exceeding $1-5 million for basic equipment setups. These high-precision manufacturing approaches, while delivering excellent quality control, operate at production rates typically below 10 cm² per hour, creating a fundamental bottleneck for mass-market applications.

Cost analysis reveals that laboratory-grade SERS substrates currently retail between $50-200 per cm², positioning them primarily for high-value analytical applications rather than widespread industrial coating uses. Material costs constitute approximately 15-25% of the final product price, with manufacturing overhead and specialized handling requirements accounting for the majority of expenses. The cost structure becomes particularly prohibitive when considering the surface area requirements for commercial hydrophobic coating applications, which often demand coverage of several square meters.

Recent innovations in roll-to-roll nanoimprint lithography and solution-based self-assembly techniques demonstrate promising pathways toward scalability. These emerging methods have demonstrated production capabilities of up to 0.5-1 m²/hour at pilot scales, with projected costs potentially decreasing to $5-15 per cm² at industrial volumes. Several manufacturers have reported successful pilot production runs using these techniques, though consistency in SERS enhancement factors across large substrate areas remains a technical challenge.

Economic modeling indicates that a price point below $1 per cm² represents the critical threshold for widespread adoption in commercial hydrophobic coating applications. Achieving this target requires further optimization of production yields, which currently range from 60-85% depending on the manufacturing method employed. Material substitution strategies, particularly replacing noble metals with plasmonic alternatives, could potentially reduce raw material costs by 30-50%, though often at the expense of performance characteristics.

The equipment depreciation model significantly impacts overall production economics, with most specialized nanofabrication tools having effective operational lifespans of 5-7 years before requiring substantial upgrades. Companies pursuing vertical integration strategies have demonstrated 20-30% cost advantages compared to those relying on contract manufacturing arrangements, particularly when production volumes exceed 10,000 cm² monthly. These economic factors collectively shape the competitive landscape and influence market entry strategies for new participants in the SERS substrate sector.

Cost analysis reveals that laboratory-grade SERS substrates currently retail between $50-200 per cm², positioning them primarily for high-value analytical applications rather than widespread industrial coating uses. Material costs constitute approximately 15-25% of the final product price, with manufacturing overhead and specialized handling requirements accounting for the majority of expenses. The cost structure becomes particularly prohibitive when considering the surface area requirements for commercial hydrophobic coating applications, which often demand coverage of several square meters.

Recent innovations in roll-to-roll nanoimprint lithography and solution-based self-assembly techniques demonstrate promising pathways toward scalability. These emerging methods have demonstrated production capabilities of up to 0.5-1 m²/hour at pilot scales, with projected costs potentially decreasing to $5-15 per cm² at industrial volumes. Several manufacturers have reported successful pilot production runs using these techniques, though consistency in SERS enhancement factors across large substrate areas remains a technical challenge.

Economic modeling indicates that a price point below $1 per cm² represents the critical threshold for widespread adoption in commercial hydrophobic coating applications. Achieving this target requires further optimization of production yields, which currently range from 60-85% depending on the manufacturing method employed. Material substitution strategies, particularly replacing noble metals with plasmonic alternatives, could potentially reduce raw material costs by 30-50%, though often at the expense of performance characteristics.

The equipment depreciation model significantly impacts overall production economics, with most specialized nanofabrication tools having effective operational lifespans of 5-7 years before requiring substantial upgrades. Companies pursuing vertical integration strategies have demonstrated 20-30% cost advantages compared to those relying on contract manufacturing arrangements, particularly when production volumes exceed 10,000 cm² monthly. These economic factors collectively shape the competitive landscape and influence market entry strategies for new participants in the SERS substrate sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!