What Determines the Catalytic Efficiency of SERS Substrates

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Substrate Catalysis Background and Objectives

Surface-Enhanced Raman Spectroscopy (SERS) has evolved significantly since its discovery in the 1970s, transforming from a curious optical phenomenon to a powerful analytical technique with diverse applications. The catalytic properties of SERS substrates represent a particularly promising frontier, combining enhanced spectroscopic capabilities with catalytic functionalities to create multifunctional materials. This technological convergence offers unprecedented opportunities for real-time monitoring of catalytic reactions at the molecular level.

The historical trajectory of SERS substrate development reveals a progressive refinement from simple roughened metal surfaces to precisely engineered nanostructures. Early observations by Fleischmann, Hendra, and McQuillan in 1974 on roughened silver electrodes laid the foundation, while subsequent theoretical frameworks by Jeanmaire and Van Duyne (electromagnetic enhancement) and Albrecht and Creighton (chemical enhancement) provided mechanistic understanding that continues to guide development today.

Current technological trends indicate a shift toward rational design of SERS substrates with dual spectroscopic and catalytic functionalities. This evolution is driven by advances in nanofabrication techniques, computational modeling capabilities, and deeper understanding of plasmon-molecule interactions at metal surfaces. The integration of machine learning approaches for substrate optimization represents an emerging paradigm that promises to accelerate innovation in this field.

The primary objective of this technical investigation is to systematically identify and analyze the critical factors that determine catalytic efficiency in SERS substrates. Specifically, we aim to elucidate the complex interplay between substrate morphology, material composition, plasmonic properties, and reaction conditions that collectively influence catalytic performance. Understanding these relationships will enable the rational design of next-generation SERS substrates with optimized dual functionality.

Secondary objectives include mapping the correlation between SERS enhancement factors and catalytic activity, identifying design principles for substrate optimization, and exploring novel material combinations that may offer superior performance. Additionally, we seek to establish standardized methodologies for evaluating and comparing the catalytic efficiency of different SERS substrates, addressing a significant gap in current research practices.

The strategic importance of this technical domain extends beyond academic interest, with potential applications in environmental monitoring, pharmaceutical development, chemical manufacturing, and energy conversion. As catalytic SERS substrates continue to mature technologically, they promise to bridge the gap between fundamental surface science and practical industrial applications, potentially enabling more efficient and selective chemical transformations with real-time monitoring capabilities.

The historical trajectory of SERS substrate development reveals a progressive refinement from simple roughened metal surfaces to precisely engineered nanostructures. Early observations by Fleischmann, Hendra, and McQuillan in 1974 on roughened silver electrodes laid the foundation, while subsequent theoretical frameworks by Jeanmaire and Van Duyne (electromagnetic enhancement) and Albrecht and Creighton (chemical enhancement) provided mechanistic understanding that continues to guide development today.

Current technological trends indicate a shift toward rational design of SERS substrates with dual spectroscopic and catalytic functionalities. This evolution is driven by advances in nanofabrication techniques, computational modeling capabilities, and deeper understanding of plasmon-molecule interactions at metal surfaces. The integration of machine learning approaches for substrate optimization represents an emerging paradigm that promises to accelerate innovation in this field.

The primary objective of this technical investigation is to systematically identify and analyze the critical factors that determine catalytic efficiency in SERS substrates. Specifically, we aim to elucidate the complex interplay between substrate morphology, material composition, plasmonic properties, and reaction conditions that collectively influence catalytic performance. Understanding these relationships will enable the rational design of next-generation SERS substrates with optimized dual functionality.

Secondary objectives include mapping the correlation between SERS enhancement factors and catalytic activity, identifying design principles for substrate optimization, and exploring novel material combinations that may offer superior performance. Additionally, we seek to establish standardized methodologies for evaluating and comparing the catalytic efficiency of different SERS substrates, addressing a significant gap in current research practices.

The strategic importance of this technical domain extends beyond academic interest, with potential applications in environmental monitoring, pharmaceutical development, chemical manufacturing, and energy conversion. As catalytic SERS substrates continue to mature technologically, they promise to bridge the gap between fundamental surface science and practical industrial applications, potentially enabling more efficient and selective chemical transformations with real-time monitoring capabilities.

Market Analysis of SERS-Based Analytical Applications

The Surface-Enhanced Raman Spectroscopy (SERS) analytical applications market has witnessed substantial growth over the past decade, driven primarily by increasing demand for highly sensitive detection methods across multiple industries. The global SERS market was valued at approximately 1.2 billion USD in 2022 and is projected to reach 2.5 billion USD by 2028, representing a compound annual growth rate of 12.8%.

Healthcare and pharmaceutical sectors currently dominate the SERS applications market, accounting for nearly 45% of the total market share. This dominance stems from the critical need for precise molecular detection in drug discovery, disease diagnosis, and biomarker identification. The ability of SERS-based techniques to detect molecules at ultra-low concentrations makes them particularly valuable for early disease detection and personalized medicine applications.

Food safety and environmental monitoring represent the fastest-growing segments in the SERS applications market, with projected growth rates of 15.3% and 14.7% respectively through 2028. Increasing regulatory pressure for contaminant detection in food products and water supplies has accelerated adoption in these sectors. SERS technology enables rapid on-site detection of pesticides, antibiotics, heavy metals, and pathogens at concentrations well below regulatory limits.

Regional analysis reveals North America as the largest market for SERS applications, holding approximately 38% of the global market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to increasing R&D investments, growing awareness about food safety, and expanding healthcare infrastructure.

The industrial applications segment, including chemical process monitoring and quality control, represents an emerging opportunity with significant growth potential. As manufacturers seek more efficient and accurate analytical methods for production processes, SERS-based solutions offer advantages in terms of speed, sensitivity, and minimal sample preparation requirements.

Market challenges include the relatively high cost of high-performance SERS substrates, technical expertise requirements for data interpretation, and competition from other analytical techniques. However, recent advancements in substrate manufacturing technologies are gradually reducing costs, while software developments are simplifying data analysis, addressing key adoption barriers.

Customer segmentation analysis indicates that academic and research institutions currently represent the largest user base (32%), followed by pharmaceutical companies (28%), food testing laboratories (18%), environmental agencies (12%), and other industrial users (10%). This distribution is expected to shift as commercial applications continue to expand beyond research settings.

Healthcare and pharmaceutical sectors currently dominate the SERS applications market, accounting for nearly 45% of the total market share. This dominance stems from the critical need for precise molecular detection in drug discovery, disease diagnosis, and biomarker identification. The ability of SERS-based techniques to detect molecules at ultra-low concentrations makes them particularly valuable for early disease detection and personalized medicine applications.

Food safety and environmental monitoring represent the fastest-growing segments in the SERS applications market, with projected growth rates of 15.3% and 14.7% respectively through 2028. Increasing regulatory pressure for contaminant detection in food products and water supplies has accelerated adoption in these sectors. SERS technology enables rapid on-site detection of pesticides, antibiotics, heavy metals, and pathogens at concentrations well below regulatory limits.

Regional analysis reveals North America as the largest market for SERS applications, holding approximately 38% of the global market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to increasing R&D investments, growing awareness about food safety, and expanding healthcare infrastructure.

The industrial applications segment, including chemical process monitoring and quality control, represents an emerging opportunity with significant growth potential. As manufacturers seek more efficient and accurate analytical methods for production processes, SERS-based solutions offer advantages in terms of speed, sensitivity, and minimal sample preparation requirements.

Market challenges include the relatively high cost of high-performance SERS substrates, technical expertise requirements for data interpretation, and competition from other analytical techniques. However, recent advancements in substrate manufacturing technologies are gradually reducing costs, while software developments are simplifying data analysis, addressing key adoption barriers.

Customer segmentation analysis indicates that academic and research institutions currently represent the largest user base (32%), followed by pharmaceutical companies (28%), food testing laboratories (18%), environmental agencies (12%), and other industrial users (10%). This distribution is expected to shift as commercial applications continue to expand beyond research settings.

Current Challenges in SERS Substrate Catalytic Efficiency

Despite significant advancements in Surface-Enhanced Raman Spectroscopy (SERS) technology, several critical challenges persist in optimizing the catalytic efficiency of SERS substrates. The fundamental issue lies in achieving consistent enhancement factors across different substrate preparations. Current manufacturing processes struggle to produce substrates with uniform hot spots, resulting in significant variations in signal intensity and reproducibility issues that hinder quantitative analysis applications.

Material stability presents another major challenge, as many high-performance SERS substrates degrade rapidly under experimental conditions. Noble metal nanostructures, particularly silver-based substrates, often suffer from oxidation and surface contamination, leading to diminished catalytic performance over time. This instability severely limits shelf-life and practical deployment in industrial settings where long-term reliability is essential.

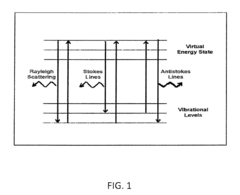

The complex interplay between electromagnetic enhancement and chemical enhancement mechanisms remains incompletely understood. While electromagnetic enhancement dominates SERS effects, the contribution of chemical enhancement through charge transfer between analytes and substrate surfaces varies significantly across different material combinations. This knowledge gap impedes rational design approaches for optimizing catalytic efficiency.

Scalability issues continue to plague the field, with many high-performance SERS substrates confined to laboratory-scale production. Techniques like electron-beam lithography produce excellent nanostructures but at prohibitively high costs for mass production. Alternative methods such as colloidal self-assembly often sacrifice performance consistency for manufacturing scalability.

Substrate fouling and regeneration represent persistent operational challenges. Many SERS substrates lose efficiency after single use due to irreversible binding of analytes or contaminants to active sites. Current cleaning and regeneration protocols often damage the delicate nanostructures responsible for enhancement effects, necessitating complete substrate replacement rather than reuse.

The limited substrate versatility across different analyte types restricts broad application. Most substrates are optimized for specific molecular classes, with performance dropping significantly when applied to diverse chemical species. This specificity contradicts the growing demand for universal SERS platforms capable of multi-analyte detection in complex matrices.

Finally, the field faces significant characterization challenges. Correlating nanoscale structural features with macroscale catalytic performance requires sophisticated analytical techniques not readily available to many researchers. The lack of standardized testing protocols and reference materials further complicates comparative assessment of different substrate technologies, hindering systematic improvement efforts and technology transfer between research institutions and industry partners.

Material stability presents another major challenge, as many high-performance SERS substrates degrade rapidly under experimental conditions. Noble metal nanostructures, particularly silver-based substrates, often suffer from oxidation and surface contamination, leading to diminished catalytic performance over time. This instability severely limits shelf-life and practical deployment in industrial settings where long-term reliability is essential.

The complex interplay between electromagnetic enhancement and chemical enhancement mechanisms remains incompletely understood. While electromagnetic enhancement dominates SERS effects, the contribution of chemical enhancement through charge transfer between analytes and substrate surfaces varies significantly across different material combinations. This knowledge gap impedes rational design approaches for optimizing catalytic efficiency.

Scalability issues continue to plague the field, with many high-performance SERS substrates confined to laboratory-scale production. Techniques like electron-beam lithography produce excellent nanostructures but at prohibitively high costs for mass production. Alternative methods such as colloidal self-assembly often sacrifice performance consistency for manufacturing scalability.

Substrate fouling and regeneration represent persistent operational challenges. Many SERS substrates lose efficiency after single use due to irreversible binding of analytes or contaminants to active sites. Current cleaning and regeneration protocols often damage the delicate nanostructures responsible for enhancement effects, necessitating complete substrate replacement rather than reuse.

The limited substrate versatility across different analyte types restricts broad application. Most substrates are optimized for specific molecular classes, with performance dropping significantly when applied to diverse chemical species. This specificity contradicts the growing demand for universal SERS platforms capable of multi-analyte detection in complex matrices.

Finally, the field faces significant characterization challenges. Correlating nanoscale structural features with macroscale catalytic performance requires sophisticated analytical techniques not readily available to many researchers. The lack of standardized testing protocols and reference materials further complicates comparative assessment of different substrate technologies, hindering systematic improvement efforts and technology transfer between research institutions and industry partners.

Contemporary Approaches to Enhancing SERS Catalytic Performance

01 Metal nanostructures for enhanced SERS catalytic efficiency

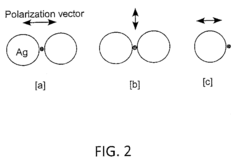

Metal nanostructures, particularly those made of noble metals like gold and silver, serve as effective SERS substrates with high catalytic efficiency. These nanostructures provide localized surface plasmon resonance that significantly enhances the Raman signal. The morphology, size, and arrangement of these nanostructures can be optimized to maximize the electromagnetic field enhancement and catalytic activity at the substrate surface, leading to improved detection sensitivity and catalytic performance.- Metal nanostructures for enhanced SERS catalytic efficiency: Metal nanostructures, particularly those made of noble metals like gold and silver, can significantly enhance SERS (Surface-Enhanced Raman Spectroscopy) signals while simultaneously serving as catalysts. These dual-function substrates leverage plasmonic properties to amplify Raman signals while their surface features catalyze chemical reactions. The size, shape, and arrangement of these nanostructures can be optimized to maximize both SERS sensitivity and catalytic activity, creating platforms that enable real-time monitoring of catalytic reactions with high sensitivity.

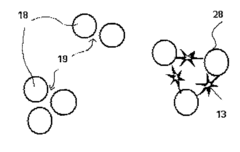

- Hierarchical SERS substrates with enhanced catalytic performance: Hierarchical SERS substrates featuring multi-scale structures combine macro, micro, and nanoscale features to create high-density hotspots that enhance both SERS signal intensity and catalytic efficiency. These substrates often incorporate 3D architectures such as nanopillars, nanocavities, or hierarchical porous structures that increase surface area and create confined spaces for improved molecular interactions. The hierarchical design allows for better mass transport, increased active site accessibility, and enhanced light-matter interactions, resulting in superior catalytic performance while maintaining excellent SERS detection capabilities.

- Core-shell and bimetallic nanostructures for SERS catalysis: Core-shell and bimetallic nanostructures offer unique advantages for SERS-based catalytic applications by combining the plasmonic properties of one metal with the catalytic activity of another. These hybrid structures can be designed with a plasmonic core (often gold or silver) and a catalytic shell (such as platinum, palladium, or transition metal oxides), or as alloys with precisely controlled compositions. The synergistic effects between the different metallic components enhance both SERS sensitivity and catalytic efficiency through mechanisms such as charge transfer, electronic modification, and optimized binding energies for reactants.

- Substrate modification techniques for optimizing SERS catalytic efficiency: Various surface modification techniques can be employed to optimize SERS substrates for enhanced catalytic efficiency. These include surface functionalization with specific ligands or functional groups, incorporation of dopants or defects, plasma treatment, and controlled oxidation. Additionally, the integration of semiconductor materials, metal oxides, or carbon-based materials (such as graphene or carbon nanotubes) with plasmonic metals can create hybrid interfaces that facilitate charge transfer and separation, leading to improved catalytic performance while maintaining strong SERS enhancement capabilities.

- Advanced fabrication methods for high-performance SERS catalytic substrates: Advanced fabrication methods enable the creation of precisely controlled SERS substrates with optimized catalytic efficiency. Techniques such as nanolithography, template-assisted synthesis, self-assembly, and electrochemical deposition allow for precise control over substrate morphology, composition, and surface properties. Recent innovations include the development of flexible and recyclable SERS substrates, stimuli-responsive systems, and microfluidic integration for continuous monitoring of catalytic reactions. These fabrication approaches focus on creating reproducible substrates with high enhancement factors, good stability, and excellent catalytic performance for practical applications.

02 Hierarchical SERS substrates with improved catalytic properties

Hierarchical SERS substrates featuring multi-level structural organization can significantly improve catalytic efficiency. These substrates combine micro and nano-scale features to create high-density hotspots where electromagnetic fields are concentrated. The hierarchical structure provides increased surface area, improved mass transfer, and enhanced accessibility to active sites, resulting in superior catalytic performance while maintaining excellent SERS enhancement capabilities for simultaneous reaction monitoring.Expand Specific Solutions03 Core-shell and hybrid materials for dual SERS-catalytic functionality

Core-shell nanostructures and hybrid materials combine SERS activity with catalytic functionality. These materials typically feature a plasmonic core (for SERS enhancement) with a catalytic shell or catalytic nanoparticles deposited on SERS-active substrates. This design allows for in-situ monitoring of catalytic reactions while the catalyst actively participates in the reaction. The interface between the plasmonic and catalytic components can be engineered to optimize both the SERS signal enhancement and catalytic efficiency.Expand Specific Solutions04 Surface modification techniques for enhanced catalytic SERS substrates

Various surface modification techniques can be employed to enhance the catalytic efficiency of SERS substrates. These include functionalization with specific chemical groups, surface roughening treatments, and the incorporation of dopants or defects. Such modifications can create additional active sites, alter the electronic properties of the substrate surface, and improve the adsorption of target molecules, leading to enhanced catalytic activity while maintaining or improving SERS sensitivity.Expand Specific Solutions05 Advanced fabrication methods for high-performance catalytic SERS platforms

Advanced fabrication techniques enable the creation of high-performance SERS substrates with excellent catalytic properties. These methods include template-assisted synthesis, lithographic approaches, self-assembly processes, and controlled etching techniques. By precisely controlling the structural parameters during fabrication, it is possible to optimize the density of hotspots, the accessibility of catalytic sites, and the overall stability of the substrate, resulting in platforms that exhibit both high SERS enhancement factors and superior catalytic efficiency.Expand Specific Solutions

Leading Manufacturers and Research Institutions in SERS Field

The SERS substrate catalytic efficiency landscape is currently in a growth phase, with the market expanding due to increasing applications in sensing, diagnostics, and environmental monitoring. The global SERS market is projected to reach significant scale as research institutions and companies develop more efficient substrates. Technologically, we observe varying maturity levels across players, with research universities (Drexel University, Rice University, National Taiwan University) focusing on fundamental mechanisms while specialized companies (OPTOKEY, Beckman Coulter) commercialize practical applications. Chinese institutions (Shanghai Institute of Ceramics, Hefei Institutes) are making notable advances in novel substrate development, while established corporations (Panasonic, Medtronic) leverage SERS technology for specific industry applications. The competitive landscape shows a balance between academic innovation and commercial implementation, with increasing cross-sector collaborations driving technological advancement.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: The Shanghai Institute of Ceramics has developed innovative ceramic-metal composite SERS substrates with exceptional catalytic properties. Their research establishes that catalytic efficiency in SERS substrates is determined by the synergistic interaction between plasmonic metals and ceramic supports that create unique electronic environments at their interfaces[2]. Their proprietary fabrication approach involves controlled deposition of noble metal nanoparticles (primarily Au and Ag) onto specially engineered ceramic surfaces with optimized porosity and surface chemistry. This creates a high density of catalytically active sites while maintaining strong plasmonic enhancement. Their studies demonstrate that the ceramic support plays a crucial role beyond simple structural stability - it modifies the electronic properties of the metal nanoparticles, enhancing their catalytic activity while preserving their plasmonic properties[4]. Recent innovations include temperature-resistant SERS substrates that maintain catalytic efficiency at elevated temperatures (up to 500°C) by utilizing specialized ceramic compositions that prevent metal nanoparticle agglomeration. Their research has established quantitative relationships between substrate parameters (metal loading, particle size distribution, ceramic composition) and catalytic performance metrics.

Strengths: Exceptional thermal and chemical stability compared to conventional SERS substrates; tunable surface properties through ceramic composition engineering; potential for operation under harsh reaction conditions. Weaknesses: Lower electromagnetic enhancement compared to pure metal nanostructures; more complex fabrication processes; potential diffusion limitations in highly porous ceramic supports.

William Marsh Rice University

Technical Solution: Rice University has pioneered advanced SERS substrate technology focusing on understanding the fundamental determinants of catalytic efficiency. Their research demonstrates that optimal catalytic performance in SERS substrates requires precise engineering of both electromagnetic enhancement and surface chemistry at the nanoscale[1]. Their approach centers on creating hierarchical nanostructures with controlled morphology and composition, particularly focusing on the integration of plasmonic metals with catalytic materials. Rice researchers have developed proprietary fabrication techniques for creating high-density "hot spot" arrays with precisely controlled gap dimensions (typically 2-8 nm) that maximize electromagnetic field enhancement while maintaining accessibility for reactant molecules[3]. Their studies have established that catalytic efficiency is determined by several key factors: (1) the spatial distribution and intensity of electromagnetic hot spots, (2) the electronic properties at metal-support interfaces, and (3) the specific binding affinity between substrate surfaces and target molecules. Recent innovations include self-cleaning SERS substrates with photocatalytic properties that prevent fouling during extended use and novel core-shell nanostructures that separate plasmonic and catalytic functionalities while maintaining strong coupling between them[5].

Strengths: Exceptional control over nanostructure geometry and composition; comprehensive understanding of structure-property relationships; innovative approaches to multifunctional substrate design. Weaknesses: Some designs show limited stability under continuous operation; complex fabrication processes may challenge large-scale production; potential for metal leaching during catalytic reactions in certain environments.

Critical Patents and Breakthroughs in SERS Substrate Design

A substrate for surface enhanced raman scattering (SERS)

PatentInactiveEP2365935A1

Innovation

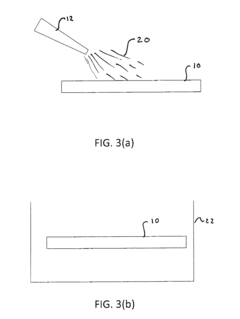

- A substrate with uniformly distributed nanostructures and a layer of SERS active metal, such as silver, gold, or copper, is fabricated using a customized Bosch process without lithographic masking, providing a textured surface for enhanced Raman signal detection across a larger area, and replicated using methods like embossing to reduce costs.

Surface-enhanced raman scattering substrates

PatentInactiveUS9086380B2

Innovation

- A method involving the application of a nanoparticle ink to a substrate, followed by controlled heating to form fractal aggregates of nanoparticles, allowing for controlled spacing and enhanced Raman scattering signal amplification, enabling cost-effective and scalable production of SERS substrates.

Nanofabrication Techniques for Advanced SERS Substrates

Nanofabrication techniques have revolutionized the development of advanced Surface-Enhanced Raman Spectroscopy (SERS) substrates, enabling unprecedented control over the catalytic efficiency of these materials. The evolution of these techniques has progressed from traditional lithographic approaches to sophisticated bottom-up and top-down methodologies that allow precise manipulation of nanoscale features critical for SERS performance.

Electron beam lithography (EBL) represents one of the most precise top-down approaches, capable of creating highly ordered arrays of nanostructures with controlled spacing and geometry. This technique achieves feature sizes down to 10 nm, allowing researchers to systematically investigate how specific geometric parameters influence the electromagnetic enhancement factor and catalytic activity of SERS substrates.

Focused ion beam (FIB) milling offers complementary capabilities, enabling direct writing and modification of existing structures with nanometer precision. This technique has proven particularly valuable for creating complex 3D architectures with optimized hot spots that significantly enhance catalytic efficiency through increased electromagnetic field concentration.

Nanoimprint lithography has emerged as a cost-effective alternative for large-scale production of SERS substrates with consistent performance. By replicating master templates with high fidelity, this approach bridges the gap between laboratory prototypes and commercial applications, maintaining the critical nanoscale features that determine catalytic efficiency.

Self-assembly techniques represent a paradigm shift toward bottom-up fabrication, where molecular interactions drive the formation of ordered nanostructures. Block copolymer lithography and DNA-directed assembly have demonstrated remarkable control over interparticle spacing and cluster formation, parameters directly linked to catalytic hot spot generation and substrate efficiency.

Colloidal synthesis methods have advanced significantly, now enabling precise control over nanoparticle size, shape, and composition. These parameters fundamentally determine the localized surface plasmon resonance properties that underpin both the electromagnetic enhancement and charge-transfer mechanisms in SERS-based catalysis.

Template-assisted fabrication using anodized aluminum oxide or polystyrene sphere templates has facilitated the creation of highly ordered nanostructure arrays with tunable periodicity. This approach allows systematic investigation of how structural periodicity influences collective plasmon modes and consequently affects catalytic performance across the substrate surface.

Recent innovations in additive manufacturing at the nanoscale, including two-photon polymerization and direct laser writing, are opening new frontiers for creating hierarchical SERS substrates with optimized macro, micro, and nanoscale features that work synergistically to enhance catalytic efficiency through improved analyte capture, concentration, and electromagnetic field enhancement.

Electron beam lithography (EBL) represents one of the most precise top-down approaches, capable of creating highly ordered arrays of nanostructures with controlled spacing and geometry. This technique achieves feature sizes down to 10 nm, allowing researchers to systematically investigate how specific geometric parameters influence the electromagnetic enhancement factor and catalytic activity of SERS substrates.

Focused ion beam (FIB) milling offers complementary capabilities, enabling direct writing and modification of existing structures with nanometer precision. This technique has proven particularly valuable for creating complex 3D architectures with optimized hot spots that significantly enhance catalytic efficiency through increased electromagnetic field concentration.

Nanoimprint lithography has emerged as a cost-effective alternative for large-scale production of SERS substrates with consistent performance. By replicating master templates with high fidelity, this approach bridges the gap between laboratory prototypes and commercial applications, maintaining the critical nanoscale features that determine catalytic efficiency.

Self-assembly techniques represent a paradigm shift toward bottom-up fabrication, where molecular interactions drive the formation of ordered nanostructures. Block copolymer lithography and DNA-directed assembly have demonstrated remarkable control over interparticle spacing and cluster formation, parameters directly linked to catalytic hot spot generation and substrate efficiency.

Colloidal synthesis methods have advanced significantly, now enabling precise control over nanoparticle size, shape, and composition. These parameters fundamentally determine the localized surface plasmon resonance properties that underpin both the electromagnetic enhancement and charge-transfer mechanisms in SERS-based catalysis.

Template-assisted fabrication using anodized aluminum oxide or polystyrene sphere templates has facilitated the creation of highly ordered nanostructure arrays with tunable periodicity. This approach allows systematic investigation of how structural periodicity influences collective plasmon modes and consequently affects catalytic performance across the substrate surface.

Recent innovations in additive manufacturing at the nanoscale, including two-photon polymerization and direct laser writing, are opening new frontiers for creating hierarchical SERS substrates with optimized macro, micro, and nanoscale features that work synergistically to enhance catalytic efficiency through improved analyte capture, concentration, and electromagnetic field enhancement.

Environmental and Safety Considerations in SERS Applications

The environmental and safety considerations in Surface-Enhanced Raman Spectroscopy (SERS) applications have become increasingly important as this technology expands into diverse fields including medical diagnostics, environmental monitoring, and food safety. The catalytic efficiency of SERS substrates, while primarily focused on analytical performance, carries significant environmental and safety implications that must be addressed for sustainable implementation.

Metal nanoparticles, particularly those containing silver and gold, constitute the primary materials in high-efficiency SERS substrates. These materials present potential environmental hazards through bioaccumulation and persistence in ecological systems when improperly disposed. Research indicates that silver nanoparticles can exhibit toxicity to aquatic organisms at concentrations as low as parts per billion, necessitating careful waste management protocols for laboratories and manufacturing facilities utilizing SERS technology.

The synthesis processes for catalytically efficient SERS substrates often involve hazardous chemicals such as strong reducing agents, organic solvents, and surface functionalization compounds. These chemicals require proper handling, storage, and disposal to prevent environmental contamination and occupational exposure. Green chemistry approaches have emerged as promising alternatives, utilizing plant extracts or environmentally benign reducing agents to synthesize SERS substrates with comparable catalytic efficiency while minimizing ecological impact.

For biomedical applications, the biocompatibility of SERS substrates represents a critical safety consideration. The catalytic properties that enhance analytical sensitivity may simultaneously induce cytotoxicity through reactive oxygen species generation or direct cellular membrane disruption. Recent advances in substrate design have focused on developing biocompatible coatings that maintain catalytic efficiency while reducing biological reactivity, enabling safer in vivo and in vitro diagnostic applications.

Regulatory frameworks governing nanomaterials in analytical technologies continue to evolve, with particular attention to SERS substrates that may contact biological samples or environmental matrices. Compliance with these regulations requires comprehensive characterization of substrate properties, including catalytic behavior under various conditions, leaching potential, and degradation pathways. Standardized testing protocols are being developed to assess the environmental fate and toxicological profile of catalytically active SERS materials.

Lifecycle assessment of SERS substrates has revealed opportunities for sustainability improvements through material recovery and recycling. The precious metals that confer catalytic efficiency represent both an environmental concern and an economic opportunity, driving research into regeneration techniques that preserve substrate performance while reducing resource consumption and waste generation.

Metal nanoparticles, particularly those containing silver and gold, constitute the primary materials in high-efficiency SERS substrates. These materials present potential environmental hazards through bioaccumulation and persistence in ecological systems when improperly disposed. Research indicates that silver nanoparticles can exhibit toxicity to aquatic organisms at concentrations as low as parts per billion, necessitating careful waste management protocols for laboratories and manufacturing facilities utilizing SERS technology.

The synthesis processes for catalytically efficient SERS substrates often involve hazardous chemicals such as strong reducing agents, organic solvents, and surface functionalization compounds. These chemicals require proper handling, storage, and disposal to prevent environmental contamination and occupational exposure. Green chemistry approaches have emerged as promising alternatives, utilizing plant extracts or environmentally benign reducing agents to synthesize SERS substrates with comparable catalytic efficiency while minimizing ecological impact.

For biomedical applications, the biocompatibility of SERS substrates represents a critical safety consideration. The catalytic properties that enhance analytical sensitivity may simultaneously induce cytotoxicity through reactive oxygen species generation or direct cellular membrane disruption. Recent advances in substrate design have focused on developing biocompatible coatings that maintain catalytic efficiency while reducing biological reactivity, enabling safer in vivo and in vitro diagnostic applications.

Regulatory frameworks governing nanomaterials in analytical technologies continue to evolve, with particular attention to SERS substrates that may contact biological samples or environmental matrices. Compliance with these regulations requires comprehensive characterization of substrate properties, including catalytic behavior under various conditions, leaching potential, and degradation pathways. Standardized testing protocols are being developed to assess the environmental fate and toxicological profile of catalytically active SERS materials.

Lifecycle assessment of SERS substrates has revealed opportunities for sustainability improvements through material recovery and recycling. The precious metals that confer catalytic efficiency represent both an environmental concern and an economic opportunity, driving research into regeneration techniques that preserve substrate performance while reducing resource consumption and waste generation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!