Examination of SERS Substrates in Metal Alloy Coatings

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Substrate Technology Background and Objectives

Surface-Enhanced Raman Spectroscopy (SERS) has evolved significantly since its discovery in the 1970s, transforming from an interesting optical phenomenon to a powerful analytical technique. The enhancement mechanism relies on electromagnetic field amplification at metal surfaces, particularly at nanoscale features where plasmon resonances occur. Initially limited to silver and gold substrates, SERS technology has progressively incorporated various metals and alloys to expand functionality and application scope.

Metal alloy coatings represent a promising frontier in SERS substrate development, offering potential advantages over single-metal systems. The historical progression from roughened electrodes to nanoparticle assemblies and now to precisely engineered alloy structures demonstrates the field's continuous innovation. Recent advances in nanofabrication techniques have enabled unprecedented control over surface morphology and composition, critical factors in SERS performance.

The primary technical objective of this research is to systematically evaluate the performance characteristics of SERS substrates incorporating metal alloy coatings. Specifically, we aim to determine how varying alloy compositions affect enhancement factors, signal stability, reproducibility, and substrate longevity. This investigation seeks to establish correlations between specific alloy formulations and their spectroscopic properties, potentially identifying optimal compositions for different analytical applications.

A secondary objective involves exploring the fundamental mechanisms underlying SERS enhancement in alloy systems. While the electromagnetic and chemical enhancement mechanisms are well-established for pure metals, their interplay in alloy systems remains incompletely understood. By examining how electronic properties of alloys influence enhancement patterns, we hope to develop predictive models for rational substrate design.

Current technological trends indicate growing interest in tunable SERS substrates that can be optimized for specific target molecules or excitation wavelengths. Alloy systems offer promising avenues for such tunability through composition-dependent plasmon resonances. The field is moving toward multifunctional SERS platforms that combine detection capabilities with other functionalities such as catalysis or controlled release.

The long-term trajectory of SERS substrate technology points toward integration with portable and field-deployable devices, requiring substrates with greater stability and reproducibility than currently available. Metal alloy coatings may address these challenges by offering improved oxidation resistance and mechanical durability compared to pure metal substrates, potentially enabling robust sensors for environmental monitoring, food safety, and point-of-care diagnostics.

This research aligns with broader scientific trends toward materials by design, where computational methods increasingly guide experimental work to develop materials with tailored properties for specific applications.

Metal alloy coatings represent a promising frontier in SERS substrate development, offering potential advantages over single-metal systems. The historical progression from roughened electrodes to nanoparticle assemblies and now to precisely engineered alloy structures demonstrates the field's continuous innovation. Recent advances in nanofabrication techniques have enabled unprecedented control over surface morphology and composition, critical factors in SERS performance.

The primary technical objective of this research is to systematically evaluate the performance characteristics of SERS substrates incorporating metal alloy coatings. Specifically, we aim to determine how varying alloy compositions affect enhancement factors, signal stability, reproducibility, and substrate longevity. This investigation seeks to establish correlations between specific alloy formulations and their spectroscopic properties, potentially identifying optimal compositions for different analytical applications.

A secondary objective involves exploring the fundamental mechanisms underlying SERS enhancement in alloy systems. While the electromagnetic and chemical enhancement mechanisms are well-established for pure metals, their interplay in alloy systems remains incompletely understood. By examining how electronic properties of alloys influence enhancement patterns, we hope to develop predictive models for rational substrate design.

Current technological trends indicate growing interest in tunable SERS substrates that can be optimized for specific target molecules or excitation wavelengths. Alloy systems offer promising avenues for such tunability through composition-dependent plasmon resonances. The field is moving toward multifunctional SERS platforms that combine detection capabilities with other functionalities such as catalysis or controlled release.

The long-term trajectory of SERS substrate technology points toward integration with portable and field-deployable devices, requiring substrates with greater stability and reproducibility than currently available. Metal alloy coatings may address these challenges by offering improved oxidation resistance and mechanical durability compared to pure metal substrates, potentially enabling robust sensors for environmental monitoring, food safety, and point-of-care diagnostics.

This research aligns with broader scientific trends toward materials by design, where computational methods increasingly guide experimental work to develop materials with tailored properties for specific applications.

Market Analysis for SERS-based Sensing Applications

The global market for Surface-Enhanced Raman Spectroscopy (SERS) sensing applications has experienced significant growth in recent years, driven by increasing demand for highly sensitive detection methods across multiple industries. The current market size for SERS-based technologies is estimated to reach $1.8 billion by 2025, with a compound annual growth rate of approximately 10.4% from 2020 to 2025.

Healthcare and life sciences represent the largest application segment, accounting for nearly 45% of the total market share. Within this sector, SERS-based biosensors for disease diagnosis, drug discovery, and biomarker detection are witnessing particularly strong demand. The ability of SERS substrates in metal alloy coatings to detect biomolecules at ultra-low concentrations positions them as valuable tools for early disease detection and personalized medicine applications.

Environmental monitoring constitutes the second-largest market segment, representing approximately 25% of the total market. Government regulations mandating stricter monitoring of pollutants and contaminants have accelerated adoption of SERS-based sensing technologies. Metal alloy SERS substrates offer superior detection capabilities for environmental toxins, heavy metals, and organic pollutants at concentrations previously undetectable by conventional methods.

Food safety testing applications account for roughly 15% of the market, with growing implementation in both developed and developing economies. The ability to rapidly detect foodborne pathogens, pesticide residues, and adulterants has made SERS-based sensing an increasingly valuable tool for regulatory compliance and consumer protection.

Regional analysis indicates North America currently leads the market with approximately 38% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is projected to witness the highest growth rate during the forecast period, driven by increasing R&D investments, growing healthcare expenditure, and rising environmental concerns in countries like China, Japan, and India.

Key market drivers include technological advancements in SERS substrate fabrication, particularly in metal alloy coatings that enhance sensitivity and reproducibility. The miniaturization of SERS devices and integration with portable platforms are expanding applications in point-of-care diagnostics and field-based environmental monitoring. Additionally, the growing need for rapid, sensitive, and specific detection methods across industries continues to fuel market expansion.

Challenges limiting wider adoption include high costs associated with specialized equipment, lack of standardization in SERS substrate preparation, and the need for skilled personnel to interpret results. However, ongoing research in cost-effective metal alloy SERS substrates and automated analysis software is expected to address these barriers and further accelerate market growth.

Healthcare and life sciences represent the largest application segment, accounting for nearly 45% of the total market share. Within this sector, SERS-based biosensors for disease diagnosis, drug discovery, and biomarker detection are witnessing particularly strong demand. The ability of SERS substrates in metal alloy coatings to detect biomolecules at ultra-low concentrations positions them as valuable tools for early disease detection and personalized medicine applications.

Environmental monitoring constitutes the second-largest market segment, representing approximately 25% of the total market. Government regulations mandating stricter monitoring of pollutants and contaminants have accelerated adoption of SERS-based sensing technologies. Metal alloy SERS substrates offer superior detection capabilities for environmental toxins, heavy metals, and organic pollutants at concentrations previously undetectable by conventional methods.

Food safety testing applications account for roughly 15% of the market, with growing implementation in both developed and developing economies. The ability to rapidly detect foodborne pathogens, pesticide residues, and adulterants has made SERS-based sensing an increasingly valuable tool for regulatory compliance and consumer protection.

Regional analysis indicates North America currently leads the market with approximately 38% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is projected to witness the highest growth rate during the forecast period, driven by increasing R&D investments, growing healthcare expenditure, and rising environmental concerns in countries like China, Japan, and India.

Key market drivers include technological advancements in SERS substrate fabrication, particularly in metal alloy coatings that enhance sensitivity and reproducibility. The miniaturization of SERS devices and integration with portable platforms are expanding applications in point-of-care diagnostics and field-based environmental monitoring. Additionally, the growing need for rapid, sensitive, and specific detection methods across industries continues to fuel market expansion.

Challenges limiting wider adoption include high costs associated with specialized equipment, lack of standardization in SERS substrate preparation, and the need for skilled personnel to interpret results. However, ongoing research in cost-effective metal alloy SERS substrates and automated analysis software is expected to address these barriers and further accelerate market growth.

Current Challenges in Metal Alloy SERS Substrates

Despite significant advancements in Surface-Enhanced Raman Spectroscopy (SERS) technology, metal alloy SERS substrates face several persistent challenges that limit their widespread application and commercial viability. The fundamental issue lies in achieving consistent enhancement factors across the substrate surface, as current manufacturing processes often produce heterogeneous distributions of "hot spots" - areas of intense electromagnetic field enhancement crucial for SERS sensitivity.

Reproducibility remains a major obstacle, with batch-to-batch variations significantly affecting analytical reliability. This inconsistency stems from difficulties in precisely controlling nanoscale features during fabrication processes, particularly when dealing with complex alloy compositions. The inherent variability undermines quantitative analysis capabilities, restricting SERS applications in standardized testing environments.

Stability issues present another critical challenge. Metal alloy substrates frequently exhibit performance degradation over time due to oxidation, particularly when exposed to atmospheric conditions or aqueous environments. This oxidation alters the plasmonic properties essential for SERS enhancement and can introduce interfering signals that compromise analytical accuracy. While noble metal components like gold offer better resistance, they significantly increase production costs.

The complexity of signal interpretation represents a substantial technical barrier. Metal alloy substrates often generate background signals that can interfere with analyte detection, especially at low concentrations. The interaction between different metallic elements in the alloy creates unique spectral signatures that require sophisticated algorithms and reference databases for accurate interpretation.

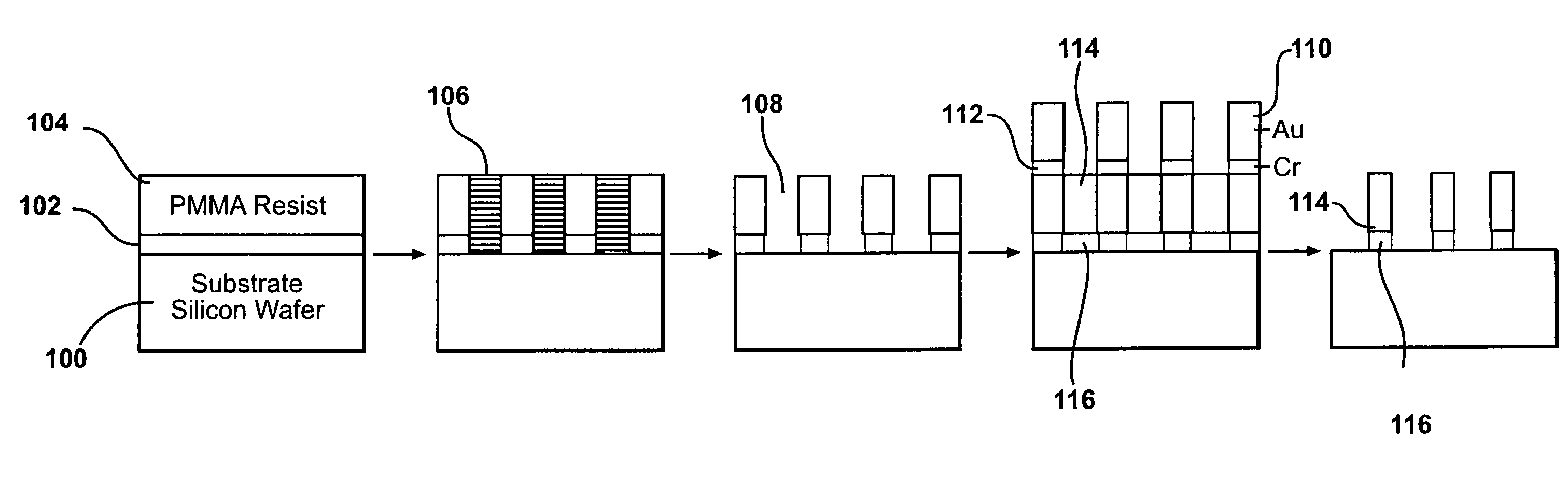

Scalability challenges persist in transitioning from laboratory-scale production to industrial manufacturing. Current fabrication methods that yield high-performance substrates, such as electron-beam lithography and focused ion beam milling, are prohibitively expensive and time-consuming for mass production. Alternative techniques like chemical synthesis methods offer better scalability but typically result in less controlled nanostructures with reduced enhancement consistency.

Biocompatibility concerns arise when considering SERS applications in biological and medical diagnostics. Some metal alloy components may exhibit cytotoxicity or interfere with biological processes, limiting their application in in vivo or ex vivo analyses. Additionally, protein adsorption on metal surfaces can create unwanted background signals and reduce sensitivity for target analytes.

Integration challenges with existing analytical platforms represent another significant hurdle. Current SERS substrate designs often require specialized instrumentation or sample preparation protocols that are difficult to incorporate into established laboratory workflows, limiting their practical utility in routine analytical settings.

Reproducibility remains a major obstacle, with batch-to-batch variations significantly affecting analytical reliability. This inconsistency stems from difficulties in precisely controlling nanoscale features during fabrication processes, particularly when dealing with complex alloy compositions. The inherent variability undermines quantitative analysis capabilities, restricting SERS applications in standardized testing environments.

Stability issues present another critical challenge. Metal alloy substrates frequently exhibit performance degradation over time due to oxidation, particularly when exposed to atmospheric conditions or aqueous environments. This oxidation alters the plasmonic properties essential for SERS enhancement and can introduce interfering signals that compromise analytical accuracy. While noble metal components like gold offer better resistance, they significantly increase production costs.

The complexity of signal interpretation represents a substantial technical barrier. Metal alloy substrates often generate background signals that can interfere with analyte detection, especially at low concentrations. The interaction between different metallic elements in the alloy creates unique spectral signatures that require sophisticated algorithms and reference databases for accurate interpretation.

Scalability challenges persist in transitioning from laboratory-scale production to industrial manufacturing. Current fabrication methods that yield high-performance substrates, such as electron-beam lithography and focused ion beam milling, are prohibitively expensive and time-consuming for mass production. Alternative techniques like chemical synthesis methods offer better scalability but typically result in less controlled nanostructures with reduced enhancement consistency.

Biocompatibility concerns arise when considering SERS applications in biological and medical diagnostics. Some metal alloy components may exhibit cytotoxicity or interfere with biological processes, limiting their application in in vivo or ex vivo analyses. Additionally, protein adsorption on metal surfaces can create unwanted background signals and reduce sensitivity for target analytes.

Integration challenges with existing analytical platforms represent another significant hurdle. Current SERS substrate designs often require specialized instrumentation or sample preparation protocols that are difficult to incorporate into established laboratory workflows, limiting their practical utility in routine analytical settings.

Existing Metal Alloy Coating Solutions for SERS

01 Metal alloy nanostructures for SERS enhancement

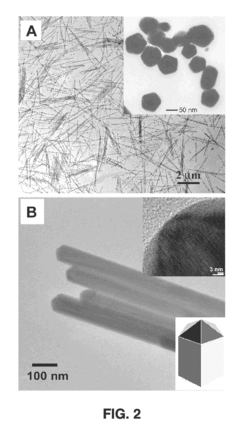

Metal alloy nanostructures can be used as SERS substrates to enhance Raman signals. These alloys, typically combining noble metals like gold, silver, and copper, create unique plasmonic properties that can significantly improve SERS sensitivity compared to single metal substrates. The specific composition and ratio of metals in the alloy can be tailored to optimize the enhancement factor and tune the resonance wavelength for specific applications.- Metal alloy nanostructures for SERS enhancement: Metal alloy nanostructures can be used as SERS substrates to enhance Raman signals. These alloys, typically containing noble metals like gold, silver, or copper, provide improved plasmonic properties compared to single metal substrates. The specific composition and ratio of metals in the alloy can be optimized to achieve maximum SERS enhancement factors. These nanostructures can be fabricated in various forms such as nanoparticles, nanorods, or thin films to create effective SERS-active surfaces.

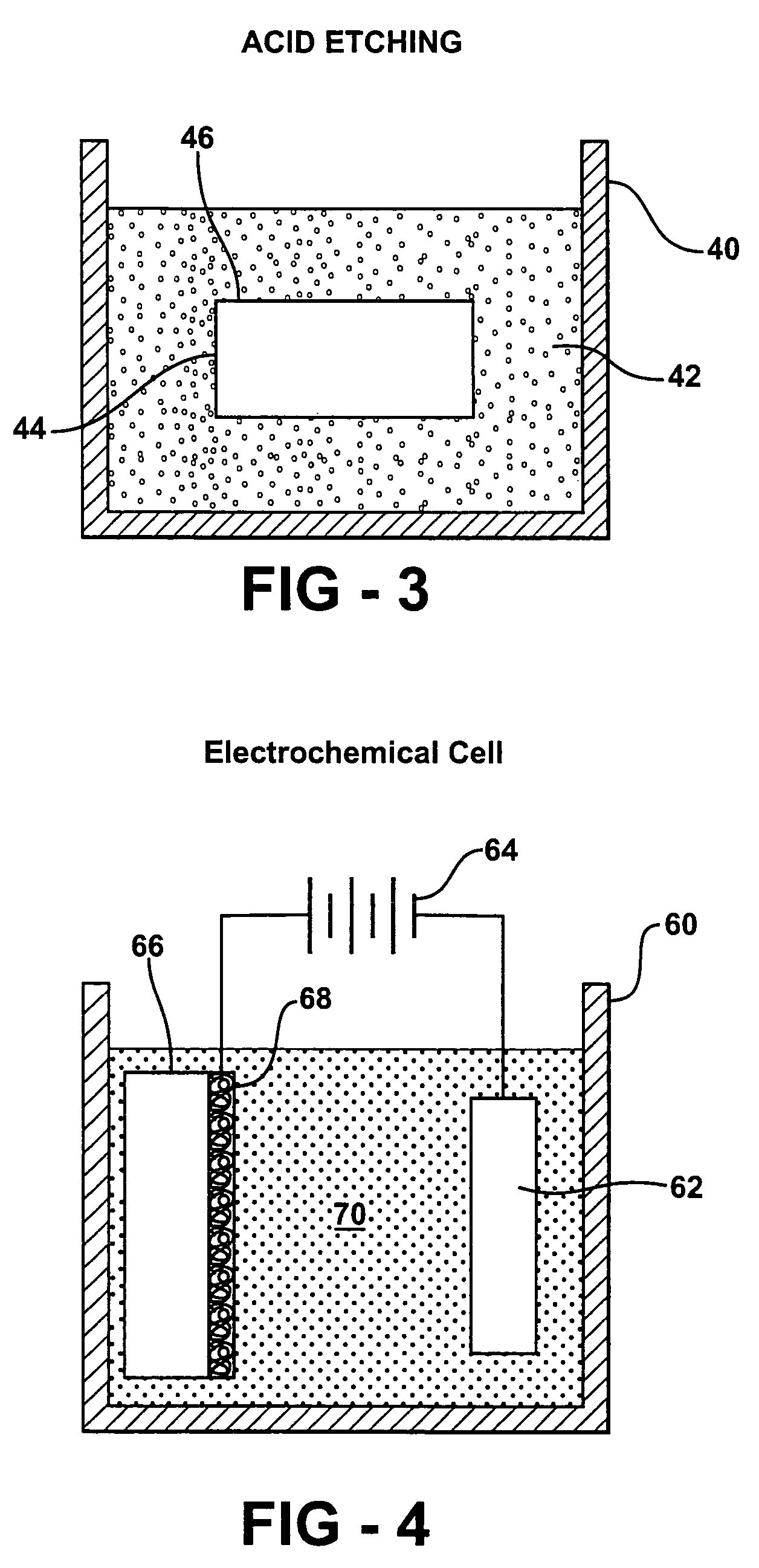

- Surface roughness and morphology control in SERS substrates: The surface roughness and morphology of metal alloy coatings significantly impact SERS enhancement. Controlled surface features at the nanoscale, such as nanopillars, nanogaps, and nanotips, create electromagnetic hot spots that amplify Raman signals. Various fabrication techniques including electrodeposition, chemical etching, and nanolithography can be employed to create optimized surface morphologies. The size, spacing, and distribution of these surface features can be tailored to maximize the enhancement factor for specific analytical applications.

- Core-shell and multilayer SERS substrates: Core-shell and multilayer structures using metal alloys provide enhanced SERS performance through optimized plasmonic coupling. These structures typically consist of a core material (often a dielectric or different metal) coated with a SERS-active metal alloy layer. The thickness and composition of each layer can be precisely controlled to tune the plasmonic resonance. This approach allows for the creation of substrates with higher sensitivity, stability, and reproducibility compared to single-layer systems, making them suitable for quantitative analysis applications.

- Bimetallic and trimetallic alloy systems for SERS: Bimetallic and trimetallic alloy systems offer superior SERS enhancement through synergistic effects between different metals. Common combinations include Au-Ag, Au-Cu, Ag-Cu, and Au-Ag-Cu alloys, which provide broader plasmonic resonance ranges and higher enhancement factors than single metals. The ratio of metals can be adjusted to optimize performance for specific wavelengths of excitation light. These systems benefit from the combined advantages of their constituent metals, such as the chemical stability of gold with the higher enhancement capability of silver.

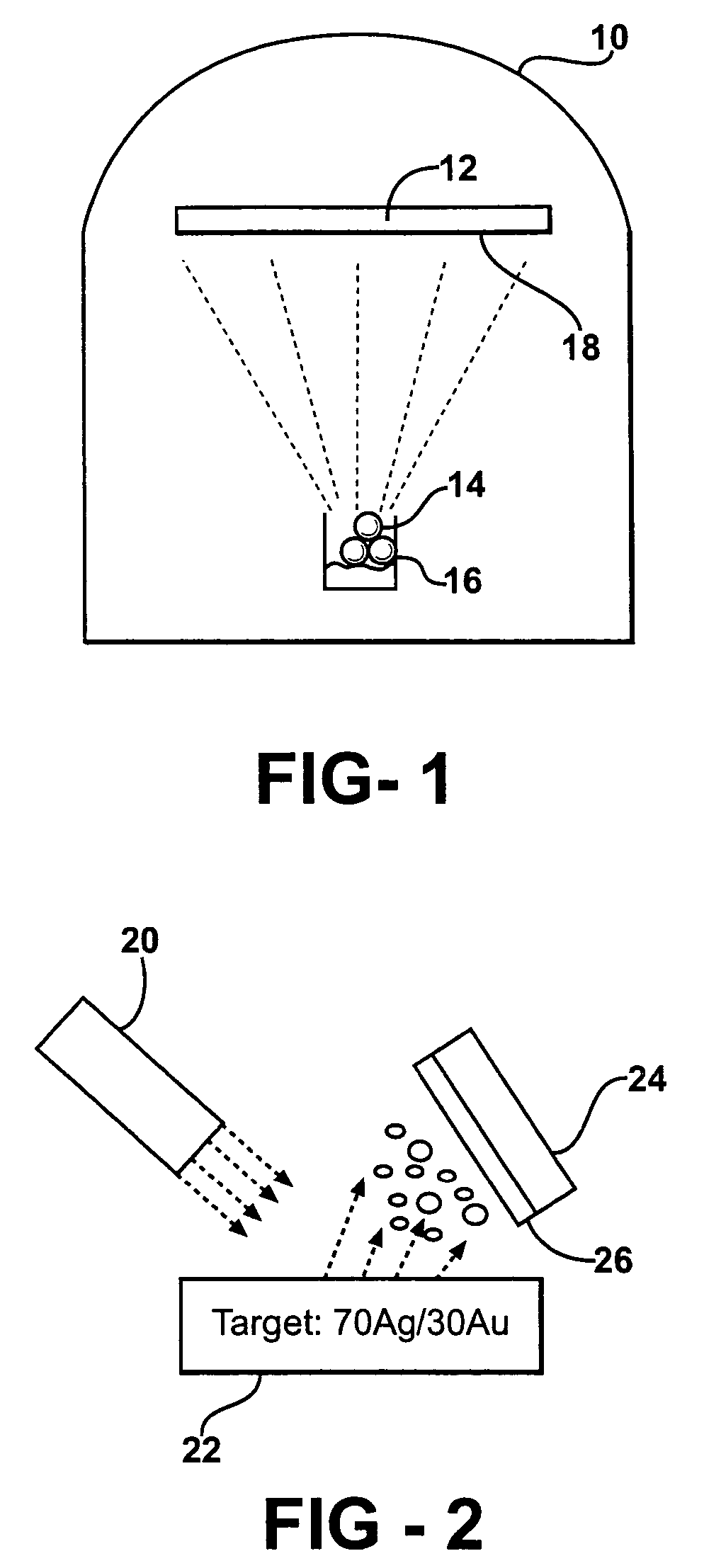

- Substrate fabrication techniques and post-processing methods: Various fabrication techniques and post-processing methods are employed to create effective SERS substrates with metal alloy coatings. These include physical vapor deposition, sputtering, electrochemical deposition, and solution-based synthesis. Post-processing treatments such as thermal annealing, plasma treatment, and chemical modification can further enhance SERS performance by optimizing surface properties. These processes control critical parameters such as crystallinity, grain size, and surface energy, which directly impact the enhancement factor and reproducibility of the SERS substrate.

02 Surface morphology control for SERS substrates

The surface morphology of metal alloy coatings plays a crucial role in SERS enhancement. Techniques to create roughened surfaces, nanopatterned structures, or hierarchical architectures can significantly increase the number of 'hot spots' where electromagnetic field enhancement occurs. Methods such as electrodeposition, chemical etching, and nanolithography can be used to control surface features at the nanoscale, optimizing the substrate for maximum SERS signal enhancement.Expand Specific Solutions03 Core-shell and multilayer SERS substrates

Core-shell and multilayer structures incorporating metal alloys provide advanced platforms for SERS enhancement. These structures typically consist of a core material (which may be metallic, polymeric, or ceramic) coated with layers of metal alloys. The layered architecture allows for precise tuning of plasmonic properties and can create additional enhancement mechanisms through coupled plasmon resonances between layers, resulting in significantly improved SERS performance.Expand Specific Solutions04 Bimetallic and trimetallic alloy systems for SERS

Specific bimetallic and trimetallic alloy systems have been developed as high-performance SERS substrates. These include Au-Ag, Au-Cu, Ag-Cu, and Au-Ag-Cu combinations, each offering distinct advantages for different applications. The synergistic effects between different metals can lead to enhanced electromagnetic field localization, improved stability, and broader plasmon resonance bands compared to single metal systems, making them versatile for various SERS detection scenarios.Expand Specific Solutions05 Fabrication methods for alloy-based SERS substrates

Various fabrication methods have been developed to create metal alloy coatings for SERS applications. These include physical vapor deposition, chemical reduction, electrochemical deposition, and laser ablation techniques. Each method offers different advantages in terms of controlling alloy composition, thickness, and nanostructure formation. Advanced fabrication approaches can incorporate templates or self-assembly processes to create highly ordered SERS-active surfaces with reproducible enhancement factors.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Surface-Enhanced Raman Spectroscopy (SERS) substrate technology in metal alloy coatings is currently in a growth phase, with the market expanding due to increasing applications in biosensing, chemical detection, and materials science. The global SERS market is projected to reach significant value as research institutions and companies advance substrate development. Leading academic institutions (Penn State Research Foundation, Northwestern University, Tsinghua University) are driving fundamental research, while companies like Hamamatsu Photonics and Intel are developing commercial applications. The technology shows varying maturity levels, with established players focusing on optimization and newcomers exploring novel alloy compositions. Research collaborations between universities and industry partners are accelerating innovation, particularly in nanofabrication techniques that enhance sensitivity and reproducibility of metal alloy SERS substrates.

Nanexa AB

Technical Solution: Nanexa AB has developed proprietary PharmaShell® technology that incorporates SERS-active metal alloy coatings for both analytical and biomedical applications. Their approach utilizes atomic layer deposition (ALD) to create precisely controlled nanometer-thick alloy layers of gold-silver, gold-palladium, and silver-copper on various substrate materials. This technique enables exceptional uniformity and reproducibility in SERS signal generation. Nanexa's metal alloy SERS substrates feature engineered nanogap structures that create "hot spots" with electromagnetic field enhancements up to 10^10, allowing for ultrasensitive detection of biomolecules and pharmaceutical compounds. The company has optimized their alloy compositions to provide maximum stability while maintaining high SERS activity, with demonstrated shelf-life exceeding 12 months without significant performance degradation. Their technology allows for customized surface chemistries to target specific analytes while minimizing non-specific binding.

Strengths: Exceptional precision in layer thickness control through ALD technology; outstanding reproducibility between production batches; extended shelf-life stability; customizable surface chemistry for specific applications. Weaknesses: Higher production costs due to specialized ALD equipment requirements; limited scalability for mass production; longer manufacturing time compared to conventional deposition methods.

Agency for Science, Technology & Research

Technical Solution: The Agency for Science, Technology & Research (A*STAR) has developed advanced SERS substrates using noble metal alloy coatings, particularly focusing on gold-silver (Au-Ag) and gold-copper (Au-Cu) nanostructures. Their approach involves precise control of alloy composition ratios to optimize plasmonic properties and enhance Raman signal amplification. A*STAR researchers have pioneered a galvanic replacement reaction method that creates hollow nanostructures with tunable plasmon resonances across the visible to near-infrared spectrum. Their substrates demonstrate enhancement factors exceeding 10^8 compared to conventional Raman spectroscopy, with detection limits reaching single-molecule sensitivity for certain analytes. The agency has also developed specialized surface functionalization techniques to improve target molecule adsorption while maintaining high reproducibility with relative standard deviations below 10% across batches.

Strengths: Exceptional sensitivity with enhancement factors exceeding 10^8; highly tunable plasmonic properties through precise alloy composition control; excellent reproducibility with <10% RSD. Weaknesses: Higher production costs compared to single-metal substrates; potential stability issues in certain chemical environments; more complex manufacturing process requiring specialized equipment.

Key Innovations in SERS Enhancement Mechanisms

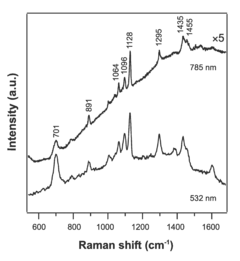

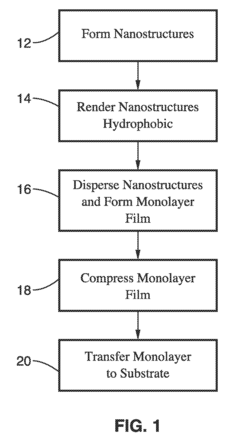

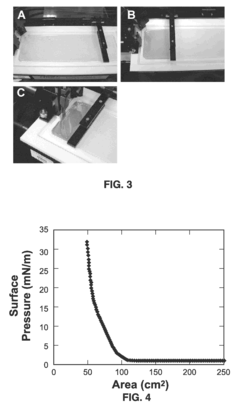

Surface-enhanced raman spectroscopy substrate for arsenic sensing in groundwater

PatentActiveUS9057705B2

Innovation

- The Langmuir-Blodgett technique is adapted to assemble monolayers of nanostructures by surface functionalization, allowing for the formation of ordered monolayers of silver nanowires with controlled shapes, such as cube-shaped, plate-shaped, rod-shaped, and hexagon-shaped nanostructures, and their subsequent compression to create aligned, close-packed arrays that function as surface-enhanced Raman spectroscopy (SERS) substrates.

Surface enhanced Raman spectroscopy (SERS) substrates exhibiting uniform high enhancement and stability

PatentInactiveUS7450227B2

Innovation

- The development of porous metal substrates, specifically gold substrates created by depositing a gold-silver alloy film and removing the silver through acid etching or electrochemical roughening, resulting in a textured surface that enhances SERS signals uniformly and stably.

Standardization and Quality Control Protocols

The establishment of standardization and quality control protocols is critical for the reliable implementation of SERS substrates in metal alloy coatings. Current research indicates significant variability in SERS performance across different laboratories and manufacturing processes, highlighting the urgent need for standardized methodologies.

A comprehensive quality control framework should begin with raw material specifications. Precise requirements for metal purity, particle size distribution, and chemical composition of alloy components must be established. For instance, silver-gold alloy substrates require strict control of elemental ratios to maintain consistent plasmonic properties, with deviations of less than 1% recommended to ensure reproducible enhancement factors.

Manufacturing process parameters represent another crucial aspect requiring standardization. Temperature profiles during thermal deposition, electrochemical deposition rates, and post-processing treatments significantly impact the final SERS performance. Documentation of these parameters should follow ISO 9001 guidelines, with specific adaptations for nanofabrication processes involved in SERS substrate production.

Analytical validation protocols must be implemented at multiple stages of production. Surface characterization techniques including SEM, AFM, and XPS should be employed with defined sampling frequencies and acceptance criteria. For example, roughness parameters measured by AFM should fall within predetermined ranges (typically Ra values between 5-20 nm for optimal SERS activity), while XPS should confirm expected elemental compositions within ±2% tolerance.

Performance testing standardization represents perhaps the most critical component of quality control. Reference analytes such as 4-aminothiophenol or rhodamine 6G should be utilized at specified concentrations to benchmark enhancement factors. Signal-to-noise ratios, peak positions, and relative intensities must be documented against certified reference materials to enable cross-laboratory comparisons.

Statistical process control methods should be adapted specifically for SERS substrate manufacturing. Control charts tracking key performance indicators such as enhancement factor consistency, batch-to-batch variability, and shelf-life stability provide essential feedback for continuous process improvement. Implementation of six-sigma methodologies can help identify critical process variables affecting SERS performance.

Certification and traceability systems must be established to ensure that substrates meet defined performance criteria. This includes documentation of calibration standards, measurement uncertainties, and verification against international reference materials where available. The development of round-robin testing programs between laboratories would further strengthen standardization efforts in this rapidly evolving field.

A comprehensive quality control framework should begin with raw material specifications. Precise requirements for metal purity, particle size distribution, and chemical composition of alloy components must be established. For instance, silver-gold alloy substrates require strict control of elemental ratios to maintain consistent plasmonic properties, with deviations of less than 1% recommended to ensure reproducible enhancement factors.

Manufacturing process parameters represent another crucial aspect requiring standardization. Temperature profiles during thermal deposition, electrochemical deposition rates, and post-processing treatments significantly impact the final SERS performance. Documentation of these parameters should follow ISO 9001 guidelines, with specific adaptations for nanofabrication processes involved in SERS substrate production.

Analytical validation protocols must be implemented at multiple stages of production. Surface characterization techniques including SEM, AFM, and XPS should be employed with defined sampling frequencies and acceptance criteria. For example, roughness parameters measured by AFM should fall within predetermined ranges (typically Ra values between 5-20 nm for optimal SERS activity), while XPS should confirm expected elemental compositions within ±2% tolerance.

Performance testing standardization represents perhaps the most critical component of quality control. Reference analytes such as 4-aminothiophenol or rhodamine 6G should be utilized at specified concentrations to benchmark enhancement factors. Signal-to-noise ratios, peak positions, and relative intensities must be documented against certified reference materials to enable cross-laboratory comparisons.

Statistical process control methods should be adapted specifically for SERS substrate manufacturing. Control charts tracking key performance indicators such as enhancement factor consistency, batch-to-batch variability, and shelf-life stability provide essential feedback for continuous process improvement. Implementation of six-sigma methodologies can help identify critical process variables affecting SERS performance.

Certification and traceability systems must be established to ensure that substrates meet defined performance criteria. This includes documentation of calibration standards, measurement uncertainties, and verification against international reference materials where available. The development of round-robin testing programs between laboratories would further strengthen standardization efforts in this rapidly evolving field.

Environmental Impact of SERS Substrate Production

The production of Surface-Enhanced Raman Spectroscopy (SERS) substrates incorporating metal alloy coatings presents significant environmental considerations that warrant thorough examination. The manufacturing processes typically involve hazardous chemicals, heavy metals, and energy-intensive procedures that can contribute to environmental degradation if not properly managed.

Primary environmental concerns stem from the use of noble metals such as gold, silver, and copper in SERS substrate production. Mining operations for these metals are associated with habitat destruction, soil erosion, and water pollution. Additionally, the extraction processes generate substantial carbon emissions, contributing to climate change. For instance, gold mining alone is responsible for approximately 0.2% of global greenhouse gas emissions.

Chemical processes involved in metal alloy coating deposition frequently utilize toxic substances including strong acids, organic solvents, and reducing agents. These chemicals, if improperly handled or disposed of, can contaminate water systems and soil. Particularly concerning are chemicals like hydrofluoric acid and cyanide compounds, which pose severe environmental hazards even in small quantities.

Energy consumption represents another significant environmental impact factor. High-temperature annealing processes and vacuum deposition techniques required for creating uniform metal alloy coatings demand substantial energy inputs. This energy demand translates to increased carbon footprints, especially in regions where electricity generation relies heavily on fossil fuels.

Waste management challenges are equally pressing. The production of SERS substrates generates various waste streams including spent solutions, etching byproducts, and defective substrates. These materials often contain heavy metals that require specialized disposal procedures to prevent environmental contamination.

Recent advancements in green chemistry approaches offer promising pathways to mitigate these environmental impacts. Researchers have developed eco-friendly synthesis methods utilizing plant extracts as reducing agents, thereby reducing dependence on toxic chemicals. Additionally, recycling technologies for recovering precious metals from spent SERS substrates are emerging, potentially creating closed-loop manufacturing systems.

Life cycle assessment studies indicate that the environmental footprint of SERS substrate production could be reduced by approximately 40% through implementation of best practices including energy-efficient manufacturing processes, chemical substitution, and effective waste management protocols. As regulatory frameworks around electronic waste and hazardous materials continue to strengthen globally, manufacturers are increasingly incentivized to adopt more sustainable production methods.

Primary environmental concerns stem from the use of noble metals such as gold, silver, and copper in SERS substrate production. Mining operations for these metals are associated with habitat destruction, soil erosion, and water pollution. Additionally, the extraction processes generate substantial carbon emissions, contributing to climate change. For instance, gold mining alone is responsible for approximately 0.2% of global greenhouse gas emissions.

Chemical processes involved in metal alloy coating deposition frequently utilize toxic substances including strong acids, organic solvents, and reducing agents. These chemicals, if improperly handled or disposed of, can contaminate water systems and soil. Particularly concerning are chemicals like hydrofluoric acid and cyanide compounds, which pose severe environmental hazards even in small quantities.

Energy consumption represents another significant environmental impact factor. High-temperature annealing processes and vacuum deposition techniques required for creating uniform metal alloy coatings demand substantial energy inputs. This energy demand translates to increased carbon footprints, especially in regions where electricity generation relies heavily on fossil fuels.

Waste management challenges are equally pressing. The production of SERS substrates generates various waste streams including spent solutions, etching byproducts, and defective substrates. These materials often contain heavy metals that require specialized disposal procedures to prevent environmental contamination.

Recent advancements in green chemistry approaches offer promising pathways to mitigate these environmental impacts. Researchers have developed eco-friendly synthesis methods utilizing plant extracts as reducing agents, thereby reducing dependence on toxic chemicals. Additionally, recycling technologies for recovering precious metals from spent SERS substrates are emerging, potentially creating closed-loop manufacturing systems.

Life cycle assessment studies indicate that the environmental footprint of SERS substrate production could be reduced by approximately 40% through implementation of best practices including energy-efficient manufacturing processes, chemical substitution, and effective waste management protocols. As regulatory frameworks around electronic waste and hazardous materials continue to strengthen globally, manufacturers are increasingly incentivized to adopt more sustainable production methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!