Research on the Surface Modification of SERS Substrates

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Substrate Evolution and Research Objectives

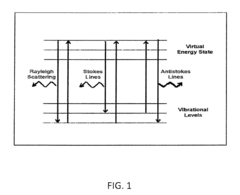

Surface-enhanced Raman spectroscopy (SERS) has evolved significantly since its discovery in the 1970s, transforming from an unexplained phenomenon to a powerful analytical technique with applications spanning from biomedical diagnostics to environmental monitoring. The evolution of SERS substrates represents a critical timeline in the advancement of this technology, with each generation addressing previous limitations while introducing new capabilities.

Early SERS substrates consisted primarily of electrochemically roughened metal surfaces, particularly silver, which provided enhancement factors of 10^4-10^6. These rudimentary substrates suffered from poor reproducibility and stability issues, limiting their practical applications. The 1990s witnessed the emergence of colloidal nanoparticles as SERS substrates, offering improved control over surface properties but still facing challenges in terms of aggregation and signal consistency.

The early 2000s marked a paradigm shift with the introduction of lithographically fabricated substrates, enabling precise control over nanostructure geometry and spacing. This period also saw the development of the first commercial SERS substrates, although their performance varied considerably between manufacturers. Recent advancements have focused on hierarchical structures combining features at multiple length scales to maximize enhancement factors while maintaining reproducibility.

Current research objectives in SERS substrate surface modification are multifaceted and ambitious. Primary goals include achieving ultrahigh sensitivity with single-molecule detection capabilities across a broader range of analytes, particularly those with weak Raman cross-sections. Researchers aim to develop substrates with enhancement factors exceeding 10^10 while maintaining batch-to-batch reproducibility with coefficient of variation below 5%.

Another critical objective is extending substrate shelf-life beyond the current industry standard of 6-12 months to 3-5 years without performance degradation. This requires innovative surface passivation strategies that preserve plasmonic properties while preventing oxidation and contamination. Researchers are also pursuing substrates with tunable surface chemistry that can be modified in situ to target specific analytes without compromising enhancement factors.

The integration of SERS substrates with microfluidic platforms represents another frontier, with objectives focused on developing surface modifications compatible with continuous flow systems and resistant to biofouling. Additionally, there is growing interest in environmentally sustainable substrate fabrication methods that reduce dependence on precious metals through the use of alternative plasmonic materials or core-shell architectures that minimize noble metal content.

These research objectives collectively aim to transform SERS from a specialized laboratory technique to a ubiquitous analytical tool accessible across diverse fields and applications, driving innovation in surface modification strategies that balance enhancement performance with practical considerations of cost, stability, and ease of use.

Early SERS substrates consisted primarily of electrochemically roughened metal surfaces, particularly silver, which provided enhancement factors of 10^4-10^6. These rudimentary substrates suffered from poor reproducibility and stability issues, limiting their practical applications. The 1990s witnessed the emergence of colloidal nanoparticles as SERS substrates, offering improved control over surface properties but still facing challenges in terms of aggregation and signal consistency.

The early 2000s marked a paradigm shift with the introduction of lithographically fabricated substrates, enabling precise control over nanostructure geometry and spacing. This period also saw the development of the first commercial SERS substrates, although their performance varied considerably between manufacturers. Recent advancements have focused on hierarchical structures combining features at multiple length scales to maximize enhancement factors while maintaining reproducibility.

Current research objectives in SERS substrate surface modification are multifaceted and ambitious. Primary goals include achieving ultrahigh sensitivity with single-molecule detection capabilities across a broader range of analytes, particularly those with weak Raman cross-sections. Researchers aim to develop substrates with enhancement factors exceeding 10^10 while maintaining batch-to-batch reproducibility with coefficient of variation below 5%.

Another critical objective is extending substrate shelf-life beyond the current industry standard of 6-12 months to 3-5 years without performance degradation. This requires innovative surface passivation strategies that preserve plasmonic properties while preventing oxidation and contamination. Researchers are also pursuing substrates with tunable surface chemistry that can be modified in situ to target specific analytes without compromising enhancement factors.

The integration of SERS substrates with microfluidic platforms represents another frontier, with objectives focused on developing surface modifications compatible with continuous flow systems and resistant to biofouling. Additionally, there is growing interest in environmentally sustainable substrate fabrication methods that reduce dependence on precious metals through the use of alternative plasmonic materials or core-shell architectures that minimize noble metal content.

These research objectives collectively aim to transform SERS from a specialized laboratory technique to a ubiquitous analytical tool accessible across diverse fields and applications, driving innovation in surface modification strategies that balance enhancement performance with practical considerations of cost, stability, and ease of use.

Market Analysis of SERS-based Sensing Applications

The global Surface-Enhanced Raman Spectroscopy (SERS) market has been experiencing robust growth, with a market value reaching $1.2 billion in 2022 and projected to expand at a CAGR of 9.8% through 2030. This growth is primarily driven by increasing applications in biomedical diagnostics, environmental monitoring, food safety, and security sectors. The SERS-based sensing applications market is particularly dynamic due to the technique's exceptional sensitivity, allowing for detection down to single-molecule levels.

Healthcare and life sciences currently dominate the SERS application landscape, accounting for approximately 45% of the market share. The demand for rapid, accurate diagnostic tools for diseases, including cancer and infectious diseases, has significantly boosted adoption in clinical settings. Pharmaceutical companies are increasingly utilizing SERS for drug discovery and development processes, creating a substantial market segment worth approximately $320 million annually.

Environmental monitoring represents the fastest-growing application sector, with a growth rate of 12.3% annually. This surge is attributed to stricter environmental regulations worldwide and growing concerns about water and air quality. SERS technology enables the detection of pollutants, heavy metals, and microplastics at concentrations previously undetectable by conventional methods, making it invaluable for regulatory compliance and environmental research.

Food safety applications constitute another significant market segment, valued at approximately $210 million. The ability of SERS to detect pesticides, antibiotics, melamine, and other contaminants in food products with minimal sample preparation has attracted substantial interest from food production companies and regulatory bodies alike.

Regional analysis reveals North America as the largest market for SERS-based sensing applications, holding approximately 38% of the global market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to increasing R&D investments, particularly in China, Japan, and South Korea.

The market is characterized by a growing demand for portable and field-deployable SERS devices, which is creating new opportunities for technology providers. This trend toward miniaturization and automation is expected to expand the addressable market by making SERS technology accessible to non-specialist users across various industries.

Customer pain points in the current market include the high cost of SERS substrates, challenges in achieving consistent enhancement factors, and the need for specialized expertise for data interpretation. These challenges represent significant market opportunities for companies developing surface-modified SERS substrates with improved stability, reproducibility, and user-friendly interfaces.

Healthcare and life sciences currently dominate the SERS application landscape, accounting for approximately 45% of the market share. The demand for rapid, accurate diagnostic tools for diseases, including cancer and infectious diseases, has significantly boosted adoption in clinical settings. Pharmaceutical companies are increasingly utilizing SERS for drug discovery and development processes, creating a substantial market segment worth approximately $320 million annually.

Environmental monitoring represents the fastest-growing application sector, with a growth rate of 12.3% annually. This surge is attributed to stricter environmental regulations worldwide and growing concerns about water and air quality. SERS technology enables the detection of pollutants, heavy metals, and microplastics at concentrations previously undetectable by conventional methods, making it invaluable for regulatory compliance and environmental research.

Food safety applications constitute another significant market segment, valued at approximately $210 million. The ability of SERS to detect pesticides, antibiotics, melamine, and other contaminants in food products with minimal sample preparation has attracted substantial interest from food production companies and regulatory bodies alike.

Regional analysis reveals North America as the largest market for SERS-based sensing applications, holding approximately 38% of the global market share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to increasing R&D investments, particularly in China, Japan, and South Korea.

The market is characterized by a growing demand for portable and field-deployable SERS devices, which is creating new opportunities for technology providers. This trend toward miniaturization and automation is expected to expand the addressable market by making SERS technology accessible to non-specialist users across various industries.

Customer pain points in the current market include the high cost of SERS substrates, challenges in achieving consistent enhancement factors, and the need for specialized expertise for data interpretation. These challenges represent significant market opportunities for companies developing surface-modified SERS substrates with improved stability, reproducibility, and user-friendly interfaces.

Current Challenges in SERS Substrate Surface Modification

Despite significant advancements in Surface-Enhanced Raman Spectroscopy (SERS) technology, several critical challenges persist in the surface modification of SERS substrates that impede their widespread application and commercialization. The primary challenge remains achieving consistent and reproducible enhancement factors across the substrate surface. Current manufacturing processes often result in non-uniform "hot spots," leading to significant signal variations that compromise analytical reliability and quantitative capabilities.

Stability issues present another major obstacle, as many high-performance SERS substrates suffer from rapid degradation under ambient conditions. The oxidation of metallic nanostructures (particularly silver), molecular desorption, and structural changes over time significantly reduce shelf-life and operational durability. This instability severely limits practical applications, especially in field-deployable sensing scenarios where environmental control is minimal.

Biocompatibility concerns emerge when SERS substrates are intended for biological applications. Many surface modification approaches employ toxic chemicals or create surfaces incompatible with biological samples, restricting their use in medical diagnostics and in vivo sensing. The challenge of developing modification protocols that maintain SERS activity while ensuring biocompatibility remains largely unresolved.

Scalable manufacturing represents a significant hurdle in transitioning from laboratory demonstrations to commercial products. Current high-performance SERS substrates often rely on sophisticated fabrication techniques like electron-beam lithography or complex chemical synthesis routes that are difficult to scale up while maintaining cost-effectiveness and performance consistency.

Selectivity and specificity limitations constrain the application of SERS in complex sample matrices. Current surface modification strategies struggle to effectively discriminate between target analytes and interfering substances, resulting in compromised detection specificity. The development of molecular recognition elements that can be integrated with SERS-active surfaces without diminishing enhancement capabilities remains challenging.

Cost considerations further complicate widespread adoption, as many high-performance SERS substrates require expensive noble metals (gold, silver) and sophisticated fabrication equipment. The economic viability of SERS technology depends on developing cost-effective surface modification approaches that maintain performance while reducing material and manufacturing expenses.

Environmental sustainability has emerged as a recent concern, with traditional SERS substrate fabrication and modification processes often involving hazardous chemicals and generating significant waste. Developing green chemistry approaches for surface modification that minimize environmental impact while maintaining performance represents an evolving challenge in the field.

Stability issues present another major obstacle, as many high-performance SERS substrates suffer from rapid degradation under ambient conditions. The oxidation of metallic nanostructures (particularly silver), molecular desorption, and structural changes over time significantly reduce shelf-life and operational durability. This instability severely limits practical applications, especially in field-deployable sensing scenarios where environmental control is minimal.

Biocompatibility concerns emerge when SERS substrates are intended for biological applications. Many surface modification approaches employ toxic chemicals or create surfaces incompatible with biological samples, restricting their use in medical diagnostics and in vivo sensing. The challenge of developing modification protocols that maintain SERS activity while ensuring biocompatibility remains largely unresolved.

Scalable manufacturing represents a significant hurdle in transitioning from laboratory demonstrations to commercial products. Current high-performance SERS substrates often rely on sophisticated fabrication techniques like electron-beam lithography or complex chemical synthesis routes that are difficult to scale up while maintaining cost-effectiveness and performance consistency.

Selectivity and specificity limitations constrain the application of SERS in complex sample matrices. Current surface modification strategies struggle to effectively discriminate between target analytes and interfering substances, resulting in compromised detection specificity. The development of molecular recognition elements that can be integrated with SERS-active surfaces without diminishing enhancement capabilities remains challenging.

Cost considerations further complicate widespread adoption, as many high-performance SERS substrates require expensive noble metals (gold, silver) and sophisticated fabrication equipment. The economic viability of SERS technology depends on developing cost-effective surface modification approaches that maintain performance while reducing material and manufacturing expenses.

Environmental sustainability has emerged as a recent concern, with traditional SERS substrate fabrication and modification processes often involving hazardous chemicals and generating significant waste. Developing green chemistry approaches for surface modification that minimize environmental impact while maintaining performance represents an evolving challenge in the field.

Contemporary Surface Modification Approaches for SERS

01 Metal nanostructure surface modifications for SERS enhancement

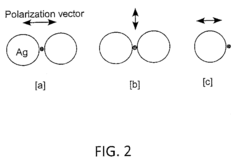

Surface modifications of metal nanostructures can significantly enhance SERS sensitivity. These modifications include creating nanogaps, roughened surfaces, or specific patterns on gold, silver, or other noble metal substrates. The modified surfaces provide increased electromagnetic field enhancement at hot spots, resulting in improved Raman signal intensity. Various techniques such as chemical etching, electrodeposition, and nanolithography can be employed to create these optimized SERS-active surfaces.- Metal nanostructure surface modifications for SERS enhancement: Surface modifications of metal nanostructures can significantly enhance SERS sensitivity. These modifications typically involve altering the surface chemistry or morphology of noble metal (gold, silver) substrates to increase the electromagnetic field enhancement. Techniques include creating nanoscale roughness, controlled etching processes, and developing hierarchical structures that create 'hot spots' where the Raman signal is amplified by several orders of magnitude.

- Polymer and organic coating modifications for SERS substrates: Polymer and organic coatings can be applied to SERS substrates to improve selectivity, stability, and performance. These modifications include functionalization with polymers, self-assembled monolayers, and biomolecules that can serve as selective capture agents for target analytes. The organic layers can protect the metal surface from oxidation while simultaneously providing binding sites for specific molecular interactions, enhancing both the durability and analytical capabilities of the SERS platform.

- Nanofabrication techniques for SERS substrate modification: Advanced nanofabrication techniques enable precise control over SERS substrate surface properties. These include lithographic methods, template-assisted synthesis, and self-assembly approaches to create optimized surface structures. The techniques allow for the creation of periodic arrays, controlled interparticle spacing, and specific geometries that maximize plasmonic coupling effects. These fabrication methods can produce reproducible substrates with consistent enhancement factors, addressing one of the major challenges in SERS technology.

- Chemical functionalization strategies for target-specific SERS detection: Chemical functionalization of SERS substrates enables target-specific molecular detection. By attaching recognition elements such as antibodies, aptamers, or molecularly imprinted polymers to the substrate surface, these modifications create highly selective sensing platforms. The functionalization strategies often involve multi-step chemical processes to covalently bind the recognition elements while maintaining the plasmonic properties of the underlying substrate. This approach is particularly valuable for biosensing applications where specificity is crucial.

- Composite and hybrid SERS substrate modifications: Composite and hybrid materials represent an innovative approach to SERS substrate modification. These include combinations of different metals, metal-semiconductor hybrids, and metal-carbon nanomaterial composites. The synergistic effects between the different components can lead to enhanced electromagnetic fields, improved stability, and additional functionalities. These hybrid structures often incorporate materials like graphene, carbon nanotubes, or metal oxides to create multifunctional SERS platforms with superior performance characteristics.

02 Polymer and organic coating modifications for SERS substrates

Polymer and organic coatings can be applied to SERS substrates to improve their performance and functionality. These coatings can enhance analyte capture, provide selectivity, protect the metal surface from oxidation, or improve wettability. Common approaches include self-assembled monolayers, hydrophilic/hydrophobic modifications, and stimuli-responsive polymer layers. These surface modifications enable better analyte-substrate interactions and can significantly improve detection sensitivity and specificity.Expand Specific Solutions03 Biomolecular functionalization of SERS substrates

SERS substrates can be functionalized with biomolecules such as antibodies, aptamers, or DNA to create highly specific biosensors. These biomolecular modifications provide selective binding sites for target analytes, enabling specific detection in complex biological samples. The functionalization typically involves chemical linkers that attach the biomolecules to the metal surface while maintaining their biological activity. This approach allows for the development of sensitive and selective SERS-based diagnostic platforms for medical and environmental applications.Expand Specific Solutions04 Nanomaterial incorporation for enhanced SERS performance

Various nanomaterials can be incorporated onto SERS substrates to enhance their performance. These include carbon-based materials (graphene, carbon nanotubes), metal oxide nanoparticles, quantum dots, and other 2D materials. These nanomaterials can provide additional enhancement mechanisms, improve substrate stability, or add multifunctionality. Hybrid structures combining different nanomaterials with traditional metal SERS substrates often demonstrate superior sensitivity and broader applicability compared to conventional substrates.Expand Specific Solutions05 Surface patterning and hierarchical structures for SERS

Creating specific patterns and hierarchical structures on SERS substrates can optimize their performance. These include periodic arrays, 3D structures, and multi-scale architectures that maximize the density of hot spots. Advanced fabrication techniques such as lithography, template-assisted growth, and self-assembly are used to create these complex structures. The resulting substrates often feature enhanced reproducibility, uniformity, and signal amplification compared to randomly structured surfaces, making them suitable for quantitative SERS applications.Expand Specific Solutions

Leading Research Groups and Companies in SERS Field

The Surface Modification of SERS Substrates market is currently in a growth phase, characterized by increasing research activities and commercial applications. The global market size is estimated to be expanding at a CAGR of 10-15%, driven by demand in analytical chemistry, biosensing, and medical diagnostics. Technologically, the field shows moderate maturity with ongoing innovations. Leading academic institutions (University of Houston, Penn State Research Foundation, Jilin University) are advancing fundamental research, while established corporations (IBM, Intel, Corning) focus on commercial applications. Research organizations (Industrial Technology Research Institute, Agency for Science, Technology & Research) bridge the gap between academia and industry. Specialized companies like IMRA America and Nanexa AB are developing proprietary surface modification techniques, indicating a competitive landscape with diverse players across the innovation spectrum.

University of Houston

Technical Solution: University of Houston has developed innovative SERS substrate modification techniques focusing on hierarchical nanostructures. Their approach combines top-down lithography with bottom-up self-assembly to create highly ordered and reproducible SERS substrates. They've pioneered the use of atomic layer deposition (ALD) to precisely control the thickness and composition of metal oxide layers on plasmonic nanostructures, creating core-shell architectures that significantly enhance electromagnetic field localization. Their research demonstrates that ultrathin Al2O3 coatings (2-5 nm) on silver nanoparticles can improve SERS enhancement factors by up to 10-fold while providing chemical stability against oxidation. Additionally, they've developed biofunctionalized SERS substrates using self-assembled monolayers of thiolated molecules for selective detection of biomolecules at concentrations as low as 10^-12 M.

Strengths: Exceptional control over nanostructure geometry and spacing enables reproducible enhancement factors across large substrate areas. Their ALD-based modification techniques provide excellent stability in harsh chemical environments while maintaining high sensitivity. Weaknesses: The complex fabrication processes involving multiple steps may limit cost-effective scaling for commercial applications, and the specialized equipment requirements create barriers to widespread adoption.

Penn State Research Foundation

Technical Solution: Penn State Research Foundation has developed sophisticated SERS substrate modification technologies focusing on nanoporous metal films and plasmonic metamaterials. Their approach utilizes dealloying techniques to create nanoporous gold films with tunable pore sizes (20-100 nm) and ligament dimensions, providing three-dimensional SERS-active structures with high surface area and abundant hotspots. They've pioneered the use of oblique angle deposition to create slanted nanocolumnar structures with controlled spacing and orientation, demonstrating polarization-dependent SERS enhancement that enables multiplexed detection capabilities. Their research shows that post-deposition thermal annealing at precisely controlled temperatures (250-350°C) can optimize the plasmonic properties of these structures, increasing enhancement factors by up to 5-fold. Additionally, they've developed novel surface functionalization protocols using mixed-length thiolated self-assembled monolayers that create nanoscale spacing between the analyte and metal surface, preventing fluorescence quenching while maintaining strong SERS signals for fluorophore-labeled biomolecules.

Strengths: Their three-dimensional nanoporous structures provide exceptionally high density of hotspots per unit area, resulting in lower detection limits compared to conventional two-dimensional substrates. The polarization-dependent properties enable advanced multiplexing capabilities not available with standard SERS platforms. Weaknesses: The dealloying process can introduce variability in pore structure and distribution, potentially affecting reproducibility across large substrate areas, and the complex three-dimensional structures may present challenges for analyte recovery after measurement.

Key Patents and Breakthroughs in SERS Surface Chemistry

Surface-enhanced raman scattering substrates

PatentInactiveUS9086380B2

Innovation

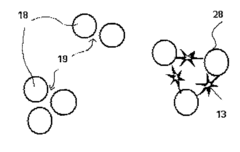

- A method involving the application of a nanoparticle ink to a substrate, followed by controlled heating to form fractal aggregates of nanoparticles, allowing for controlled spacing and enhanced Raman scattering signal amplification, enabling cost-effective and scalable production of SERS substrates.

A substrate for surface enhanced raman scattering (SERS)

PatentWO2010056258A1

Innovation

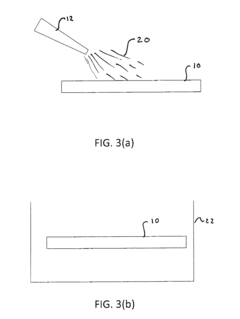

- A substrate with uniformly distributed nanostructures and a layer of SERS active metal, such as silver, gold, or copper, is fabricated using a customized Bosch process without lithographic masking, providing a textured surface for enhanced Raman signal detection across a larger area, and replicated using embossing or stamping techniques to reduce costs.

Nanofabrication Techniques for Advanced SERS Substrates

Nanofabrication techniques have revolutionized the development of advanced SERS substrates, enabling unprecedented control over surface morphology and enhancement capabilities. Traditional fabrication methods such as physical vapor deposition and chemical etching have been complemented by sophisticated approaches including electron-beam lithography, focused ion beam milling, and nanoimprint lithography. These techniques allow for precise manipulation of nanoscale features critical for SERS performance.

Colloidal lithography has emerged as a cost-effective alternative for creating large-area periodic nanostructures with controlled interparticle spacing. This technique utilizes self-assembled monolayers of nanospheres as templates, offering scalability advantages over more equipment-intensive methods. Recent advances in colloidal lithography have achieved sub-10 nm gap structures, approaching the theoretical limits for maximum electromagnetic field enhancement.

Template-assisted fabrication represents another significant advancement, where anodized aluminum oxide or block copolymer templates guide the formation of highly ordered nanostructures. These approaches facilitate the creation of high-density arrays with precisely controlled dimensions and spacing, critical parameters for optimizing SERS hot spots.

Bottom-up chemical synthesis methods have gained prominence for their versatility in creating complex 3D nanostructures. Seed-mediated growth, galvanic replacement reactions, and controlled aggregation processes enable the synthesis of branched nanoparticles, core-shell structures, and hierarchical assemblies with enhanced plasmonic properties. These chemically synthesized substrates often exhibit superior enhancement factors compared to their lithographically fabricated counterparts.

Hybrid fabrication approaches combining top-down and bottom-up methodologies represent the cutting edge of SERS substrate development. For instance, lithographically defined templates can be used to direct the assembly of chemically synthesized nanoparticles, creating hierarchical structures with optimized hot spot distributions. These hybrid approaches leverage the precision of lithography with the versatility of chemical synthesis.

Recent innovations in nanofabrication include the development of flexible and stretchable SERS substrates through techniques such as transfer printing and strain engineering. These advances have expanded the application scope of SERS to conformable surfaces and point-of-care diagnostics. Additionally, the integration of stimuli-responsive materials has enabled the creation of dynamic SERS substrates whose enhancement properties can be modulated by external triggers such as pH, temperature, or light.

The continued refinement of nanofabrication techniques remains essential for addressing key challenges in SERS substrate development, including reproducibility, stability, and cost-effectiveness. Emerging approaches such as DNA-directed assembly and 3D printing at the nanoscale promise to further expand the design space for next-generation SERS platforms.

Colloidal lithography has emerged as a cost-effective alternative for creating large-area periodic nanostructures with controlled interparticle spacing. This technique utilizes self-assembled monolayers of nanospheres as templates, offering scalability advantages over more equipment-intensive methods. Recent advances in colloidal lithography have achieved sub-10 nm gap structures, approaching the theoretical limits for maximum electromagnetic field enhancement.

Template-assisted fabrication represents another significant advancement, where anodized aluminum oxide or block copolymer templates guide the formation of highly ordered nanostructures. These approaches facilitate the creation of high-density arrays with precisely controlled dimensions and spacing, critical parameters for optimizing SERS hot spots.

Bottom-up chemical synthesis methods have gained prominence for their versatility in creating complex 3D nanostructures. Seed-mediated growth, galvanic replacement reactions, and controlled aggregation processes enable the synthesis of branched nanoparticles, core-shell structures, and hierarchical assemblies with enhanced plasmonic properties. These chemically synthesized substrates often exhibit superior enhancement factors compared to their lithographically fabricated counterparts.

Hybrid fabrication approaches combining top-down and bottom-up methodologies represent the cutting edge of SERS substrate development. For instance, lithographically defined templates can be used to direct the assembly of chemically synthesized nanoparticles, creating hierarchical structures with optimized hot spot distributions. These hybrid approaches leverage the precision of lithography with the versatility of chemical synthesis.

Recent innovations in nanofabrication include the development of flexible and stretchable SERS substrates through techniques such as transfer printing and strain engineering. These advances have expanded the application scope of SERS to conformable surfaces and point-of-care diagnostics. Additionally, the integration of stimuli-responsive materials has enabled the creation of dynamic SERS substrates whose enhancement properties can be modulated by external triggers such as pH, temperature, or light.

The continued refinement of nanofabrication techniques remains essential for addressing key challenges in SERS substrate development, including reproducibility, stability, and cost-effectiveness. Emerging approaches such as DNA-directed assembly and 3D printing at the nanoscale promise to further expand the design space for next-generation SERS platforms.

Standardization and Reproducibility Considerations

Standardization remains a critical challenge in the field of Surface-Enhanced Raman Spectroscopy (SERS) substrate development. Despite significant advancements in surface modification techniques, the lack of universally accepted protocols for substrate preparation, modification, and testing has hindered widespread industrial adoption. Current research indicates that reproducibility issues stem from variations in nanofabrication processes, inconsistent surface chemistry protocols, and environmental factors affecting substrate performance.

Industry stakeholders have begun collaborative efforts to establish standardized testing methodologies for SERS substrates. These initiatives focus on defining benchmark molecules, standardized measurement conditions, and statistical analysis frameworks to enable meaningful comparison between different surface modification approaches. The International Organization for Standardization (ISO) has recently formed a technical committee specifically addressing nanoscale measurements in spectroscopy, with SERS substrate standardization as a priority area.

Quantitative reproducibility metrics have emerged as essential tools for evaluating surface modification techniques. Enhancement factor (EF) calculations, signal relative standard deviation (RSD), and substrate-to-substrate consistency measurements provide objective criteria for comparing different approaches. Leading research groups now routinely report these metrics, with industry standards generally requiring RSDs below 15% for commercial viability.

Batch-to-batch consistency presents particular challenges for chemically modified SERS substrates. Recent innovations in automated surface modification systems have demonstrated significant improvements, reducing variation from typical ranges of 30-40% down to 10-15% in controlled manufacturing environments. Quality control protocols increasingly incorporate machine learning algorithms to identify and compensate for subtle variations in surface chemistry.

Long-term stability of modified surfaces represents another critical reproducibility consideration. Environmental factors including humidity, temperature fluctuations, and exposure to atmospheric contaminants can significantly impact substrate performance over time. Advanced encapsulation techniques and protective surface chemistries have extended typical shelf-life from weeks to months, with some commercial products now claiming stability for up to one year under appropriate storage conditions.

Interlaboratory comparison studies have highlighted the need for standardized reporting of experimental conditions. Parameters such as laser power density, integration time, and sample preparation protocols significantly impact measured SERS performance but are inconsistently documented in literature. The development of digital laboratory notebooks with standardized reporting templates has begun addressing this challenge, facilitating more meaningful comparison between research results from different institutions.

Industry stakeholders have begun collaborative efforts to establish standardized testing methodologies for SERS substrates. These initiatives focus on defining benchmark molecules, standardized measurement conditions, and statistical analysis frameworks to enable meaningful comparison between different surface modification approaches. The International Organization for Standardization (ISO) has recently formed a technical committee specifically addressing nanoscale measurements in spectroscopy, with SERS substrate standardization as a priority area.

Quantitative reproducibility metrics have emerged as essential tools for evaluating surface modification techniques. Enhancement factor (EF) calculations, signal relative standard deviation (RSD), and substrate-to-substrate consistency measurements provide objective criteria for comparing different approaches. Leading research groups now routinely report these metrics, with industry standards generally requiring RSDs below 15% for commercial viability.

Batch-to-batch consistency presents particular challenges for chemically modified SERS substrates. Recent innovations in automated surface modification systems have demonstrated significant improvements, reducing variation from typical ranges of 30-40% down to 10-15% in controlled manufacturing environments. Quality control protocols increasingly incorporate machine learning algorithms to identify and compensate for subtle variations in surface chemistry.

Long-term stability of modified surfaces represents another critical reproducibility consideration. Environmental factors including humidity, temperature fluctuations, and exposure to atmospheric contaminants can significantly impact substrate performance over time. Advanced encapsulation techniques and protective surface chemistries have extended typical shelf-life from weeks to months, with some commercial products now claiming stability for up to one year under appropriate storage conditions.

Interlaboratory comparison studies have highlighted the need for standardized reporting of experimental conditions. Parameters such as laser power density, integration time, and sample preparation protocols significantly impact measured SERS performance but are inconsistently documented in literature. The development of digital laboratory notebooks with standardized reporting templates has begun addressing this challenge, facilitating more meaningful comparison between research results from different institutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!