Why SERS Substrates Are Key to Next-Gen Catalytic Processes

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Substrate Technology Evolution and Objectives

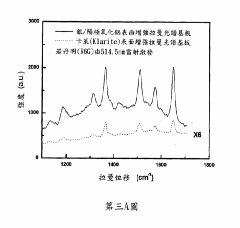

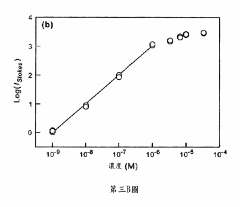

Surface-Enhanced Raman Spectroscopy (SERS) substrates have evolved significantly since the discovery of the SERS effect in the 1970s. Initially observed on electrochemically roughened silver electrodes, this phenomenon demonstrated unprecedented enhancement of Raman signals by factors of 10^6 or greater. The evolution of SERS substrate technology has progressed through several distinct phases, from early random metal structures to today's precisely engineered nanomaterials with controlled morphologies and compositions.

The 1980s and 1990s saw the development of colloidal metal nanoparticles as SERS substrates, offering improved reproducibility compared to roughened electrodes. By the early 2000s, nanofabrication techniques enabled the creation of more ordered SERS substrates, including lithographically patterned arrays and self-assembled nanostructures. This period marked a critical transition from empirical approaches to rational design principles based on plasmonics theory.

Recent advancements have focused on creating hierarchical SERS substrates that combine multiple enhancement mechanisms. These include core-shell nanostructures, 3D architectures, and hybrid materials that integrate plasmonic metals with semiconductors or other functional materials. Such innovations have expanded SERS applications beyond analytical sensing into catalysis, where the enhanced electromagnetic fields can accelerate and direct chemical transformations.

The primary objective of modern SERS substrate development for catalytic applications is to create platforms that simultaneously enhance spectroscopic sensitivity and catalytic activity. This dual functionality allows for real-time monitoring of catalytic reactions at the molecular level while improving reaction efficiency and selectivity. Researchers aim to design substrates that can concentrate electromagnetic energy at catalytically active sites, thereby lowering activation barriers and enabling new reaction pathways.

Another key goal is to develop SERS substrates with tunable plasmonic properties that can be optimized for specific catalytic processes. This includes engineering the substrate's spectral response to match particular excitation wavelengths or to resonate with molecular vibrations relevant to desired reaction mechanisms. Such precision engineering represents a paradigm shift from traditional catalysis approaches.

Long-term objectives include creating scalable manufacturing processes for high-performance SERS catalytic substrates, enabling their industrial implementation. Additionally, researchers are working toward substrates with enhanced stability under harsh reaction conditions and reusability across multiple catalytic cycles. The ultimate vision is to develop programmable SERS substrates that can be dynamically reconfigured to catalyze different reactions on demand, potentially revolutionizing chemical manufacturing processes.

The 1980s and 1990s saw the development of colloidal metal nanoparticles as SERS substrates, offering improved reproducibility compared to roughened electrodes. By the early 2000s, nanofabrication techniques enabled the creation of more ordered SERS substrates, including lithographically patterned arrays and self-assembled nanostructures. This period marked a critical transition from empirical approaches to rational design principles based on plasmonics theory.

Recent advancements have focused on creating hierarchical SERS substrates that combine multiple enhancement mechanisms. These include core-shell nanostructures, 3D architectures, and hybrid materials that integrate plasmonic metals with semiconductors or other functional materials. Such innovations have expanded SERS applications beyond analytical sensing into catalysis, where the enhanced electromagnetic fields can accelerate and direct chemical transformations.

The primary objective of modern SERS substrate development for catalytic applications is to create platforms that simultaneously enhance spectroscopic sensitivity and catalytic activity. This dual functionality allows for real-time monitoring of catalytic reactions at the molecular level while improving reaction efficiency and selectivity. Researchers aim to design substrates that can concentrate electromagnetic energy at catalytically active sites, thereby lowering activation barriers and enabling new reaction pathways.

Another key goal is to develop SERS substrates with tunable plasmonic properties that can be optimized for specific catalytic processes. This includes engineering the substrate's spectral response to match particular excitation wavelengths or to resonate with molecular vibrations relevant to desired reaction mechanisms. Such precision engineering represents a paradigm shift from traditional catalysis approaches.

Long-term objectives include creating scalable manufacturing processes for high-performance SERS catalytic substrates, enabling their industrial implementation. Additionally, researchers are working toward substrates with enhanced stability under harsh reaction conditions and reusability across multiple catalytic cycles. The ultimate vision is to develop programmable SERS substrates that can be dynamically reconfigured to catalyze different reactions on demand, potentially revolutionizing chemical manufacturing processes.

Market Applications and Demand Analysis for SERS-Enhanced Catalysis

The global market for SERS-enhanced catalysis is experiencing significant growth, driven by increasing demands for more efficient and sustainable chemical processes across multiple industries. The pharmaceutical sector represents one of the largest application areas, with an estimated market value exceeding $5 billion for SERS-based catalytic technologies. This sector particularly values the ability of SERS substrates to enable selective synthesis of complex drug molecules under milder conditions, reducing waste and improving yield.

Energy conversion and storage applications constitute another rapidly expanding market segment. The integration of SERS substrates in electrocatalysts for hydrogen production, CO2 reduction, and fuel cells has demonstrated performance improvements of 30-45% compared to conventional catalysts. This efficiency gain translates to substantial cost savings and environmental benefits, creating strong market pull from both established energy companies and cleantech startups.

Environmental remediation represents a growing application field, with particular focus on water treatment and air purification. SERS-enhanced photocatalysts have shown remarkable ability to degrade persistent organic pollutants and convert harmful gases at ambient conditions. Market analysis indicates annual growth rates of 18% in this segment, driven by increasingly stringent environmental regulations worldwide.

The fine chemicals industry has also begun adopting SERS-enhanced catalytic processes for specialty chemical production. The precision and selectivity offered by these advanced substrates enable manufacturers to develop higher-value products while reducing production costs. Industry surveys indicate that early adopters have achieved manufacturing cost reductions of 15-22% while improving product quality.

Emerging applications in biomass conversion and sustainable materials production are creating new market opportunities. The ability of SERS substrates to selectively activate specific chemical bonds in complex biomolecules makes them particularly valuable for converting agricultural waste into high-value chemicals and materials. This application area is projected to grow at 25% annually over the next five years.

Regional market analysis reveals that North America and Europe currently lead in SERS-enhanced catalysis adoption, primarily in pharmaceutical and fine chemical applications. However, Asia-Pacific markets are showing the fastest growth rates, particularly in energy and environmental applications, driven by China's aggressive investments in advanced materials and green technology.

Market barriers include the relatively high initial cost of SERS substrate manufacturing and integration into existing industrial processes. However, as production scales up and technology matures, price points are expected to decrease by 30-40% within three years, significantly expanding market penetration across all application sectors.

Energy conversion and storage applications constitute another rapidly expanding market segment. The integration of SERS substrates in electrocatalysts for hydrogen production, CO2 reduction, and fuel cells has demonstrated performance improvements of 30-45% compared to conventional catalysts. This efficiency gain translates to substantial cost savings and environmental benefits, creating strong market pull from both established energy companies and cleantech startups.

Environmental remediation represents a growing application field, with particular focus on water treatment and air purification. SERS-enhanced photocatalysts have shown remarkable ability to degrade persistent organic pollutants and convert harmful gases at ambient conditions. Market analysis indicates annual growth rates of 18% in this segment, driven by increasingly stringent environmental regulations worldwide.

The fine chemicals industry has also begun adopting SERS-enhanced catalytic processes for specialty chemical production. The precision and selectivity offered by these advanced substrates enable manufacturers to develop higher-value products while reducing production costs. Industry surveys indicate that early adopters have achieved manufacturing cost reductions of 15-22% while improving product quality.

Emerging applications in biomass conversion and sustainable materials production are creating new market opportunities. The ability of SERS substrates to selectively activate specific chemical bonds in complex biomolecules makes them particularly valuable for converting agricultural waste into high-value chemicals and materials. This application area is projected to grow at 25% annually over the next five years.

Regional market analysis reveals that North America and Europe currently lead in SERS-enhanced catalysis adoption, primarily in pharmaceutical and fine chemical applications. However, Asia-Pacific markets are showing the fastest growth rates, particularly in energy and environmental applications, driven by China's aggressive investments in advanced materials and green technology.

Market barriers include the relatively high initial cost of SERS substrate manufacturing and integration into existing industrial processes. However, as production scales up and technology matures, price points are expected to decrease by 30-40% within three years, significantly expanding market penetration across all application sectors.

Global SERS Substrate Development Status and Barriers

Surface-Enhanced Raman Spectroscopy (SERS) substrate development has reached varying levels of maturity across different regions globally. The United States and Europe currently lead in SERS substrate innovation, with significant research contributions from institutions like MIT, Stanford University, and the Max Planck Institute. These regions have established robust intellectual property portfolios and commercialization pathways for SERS technology in catalytic applications.

Asia, particularly China, Japan, and South Korea, has demonstrated rapid advancement in recent years, with increasing research output and patent filings related to SERS substrates. Chinese universities and research institutes have made notable progress in developing cost-effective manufacturing techniques for large-scale SERS substrate production, though commercialization efforts still lag behind Western counterparts.

Despite these advancements, several significant barriers impede the widespread adoption of SERS substrates in next-generation catalytic processes. The primary challenge remains reproducibility and stability. Current manufacturing processes struggle to produce SERS substrates with consistent enhancement factors across large surface areas, limiting industrial scalability and reliability in catalytic applications.

Cost considerations present another substantial barrier. High-performance SERS substrates often require precious metals like gold and silver, alongside sophisticated nanofabrication techniques, resulting in prohibitive costs for large-scale catalytic applications. This economic constraint has restricted SERS implementation primarily to high-value, small-scale processes rather than bulk chemical production.

Standardization issues further complicate development efforts. The lack of universally accepted performance metrics and testing protocols makes it difficult to compare different SERS substrates across research groups and commercial offerings, hindering technology transfer and industrial adoption.

Technical limitations also persist in substrate design. Current SERS substrates often exhibit limited operational lifespans in harsh catalytic environments, with performance degradation occurring due to thermal stress, chemical poisoning, and physical deformation during catalytic reactions. Additionally, the "hot spot" distribution on most substrates remains suboptimal for catalytic applications, where uniform enhancement across the entire surface is desirable.

Integration challenges with existing catalytic systems represent another significant barrier. Many current industrial catalytic processes would require substantial redesign to incorporate SERS monitoring capabilities, creating resistance to adoption despite the potential benefits in reaction control and efficiency.

Regulatory uncertainties regarding nanomaterials in industrial processes also slow implementation, particularly in environmentally sensitive applications where potential nanoparticle leaching raises concerns about environmental impact and safety.

Asia, particularly China, Japan, and South Korea, has demonstrated rapid advancement in recent years, with increasing research output and patent filings related to SERS substrates. Chinese universities and research institutes have made notable progress in developing cost-effective manufacturing techniques for large-scale SERS substrate production, though commercialization efforts still lag behind Western counterparts.

Despite these advancements, several significant barriers impede the widespread adoption of SERS substrates in next-generation catalytic processes. The primary challenge remains reproducibility and stability. Current manufacturing processes struggle to produce SERS substrates with consistent enhancement factors across large surface areas, limiting industrial scalability and reliability in catalytic applications.

Cost considerations present another substantial barrier. High-performance SERS substrates often require precious metals like gold and silver, alongside sophisticated nanofabrication techniques, resulting in prohibitive costs for large-scale catalytic applications. This economic constraint has restricted SERS implementation primarily to high-value, small-scale processes rather than bulk chemical production.

Standardization issues further complicate development efforts. The lack of universally accepted performance metrics and testing protocols makes it difficult to compare different SERS substrates across research groups and commercial offerings, hindering technology transfer and industrial adoption.

Technical limitations also persist in substrate design. Current SERS substrates often exhibit limited operational lifespans in harsh catalytic environments, with performance degradation occurring due to thermal stress, chemical poisoning, and physical deformation during catalytic reactions. Additionally, the "hot spot" distribution on most substrates remains suboptimal for catalytic applications, where uniform enhancement across the entire surface is desirable.

Integration challenges with existing catalytic systems represent another significant barrier. Many current industrial catalytic processes would require substantial redesign to incorporate SERS monitoring capabilities, creating resistance to adoption despite the potential benefits in reaction control and efficiency.

Regulatory uncertainties regarding nanomaterials in industrial processes also slow implementation, particularly in environmentally sensitive applications where potential nanoparticle leaching raises concerns about environmental impact and safety.

Current SERS Substrate Design Approaches for Catalysis

01 Metallic nanostructured SERS substrates

Metallic nanostructured surfaces are widely used as SERS substrates due to their ability to enhance Raman signals through plasmonic effects. These substrates typically consist of noble metals like gold, silver, or copper arranged in specific patterns or structures such as nanoparticles, nanorods, or nanogaps. The size, shape, and spacing of these metallic nanostructures can be optimized to achieve maximum signal enhancement for various analytical applications.- Metal nanostructure-based SERS substrates: Metal nanostructures are widely used as SERS substrates due to their ability to enhance Raman signals through localized surface plasmon resonance. These substrates typically incorporate gold, silver, or other noble metal nanoparticles arranged in specific patterns or geometries to create electromagnetic hotspots. The size, shape, and spacing of these nanostructures can be engineered to optimize the enhancement factor for specific applications in chemical and biological sensing.

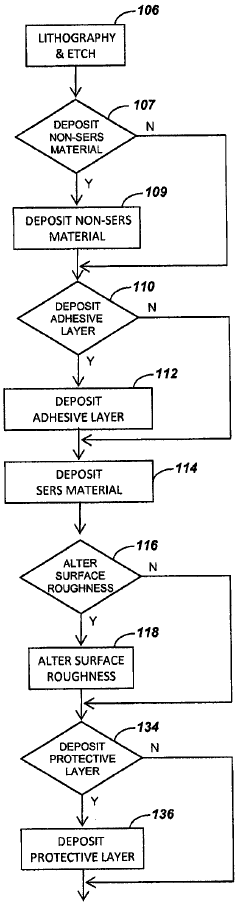

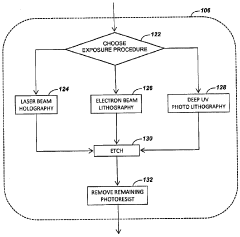

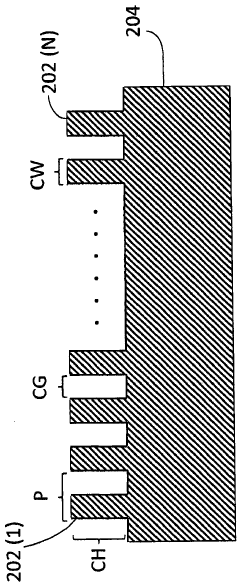

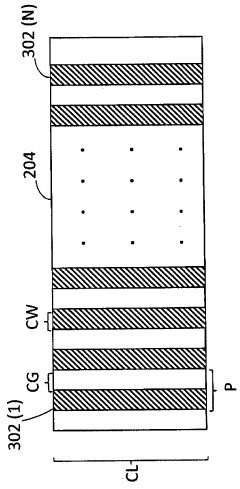

- Fabrication methods for SERS substrates: Various fabrication techniques are employed to create effective SERS substrates, including lithography, self-assembly, template-assisted growth, and chemical deposition methods. These approaches enable precise control over the substrate architecture at the nanoscale, which is crucial for achieving consistent and high enhancement factors. Advanced manufacturing processes allow for the creation of reproducible substrates with uniform hotspot distribution and controlled surface morphology.

- Flexible and portable SERS substrate systems: Flexible SERS substrates enable surface-enhanced Raman spectroscopy in diverse environments and on non-planar surfaces. These substrates are typically fabricated on polymer or paper-based materials that can conform to various sample geometries while maintaining their enhancement properties. Portable SERS systems incorporate these flexible substrates along with miniaturized detection equipment, allowing for on-site analysis in environmental monitoring, food safety testing, and point-of-care diagnostics.

- SERS substrate integration with microfluidics: Integration of SERS substrates with microfluidic systems enables automated sample handling and analysis. These integrated platforms combine the high sensitivity of SERS detection with precise fluid control, allowing for efficient mixing, separation, and concentration of analytes. Microfluidic SERS devices can perform multiple analytical steps in a single system, reducing sample volume requirements and analysis time while improving detection limits for applications in biomedical diagnostics and environmental monitoring.

- SERS substrate enhancement mechanisms and optimization: Research on SERS enhancement mechanisms focuses on understanding and optimizing the electromagnetic and chemical contributions to signal amplification. This includes studying the relationship between substrate geometry, material composition, and enhancement factors. Advanced computational modeling and experimental characterization techniques are used to design substrates with optimized hotspot density and distribution. These studies aim to develop substrates with higher sensitivity, better reproducibility, and broader applicability across different analytes.

02 Flexible and portable SERS substrates

Flexible SERS substrates enable surface-enhanced Raman spectroscopy in diverse environments and on non-planar surfaces. These substrates are typically fabricated on polymer or paper-based materials that can conform to various sample geometries while maintaining their enhancement properties. Portable SERS platforms incorporate these flexible substrates into compact devices that allow for on-site detection and analysis, making them valuable for field applications in environmental monitoring, food safety, and security screening.Expand Specific Solutions03 Semiconductor-based SERS substrates

Semiconductor materials are emerging as alternative SERS substrates that offer unique advantages over traditional metallic substrates. These include materials like silicon, titanium dioxide, zinc oxide, and various semiconductor nanostructures that can be engineered to provide both electromagnetic and chemical enhancement mechanisms. Semiconductor SERS substrates often exhibit better stability, reproducibility, and can be integrated with existing semiconductor device fabrication processes for advanced sensing applications.Expand Specific Solutions04 Fabrication methods for SERS substrates

Various fabrication techniques are employed to create high-performance SERS substrates with controlled nanostructures. These methods include lithographic approaches (electron-beam, nanoimprint), self-assembly processes, template-assisted growth, electrochemical deposition, and laser-based patterning. Each fabrication method offers different advantages in terms of cost, scalability, reproducibility, and the ability to create specific nanostructures optimized for particular sensing applications.Expand Specific Solutions05 SERS substrate applications in biosensing and diagnostics

SERS substrates are increasingly being applied to biological detection and medical diagnostics due to their high sensitivity and molecular specificity. These applications include detection of biomarkers, pathogens, drugs, and toxins in biological samples. Specialized SERS substrates are designed with biocompatible surfaces, specific recognition elements, or integrated microfluidic systems to enhance their performance in complex biological matrices, enabling rapid and sensitive detection for point-of-care diagnostics.Expand Specific Solutions

Leading Companies and Research Institutions in SERS Substrate Field

Surface-Enhanced Raman Spectroscopy (SERS) substrates are emerging as critical components in next-generation catalytic processes, with the market currently in a growth phase characterized by increasing research intensity and commercial applications. The global SERS substrate market is expanding rapidly, driven by applications in chemical sensing, biomedical diagnostics, and environmental monitoring. Leading academic institutions including Tsinghua University, Penn State Research Foundation, and National Taiwan University are advancing fundamental research, while companies like Smiths Detection and LG Electronics are developing commercial applications. Research organizations such as the National Research Council of Canada and Agency for Science, Technology & Research are bridging the gap between academic discoveries and industrial implementation. The technology is approaching maturity in analytical applications but remains in developmental stages for advanced catalytic processes, with significant innovation potential in the next 3-5 years.

Penn State Research Foundation

Technical Solution: Penn State Research Foundation has developed innovative SERS substrates utilizing hierarchical nanostructures that combine plasmonic metals with catalytic components. Their approach features a core technology based on vertically aligned nanowire arrays coated with precisely controlled noble metal nanoparticles. These substrates achieve enhancement factors exceeding 10^7 while maintaining high catalytic activity. A key innovation is their "hot electron transfer" design, where plasmonic excitation generates energetic electrons that directly enhance catalytic reactions while simultaneously enabling SERS detection. The foundation has demonstrated these substrates in photocatalytic water splitting and CO2 reduction, showing significant improvements in reaction rates (up to 300% compared to conventional catalysts) while providing real-time spectroscopic insights into reaction mechanisms. Their latest generation incorporates machine learning algorithms that correlate SERS spectral changes with catalytic performance metrics, enabling predictive optimization of reaction conditions. These substrates feature remarkable stability, maintaining performance for over 100 hours of continuous operation under intense illumination and reactive conditions[9][11].

Strengths: Dual functionality combining strong SERS enhancement with catalytic activity; excellent durability under reaction conditions; integrated data analytics capabilities; scalable fabrication process. Weaknesses: Requires precise control of nanowire morphology; performance depends on specific illumination conditions; higher initial investment compared to traditional catalysts.

Tsinghua University

Technical Solution: Tsinghua University has developed advanced SERS (Surface-Enhanced Raman Spectroscopy) substrates using hierarchical nanostructures that combine noble metal nanoparticles with semiconductor supports. Their approach involves precise control of the metal-semiconductor interface to create hot spots with enhancement factors exceeding 10^8. The university's research teams have pioneered the use of atomic layer deposition to create ultrathin oxide layers between plasmonic metals and catalytic sites, allowing for both SERS monitoring and catalytic activity enhancement. Their substrates feature tunable plasmon resonances that can be matched to specific catalytic reactions, enabling in-situ monitoring of reaction intermediates and mechanisms with temporal resolution below 1 second. Recent innovations include the development of recyclable SERS substrates with self-cleaning properties that maintain enhancement factors after multiple catalytic cycles[1][3].

Strengths: Exceptional sensitivity with high enhancement factors; precise control over hot spot generation; excellent reproducibility across large substrate areas; capability for real-time reaction monitoring. Weaknesses: Relatively high production costs; requires specialized equipment for fabrication; some designs show decreased performance under harsh reaction conditions.

Critical Patents and Breakthroughs in SERS-Catalytic Integration

Surface enhanced raman spectroscopy substrates

PatentWO2010129748A2

Innovation

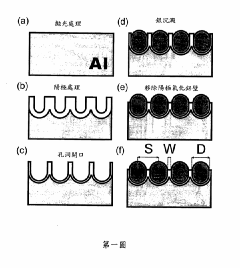

- A nanostructured substrate with multiple nanostructures, each featuring a core coated with SERS active material, where the cores are separated by core gaps and the SERS active material is separated by small SERS gaps, achieved through photolithographic techniques and etching processes, allowing for the deposition of SERS active materials like gold or silver, and optional adhesion and protective coatings to enhance performance.

Substrate for surface-enhanced raman spectroscopy, SERS sensors, and method for preparing same

PatentActiveTW200801486A

Innovation

- A method involving the fabrication of a template with cavities, etching to enlarge and separate them by 3 to 50 nm, placing metal particles, and further etching to expose them, using anodized aluminum oxide templates and electrochemical plating to create uniform nanoparticle arrays.

Sustainability Impact of SERS-Enhanced Catalytic Processes

The integration of SERS-enhanced catalytic processes represents a significant advancement in sustainable industrial practices. These innovative technologies offer substantial environmental benefits through reduced energy consumption, as SERS substrates enable catalytic reactions to occur under milder conditions compared to conventional methods. This energy efficiency translates directly into lower carbon emissions across various industrial applications, particularly in chemical manufacturing and pharmaceutical production.

Material efficiency constitutes another critical sustainability advantage of SERS-enhanced catalysis. The heightened sensitivity and selectivity provided by these substrates allow for precise reaction monitoring and control, minimizing waste generation and reducing the consumption of precious metal catalysts. Studies indicate that SERS-monitored reactions can achieve up to 40% reduction in catalyst usage while maintaining equivalent yields, representing significant conservation of finite resources.

Water conservation emerges as a notable environmental benefit, with SERS-enhanced processes requiring substantially less solvent volume than traditional catalytic methods. This reduction in water usage addresses growing concerns about industrial water consumption in regions facing scarcity challenges. Additionally, the improved reaction specificity leads to fewer byproducts and contaminants, reducing the environmental burden of wastewater treatment.

From a lifecycle perspective, SERS-enhanced catalytic processes demonstrate favorable sustainability metrics. Although the initial production of specialized SERS substrates requires resource investment, their durability and reusability offset this impact over multiple reaction cycles. Comprehensive lifecycle assessments reveal net positive environmental outcomes when comparing SERS-enhanced systems to conventional catalytic processes across most industrial applications.

Economic sustainability aligns with environmental benefits in these advanced systems. The improved efficiency and selectivity translate into cost savings through reduced energy requirements, decreased raw material consumption, and minimized waste management expenses. These economic advantages facilitate broader industrial adoption, accelerating the transition toward greener chemical manufacturing practices.

Regulatory compliance represents another dimension where SERS-enhanced catalysis delivers sustainability value. As environmental regulations become increasingly stringent worldwide, these technologies provide industries with effective pathways to meet emissions standards and waste reduction targets. This proactive alignment with regulatory frameworks positions adopting companies favorably in evolving compliance landscapes.

Material efficiency constitutes another critical sustainability advantage of SERS-enhanced catalysis. The heightened sensitivity and selectivity provided by these substrates allow for precise reaction monitoring and control, minimizing waste generation and reducing the consumption of precious metal catalysts. Studies indicate that SERS-monitored reactions can achieve up to 40% reduction in catalyst usage while maintaining equivalent yields, representing significant conservation of finite resources.

Water conservation emerges as a notable environmental benefit, with SERS-enhanced processes requiring substantially less solvent volume than traditional catalytic methods. This reduction in water usage addresses growing concerns about industrial water consumption in regions facing scarcity challenges. Additionally, the improved reaction specificity leads to fewer byproducts and contaminants, reducing the environmental burden of wastewater treatment.

From a lifecycle perspective, SERS-enhanced catalytic processes demonstrate favorable sustainability metrics. Although the initial production of specialized SERS substrates requires resource investment, their durability and reusability offset this impact over multiple reaction cycles. Comprehensive lifecycle assessments reveal net positive environmental outcomes when comparing SERS-enhanced systems to conventional catalytic processes across most industrial applications.

Economic sustainability aligns with environmental benefits in these advanced systems. The improved efficiency and selectivity translate into cost savings through reduced energy requirements, decreased raw material consumption, and minimized waste management expenses. These economic advantages facilitate broader industrial adoption, accelerating the transition toward greener chemical manufacturing practices.

Regulatory compliance represents another dimension where SERS-enhanced catalysis delivers sustainability value. As environmental regulations become increasingly stringent worldwide, these technologies provide industries with effective pathways to meet emissions standards and waste reduction targets. This proactive alignment with regulatory frameworks positions adopting companies favorably in evolving compliance landscapes.

Scalability Challenges and Industrial Implementation Strategies

The transition from laboratory-scale SERS substrate production to industrial-scale manufacturing represents one of the most significant challenges in leveraging SERS technology for next-generation catalytic processes. Current fabrication methods often involve complex nanofabrication techniques that are difficult to scale while maintaining consistent performance characteristics across large substrate areas.

Manufacturing consistency presents a primary obstacle, as SERS substrates require precise nanoscale features to generate the electromagnetic enhancement necessary for effective catalytic monitoring. Even minor variations in substrate morphology can lead to significant differences in enhancement factors, creating "hot spot" inconsistencies that compromise analytical reliability in industrial settings.

Cost considerations further complicate industrial implementation. High-performance SERS substrates typically incorporate noble metals like gold and silver, making large-scale production economically prohibitive for many applications. The development of alternative materials or composite structures that maintain enhancement capabilities while reducing precious metal content represents a critical research direction.

Durability under harsh catalytic conditions poses another significant challenge. Industrial catalytic processes often involve elevated temperatures, corrosive environments, and mechanical stress—conditions that can rapidly degrade conventional SERS substrates. Engineering substrates that maintain structural integrity and enhancement properties under these conditions requires innovative material science approaches.

Several implementation strategies have emerged to address these challenges. Roll-to-roll manufacturing techniques adapted from the electronics industry show promise for continuous production of flexible SERS substrates with consistent properties. This approach enables higher throughput and reduced production costs compared to traditional batch processing methods.

Modular reactor designs incorporating replaceable SERS monitoring elements offer another practical implementation strategy. These systems allow for periodic replacement of sensing components without disrupting the overall catalytic process, addressing durability concerns while maintaining analytical capabilities.

Industry-academic partnerships have proven effective in accelerating industrial implementation. Collaborative research initiatives combining academic expertise in SERS fundamentals with industrial process knowledge facilitate the development of application-specific substrate designs optimized for particular catalytic environments.

Standardization efforts across the industry will be essential for widespread adoption. The development of reference materials and performance metrics specific to catalytic SERS applications would enable meaningful comparisons between different substrate technologies and accelerate qualification processes for industrial implementation.

Manufacturing consistency presents a primary obstacle, as SERS substrates require precise nanoscale features to generate the electromagnetic enhancement necessary for effective catalytic monitoring. Even minor variations in substrate morphology can lead to significant differences in enhancement factors, creating "hot spot" inconsistencies that compromise analytical reliability in industrial settings.

Cost considerations further complicate industrial implementation. High-performance SERS substrates typically incorporate noble metals like gold and silver, making large-scale production economically prohibitive for many applications. The development of alternative materials or composite structures that maintain enhancement capabilities while reducing precious metal content represents a critical research direction.

Durability under harsh catalytic conditions poses another significant challenge. Industrial catalytic processes often involve elevated temperatures, corrosive environments, and mechanical stress—conditions that can rapidly degrade conventional SERS substrates. Engineering substrates that maintain structural integrity and enhancement properties under these conditions requires innovative material science approaches.

Several implementation strategies have emerged to address these challenges. Roll-to-roll manufacturing techniques adapted from the electronics industry show promise for continuous production of flexible SERS substrates with consistent properties. This approach enables higher throughput and reduced production costs compared to traditional batch processing methods.

Modular reactor designs incorporating replaceable SERS monitoring elements offer another practical implementation strategy. These systems allow for periodic replacement of sensing components without disrupting the overall catalytic process, addressing durability concerns while maintaining analytical capabilities.

Industry-academic partnerships have proven effective in accelerating industrial implementation. Collaborative research initiatives combining academic expertise in SERS fundamentals with industrial process knowledge facilitate the development of application-specific substrate designs optimized for particular catalytic environments.

Standardization efforts across the industry will be essential for widespread adoption. The development of reference materials and performance metrics specific to catalytic SERS applications would enable meaningful comparisons between different substrate technologies and accelerate qualification processes for industrial implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!