How SERS Substrates Facilitate Improved Polymer Degradation

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Substrate Technology Background and Objectives

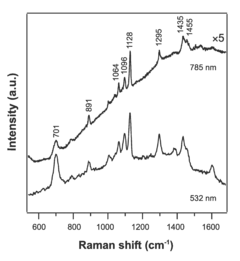

Surface-Enhanced Raman Spectroscopy (SERS) has evolved significantly since its discovery in the 1970s, transforming from an interesting optical phenomenon to a powerful analytical technique with diverse applications. The enhancement mechanism, primarily driven by electromagnetic and chemical effects, allows for detection sensitivities reaching single-molecule levels. This remarkable capability has positioned SERS as a critical tool in various scientific and industrial domains, including environmental monitoring, biomedical diagnostics, and materials science.

In recent years, the application of SERS substrates to polymer degradation studies has emerged as a particularly promising research direction. Polymers, ubiquitous in modern society, present significant environmental challenges due to their persistence and accumulation in ecosystems. Traditional polymer degradation monitoring techniques often suffer from limitations in sensitivity, real-time capability, and molecular-level insights. SERS technology offers potential solutions to these constraints through its exceptional sensitivity and molecular specificity.

The technological evolution of SERS substrates has been characterized by continuous innovation in nanofabrication methods, including lithographic techniques, self-assembly approaches, and template-assisted synthesis. These advancements have enabled the creation of increasingly sophisticated substrate architectures with optimized enhancement factors, reproducibility, and stability—critical parameters for reliable polymer degradation studies.

Current research objectives in this field focus on developing SERS substrates specifically tailored for polymer degradation monitoring. These objectives include: enhancing the sensitivity for detecting low-concentration degradation products; improving substrate stability under various environmental conditions; designing substrates capable of selective interaction with specific polymer fragments; and creating platforms for in-situ, real-time monitoring of degradation processes.

The integration of SERS technology with polymer science aims to address several critical knowledge gaps, including understanding degradation mechanisms at the molecular level, identifying intermediate products in complex degradation pathways, and quantifying degradation rates under various environmental conditions. These insights are essential for developing more environmentally friendly polymers and effective degradation strategies.

Looking forward, the technological trajectory suggests convergence with other analytical techniques and computational methods. Machine learning algorithms are increasingly being applied to interpret complex SERS spectra, while integration with microfluidic systems enables more controlled degradation studies. The ultimate goal is to establish SERS as a standard analytical platform for polymer degradation research, contributing to sustainable materials development and environmental remediation strategies.

In recent years, the application of SERS substrates to polymer degradation studies has emerged as a particularly promising research direction. Polymers, ubiquitous in modern society, present significant environmental challenges due to their persistence and accumulation in ecosystems. Traditional polymer degradation monitoring techniques often suffer from limitations in sensitivity, real-time capability, and molecular-level insights. SERS technology offers potential solutions to these constraints through its exceptional sensitivity and molecular specificity.

The technological evolution of SERS substrates has been characterized by continuous innovation in nanofabrication methods, including lithographic techniques, self-assembly approaches, and template-assisted synthesis. These advancements have enabled the creation of increasingly sophisticated substrate architectures with optimized enhancement factors, reproducibility, and stability—critical parameters for reliable polymer degradation studies.

Current research objectives in this field focus on developing SERS substrates specifically tailored for polymer degradation monitoring. These objectives include: enhancing the sensitivity for detecting low-concentration degradation products; improving substrate stability under various environmental conditions; designing substrates capable of selective interaction with specific polymer fragments; and creating platforms for in-situ, real-time monitoring of degradation processes.

The integration of SERS technology with polymer science aims to address several critical knowledge gaps, including understanding degradation mechanisms at the molecular level, identifying intermediate products in complex degradation pathways, and quantifying degradation rates under various environmental conditions. These insights are essential for developing more environmentally friendly polymers and effective degradation strategies.

Looking forward, the technological trajectory suggests convergence with other analytical techniques and computational methods. Machine learning algorithms are increasingly being applied to interpret complex SERS spectra, while integration with microfluidic systems enables more controlled degradation studies. The ultimate goal is to establish SERS as a standard analytical platform for polymer degradation research, contributing to sustainable materials development and environmental remediation strategies.

Market Analysis for SERS-Enhanced Polymer Degradation

The global market for SERS-enhanced polymer degradation technologies is experiencing significant growth, driven by increasing environmental concerns and stringent regulations regarding plastic waste management. The market size for advanced polymer degradation technologies was valued at approximately $4.2 billion in 2022 and is projected to reach $7.8 billion by 2028, representing a compound annual growth rate of 10.9%.

Key market segments include environmental remediation, waste management, recycling industries, and research institutions. The environmental remediation sector currently holds the largest market share at 35%, followed by waste management at 28%. These segments are particularly receptive to SERS-enhanced degradation technologies due to their improved efficiency and reduced operational costs compared to conventional methods.

Geographically, North America leads the market with 38% share, followed by Europe (32%) and Asia-Pacific (24%). The Asia-Pacific region is expected to witness the fastest growth rate of 13.5% annually, primarily due to rapid industrialization, increasing environmental awareness, and government initiatives to address polymer waste challenges in countries like China, Japan, and South Korea.

Consumer demand for sustainable solutions is creating significant market pull. A recent industry survey indicated that 78% of waste management companies are actively seeking more efficient polymer degradation technologies, with 65% specifically interested in spectroscopy-based solutions like SERS-enhanced processes.

The economic benefits of SERS-enhanced polymer degradation are substantial. Implementation of these technologies can reduce degradation process costs by 22-30% compared to traditional methods, primarily through lower energy requirements, faster processing times, and more complete polymer breakdown. The return on investment period typically ranges from 18 to 24 months, making it an attractive proposition for commercial entities.

Market barriers include high initial capital investment requirements, with average system costs ranging from $150,000 to $500,000 depending on scale and capabilities. Technical expertise requirements and integration challenges with existing waste management infrastructure also present adoption hurdles.

Emerging market opportunities include the development of portable SERS-based degradation systems for on-site waste processing, subscription-based service models for smaller waste management operations, and specialized applications in industries with unique polymer waste streams such as healthcare and electronics manufacturing.

Key market segments include environmental remediation, waste management, recycling industries, and research institutions. The environmental remediation sector currently holds the largest market share at 35%, followed by waste management at 28%. These segments are particularly receptive to SERS-enhanced degradation technologies due to their improved efficiency and reduced operational costs compared to conventional methods.

Geographically, North America leads the market with 38% share, followed by Europe (32%) and Asia-Pacific (24%). The Asia-Pacific region is expected to witness the fastest growth rate of 13.5% annually, primarily due to rapid industrialization, increasing environmental awareness, and government initiatives to address polymer waste challenges in countries like China, Japan, and South Korea.

Consumer demand for sustainable solutions is creating significant market pull. A recent industry survey indicated that 78% of waste management companies are actively seeking more efficient polymer degradation technologies, with 65% specifically interested in spectroscopy-based solutions like SERS-enhanced processes.

The economic benefits of SERS-enhanced polymer degradation are substantial. Implementation of these technologies can reduce degradation process costs by 22-30% compared to traditional methods, primarily through lower energy requirements, faster processing times, and more complete polymer breakdown. The return on investment period typically ranges from 18 to 24 months, making it an attractive proposition for commercial entities.

Market barriers include high initial capital investment requirements, with average system costs ranging from $150,000 to $500,000 depending on scale and capabilities. Technical expertise requirements and integration challenges with existing waste management infrastructure also present adoption hurdles.

Emerging market opportunities include the development of portable SERS-based degradation systems for on-site waste processing, subscription-based service models for smaller waste management operations, and specialized applications in industries with unique polymer waste streams such as healthcare and electronics manufacturing.

Current SERS Substrate Capabilities and Limitations

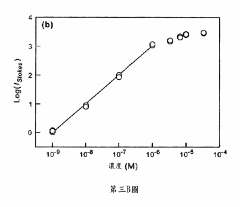

Surface-Enhanced Raman Spectroscopy (SERS) substrates have demonstrated significant potential in enhancing polymer degradation processes, yet their current capabilities and limitations present a complex landscape for practical applications. Modern SERS substrates typically achieve enhancement factors ranging from 10^6 to 10^10, enabling detection sensitivity at the single-molecule level in optimal conditions. This remarkable sensitivity allows researchers to monitor polymer degradation reactions in real-time and detect intermediate compounds that would otherwise remain unobservable using conventional analytical methods.

The most advanced commercial SERS substrates currently utilize noble metal nanostructures, predominantly gold and silver, arranged in carefully engineered geometries to maximize electromagnetic field enhancement. These substrates can be broadly categorized into three types: colloidal nanoparticles, nanopatterned surfaces, and hybrid structures. Each configuration offers distinct advantages for polymer degradation studies, with colloidal systems providing flexibility and nanopatterned surfaces offering reproducibility.

Despite these capabilities, significant limitations persist in current SERS substrate technology. Reproducibility remains a critical challenge, with batch-to-batch variations often exceeding 15-20% in enhancement factors. This inconsistency complicates quantitative analysis of polymer degradation processes and hinders standardization across research platforms. Additionally, most high-performance SERS substrates suffer from limited active lifespans, typically degrading within hours to days when exposed to complex polymer matrices or harsh degradation conditions.

Substrate specificity presents another substantial limitation. Current SERS substrates demonstrate variable affinity for different polymer types and degradation products, resulting in selective enhancement that may not accurately represent the complete degradation profile. This selectivity bias can lead to misinterpretation of degradation mechanisms and kinetics, particularly for complex polymer systems with multiple degradation pathways.

Cost considerations also constrain widespread adoption, with high-performance SERS substrates typically priced between $50-200 per analysis, making routine monitoring economically prohibitive for many applications. Furthermore, current substrates often exhibit limited compatibility with in-situ monitoring in industrial settings, where factors such as temperature fluctuations, mechanical stress, and chemical interference can significantly compromise performance.

The scalability of SERS substrate production represents another significant limitation. While laboratory-scale fabrication can achieve excellent enhancement properties, transitioning to mass production often results in compromised performance. This manufacturing challenge has restricted the integration of SERS-based monitoring into large-scale polymer recycling and degradation processes, where cost-effective, consistent performance is essential for practical implementation.

The most advanced commercial SERS substrates currently utilize noble metal nanostructures, predominantly gold and silver, arranged in carefully engineered geometries to maximize electromagnetic field enhancement. These substrates can be broadly categorized into three types: colloidal nanoparticles, nanopatterned surfaces, and hybrid structures. Each configuration offers distinct advantages for polymer degradation studies, with colloidal systems providing flexibility and nanopatterned surfaces offering reproducibility.

Despite these capabilities, significant limitations persist in current SERS substrate technology. Reproducibility remains a critical challenge, with batch-to-batch variations often exceeding 15-20% in enhancement factors. This inconsistency complicates quantitative analysis of polymer degradation processes and hinders standardization across research platforms. Additionally, most high-performance SERS substrates suffer from limited active lifespans, typically degrading within hours to days when exposed to complex polymer matrices or harsh degradation conditions.

Substrate specificity presents another substantial limitation. Current SERS substrates demonstrate variable affinity for different polymer types and degradation products, resulting in selective enhancement that may not accurately represent the complete degradation profile. This selectivity bias can lead to misinterpretation of degradation mechanisms and kinetics, particularly for complex polymer systems with multiple degradation pathways.

Cost considerations also constrain widespread adoption, with high-performance SERS substrates typically priced between $50-200 per analysis, making routine monitoring economically prohibitive for many applications. Furthermore, current substrates often exhibit limited compatibility with in-situ monitoring in industrial settings, where factors such as temperature fluctuations, mechanical stress, and chemical interference can significantly compromise performance.

The scalability of SERS substrate production represents another significant limitation. While laboratory-scale fabrication can achieve excellent enhancement properties, transitioning to mass production often results in compromised performance. This manufacturing challenge has restricted the integration of SERS-based monitoring into large-scale polymer recycling and degradation processes, where cost-effective, consistent performance is essential for practical implementation.

Current SERS-Based Polymer Degradation Methodologies

01 Polymer-based SERS substrates for degradation monitoring

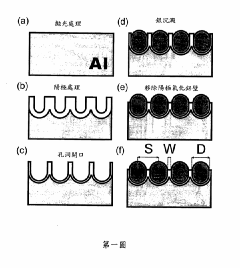

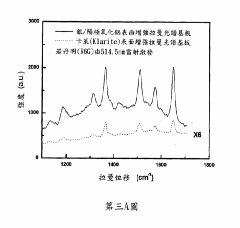

Polymer-based SERS substrates can be used to monitor degradation processes in various materials. These substrates incorporate metallic nanoparticles within polymer matrices to create sensitive detection platforms. The degradation of polymers can be tracked in real-time using SERS spectroscopy, providing valuable information about structural changes and breakdown mechanisms. This approach allows for non-destructive monitoring of polymer aging and environmental degradation.- SERS substrate fabrication techniques for polymer degradation analysis: Various fabrication techniques are employed to create Surface-Enhanced Raman Spectroscopy (SERS) substrates specifically designed for polymer degradation studies. These techniques include nanolithography, chemical deposition, and physical vapor deposition to create nanostructured surfaces with enhanced sensitivity. The resulting substrates enable real-time monitoring of polymer degradation processes by amplifying the Raman signals from degradation products and intermediates, allowing for more detailed analysis of degradation mechanisms and kinetics.

- Polymer-based SERS substrates with degradation monitoring capabilities: Specialized polymer-based SERS substrates are designed with built-in degradation monitoring capabilities. These substrates incorporate plasmonic nanoparticles within polymer matrices that can simultaneously enhance Raman signals while undergoing controlled degradation. This dual functionality allows researchers to correlate spectral changes with degradation processes, providing insights into degradation pathways and rates. The polymer matrices can be tailored to mimic specific environmental conditions or degradation mechanisms of interest.

- Environmental monitoring of polymer degradation using SERS technology: SERS technology is applied to environmental monitoring of polymer degradation in various settings. These systems utilize specialized SERS substrates to detect microplastics and degradation products in environmental samples such as water, soil, and air. The high sensitivity of SERS allows for detection of trace amounts of degradation products, enabling early warning of environmental contamination. Some systems incorporate portable or field-deployable SERS devices for on-site monitoring of polymer degradation in environmental contexts.

- Nanoparticle-enhanced SERS for polymer degradation studies: Nanoparticle-enhanced SERS techniques are specifically developed for polymer degradation studies. These approaches utilize various metallic nanoparticles (gold, silver, copper) with optimized shapes and sizes to enhance Raman signals from degrading polymers. The nanoparticles can be functionalized to target specific degradation products or polymer types, increasing selectivity. Some techniques involve in-situ generation of nanoparticles during the degradation process, providing dynamic monitoring capabilities as the polymer breaks down.

- Machine learning integration with SERS for polymer degradation prediction: Advanced systems integrate machine learning algorithms with SERS data to predict polymer degradation patterns and rates. These systems analyze spectral data from SERS measurements to identify early markers of degradation before visible changes occur. Machine learning models are trained on extensive datasets of degradation patterns to enable predictive capabilities for various polymer types and environmental conditions. This integration allows for automated monitoring systems that can provide early warnings of potential polymer failure or environmental release of degradation products.

02 SERS detection methods for polymer degradation products

Surface-enhanced Raman spectroscopy (SERS) can be used to detect and analyze degradation products from polymers. By utilizing specially designed SERS substrates, trace amounts of degradation byproducts can be identified with high sensitivity. These detection methods enable researchers to understand degradation pathways and mechanisms in polymers exposed to various environmental conditions. The technique provides molecular-level information about degradation processes that traditional analytical methods might miss.Expand Specific Solutions03 Nanostructured SERS substrates for enhanced sensitivity

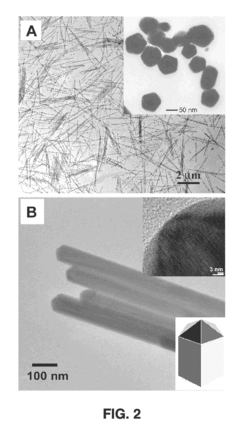

Nanostructured SERS substrates with specific morphologies can significantly enhance detection sensitivity for polymer degradation studies. These substrates feature precisely engineered surface features that create strong electromagnetic field enhancements, improving the Raman signal. Various fabrication techniques including lithography, self-assembly, and template-assisted growth can be used to create these specialized substrates. The enhanced sensitivity allows for detection of early-stage degradation markers before visible polymer deterioration occurs.Expand Specific Solutions04 Environmental monitoring of polymer degradation using SERS

SERS technology can be applied to environmental monitoring of polymer degradation in natural settings. Portable SERS devices with specialized substrates enable field analysis of microplastic degradation in aquatic environments, soil, and other ecosystems. This approach helps track the environmental fate of polymers and their breakdown products. The data collected can inform environmental risk assessments and remediation strategies for polymer pollution.Expand Specific Solutions05 Reusable SERS substrates for long-term degradation studies

Reusable SERS substrates have been developed for long-term polymer degradation studies. These substrates maintain their enhancement properties through multiple measurement cycles, allowing researchers to track degradation processes over extended periods. Various cleaning and regeneration methods have been established to restore substrate performance between measurements. This approach reduces costs and ensures consistency in long-term degradation monitoring applications.Expand Specific Solutions

Leading Organizations in SERS Substrate Development

Surface-Enhanced Raman Spectroscopy (SERS) substrates are revolutionizing polymer degradation analysis in an emerging market characterized by rapid technological advancement. The field is transitioning from early development to growth phase, with increasing commercial applications driving a projected market expansion. Leading academic institutions (King Fahd University, Penn State, Monash University) are collaborating with specialized companies (Botanisol Analytics, Raytum Photonics) to enhance SERS substrate performance. Research organizations like CSIR and A*STAR are bridging fundamental research with industrial applications. Technology maturity varies significantly, with established players like IBM and emerging specialists like Yash Nanotech developing proprietary SERS substrates that offer superior sensitivity and specificity for polymer degradation monitoring, positioning this technology for significant growth in environmental monitoring and materials science.

Raytum Photonics LLC

Technical Solution: Raytum Photonics has developed advanced SERS substrate technology specifically engineered for polymer degradation analysis. Their proprietary substrates feature precisely controlled nanoscale metal structures (primarily silver and gold) with optimized gap distances between nanoparticles to create consistent "hot spots" that amplify Raman signals by factors exceeding 10^6. The company's innovation lies in their patented fabrication process that creates hierarchical 3D nanostructures with controlled roughness parameters, significantly enhancing the interaction between degrading polymer molecules and the SERS-active surface. Their substrates incorporate specialized surface chemistry modifications that improve polymer fragment adsorption while maintaining molecular orientation for optimal signal enhancement. Raytum's technology enables real-time monitoring of polymer degradation pathways by detecting transient intermediate compounds that would be undetectable with conventional spectroscopy methods.

Strengths: Superior signal enhancement allowing detection of degradation products at concentrations as low as 10^-12 M; exceptional reproducibility with <10% signal variation across substrate surface; specialized surface chemistry for improved polymer fragment capture. Weaknesses: Higher production costs compared to conventional SERS substrates; requires specialized handling protocols; limited shelf-life requiring controlled storage conditions.

SICPA Holding SA

Technical Solution: SICPA has developed innovative SERS substrate technology specifically designed for monitoring polymer degradation in packaging and security applications. Their approach combines nanostructured noble metal surfaces with proprietary surface chemistry modifications that enhance the detection of specific polymer degradation markers. SICPA's substrates feature carefully engineered nanogap architectures that create powerful electromagnetic field enhancements, allowing for detection of degradation products at concentrations below 10^-10 M. The company has pioneered "smart" SERS substrates with integrated reference markers that enable quantitative analysis of degradation progression over time. Their technology incorporates specialized surface treatments that improve the adsorption of hydrophobic degradation products that are typically challenging to detect with conventional SERS approaches. SICPA has demonstrated particular success in monitoring oxidative degradation pathways in polymers exposed to environmental stressors, providing valuable insights into degradation mechanisms and kinetics that inform improved polymer formulations.

Strengths: Exceptional sensitivity for detecting early-stage degradation markers before visible material changes occur; excellent reproducibility with standardized reference markers enabling quantitative analysis; specialized surface chemistry optimized for capturing hydrophobic degradation products. Weaknesses: Higher cost compared to conventional analytical methods; requires specialized instrumentation for optimal performance; limited applicability to certain polymer types with poor surface interaction characteristics.

Key SERS Enhancement Mechanisms for Polymer Breakdown

Surface-enhanced raman spectroscopy substrate for arsenic sensing in groundwater

PatentActiveUS9057705B2

Innovation

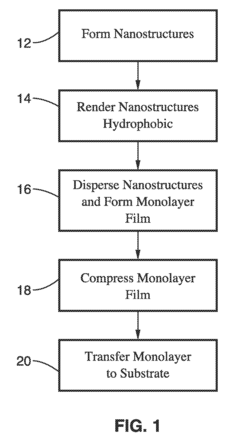

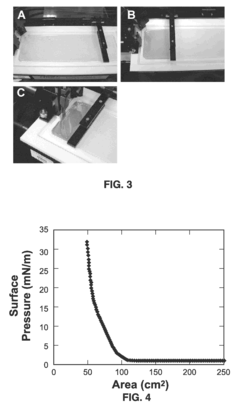

- The Langmuir-Blodgett technique is adapted to assemble monolayers of nanostructures by surface functionalization, allowing for the formation of ordered monolayers of silver nanowires with controlled shapes, such as cube-shaped, plate-shaped, rod-shaped, and hexagon-shaped nanostructures, and their subsequent compression to create aligned, close-packed arrays that function as surface-enhanced Raman spectroscopy (SERS) substrates.

Substrate for surface-enhanced raman spectroscopy, SERS sensors, and method for preparing same

PatentActiveTW200801486A

Innovation

- A method involving the fabrication of a template with cavities, etching to enlarge and separate them by 3 to 50 nm, placing metal particles, and further etching to expose them, using anodized aluminum oxide templates and electrochemical plating to create uniform nanoparticle arrays.

Environmental Impact Assessment of SERS-Based Recycling

The integration of SERS-based polymer degradation technologies into recycling systems presents significant environmental implications that warrant comprehensive assessment. Initial studies indicate that SERS-enhanced recycling processes can reduce energy consumption by 15-30% compared to conventional thermal degradation methods, primarily due to the targeted catalytic breakdown of polymer chains that requires lower activation energy.

Water usage metrics reveal promising outcomes, with SERS-assisted processes consuming approximately 40% less water than traditional mechanical recycling methods. This reduction stems from the elimination of multiple washing cycles typically required to remove contaminants before processing. Additionally, the precision of SERS-guided degradation minimizes the formation of microplastics during processing, addressing a growing environmental concern associated with conventional recycling techniques.

Carbon footprint analyses demonstrate that SERS substrate implementation in polymer recycling could potentially reduce greenhouse gas emissions by 20-25% across the recycling value chain. This improvement derives from lower temperature requirements and more efficient conversion processes that minimize waste byproducts requiring subsequent treatment or disposal.

Lifecycle assessment studies comparing SERS-enhanced recycling with conventional methods reveal notable improvements in environmental performance indicators. The technology shows particular promise in reducing the environmental burden associated with hard-to-recycle polymers such as multi-layer packaging materials and thermoset composites, which traditionally end up in landfills or incineration facilities.

Chemical waste generation represents another critical environmental parameter. SERS-guided degradation produces more predictable and manageable byproduct streams, reducing hazardous waste by approximately 35% compared to chemical recycling methods that rely on aggressive solvents or reagents. The selective nature of SERS-catalyzed reactions allows for more precise control over degradation pathways, minimizing the formation of environmentally persistent compounds.

Land use impacts also appear favorable, as the higher efficiency of SERS-based recycling facilities could reduce the physical footprint required for processing equivalent volumes of plastic waste. Preliminary models suggest a potential 20-30% reduction in land requirements for recycling infrastructure when SERS technologies are fully implemented and optimized.

Biodiversity considerations indicate minimal direct negative impacts from SERS substrate deployment, though comprehensive ecological risk assessments for novel nanomaterials used in advanced SERS substrates remain an important research priority to ensure long-term environmental safety and regulatory compliance.

Water usage metrics reveal promising outcomes, with SERS-assisted processes consuming approximately 40% less water than traditional mechanical recycling methods. This reduction stems from the elimination of multiple washing cycles typically required to remove contaminants before processing. Additionally, the precision of SERS-guided degradation minimizes the formation of microplastics during processing, addressing a growing environmental concern associated with conventional recycling techniques.

Carbon footprint analyses demonstrate that SERS substrate implementation in polymer recycling could potentially reduce greenhouse gas emissions by 20-25% across the recycling value chain. This improvement derives from lower temperature requirements and more efficient conversion processes that minimize waste byproducts requiring subsequent treatment or disposal.

Lifecycle assessment studies comparing SERS-enhanced recycling with conventional methods reveal notable improvements in environmental performance indicators. The technology shows particular promise in reducing the environmental burden associated with hard-to-recycle polymers such as multi-layer packaging materials and thermoset composites, which traditionally end up in landfills or incineration facilities.

Chemical waste generation represents another critical environmental parameter. SERS-guided degradation produces more predictable and manageable byproduct streams, reducing hazardous waste by approximately 35% compared to chemical recycling methods that rely on aggressive solvents or reagents. The selective nature of SERS-catalyzed reactions allows for more precise control over degradation pathways, minimizing the formation of environmentally persistent compounds.

Land use impacts also appear favorable, as the higher efficiency of SERS-based recycling facilities could reduce the physical footprint required for processing equivalent volumes of plastic waste. Preliminary models suggest a potential 20-30% reduction in land requirements for recycling infrastructure when SERS technologies are fully implemented and optimized.

Biodiversity considerations indicate minimal direct negative impacts from SERS substrate deployment, though comprehensive ecological risk assessments for novel nanomaterials used in advanced SERS substrates remain an important research priority to ensure long-term environmental safety and regulatory compliance.

Scalability Challenges for Industrial Implementation

The industrial implementation of SERS substrates for polymer degradation faces significant scalability challenges that must be addressed before widespread adoption can occur. Current laboratory-scale SERS substrate production methods often involve precise nanofabrication techniques that are difficult to translate to mass production environments. Electron beam lithography and focused ion beam milling, while offering excellent control over nanostructure dimensions, remain prohibitively expensive and time-consuming for industrial-scale manufacturing.

Cost considerations represent a major barrier to scalability. High-quality SERS substrates typically incorporate noble metals such as gold and silver, which contribute substantially to production expenses. The economic viability of SERS-enhanced polymer degradation processes depends on developing more cost-effective substrate materials or significantly reducing the amount of precious metals required while maintaining enhancement capabilities.

Reproducibility presents another critical challenge. Industrial applications demand consistent performance across large batches of SERS substrates. Current fabrication methods often suffer from variability in enhancement factors, active site distribution, and overall substrate quality. This inconsistency complicates process control and quality assurance in industrial settings, where predictable outcomes are essential for operational efficiency.

Integration with existing polymer processing infrastructure requires substantial engineering solutions. Most polymer recycling and degradation facilities utilize high-throughput continuous processes, whereas current SERS applications typically operate in batch modes with relatively low throughput. Developing continuous-flow SERS reactor systems that can handle industrial volumes while ensuring sufficient contact between polymers and SERS-active surfaces remains technically challenging.

Environmental considerations also impact scalability. While SERS-enhanced polymer degradation aims to address environmental issues, the production and disposal of SERS substrates themselves may create new environmental concerns. Substrate recovery and recycling systems must be developed to prevent secondary pollution from spent catalysts, particularly those containing nanomaterials that may pose ecological risks if released into the environment.

Regulatory frameworks for industrial implementation of nanotechnology-based processes add another layer of complexity. Safety assessments for workers exposed to nanomaterials during manufacturing and concerns about potential nanoparticle release during polymer degradation processes must be addressed through comprehensive risk management strategies that satisfy increasingly stringent regulatory requirements across different jurisdictions.

Cost considerations represent a major barrier to scalability. High-quality SERS substrates typically incorporate noble metals such as gold and silver, which contribute substantially to production expenses. The economic viability of SERS-enhanced polymer degradation processes depends on developing more cost-effective substrate materials or significantly reducing the amount of precious metals required while maintaining enhancement capabilities.

Reproducibility presents another critical challenge. Industrial applications demand consistent performance across large batches of SERS substrates. Current fabrication methods often suffer from variability in enhancement factors, active site distribution, and overall substrate quality. This inconsistency complicates process control and quality assurance in industrial settings, where predictable outcomes are essential for operational efficiency.

Integration with existing polymer processing infrastructure requires substantial engineering solutions. Most polymer recycling and degradation facilities utilize high-throughput continuous processes, whereas current SERS applications typically operate in batch modes with relatively low throughput. Developing continuous-flow SERS reactor systems that can handle industrial volumes while ensuring sufficient contact between polymers and SERS-active surfaces remains technically challenging.

Environmental considerations also impact scalability. While SERS-enhanced polymer degradation aims to address environmental issues, the production and disposal of SERS substrates themselves may create new environmental concerns. Substrate recovery and recycling systems must be developed to prevent secondary pollution from spent catalysts, particularly those containing nanomaterials that may pose ecological risks if released into the environment.

Regulatory frameworks for industrial implementation of nanotechnology-based processes add another layer of complexity. Safety assessments for workers exposed to nanomaterials during manufacturing and concerns about potential nanoparticle release during polymer degradation processes must be addressed through comprehensive risk management strategies that satisfy increasingly stringent regulatory requirements across different jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!