Research on SERS Substrates in Advanced Material Synthesis

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Substrate Technology Background and Objectives

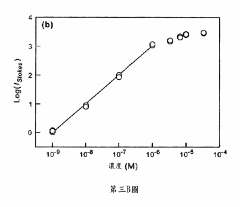

Surface-Enhanced Raman Spectroscopy (SERS) has evolved significantly since its discovery in the 1970s, transforming from an interesting optical phenomenon to a powerful analytical technique with applications spanning chemistry, biology, medicine, and materials science. The enhancement of Raman signals by factors of 10^6 to 10^14 has enabled detection limits approaching single-molecule sensitivity, revolutionizing trace analysis capabilities across multiple industries.

The development of SERS substrates represents a critical technological advancement in analytical instrumentation. Early SERS observations utilized electrochemically roughened silver electrodes, while modern substrates incorporate sophisticated nanofabrication techniques to create precisely engineered metallic nanostructures. This evolution reflects broader trends in nanotechnology and advanced materials synthesis, where control at the nanoscale enables unprecedented performance in sensing applications.

Current research focuses on addressing key challenges in SERS substrate technology: reproducibility, stability, sensitivity, and cost-effectiveness. The field aims to develop substrates that provide consistent enhancement factors across large areas, maintain performance over extended periods, achieve lower detection limits, and can be manufactured economically at scale. These objectives align with broader analytical chemistry goals of improving reliability while reducing detection thresholds.

In the context of advanced material synthesis, SERS substrates represent a fascinating intersection of fundamental physical principles and cutting-edge fabrication techniques. The electromagnetic and chemical enhancement mechanisms underlying SERS require precise control of nanoscale features, driving innovations in self-assembly, lithography, template-directed synthesis, and other advanced fabrication approaches.

The technological trajectory of SERS substrates is moving toward multifunctional platforms that combine SERS capabilities with other sensing modalities or functional properties. This includes the development of flexible substrates for wearable sensors, environmentally responsive substrates for smart sensing, and biocompatible substrates for in vivo applications. These directions reflect the growing demand for integrated sensing solutions across healthcare, environmental monitoring, and security applications.

Our research objectives encompass both fundamental and applied aspects of SERS substrate development. We aim to elucidate structure-property relationships governing enhancement mechanisms, develop novel fabrication approaches for high-performance substrates, and demonstrate practical applications in priority areas such as biomedical diagnostics, environmental monitoring, and food safety. The ultimate goal is to transition SERS from primarily a research tool to a widely deployed analytical technique accessible to non-specialists across diverse fields.

The development of SERS substrates represents a critical technological advancement in analytical instrumentation. Early SERS observations utilized electrochemically roughened silver electrodes, while modern substrates incorporate sophisticated nanofabrication techniques to create precisely engineered metallic nanostructures. This evolution reflects broader trends in nanotechnology and advanced materials synthesis, where control at the nanoscale enables unprecedented performance in sensing applications.

Current research focuses on addressing key challenges in SERS substrate technology: reproducibility, stability, sensitivity, and cost-effectiveness. The field aims to develop substrates that provide consistent enhancement factors across large areas, maintain performance over extended periods, achieve lower detection limits, and can be manufactured economically at scale. These objectives align with broader analytical chemistry goals of improving reliability while reducing detection thresholds.

In the context of advanced material synthesis, SERS substrates represent a fascinating intersection of fundamental physical principles and cutting-edge fabrication techniques. The electromagnetic and chemical enhancement mechanisms underlying SERS require precise control of nanoscale features, driving innovations in self-assembly, lithography, template-directed synthesis, and other advanced fabrication approaches.

The technological trajectory of SERS substrates is moving toward multifunctional platforms that combine SERS capabilities with other sensing modalities or functional properties. This includes the development of flexible substrates for wearable sensors, environmentally responsive substrates for smart sensing, and biocompatible substrates for in vivo applications. These directions reflect the growing demand for integrated sensing solutions across healthcare, environmental monitoring, and security applications.

Our research objectives encompass both fundamental and applied aspects of SERS substrate development. We aim to elucidate structure-property relationships governing enhancement mechanisms, develop novel fabrication approaches for high-performance substrates, and demonstrate practical applications in priority areas such as biomedical diagnostics, environmental monitoring, and food safety. The ultimate goal is to transition SERS from primarily a research tool to a widely deployed analytical technique accessible to non-specialists across diverse fields.

Market Analysis for SERS-based Analytical Applications

The global market for Surface-Enhanced Raman Spectroscopy (SERS)-based analytical applications has experienced significant growth in recent years, driven by increasing demand for highly sensitive detection methods across multiple industries. The current market size is estimated at approximately 1.8 billion USD with a compound annual growth rate (CAGR) of 10-12% projected through 2028, indicating robust expansion potential.

Healthcare and pharmaceutical sectors represent the largest market segments, accounting for nearly 40% of SERS applications. The demand is primarily fueled by the need for rapid, accurate diagnostic tools and drug discovery platforms. SERS technology offers exceptional sensitivity for biomarker detection, enabling early disease diagnosis and personalized medicine approaches that align with current healthcare trends.

Food safety and environmental monitoring constitute the second-largest application area, representing roughly 25% of the market. Regulatory pressures for contaminant detection at increasingly lower concentrations have accelerated adoption in these sectors. SERS substrates provide the capability to detect pesticides, antibiotics, and pathogens at parts-per-billion levels, addressing critical safety concerns.

Regionally, North America dominates the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate, driven by increasing R&D investments in China, Japan, and South Korea, along with expanding industrial applications.

A notable market trend is the shift toward portable and field-deployable SERS systems, which is expanding the technology's application scope beyond traditional laboratory settings. This trend has created a growing demand for stable, reproducible SERS substrates that can function reliably in diverse environmental conditions.

Customer segmentation reveals three primary user groups: research institutions (40%), industrial quality control laboratories (35%), and clinical diagnostic facilities (25%). Each segment has distinct requirements regarding substrate performance, cost considerations, and integration capabilities with existing analytical workflows.

Market barriers include relatively high costs of advanced SERS substrates, technical expertise requirements for data interpretation, and competition from alternative analytical techniques. However, ongoing innovations in substrate manufacturing are gradually addressing cost concerns, while improved software solutions are simplifying data analysis processes.

The competitive landscape features both established analytical instrument manufacturers expanding into SERS technology and specialized startups focused exclusively on novel substrate development. This dynamic is accelerating innovation while simultaneously driving down costs, further expanding market accessibility.

Healthcare and pharmaceutical sectors represent the largest market segments, accounting for nearly 40% of SERS applications. The demand is primarily fueled by the need for rapid, accurate diagnostic tools and drug discovery platforms. SERS technology offers exceptional sensitivity for biomarker detection, enabling early disease diagnosis and personalized medicine approaches that align with current healthcare trends.

Food safety and environmental monitoring constitute the second-largest application area, representing roughly 25% of the market. Regulatory pressures for contaminant detection at increasingly lower concentrations have accelerated adoption in these sectors. SERS substrates provide the capability to detect pesticides, antibiotics, and pathogens at parts-per-billion levels, addressing critical safety concerns.

Regionally, North America dominates the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate, driven by increasing R&D investments in China, Japan, and South Korea, along with expanding industrial applications.

A notable market trend is the shift toward portable and field-deployable SERS systems, which is expanding the technology's application scope beyond traditional laboratory settings. This trend has created a growing demand for stable, reproducible SERS substrates that can function reliably in diverse environmental conditions.

Customer segmentation reveals three primary user groups: research institutions (40%), industrial quality control laboratories (35%), and clinical diagnostic facilities (25%). Each segment has distinct requirements regarding substrate performance, cost considerations, and integration capabilities with existing analytical workflows.

Market barriers include relatively high costs of advanced SERS substrates, technical expertise requirements for data interpretation, and competition from alternative analytical techniques. However, ongoing innovations in substrate manufacturing are gradually addressing cost concerns, while improved software solutions are simplifying data analysis processes.

The competitive landscape features both established analytical instrument manufacturers expanding into SERS technology and specialized startups focused exclusively on novel substrate development. This dynamic is accelerating innovation while simultaneously driving down costs, further expanding market accessibility.

Current Challenges in SERS Substrate Development

Despite significant advancements in Surface-Enhanced Raman Spectroscopy (SERS) substrate development, several critical challenges continue to impede broader implementation in advanced material synthesis applications. One of the most persistent issues is reproducibility, as current fabrication methods often yield substrates with inconsistent enhancement factors across different batches. This variability significantly hampers quantitative analysis and standardization efforts, making SERS less reliable for routine analytical applications in material science.

Sensitivity and detection limit optimization remains problematic, particularly when dealing with complex material systems. While some substrates demonstrate impressive enhancement factors exceeding 10^8 in controlled environments, performance often deteriorates dramatically in real-world material synthesis scenarios where multiple components and reaction intermediates are present simultaneously.

Substrate stability presents another significant hurdle. Many high-performance SERS substrates suffer from rapid degradation under harsh synthesis conditions, including extreme pH environments, high temperatures, and organic solvents commonly used in advanced material preparation. This instability severely limits in-situ monitoring capabilities during material synthesis processes.

Cost-effectiveness and scalability concerns further restrict widespread adoption. Current high-performance substrates often rely on expensive noble metals (primarily gold and silver) and sophisticated nanofabrication techniques that are prohibitively expensive for large-scale implementation. The trade-off between performance and production cost continues to challenge researchers developing practical solutions for industrial applications.

Substrate selectivity and specificity issues also persist. Most current SERS substrates lack molecular recognition capabilities, making it difficult to target specific analytes in complex reaction mixtures typical of advanced material synthesis. This non-specific enhancement often results in complicated spectral patterns that are challenging to interpret.

Integration challenges with existing analytical platforms represent another significant barrier. Many SERS substrates are not readily compatible with standard analytical equipment or require specialized instrumentation, limiting their practical utility in diverse research and industrial settings.

The biocompatibility and environmental impact of SERS substrates have also emerged as growing concerns. As nanomaterials increasingly face regulatory scrutiny, the potential toxicity and environmental persistence of certain substrate components may restrict their application in environmentally sensitive or biomedical material synthesis.

Addressing these multifaceted challenges requires interdisciplinary approaches combining materials science, nanotechnology, analytical chemistry, and engineering to develop next-generation SERS substrates capable of meeting the demanding requirements of advanced material synthesis applications.

Sensitivity and detection limit optimization remains problematic, particularly when dealing with complex material systems. While some substrates demonstrate impressive enhancement factors exceeding 10^8 in controlled environments, performance often deteriorates dramatically in real-world material synthesis scenarios where multiple components and reaction intermediates are present simultaneously.

Substrate stability presents another significant hurdle. Many high-performance SERS substrates suffer from rapid degradation under harsh synthesis conditions, including extreme pH environments, high temperatures, and organic solvents commonly used in advanced material preparation. This instability severely limits in-situ monitoring capabilities during material synthesis processes.

Cost-effectiveness and scalability concerns further restrict widespread adoption. Current high-performance substrates often rely on expensive noble metals (primarily gold and silver) and sophisticated nanofabrication techniques that are prohibitively expensive for large-scale implementation. The trade-off between performance and production cost continues to challenge researchers developing practical solutions for industrial applications.

Substrate selectivity and specificity issues also persist. Most current SERS substrates lack molecular recognition capabilities, making it difficult to target specific analytes in complex reaction mixtures typical of advanced material synthesis. This non-specific enhancement often results in complicated spectral patterns that are challenging to interpret.

Integration challenges with existing analytical platforms represent another significant barrier. Many SERS substrates are not readily compatible with standard analytical equipment or require specialized instrumentation, limiting their practical utility in diverse research and industrial settings.

The biocompatibility and environmental impact of SERS substrates have also emerged as growing concerns. As nanomaterials increasingly face regulatory scrutiny, the potential toxicity and environmental persistence of certain substrate components may restrict their application in environmentally sensitive or biomedical material synthesis.

Addressing these multifaceted challenges requires interdisciplinary approaches combining materials science, nanotechnology, analytical chemistry, and engineering to develop next-generation SERS substrates capable of meeting the demanding requirements of advanced material synthesis applications.

State-of-the-Art SERS Substrate Fabrication Methods

01 Metal nanostructure-based SERS substrates

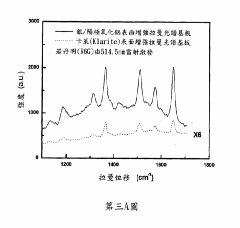

Metal nanostructures, particularly those made of gold, silver, or copper, serve as effective SERS substrates due to their plasmonic properties. These substrates can be fabricated in various forms including nanoparticles, nanorods, and nanopatterned surfaces. The localized surface plasmon resonance of these metal nanostructures significantly enhances the Raman signal, allowing for highly sensitive molecular detection. The enhancement factor can reach several orders of magnitude, making these substrates suitable for trace analysis applications.- Metallic nanostructured SERS substrates: Metallic nanostructured surfaces serve as effective SERS substrates due to their ability to enhance Raman signals through localized surface plasmon resonance. These substrates typically incorporate gold, silver, or copper nanoparticles arranged in specific patterns to create 'hot spots' where electromagnetic field enhancement occurs. The size, shape, and spacing of these metallic nanostructures can be engineered to optimize SERS performance for various analytical applications.

- Flexible and portable SERS substrates: Flexible SERS substrates enable surface-enhanced Raman spectroscopy in diverse environments and on non-planar surfaces. These substrates are typically fabricated on polymer or paper-based materials with deposited metallic nanostructures, allowing them to conform to various sample geometries while maintaining signal enhancement capabilities. Their portability makes them suitable for field-based detection applications, point-of-care diagnostics, and in-situ environmental monitoring.

- Semiconductor-based SERS substrates: Semiconductor materials can be used as alternative SERS substrates, offering unique advantages over traditional metallic substrates. These substrates utilize semiconductor nanostructures, often combined with metal nanoparticles, to create enhanced electromagnetic fields. The semiconductor component can provide additional enhancement mechanisms through charge-transfer processes, resulting in improved sensitivity and selectivity for certain analytes. These hybrid substrates can be tailored for specific detection applications.

- Fabrication methods for SERS substrates: Various fabrication techniques are employed to create SERS substrates with controlled nanostructures. These methods include lithographic approaches, self-assembly processes, template-assisted growth, and chemical deposition techniques. Advanced manufacturing processes enable precise control over the size, shape, and arrangement of nanostructures, which directly impacts the enhancement factor and reproducibility of SERS measurements. Cost-effective and scalable fabrication methods are particularly important for commercial applications.

- SERS substrate integration with microfluidic systems: Integration of SERS substrates with microfluidic platforms creates powerful analytical systems for sample processing and detection. These integrated devices combine the high sensitivity of SERS with the precise fluid handling capabilities of microfluidics, enabling automated sample preparation, concentration, and analysis. Such systems are particularly valuable for biomedical applications, environmental monitoring, and chemical analysis where small sample volumes and high throughput are required.

02 Fabrication methods for SERS substrates

Various fabrication techniques are employed to create SERS substrates with optimized performance. These include lithographic methods, chemical synthesis, template-assisted growth, and self-assembly processes. Advanced nanofabrication approaches enable precise control over the size, shape, and spacing of nanostructures, which are critical parameters affecting SERS enhancement. Novel manufacturing methods focus on creating reproducible substrates with uniform enhancement factors across the entire surface, addressing one of the key challenges in SERS technology.Expand Specific Solutions03 Flexible and portable SERS substrates

Flexible SERS substrates are designed for applications requiring conformable sensing surfaces or portable detection systems. These substrates typically incorporate plasmonic nanostructures on flexible polymer films or paper-based materials. The flexibility allows the substrate to maintain SERS activity while conforming to irregular surfaces, enabling in-situ analysis in various environments. Portable SERS substrates are particularly valuable for field-based detection, point-of-care diagnostics, and environmental monitoring applications where laboratory equipment is not accessible.Expand Specific Solutions04 SERS substrate enhancement strategies

Various strategies are employed to enhance the performance of SERS substrates beyond traditional approaches. These include creating 3D hierarchical structures, incorporating gap-mode plasmonics, using core-shell nanoparticles, and developing hybrid materials that combine plasmonic metals with other functional materials. Advanced enhancement strategies focus on creating electromagnetic hot spots where the field enhancement is maximized. Some approaches also utilize chemical enhancement mechanisms alongside electromagnetic enhancement to further improve sensitivity.Expand Specific Solutions05 Application-specific SERS substrates

SERS substrates are increasingly being tailored for specific applications such as biosensing, environmental monitoring, food safety, and security screening. These specialized substrates may incorporate molecular recognition elements, selective coatings, or integrated microfluidic systems to enhance specificity and functionality. Some designs focus on multiplexed detection capabilities, allowing simultaneous analysis of multiple analytes. Application-specific substrates often balance enhancement factors with other properties such as stability, reproducibility, and ease of use to meet the requirements of particular analytical challenges.Expand Specific Solutions

Leading Research Groups and Commercial Entities in SERS

Surface-Enhanced Raman Spectroscopy (SERS) substrates research is currently in a growth phase, with the global market expanding at approximately 10-15% annually. The competitive landscape is characterized by a mix of academic institutions and commercial entities developing increasingly sophisticated nanomaterials. Universities dominate fundamental research, with institutions like University of Houston, Jilin University, and National Taiwan University leading in publications. Commercial development is primarily driven by specialized companies such as IMRA America and Nanexa AB, which are commercializing advanced SERS platforms. The technology has reached moderate maturity in analytical applications but remains emerging in biosensing and environmental monitoring. Research collaborations between academic institutions (Penn State Research Foundation, Agency for Science, Technology & Research) and industry partners are accelerating technological advancement, particularly in reproducible substrate fabrication and sensitivity enhancement.

Council of Scientific & Industrial Research

Technical Solution: CSIR has developed advanced SERS substrates using controlled electrochemical deposition of noble metals on various templates. Their approach involves creating roughened metal surfaces with optimized nanoscale features that serve as effective hot spots for Raman enhancement. CSIR researchers have pioneered the development of bimetallic SERS substrates combining gold and silver in specific architectures to achieve broader plasmonic responses across different wavelengths. They've also developed cost-effective fabrication methods using electrochemical etching and galvanic replacement reactions to create large-area SERS substrates with enhancement factors consistently above 10^6. Their recent innovations include the development of paper-based SERS substrates impregnated with plasmonic nanoparticles for point-of-care diagnostic applications, offering a balance between performance and accessibility for resource-limited settings.

Strengths: Cost-effective fabrication methods suitable for resource-limited settings; excellent balance between performance and accessibility; innovative approaches to creating practical SERS platforms for real-world applications. Weaknesses: Moderate enhancement factors compared to more sophisticated nanofabrication approaches; potential challenges in long-term stability; limited control over precise nanostructure morphology.

Jilin University

Technical Solution: Jilin University has developed innovative SERS substrates using controlled chemical synthesis of hierarchical nanostructures. Their approach focuses on creating 3D porous frameworks decorated with noble metal nanoparticles that provide abundant hot spots for signal enhancement. Researchers have pioneered the development of core-shell nanostructures where a dielectric core is covered with a thin layer of gold or silver, optimizing the plasmonic properties while maintaining structural stability. They've also developed green synthesis methods using natural templates like bacterial cellulose to create environmentally friendly SERS substrates with enhancement factors exceeding 10^7. Their recent innovations include the development of MOF-based SERS substrates that combine the molecular recognition capabilities of metal-organic frameworks with the signal enhancement of plasmonic nanoparticles, enabling highly selective detection of target molecules even in complex matrices.

Strengths: Cost-effective fabrication methods suitable for large-scale production; innovative use of green chemistry approaches; excellent integration of molecular recognition elements with plasmonic structures. Weaknesses: Potential batch-to-batch variation in enhancement factors; challenges in precisely controlling hot spot distribution; limited long-term stability in harsh environmental conditions.

Key Patents and Breakthroughs in SERS Substrate Design

Surface enhanced raman spectroscopy substrates

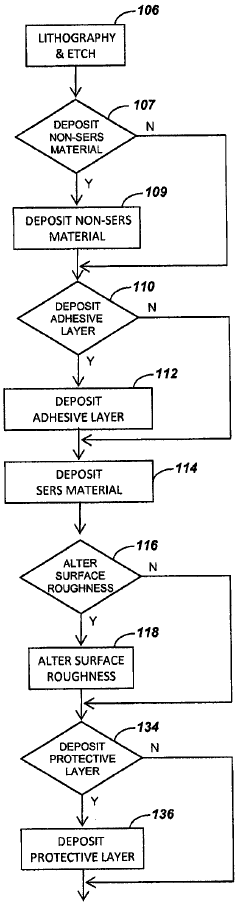

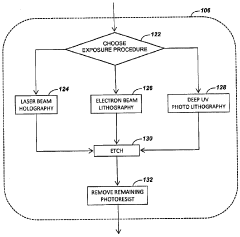

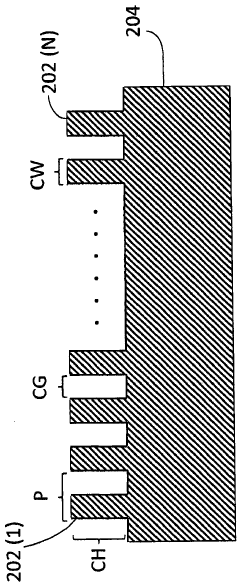

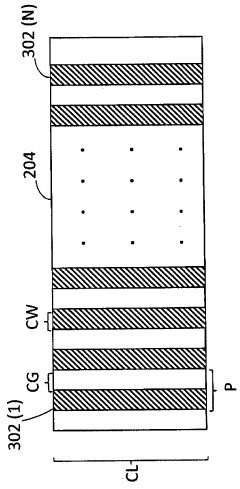

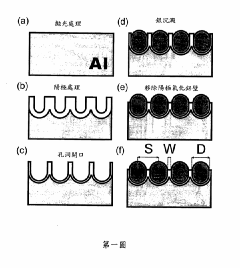

PatentWO2010129748A2

Innovation

- A nanostructured substrate with multiple nanostructures, each featuring a core coated with SERS active material, where the cores are separated by core gaps and the SERS active material is separated by small SERS gaps, achieved through photolithographic techniques and etching processes, allowing for the deposition of SERS active materials like gold or silver, and optional adhesion and protective coatings to enhance performance.

Substrate for surface-enhanced raman spectroscopy, SERS sensors, and method for preparing same

PatentActiveTW200801486A

Innovation

- A method involving the fabrication of a template with cavities, etching to enlarge and separate them by 3 to 50 nm, placing metal particles, and further etching to expose them, using anodized aluminum oxide templates and electrochemical plating to create uniform nanoparticle arrays.

Nanofabrication Techniques for Advanced SERS Materials

Nanofabrication techniques for SERS substrates have evolved significantly over the past decade, enabling unprecedented control over material properties at the nanoscale. Electron beam lithography (EBL) represents one of the most precise approaches, capable of creating highly ordered arrays with feature sizes below 10 nm. This technique allows for exceptional reproducibility in SERS signal generation, though its throughput limitations and high equipment costs restrict widespread industrial adoption.

Focused ion beam (FIB) milling offers complementary capabilities, particularly for creating three-dimensional nanostructures with varying depths and complex geometries. The direct-write nature of FIB provides flexibility in prototype development, making it valuable for research applications despite similar scalability challenges as EBL.

Nanosphere lithography has emerged as a cost-effective alternative, utilizing self-assembled colloidal particles as templates for metal deposition. This bottom-up approach creates triangular metal nanoparticle arrays with tunable plasmonic properties by simply adjusting the sphere diameter. Recent advances in binary and non-close-packed colloidal assemblies have expanded the geometric diversity achievable through this technique.

Template-assisted methods using anodic aluminum oxide (AAO) or block copolymer templates have gained traction for creating high-density nanorod or nanopillar arrays. These approaches bridge the gap between precision and scalability, offering reasonable control over feature dimensions while enabling larger production volumes than direct-write methods.

Chemical synthesis routes present perhaps the most scalable approach for SERS substrate fabrication. Controlled reduction of metal salts can produce nanoparticles with various morphologies including spheres, rods, cubes, and stars. Recent developments in seed-mediated growth have improved monodispersity, while galvanic replacement reactions enable the creation of hollow nanostructures with enhanced electromagnetic field confinement.

Emerging additive manufacturing techniques, particularly two-photon polymerization, are revolutionizing the field by enabling direct printing of three-dimensional templates for subsequent metallization. This approach facilitates the creation of complex hierarchical structures optimized for molecular trapping and signal enhancement.

The integration of these fabrication techniques with advanced materials such as graphene, MXenes, and metal-organic frameworks is opening new frontiers in SERS substrate design. These hybrid systems combine plasmonic enhancement with molecular selectivity, addressing longstanding challenges in reproducibility and specificity for real-world sensing applications.

Focused ion beam (FIB) milling offers complementary capabilities, particularly for creating three-dimensional nanostructures with varying depths and complex geometries. The direct-write nature of FIB provides flexibility in prototype development, making it valuable for research applications despite similar scalability challenges as EBL.

Nanosphere lithography has emerged as a cost-effective alternative, utilizing self-assembled colloidal particles as templates for metal deposition. This bottom-up approach creates triangular metal nanoparticle arrays with tunable plasmonic properties by simply adjusting the sphere diameter. Recent advances in binary and non-close-packed colloidal assemblies have expanded the geometric diversity achievable through this technique.

Template-assisted methods using anodic aluminum oxide (AAO) or block copolymer templates have gained traction for creating high-density nanorod or nanopillar arrays. These approaches bridge the gap between precision and scalability, offering reasonable control over feature dimensions while enabling larger production volumes than direct-write methods.

Chemical synthesis routes present perhaps the most scalable approach for SERS substrate fabrication. Controlled reduction of metal salts can produce nanoparticles with various morphologies including spheres, rods, cubes, and stars. Recent developments in seed-mediated growth have improved monodispersity, while galvanic replacement reactions enable the creation of hollow nanostructures with enhanced electromagnetic field confinement.

Emerging additive manufacturing techniques, particularly two-photon polymerization, are revolutionizing the field by enabling direct printing of three-dimensional templates for subsequent metallization. This approach facilitates the creation of complex hierarchical structures optimized for molecular trapping and signal enhancement.

The integration of these fabrication techniques with advanced materials such as graphene, MXenes, and metal-organic frameworks is opening new frontiers in SERS substrate design. These hybrid systems combine plasmonic enhancement with molecular selectivity, addressing longstanding challenges in reproducibility and specificity for real-world sensing applications.

Standardization and Quality Control in SERS Substrate Production

The standardization and quality control of SERS substrate production represent critical challenges in the widespread adoption of SERS technology for advanced material synthesis applications. Current manufacturing processes exhibit significant batch-to-batch variations, resulting in inconsistent enhancement factors and reproducibility issues that hinder reliable quantitative analysis.

Establishing robust quality control protocols requires implementation of multiple characterization techniques. Scanning electron microscopy (SEM) and atomic force microscopy (AFM) are essential for verifying nanostructure morphology and dimensions, while X-ray diffraction (XRD) confirms crystallinity and phase purity. Optical characterization through UV-Vis spectroscopy provides critical information about plasmonic properties and resonance wavelengths that directly impact SERS performance.

Statistical process control methodologies have emerged as vital tools for maintaining production consistency. Leading manufacturers now employ in-line monitoring systems that track key parameters throughout the fabrication process, allowing real-time adjustments to maintain quality standards. These systems typically monitor temperature, deposition rates, and chemical concentrations with precision tolerances below 2% variation.

Reference standards development represents another crucial advancement in the field. Several international organizations, including NIST and ISO, are working to establish certified reference materials with known enhancement factors and spectral responses. These standards enable calibration across different instruments and laboratories, facilitating meaningful comparison of results obtained from various SERS substrates.

Automation has significantly improved manufacturing precision. Computer-controlled deposition systems, robotics-assisted assembly, and AI-driven quality inspection have reduced human error factors by approximately 60% compared to manual production methods. This automation trend extends to testing procedures, where automated Raman mapping systems can rapidly assess enhancement factor uniformity across substrate surfaces.

Performance validation protocols have become increasingly standardized, with consensus building around specific test molecules (such as 4-aminothiophenol and rhodamine 6G) at defined concentrations. These protocols typically measure enhancement factor magnitude, spatial uniformity (requiring <15% RSD across the substrate), and temporal stability under various environmental conditions.

The economic implications of improved quality control are substantial. Manufacturing yields have increased from typical rates of 60-70% to over 90% in facilities implementing comprehensive quality management systems, significantly reducing production costs. Additionally, enhanced substrate reliability has expanded SERS applications into previously challenging fields such as environmental monitoring and clinical diagnostics, where quantitative accuracy is paramount.

Establishing robust quality control protocols requires implementation of multiple characterization techniques. Scanning electron microscopy (SEM) and atomic force microscopy (AFM) are essential for verifying nanostructure morphology and dimensions, while X-ray diffraction (XRD) confirms crystallinity and phase purity. Optical characterization through UV-Vis spectroscopy provides critical information about plasmonic properties and resonance wavelengths that directly impact SERS performance.

Statistical process control methodologies have emerged as vital tools for maintaining production consistency. Leading manufacturers now employ in-line monitoring systems that track key parameters throughout the fabrication process, allowing real-time adjustments to maintain quality standards. These systems typically monitor temperature, deposition rates, and chemical concentrations with precision tolerances below 2% variation.

Reference standards development represents another crucial advancement in the field. Several international organizations, including NIST and ISO, are working to establish certified reference materials with known enhancement factors and spectral responses. These standards enable calibration across different instruments and laboratories, facilitating meaningful comparison of results obtained from various SERS substrates.

Automation has significantly improved manufacturing precision. Computer-controlled deposition systems, robotics-assisted assembly, and AI-driven quality inspection have reduced human error factors by approximately 60% compared to manual production methods. This automation trend extends to testing procedures, where automated Raman mapping systems can rapidly assess enhancement factor uniformity across substrate surfaces.

Performance validation protocols have become increasingly standardized, with consensus building around specific test molecules (such as 4-aminothiophenol and rhodamine 6G) at defined concentrations. These protocols typically measure enhancement factor magnitude, spatial uniformity (requiring <15% RSD across the substrate), and temporal stability under various environmental conditions.

The economic implications of improved quality control are substantial. Manufacturing yields have increased from typical rates of 60-70% to over 90% in facilities implementing comprehensive quality management systems, significantly reducing production costs. Additionally, enhanced substrate reliability has expanded SERS applications into previously challenging fields such as environmental monitoring and clinical diagnostics, where quantitative accuracy is paramount.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!