What Are the Key Parameters for Effective SERS Substrates

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Substrate Technology Background and Objectives

Surface-Enhanced Raman Spectroscopy (SERS) has evolved significantly since its discovery in the 1970s, transforming from an interesting optical phenomenon to a powerful analytical technique with applications spanning chemistry, biology, medicine, and environmental science. The fundamental principle behind SERS involves the enhancement of Raman scattering signals when molecules are adsorbed on or near specially designed metallic surfaces, typically providing enhancement factors of 10^4 to 10^8, with some reports claiming single-molecule detection capabilities.

The historical trajectory of SERS substrate development has progressed through several distinct phases. Initially, roughened electrodes and colloidal solutions dominated the field. This was followed by the introduction of more controlled nanostructures in the 1990s and early 2000s, including nanospheres, nanorods, and nanostars. Recent years have witnessed the emergence of highly engineered substrates featuring precise geometries, optimized plasmon resonances, and functionalized surfaces designed for specific target molecules.

Current technological trends in SERS substrate development focus on achieving greater reproducibility, sensitivity, and selectivity. Researchers are increasingly employing advanced nanofabrication techniques such as electron-beam lithography, nanoimprint lithography, and self-assembly methods to create substrates with precisely controlled hot spots—regions of intense electromagnetic field enhancement responsible for the SERS effect.

The primary technical objectives in this field include developing SERS substrates with consistently high enhancement factors, batch-to-batch reproducibility, long-term stability, and cost-effective manufacturing processes. Additionally, there is growing interest in creating flexible, portable, and reusable substrates that can facilitate in-field applications and point-of-care diagnostics.

A critical aspect of SERS substrate technology involves understanding the relationship between substrate parameters and performance metrics. Key parameters include nanostructure size, shape, spacing, material composition, and surface chemistry—all of which significantly influence the electromagnetic enhancement mechanism and molecular adsorption properties.

The convergence of SERS with other technologies represents another important trend, with researchers integrating SERS substrates with microfluidics, smartphone-based detection systems, and machine learning algorithms for automated signal processing and interpretation. These integrations aim to transform SERS from a primarily laboratory-based technique to a widely accessible analytical tool.

Looking forward, the field is moving toward multifunctional SERS substrates that combine detection capabilities with other functionalities such as catalysis, drug delivery, or photothermal therapy. This evolution aligns with broader trends in nanotechnology toward creating materials and devices with programmable and responsive properties.

The historical trajectory of SERS substrate development has progressed through several distinct phases. Initially, roughened electrodes and colloidal solutions dominated the field. This was followed by the introduction of more controlled nanostructures in the 1990s and early 2000s, including nanospheres, nanorods, and nanostars. Recent years have witnessed the emergence of highly engineered substrates featuring precise geometries, optimized plasmon resonances, and functionalized surfaces designed for specific target molecules.

Current technological trends in SERS substrate development focus on achieving greater reproducibility, sensitivity, and selectivity. Researchers are increasingly employing advanced nanofabrication techniques such as electron-beam lithography, nanoimprint lithography, and self-assembly methods to create substrates with precisely controlled hot spots—regions of intense electromagnetic field enhancement responsible for the SERS effect.

The primary technical objectives in this field include developing SERS substrates with consistently high enhancement factors, batch-to-batch reproducibility, long-term stability, and cost-effective manufacturing processes. Additionally, there is growing interest in creating flexible, portable, and reusable substrates that can facilitate in-field applications and point-of-care diagnostics.

A critical aspect of SERS substrate technology involves understanding the relationship between substrate parameters and performance metrics. Key parameters include nanostructure size, shape, spacing, material composition, and surface chemistry—all of which significantly influence the electromagnetic enhancement mechanism and molecular adsorption properties.

The convergence of SERS with other technologies represents another important trend, with researchers integrating SERS substrates with microfluidics, smartphone-based detection systems, and machine learning algorithms for automated signal processing and interpretation. These integrations aim to transform SERS from a primarily laboratory-based technique to a widely accessible analytical tool.

Looking forward, the field is moving toward multifunctional SERS substrates that combine detection capabilities with other functionalities such as catalysis, drug delivery, or photothermal therapy. This evolution aligns with broader trends in nanotechnology toward creating materials and devices with programmable and responsive properties.

Market Analysis for SERS-based Analytical Applications

The global market for Surface-Enhanced Raman Spectroscopy (SERS)-based analytical applications has experienced significant growth in recent years, driven by increasing demand for highly sensitive detection methods across multiple industries. The current market size is estimated at approximately 1.5 billion USD with a compound annual growth rate (CAGR) of 10-12%, projected to reach 2.7 billion USD by 2027.

Healthcare and life sciences represent the largest market segment, accounting for nearly 45% of the total SERS applications market. Within this segment, diagnostic applications, particularly in cancer detection, infectious disease identification, and biomarker analysis, demonstrate the strongest growth potential. The pharmaceutical industry has also embraced SERS technology for drug discovery and quality control processes.

Food safety and environmental monitoring constitute the second largest application area, representing about 25% of the market. Regulatory pressures for more stringent food safety standards and environmental protection measures are driving adoption in these sectors. SERS technology enables detection of contaminants, pesticides, and pathogens at concentrations previously unattainable with conventional methods.

Geographically, North America leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate, particularly in China, Japan, and South Korea, where significant investments in research infrastructure and industrial applications are being made.

Key market drivers include increasing research funding, growing awareness of SERS advantages over conventional analytical techniques, and technological advancements that have improved substrate reproducibility and sensitivity. The development of portable and field-deployable SERS devices has expanded the technology's application scope beyond laboratory settings.

Market challenges primarily revolve around high costs associated with specialized equipment and substrates, technical expertise requirements, and standardization issues. The average cost of commercial SERS substrates remains relatively high, ranging from $20-100 per analysis, limiting widespread adoption in cost-sensitive markets.

Customer segmentation reveals three primary user groups: academic and research institutions (35%), pharmaceutical and biotechnology companies (30%), and government and regulatory agencies (20%). The remaining market share is distributed among food production companies, environmental monitoring organizations, and forensic laboratories.

Future market growth will likely be driven by innovations in substrate manufacturing that reduce costs while maintaining performance, integration with portable devices and IoT systems, and expansion into emerging application areas such as wearable diagnostics and real-time monitoring systems.

Healthcare and life sciences represent the largest market segment, accounting for nearly 45% of the total SERS applications market. Within this segment, diagnostic applications, particularly in cancer detection, infectious disease identification, and biomarker analysis, demonstrate the strongest growth potential. The pharmaceutical industry has also embraced SERS technology for drug discovery and quality control processes.

Food safety and environmental monitoring constitute the second largest application area, representing about 25% of the market. Regulatory pressures for more stringent food safety standards and environmental protection measures are driving adoption in these sectors. SERS technology enables detection of contaminants, pesticides, and pathogens at concentrations previously unattainable with conventional methods.

Geographically, North America leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate, particularly in China, Japan, and South Korea, where significant investments in research infrastructure and industrial applications are being made.

Key market drivers include increasing research funding, growing awareness of SERS advantages over conventional analytical techniques, and technological advancements that have improved substrate reproducibility and sensitivity. The development of portable and field-deployable SERS devices has expanded the technology's application scope beyond laboratory settings.

Market challenges primarily revolve around high costs associated with specialized equipment and substrates, technical expertise requirements, and standardization issues. The average cost of commercial SERS substrates remains relatively high, ranging from $20-100 per analysis, limiting widespread adoption in cost-sensitive markets.

Customer segmentation reveals three primary user groups: academic and research institutions (35%), pharmaceutical and biotechnology companies (30%), and government and regulatory agencies (20%). The remaining market share is distributed among food production companies, environmental monitoring organizations, and forensic laboratories.

Future market growth will likely be driven by innovations in substrate manufacturing that reduce costs while maintaining performance, integration with portable devices and IoT systems, and expansion into emerging application areas such as wearable diagnostics and real-time monitoring systems.

Current SERS Substrate Challenges and Limitations

Despite significant advancements in Surface-Enhanced Raman Spectroscopy (SERS) technology, current SERS substrates face several critical challenges that limit their widespread application in analytical chemistry, biomedical diagnostics, and environmental monitoring. One fundamental limitation is the inconsistency in enhancement factor reproducibility across substrate batches, which severely impacts quantitative analysis capabilities and hampers standardization efforts in the field.

The stability of SERS substrates presents another significant challenge, with many high-performance substrates exhibiting rapid degradation under ambient conditions or during storage. This instability necessitates specialized storage conditions and limits shelf-life, creating practical barriers for commercial applications and routine laboratory use. Additionally, many substrates demonstrate performance deterioration after single use, restricting their application in continuous monitoring scenarios.

Uniformity issues persist across substrate surfaces, with enhancement factors varying significantly between "hot spots" and other regions. This spatial heterogeneity creates measurement inconsistencies and requires sophisticated mapping techniques to obtain reliable data. The challenge is particularly pronounced when scaling up production from laboratory to industrial levels while maintaining consistent performance.

Sensitivity limitations remain problematic for many SERS substrates, especially when detecting analytes at ultra-low concentrations (sub-picomolar range). While theoretical enhancement factors can reach 10^10-10^11, practical substrates often achieve only 10^6-10^8, creating a significant gap between theoretical potential and practical performance.

Selectivity represents another critical challenge, as current substrates frequently lack specificity toward target analytes in complex matrices. This limitation is particularly problematic in biological samples where numerous interfering compounds exist. The development of selective recognition elements without compromising enhancement factors remains technically challenging.

Manufacturing scalability continues to impede widespread adoption, with many high-performance SERS substrates requiring sophisticated fabrication techniques like electron-beam lithography or focused ion beam milling. These approaches, while producing excellent substrates, are prohibitively expensive and time-consuming for mass production. Alternative methods often compromise performance for manufacturability.

Cost-effectiveness remains elusive, with high-performance substrates typically requiring expensive noble metals (gold, silver) and sophisticated nanofabrication techniques. This economic barrier restricts SERS technology primarily to research settings rather than routine analytical applications. The development of affordable substrates with comparable performance represents a significant industry challenge.

The stability of SERS substrates presents another significant challenge, with many high-performance substrates exhibiting rapid degradation under ambient conditions or during storage. This instability necessitates specialized storage conditions and limits shelf-life, creating practical barriers for commercial applications and routine laboratory use. Additionally, many substrates demonstrate performance deterioration after single use, restricting their application in continuous monitoring scenarios.

Uniformity issues persist across substrate surfaces, with enhancement factors varying significantly between "hot spots" and other regions. This spatial heterogeneity creates measurement inconsistencies and requires sophisticated mapping techniques to obtain reliable data. The challenge is particularly pronounced when scaling up production from laboratory to industrial levels while maintaining consistent performance.

Sensitivity limitations remain problematic for many SERS substrates, especially when detecting analytes at ultra-low concentrations (sub-picomolar range). While theoretical enhancement factors can reach 10^10-10^11, practical substrates often achieve only 10^6-10^8, creating a significant gap between theoretical potential and practical performance.

Selectivity represents another critical challenge, as current substrates frequently lack specificity toward target analytes in complex matrices. This limitation is particularly problematic in biological samples where numerous interfering compounds exist. The development of selective recognition elements without compromising enhancement factors remains technically challenging.

Manufacturing scalability continues to impede widespread adoption, with many high-performance SERS substrates requiring sophisticated fabrication techniques like electron-beam lithography or focused ion beam milling. These approaches, while producing excellent substrates, are prohibitively expensive and time-consuming for mass production. Alternative methods often compromise performance for manufacturability.

Cost-effectiveness remains elusive, with high-performance substrates typically requiring expensive noble metals (gold, silver) and sophisticated nanofabrication techniques. This economic barrier restricts SERS technology primarily to research settings rather than routine analytical applications. The development of affordable substrates with comparable performance represents a significant industry challenge.

Current SERS Substrate Design Approaches

01 Nanostructured SERS substrates for enhanced sensitivity

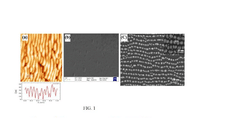

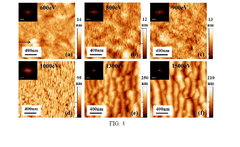

Nanostructured materials are used as SERS substrates to enhance detection sensitivity. These substrates typically incorporate metallic nanoparticles, nanorods, or nanopatterned surfaces that create localized surface plasmon resonance effects. The specific geometry and arrangement of these nanostructures can significantly amplify the Raman signal, allowing for detection of trace amounts of analytes. These substrates often achieve enhancement factors of several orders of magnitude compared to conventional Raman spectroscopy.- Nanostructured SERS substrates for enhanced sensitivity: Nanostructured materials are used as SERS substrates to enhance detection sensitivity. These substrates typically incorporate metal nanoparticles, nanorods, or nanopatterned surfaces that create strong electromagnetic field enhancements at their surfaces. The specific geometry and arrangement of these nanostructures can be optimized to produce consistent hot spots, resulting in improved SERS signal intensity and detection limits for various analytes.

- Metal-based SERS substrate compositions: Various metal compositions are utilized in SERS substrates to maximize effectiveness. Noble metals such as gold, silver, and copper are commonly employed due to their favorable plasmonic properties. These metals can be deposited as thin films, nanoparticle arrays, or complex architectures on supporting materials. The choice of metal and its specific formulation significantly impacts the wavelength response, stability, and overall enhancement factor of the SERS substrate.

- Fabrication methods for reproducible SERS substrates: Advanced fabrication techniques are critical for creating reproducible and effective SERS substrates. Methods include lithographic approaches, self-assembly processes, template-assisted growth, and chemical deposition techniques. These fabrication methods focus on controlling the size, spacing, and morphology of the active SERS features to ensure consistent enhancement factors across the substrate surface, which is essential for quantitative analysis applications.

- Substrate functionalization for target-specific detection: Functionalization of SERS substrates with specific recognition elements enhances their effectiveness for targeted analyte detection. By incorporating molecular recognition elements such as antibodies, aptamers, or selective binding agents onto the SERS-active surface, these substrates can selectively capture target molecules from complex mixtures. This approach improves detection specificity and can lower detection limits by concentrating analytes at the enhanced electromagnetic field regions.

- Portable and integrated SERS detection systems: Integrated systems combining optimized SERS substrates with portable detection instrumentation enhance the practical effectiveness of SERS technology. These systems incorporate miniaturized spectrometers, specialized light sources, and data processing capabilities with engineered SERS substrates. The integration enables field-deployable SERS analysis with improved usability, faster results, and maintained sensitivity compared to laboratory-based systems, making SERS technology more accessible for point-of-need applications.

02 Metal-based SERS substrate compositions

Various metal compositions are utilized in SERS substrates to optimize effectiveness. Noble metals such as gold, silver, and copper are commonly employed due to their favorable plasmonic properties. Some substrates use bimetallic or alloy structures to combine the advantages of different metals. The composition of the metal layer significantly affects the wavelength range of enhancement, stability of the substrate, and compatibility with different analytes. Advanced deposition techniques ensure uniform metal coverage for consistent SERS performance.Expand Specific Solutions03 Fabrication methods for reproducible SERS substrates

Various fabrication techniques are employed to create reproducible and effective SERS substrates. These include lithographic approaches, self-assembly methods, template-assisted growth, and chemical deposition processes. Advanced manufacturing techniques like nanoimprint lithography and electron beam lithography enable precise control over substrate geometry. Reproducibility in fabrication is crucial for quantitative analysis applications, as it ensures consistent enhancement factors across different batches of substrates. Some methods focus on scalable production for commercial viability.Expand Specific Solutions04 Substrate functionalization for target-specific detection

SERS substrates can be functionalized with specific molecules or materials to enhance selectivity for target analytes. Surface modification with recognition elements such as antibodies, aptamers, or molecular imprinted polymers enables highly specific detection capabilities. These functionalized substrates can selectively capture target molecules, bringing them into the enhanced electromagnetic field regions. This approach improves both sensitivity and specificity in complex sample matrices, making SERS detection more practical for real-world applications in medical diagnostics, environmental monitoring, and food safety.Expand Specific Solutions05 Portable and integrated SERS detection systems

Integrated systems combine effective SERS substrates with portable detection instrumentation for field applications. These systems incorporate miniaturized optics, lasers, and detectors alongside optimized substrates to enable on-site analysis. Some designs include microfluidic sample handling for automated processing. The integration of hardware and substrate technology addresses practical challenges in sample preparation, measurement reproducibility, and data analysis. These portable systems extend SERS applications beyond laboratory settings to point-of-care diagnostics, environmental monitoring, and security screening.Expand Specific Solutions

Leading SERS Substrate Manufacturers and Research Groups

The SERS substrate market is currently in a growth phase, characterized by increasing research activities and commercial applications. The global market size for SERS technology is expanding, driven by applications in biosensing, chemical detection, and medical diagnostics. Technologically, the field shows varying maturity levels across different substrate designs. Leading academic institutions like Sun Yat-Sen University, University of Notre Dame, and Nanyang Technological University are advancing fundamental research, while companies such as Smiths Detection and Yash Nanotech are commercializing applications. Research organizations including the National Research Council of Canada and Agency for Science, Technology & Research are bridging the gap between academic discoveries and industrial implementation. The competitive landscape reveals a balanced ecosystem of academic innovation and commercial development, with significant progress in substrate fabrication techniques, reproducibility, and sensitivity enhancement.

Penn State Research Foundation

Technical Solution: Penn State Research Foundation has developed innovative SERS substrates using precisely controlled noble metal nanostructures. Their approach focuses on engineering the morphology and arrangement of silver and gold nanoparticles to optimize electromagnetic field enhancement. Their research has identified critical parameters including nanoparticle size (optimal range 50-100 nm for visible light excitation), interparticle spacing (2-8 nm for maximum hot spot intensity), and surface roughness features (5-20 nm protrusions). A key innovation is their development of wrinkled metallic films created through strain-engineering of polymer substrates, which provides high-density hot spots with enhancement factors exceeding 10^9. They've also pioneered the use of DNA-directed assembly to create precisely spaced nanoparticle dimers and trimers with consistent gap sizes down to 1 nm, enabling single-molecule detection capabilities. Recent work includes developing magnetically responsive SERS substrates that can be manipulated in solution to concentrate analytes at detection sites.

Strengths: Exceptional control over hot spot geometry and spacing through DNA-directed assembly, providing highly reproducible enhancement factors. Their wrinkled film substrates combine high performance with relatively simple fabrication methods suitable for scaling. Weaknesses: Some designs require specialized surface chemistry that limits the range of compatible analytes. The DNA-templated structures show reduced stability at elevated temperatures or in certain buffer conditions.

Agency for Science, Technology & Research

Technical Solution: The Agency for Science, Technology & Research has developed proprietary SERS substrates utilizing bimetallic core-shell nanostructures optimized for maximum field enhancement. Their approach focuses on precise control of the metallic shell thickness (5-15 nm) over silver or gold cores to create tunable plasmon resonances across the visible to near-IR spectrum. A key innovation is their development of gap-engineered nanoparticle assemblies where interparticle spacing is controlled at the sub-nanometer level (0.5-2 nm) using molecular spacers, creating extremely intense electromagnetic fields at junctions. Their research has identified that optimal SERS performance requires not only appropriate nanoparticle morphology but also careful surface chemistry modification to enhance analyte adsorption. They've pioneered the use of directed self-assembly techniques to create large-area, uniform SERS substrates with enhancement factors consistently above 10^7 and relative standard deviations below 10% across 4-inch wafers.

Strengths: Exceptional reproducibility and uniformity across large substrate areas, making them suitable for commercial applications requiring consistent performance. Their bimetallic structures provide tunable plasmon resonances that can be optimized for specific target analytes. Weaknesses: The complex surface chemistry required for optimal performance can be sensitive to environmental conditions and storage time. Some designs show reduced performance when detecting large biomolecules due to distance-dependent field decay.

Critical Parameters Analysis for SERS Enhancement

A rapid, low-cost process for the preparation of surface enhanced raman spectroscopy (SERS) substrate and SERS substrate prepared thereby

PatentPendingIN202321081756A

Innovation

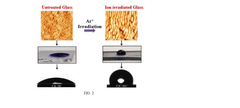

- A rapid, low-cost process involving Ar ion beam patterning of sodalime glass followed by Physical Vapor Deposition (PVD) of Ag nanoparticles to create highly regular arrays with controlled 5 nm gaps, enhancing SERS intensity and stability.

A substrate for surface enhanced raman scattering (SERS)

PatentWO2010056258A1

Innovation

- A substrate with uniformly distributed nanostructures and a layer of SERS active metal, such as silver, gold, or copper, is fabricated using a customized Bosch process without lithographic masking, providing a textured surface for enhanced Raman signal detection across a larger area, and replicated using embossing or stamping techniques to reduce costs.

Standardization and Reproducibility Considerations

Standardization remains a critical challenge in the development and application of SERS substrates. Despite significant advancements in substrate fabrication techniques, the lack of universally accepted standards for performance evaluation continues to hinder widespread industrial adoption. Current reproducibility issues manifest at multiple levels: batch-to-batch variations within manufacturing processes, spot-to-spot inconsistencies on individual substrates, and laboratory-to-laboratory discrepancies in measurement protocols.

The establishment of standardized characterization methodologies represents an urgent priority for the SERS community. Several international organizations, including ASTM International and the National Institute of Standards and Technology (NIST), have initiated efforts to develop reference materials and measurement protocols. These initiatives aim to create benchmark standards against which substrate performance can be objectively evaluated, facilitating meaningful comparisons across different research groups and commercial products.

Quantitative metrics for reproducibility assessment must address enhancement factor stability, spatial uniformity, and temporal consistency. Statistical approaches such as relative standard deviation (RSD) calculations across multiple measurements have emerged as valuable tools, with high-performance substrates typically demonstrating RSDs below 10%. Advanced characterization techniques including automated Raman mapping and multivariate statistical analysis provide more comprehensive evaluations of substrate homogeneity.

Manufacturing process control represents another critical dimension of reproducibility. Parameters such as temperature, humidity, and reagent purity must be rigorously monitored and controlled throughout fabrication. The implementation of quality control checkpoints at key production stages can significantly improve batch-to-batch consistency. Documentation practices, including detailed recording of fabrication parameters and environmental conditions, further support reproducibility efforts.

Interlaboratory comparison studies have revealed that measurement conditions—including laser wavelength, power density, integration time, and optical configurations—significantly impact SERS measurements. The development of standardized measurement protocols that specify these parameters represents a promising approach to reducing variability. Additionally, the inclusion of internal standards within SERS substrates provides a calibration mechanism that can compensate for instrumental variations and environmental fluctuations.

Long-term stability considerations must also be addressed through standardized aging studies and storage protocols. Environmental factors such as oxidation, contamination, and structural degradation can significantly alter substrate performance over time. Accelerated aging tests under controlled conditions offer valuable insights into shelf-life limitations and optimal storage requirements for maintaining consistent performance.

The establishment of standardized characterization methodologies represents an urgent priority for the SERS community. Several international organizations, including ASTM International and the National Institute of Standards and Technology (NIST), have initiated efforts to develop reference materials and measurement protocols. These initiatives aim to create benchmark standards against which substrate performance can be objectively evaluated, facilitating meaningful comparisons across different research groups and commercial products.

Quantitative metrics for reproducibility assessment must address enhancement factor stability, spatial uniformity, and temporal consistency. Statistical approaches such as relative standard deviation (RSD) calculations across multiple measurements have emerged as valuable tools, with high-performance substrates typically demonstrating RSDs below 10%. Advanced characterization techniques including automated Raman mapping and multivariate statistical analysis provide more comprehensive evaluations of substrate homogeneity.

Manufacturing process control represents another critical dimension of reproducibility. Parameters such as temperature, humidity, and reagent purity must be rigorously monitored and controlled throughout fabrication. The implementation of quality control checkpoints at key production stages can significantly improve batch-to-batch consistency. Documentation practices, including detailed recording of fabrication parameters and environmental conditions, further support reproducibility efforts.

Interlaboratory comparison studies have revealed that measurement conditions—including laser wavelength, power density, integration time, and optical configurations—significantly impact SERS measurements. The development of standardized measurement protocols that specify these parameters represents a promising approach to reducing variability. Additionally, the inclusion of internal standards within SERS substrates provides a calibration mechanism that can compensate for instrumental variations and environmental fluctuations.

Long-term stability considerations must also be addressed through standardized aging studies and storage protocols. Environmental factors such as oxidation, contamination, and structural degradation can significantly alter substrate performance over time. Accelerated aging tests under controlled conditions offer valuable insights into shelf-life limitations and optimal storage requirements for maintaining consistent performance.

Commercial Applications and Industry-Specific Requirements

The commercialization of SERS (Surface-Enhanced Raman Spectroscopy) substrates has expanded significantly across multiple industries, each with specific requirements tailored to their application domains. In the pharmaceutical sector, SERS substrates must demonstrate exceptional reproducibility and sensitivity for drug discovery and quality control processes. These substrates need to detect trace amounts of active pharmaceutical ingredients and impurities at concentrations as low as parts per billion, while maintaining batch-to-batch consistency for regulatory compliance.

For environmental monitoring applications, SERS substrates require durability under harsh field conditions and the ability to detect multiple pollutants simultaneously. Companies in this sector demand substrates that can withstand varying pH levels, temperature fluctuations, and exposure to complex environmental matrices without significant degradation of enhancement properties. Additionally, these substrates must be compatible with portable detection systems for on-site analysis.

The food safety industry requires SERS substrates capable of rapid detection of contaminants such as pesticides, antibiotics, and pathogens in diverse food matrices. These applications demand substrates with minimal sample preparation requirements and high specificity to avoid false positives from food components. Shelf stability becomes a critical parameter, with commercial products needing to maintain consistent performance for at least 12-18 months under standard storage conditions.

Biomedical diagnostics represents another significant commercial application, where SERS substrates must meet stringent biocompatibility standards and demonstrate high sensitivity for biomarkers in complex biological fluids. The healthcare industry requires substrates that can be integrated into point-of-care devices, necessitating miniaturization and cost-effective manufacturing processes. Regulatory approval pathways significantly influence substrate design parameters in this sector.

Security and forensic applications demand SERS substrates with exceptional specificity for detecting explosives, narcotics, and other controlled substances, often at trace levels. These substrates must perform reliably in the presence of interferents and demonstrate court-admissible levels of accuracy and precision. Companies in this space often require customized substrate formulations optimized for specific target analytes.

Manufacturing scalability represents a cross-industry requirement, with commercial viability dependent on cost-effective production methods that maintain nanoscale precision across large substrate areas. Recent market analysis indicates growing demand for disposable, single-use SERS substrates that eliminate cross-contamination concerns, particularly in regulated industries where sample integrity is paramount.

For environmental monitoring applications, SERS substrates require durability under harsh field conditions and the ability to detect multiple pollutants simultaneously. Companies in this sector demand substrates that can withstand varying pH levels, temperature fluctuations, and exposure to complex environmental matrices without significant degradation of enhancement properties. Additionally, these substrates must be compatible with portable detection systems for on-site analysis.

The food safety industry requires SERS substrates capable of rapid detection of contaminants such as pesticides, antibiotics, and pathogens in diverse food matrices. These applications demand substrates with minimal sample preparation requirements and high specificity to avoid false positives from food components. Shelf stability becomes a critical parameter, with commercial products needing to maintain consistent performance for at least 12-18 months under standard storage conditions.

Biomedical diagnostics represents another significant commercial application, where SERS substrates must meet stringent biocompatibility standards and demonstrate high sensitivity for biomarkers in complex biological fluids. The healthcare industry requires substrates that can be integrated into point-of-care devices, necessitating miniaturization and cost-effective manufacturing processes. Regulatory approval pathways significantly influence substrate design parameters in this sector.

Security and forensic applications demand SERS substrates with exceptional specificity for detecting explosives, narcotics, and other controlled substances, often at trace levels. These substrates must perform reliably in the presence of interferents and demonstrate court-admissible levels of accuracy and precision. Companies in this space often require customized substrate formulations optimized for specific target analytes.

Manufacturing scalability represents a cross-industry requirement, with commercial viability dependent on cost-effective production methods that maintain nanoscale precision across large substrate areas. Recent market analysis indicates growing demand for disposable, single-use SERS substrates that eliminate cross-contamination concerns, particularly in regulated industries where sample integrity is paramount.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!