SERS Substrates in High-Sensitivity Chemical Detection

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SERS Substrate Technology Background and Objectives

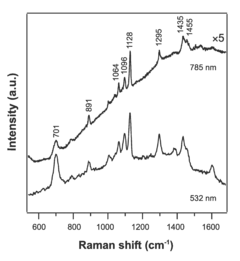

Surface-Enhanced Raman Spectroscopy (SERS) has evolved significantly since its discovery in the 1970s, revolutionizing the field of chemical detection. Initially observed as an anomalous enhancement of Raman signals from pyridine molecules adsorbed on roughened silver electrodes, SERS has developed into a powerful analytical technique capable of single-molecule detection. The technology leverages the interaction between light and metallic nanostructures to amplify Raman scattering signals by factors of 10^6 to 10^14, enabling the identification of chemical compounds at extremely low concentrations.

The evolution of SERS substrate technology has been marked by several key milestones. Early substrates consisted of electrochemically roughened metal surfaces, followed by the development of colloidal nanoparticles in the 1980s and 1990s. The 2000s witnessed the emergence of lithographically fabricated substrates with precisely controlled geometries, while recent years have seen the introduction of hierarchical structures combining multiple enhancement mechanisms.

Current technological trends in SERS substrate development focus on improving sensitivity, reproducibility, and stability. Researchers are exploring novel nanofabrication techniques, alternative plasmonic materials beyond traditional noble metals, and hybrid substrates that integrate multiple functional components. The integration of SERS with microfluidics and portable detection systems represents another significant trend, aimed at enabling real-time, in-field chemical analysis.

The primary objective of SERS substrate research is to develop materials capable of consistent, ultrasensitive detection across diverse chemical species. This includes achieving enhancement factors sufficient for single-molecule detection while maintaining batch-to-batch reproducibility. Researchers aim to expand the applicability of SERS beyond laboratory settings to real-world environments, necessitating substrates that remain stable under varying conditions and can be integrated into portable devices.

Another critical goal is to overcome the selectivity limitations of current SERS substrates. This involves designing surfaces with molecular recognition capabilities that can preferentially enhance signals from target analytes in complex mixtures. Additionally, there is growing interest in developing cost-effective manufacturing processes that enable widespread commercial adoption of SERS technology across various industries.

The convergence of nanotechnology, materials science, and analytical chemistry continues to drive innovation in SERS substrate development. As detection requirements become increasingly demanding across sectors such as environmental monitoring, food safety, pharmaceutical analysis, and security screening, SERS substrates represent a promising platform for next-generation sensing technologies that combine unprecedented sensitivity with practical field applicability.

The evolution of SERS substrate technology has been marked by several key milestones. Early substrates consisted of electrochemically roughened metal surfaces, followed by the development of colloidal nanoparticles in the 1980s and 1990s. The 2000s witnessed the emergence of lithographically fabricated substrates with precisely controlled geometries, while recent years have seen the introduction of hierarchical structures combining multiple enhancement mechanisms.

Current technological trends in SERS substrate development focus on improving sensitivity, reproducibility, and stability. Researchers are exploring novel nanofabrication techniques, alternative plasmonic materials beyond traditional noble metals, and hybrid substrates that integrate multiple functional components. The integration of SERS with microfluidics and portable detection systems represents another significant trend, aimed at enabling real-time, in-field chemical analysis.

The primary objective of SERS substrate research is to develop materials capable of consistent, ultrasensitive detection across diverse chemical species. This includes achieving enhancement factors sufficient for single-molecule detection while maintaining batch-to-batch reproducibility. Researchers aim to expand the applicability of SERS beyond laboratory settings to real-world environments, necessitating substrates that remain stable under varying conditions and can be integrated into portable devices.

Another critical goal is to overcome the selectivity limitations of current SERS substrates. This involves designing surfaces with molecular recognition capabilities that can preferentially enhance signals from target analytes in complex mixtures. Additionally, there is growing interest in developing cost-effective manufacturing processes that enable widespread commercial adoption of SERS technology across various industries.

The convergence of nanotechnology, materials science, and analytical chemistry continues to drive innovation in SERS substrate development. As detection requirements become increasingly demanding across sectors such as environmental monitoring, food safety, pharmaceutical analysis, and security screening, SERS substrates represent a promising platform for next-generation sensing technologies that combine unprecedented sensitivity with practical field applicability.

Market Analysis for High-Sensitivity Chemical Detection

The global market for high-sensitivity chemical detection technologies has experienced significant growth in recent years, driven by increasing concerns about environmental pollution, food safety, homeland security, and healthcare diagnostics. The Surface-Enhanced Raman Spectroscopy (SERS) substrate segment represents a particularly dynamic sector within this broader market, with an estimated market value exceeding $2.5 billion in 2022 and projected to grow at a compound annual growth rate (CAGR) of 9.8% through 2028.

Key application sectors driving demand include environmental monitoring, where there is growing need for real-time detection of pollutants in air, water, and soil at increasingly lower concentrations. The food safety sector represents another major market, with regulatory bodies worldwide implementing stricter standards for contaminant detection, creating substantial demand for high-sensitivity detection technologies capable of identifying trace amounts of pesticides, antibiotics, and other harmful substances.

The pharmaceutical and healthcare industries constitute a rapidly expanding market segment, utilizing SERS substrates for drug discovery, quality control, and disease biomarker detection. This application area has seen particularly strong growth following the COVID-19 pandemic, which highlighted the critical importance of rapid, sensitive diagnostic capabilities.

Geographically, North America currently dominates the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate, driven by increasing industrial activities, environmental concerns, and government investments in advanced detection technologies in countries like China, Japan, and South Korea.

Customer segmentation reveals distinct market needs across different sectors. Industrial users prioritize robustness and integration capabilities with existing systems, while research institutions focus on detection limits and versatility. Government agencies, particularly those involved in security and environmental monitoring, emphasize reliability and field-deployability.

A notable market trend is the increasing demand for portable and field-deployable detection systems, moving away from traditional laboratory-based equipment. This shift is creating new opportunities for SERS substrate technologies that can maintain high sensitivity while operating in less controlled environments.

Price sensitivity varies significantly across market segments, with research institutions often willing to pay premium prices for cutting-edge performance, while commercial applications in sectors like food safety are more cost-conscious, seeking solutions that balance performance with economic viability.

Key application sectors driving demand include environmental monitoring, where there is growing need for real-time detection of pollutants in air, water, and soil at increasingly lower concentrations. The food safety sector represents another major market, with regulatory bodies worldwide implementing stricter standards for contaminant detection, creating substantial demand for high-sensitivity detection technologies capable of identifying trace amounts of pesticides, antibiotics, and other harmful substances.

The pharmaceutical and healthcare industries constitute a rapidly expanding market segment, utilizing SERS substrates for drug discovery, quality control, and disease biomarker detection. This application area has seen particularly strong growth following the COVID-19 pandemic, which highlighted the critical importance of rapid, sensitive diagnostic capabilities.

Geographically, North America currently dominates the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate, driven by increasing industrial activities, environmental concerns, and government investments in advanced detection technologies in countries like China, Japan, and South Korea.

Customer segmentation reveals distinct market needs across different sectors. Industrial users prioritize robustness and integration capabilities with existing systems, while research institutions focus on detection limits and versatility. Government agencies, particularly those involved in security and environmental monitoring, emphasize reliability and field-deployability.

A notable market trend is the increasing demand for portable and field-deployable detection systems, moving away from traditional laboratory-based equipment. This shift is creating new opportunities for SERS substrate technologies that can maintain high sensitivity while operating in less controlled environments.

Price sensitivity varies significantly across market segments, with research institutions often willing to pay premium prices for cutting-edge performance, while commercial applications in sectors like food safety are more cost-conscious, seeking solutions that balance performance with economic viability.

Current SERS Substrate Development Status and Challenges

Surface-Enhanced Raman Spectroscopy (SERS) has emerged as a powerful analytical technique for high-sensitivity chemical detection, capable of identifying molecular fingerprints at ultra-low concentrations. The development of SERS substrates globally has reached a significant level of sophistication, yet several challenges persist that limit widespread commercial adoption and practical applications.

Current commercial SERS substrates primarily fall into three categories: metal nanoparticle colloids, nanolithography-fabricated surfaces, and template-assisted nanostructures. Gold and silver remain the dominant plasmonic materials due to their superior enhancement capabilities in the visible to near-infrared spectrum. Recent advances have introduced aluminum, copper, and bimetallic systems as cost-effective alternatives, though with generally lower enhancement factors.

The reproducibility of SERS signals represents one of the most significant challenges in the field. Batch-to-batch variations in substrate fabrication lead to inconsistent hot spot distribution and enhancement factors, complicating quantitative analysis. This issue is particularly pronounced in colloidal systems where aggregation control remains problematic despite advances in stabilization techniques.

Substrate stability presents another major hurdle. Many high-performance SERS substrates suffer from oxidation, contamination, and structural degradation over time, limiting shelf-life and field applicability. Silver-based substrates, despite offering superior enhancement factors, are particularly vulnerable to oxidation in ambient conditions, necessitating protective coatings that often reduce sensitivity.

The trade-off between sensitivity and universality continues to challenge researchers. While specialized substrates can achieve remarkable detection limits for specific analytes through molecular recognition elements, they sacrifice versatility. Conversely, universal substrates typically offer lower sensitivity across a broader range of analytes.

Manufacturing scalability remains problematic, particularly for high-performance substrates. Techniques like electron-beam lithography produce highly uniform and reproducible substrates but at prohibitive costs and limited production volumes. Alternative approaches using self-assembly or template-assisted methods offer better scalability but often with compromised performance consistency.

Geographically, SERS substrate development shows distinct patterns. North America and Europe lead in fundamental research and high-end commercial products, while Asia, particularly China, has made significant strides in cost-effective manufacturing approaches and application-specific developments. Recent collaborations between academic institutions and industry have accelerated technology transfer, though the gap between laboratory demonstrations and commercial viability remains substantial.

The integration of SERS substrates with complementary technologies represents an emerging trend, with microfluidics, portable Raman systems, and AI-assisted data analysis enhancing the practical utility of SERS-based detection platforms in field applications.

Current commercial SERS substrates primarily fall into three categories: metal nanoparticle colloids, nanolithography-fabricated surfaces, and template-assisted nanostructures. Gold and silver remain the dominant plasmonic materials due to their superior enhancement capabilities in the visible to near-infrared spectrum. Recent advances have introduced aluminum, copper, and bimetallic systems as cost-effective alternatives, though with generally lower enhancement factors.

The reproducibility of SERS signals represents one of the most significant challenges in the field. Batch-to-batch variations in substrate fabrication lead to inconsistent hot spot distribution and enhancement factors, complicating quantitative analysis. This issue is particularly pronounced in colloidal systems where aggregation control remains problematic despite advances in stabilization techniques.

Substrate stability presents another major hurdle. Many high-performance SERS substrates suffer from oxidation, contamination, and structural degradation over time, limiting shelf-life and field applicability. Silver-based substrates, despite offering superior enhancement factors, are particularly vulnerable to oxidation in ambient conditions, necessitating protective coatings that often reduce sensitivity.

The trade-off between sensitivity and universality continues to challenge researchers. While specialized substrates can achieve remarkable detection limits for specific analytes through molecular recognition elements, they sacrifice versatility. Conversely, universal substrates typically offer lower sensitivity across a broader range of analytes.

Manufacturing scalability remains problematic, particularly for high-performance substrates. Techniques like electron-beam lithography produce highly uniform and reproducible substrates but at prohibitive costs and limited production volumes. Alternative approaches using self-assembly or template-assisted methods offer better scalability but often with compromised performance consistency.

Geographically, SERS substrate development shows distinct patterns. North America and Europe lead in fundamental research and high-end commercial products, while Asia, particularly China, has made significant strides in cost-effective manufacturing approaches and application-specific developments. Recent collaborations between academic institutions and industry have accelerated technology transfer, though the gap between laboratory demonstrations and commercial viability remains substantial.

The integration of SERS substrates with complementary technologies represents an emerging trend, with microfluidics, portable Raman systems, and AI-assisted data analysis enhancing the practical utility of SERS-based detection platforms in field applications.

Current SERS Substrate Design Solutions

01 Nanostructured SERS substrates for enhanced sensitivity

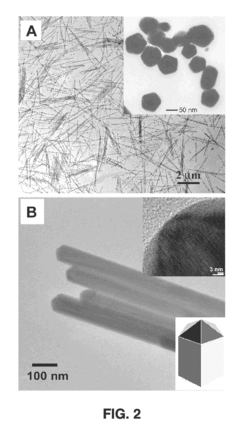

Nanostructured materials are used as SERS substrates to enhance sensitivity through increased surface area and plasmonic effects. These include nanopillars, nanorods, and nanoparticle arrays that create hotspots for electromagnetic field enhancement. The specific geometry and arrangement of these nanostructures can be optimized to maximize the SERS signal, allowing for detection of analytes at extremely low concentrations.- Nanostructured SERS substrates for enhanced sensitivity: Nanostructured materials are used as SERS substrates to enhance sensitivity through the creation of hotspots where electromagnetic fields are concentrated. These substrates often incorporate noble metal nanoparticles, nanorods, or nanogaps that generate strong localized surface plasmon resonances. The specific geometry and arrangement of these nanostructures can be optimized to maximize the enhancement factor, allowing for detection of analytes at extremely low concentrations.

- Metal-coated SERS substrates with controlled morphology: SERS substrates with controlled surface morphology and metal coating thickness demonstrate improved sensitivity. These substrates typically feature precisely engineered surface roughness, periodic structures, or hierarchical architectures coated with metals like gold or silver. The controlled deposition of metal films with optimal thickness ensures maximum electromagnetic enhancement while maintaining reproducibility across the substrate surface, leading to more reliable and sensitive SERS measurements.

- Novel materials and composites for SERS enhancement: Novel materials and composite structures are being developed to improve SERS substrate sensitivity. These include graphene-metal hybrids, metal-organic frameworks, semiconductor-metal composites, and polymer-metal nanocomposites. These advanced materials provide additional enhancement mechanisms beyond traditional plasmonic effects, such as chemical enhancement or charge transfer processes, resulting in significantly improved sensitivity for detecting various analytes.

- Fabrication techniques for high-sensitivity SERS substrates: Advanced fabrication techniques are employed to create high-sensitivity SERS substrates with precise control over nanoscale features. These methods include lithographic approaches, template-assisted synthesis, self-assembly processes, and laser-based fabrication. These techniques enable the creation of reproducible substrates with optimized hotspot density and distribution, leading to enhanced sensitivity and reliability in SERS measurements across large areas.

- Signal processing and detection methods for improved SERS sensitivity: Advanced signal processing and detection methods are implemented to improve the sensitivity of SERS measurements. These approaches include machine learning algorithms for spectral analysis, multivariate statistical methods, background subtraction techniques, and integration with microfluidic systems. By optimizing the detection and analysis of SERS signals, these methods can significantly enhance the effective sensitivity of SERS substrates, enabling detection of trace amounts of analytes even with conventional substrate materials.

02 Noble metal-based SERS substrates

Noble metals such as gold, silver, and copper are commonly used in SERS substrates due to their excellent plasmonic properties. These metals can be deposited as thin films, nanoparticles, or complex structures to create highly sensitive SERS platforms. The composition, thickness, and surface morphology of these metal layers significantly impact the sensitivity of the substrate, with certain configurations enabling single-molecule detection capabilities.Expand Specific Solutions03 Hybrid and composite SERS substrates

Hybrid and composite materials combine different components to enhance SERS sensitivity. These include metal-semiconductor composites, polymer-metal hybrids, and graphene-based structures. The synergistic effects between different materials can lead to improved electromagnetic enhancement, better substrate stability, and increased sensitivity. These composite substrates often show broader applicability across different types of analytes.Expand Specific Solutions04 Fabrication techniques for high-sensitivity SERS substrates

Advanced fabrication methods are crucial for creating highly sensitive SERS substrates. Techniques include lithography, template-assisted growth, self-assembly, and chemical etching processes. These methods enable precise control over the substrate's morphology, spacing, and uniformity, which are critical factors affecting SERS sensitivity. Novel manufacturing approaches can produce substrates with reproducible hotspots and consistent enhancement factors.Expand Specific Solutions05 Signal enhancement strategies for SERS substrates

Various strategies are employed to further enhance the sensitivity of SERS substrates beyond structural optimization. These include chemical enhancement methods, coupling with other spectroscopic techniques, surface functionalization, and the use of resonant molecules. Additional approaches involve temperature control, pH optimization, and electromagnetic field manipulation to maximize the SERS signal and improve detection limits for target analytes.Expand Specific Solutions

Key Industry Players in SERS Substrate Development

# SERS Substrates in High-Sensitivity Chemical Detection: Competitive Landscape Analysis

The Surface-Enhanced Raman Spectroscopy (SERS) substrates market is in a growth phase, with an estimated market size exceeding $250 million and projected to expand at 10-15% CAGR through 2028. The technology has reached moderate maturity but continues to evolve rapidly. Leading academic institutions (Xiamen University, Sun Yat-Sen University, National Taiwan University) are driving fundamental research, while established corporations (Intel, Corning) focus on commercial applications. Government laboratories (Naval Research Laboratory, Industrial Technology Research Institute) bridge the gap between research and implementation. The competitive landscape shows a balanced distribution between academic innovation and industrial development, with increasing collaboration between sectors to address challenges in sensitivity, reproducibility, and cost-effectiveness for widespread adoption in chemical detection applications.

The Surface-Enhanced Raman Spectroscopy (SERS) substrates market is in a growth phase, with an estimated market size exceeding $250 million and projected to expand at 10-15% CAGR through 2028. The technology has reached moderate maturity but continues to evolve rapidly. Leading academic institutions (Xiamen University, Sun Yat-Sen University, National Taiwan University) are driving fundamental research, while established corporations (Intel, Corning) focus on commercial applications. Government laboratories (Naval Research Laboratory, Industrial Technology Research Institute) bridge the gap between research and implementation. The competitive landscape shows a balanced distribution between academic innovation and industrial development, with increasing collaboration between sectors to address challenges in sensitivity, reproducibility, and cost-effectiveness for widespread adoption in chemical detection applications.

Industrial Technology Research Institute

Technical Solution: The Industrial Technology Research Institute (ITRI) has pioneered hierarchical 3D SERS substrate architectures combining micro and nanoscale features for high-sensitivity chemical detection. Their approach utilizes a multi-layer fabrication process that creates primary support structures with secondary and tertiary nanofeatures, effectively increasing the density of SERS-active sites. ITRI's substrates incorporate noble metal nanoparticles (primarily gold and silver) with precisely controlled sizes (20-80 nm) and interparticle spacing to optimize electromagnetic field enhancement[2]. A distinctive aspect of ITRI's technology is their development of flexible SERS substrates using polymer-based materials that maintain enhancement properties while conforming to irregular surfaces, enabling new application scenarios in environmental monitoring and field detection. Their substrates have demonstrated detection limits in the parts-per-billion range for various environmental contaminants and chemical warfare agents[4]. ITRI has also developed specialized surface functionalization techniques to improve selectivity toward specific target analytes.

Strengths: Exceptional sensitivity through hierarchical 3D structures; flexible substrate options for diverse sampling scenarios; good batch-to-batch reproducibility through controlled manufacturing processes. Weaknesses: More complex fabrication process than conventional 2D substrates; potential for higher background signals from the complex substrate architecture.

Corning, Inc.

Technical Solution: Corning has developed advanced SERS substrates using proprietary glass-based nanofabrication techniques. Their technology involves precisely engineered metallic nanostructures (primarily silver and gold) deposited on specialized glass surfaces to create highly uniform and reproducible SERS-active sites. Corning's approach focuses on creating optimized "hot spots" through controlled nanogap architectures that significantly enhance electromagnetic fields. Their substrates incorporate both regular array patterns and controlled random distributions to maximize signal enhancement factors, reportedly achieving enhancement factors of 10^6 to 10^8 for various chemical analytes[1]. Corning has particularly focused on developing SERS substrates with extended shelf-life through protective coatings that prevent oxidation while maintaining enhancement properties, addressing a key limitation in commercial SERS applications[3]. Their manufacturing process employs scalable techniques compatible with high-volume production, including advanced lithography and controlled deposition methods.

Strengths: Superior reproducibility and uniformity compared to many competitors; excellent shelf stability through proprietary protective coatings; scalable manufacturing process suitable for commercial applications. Weaknesses: Higher production costs compared to some competing technologies; optimization may be specific to particular analyte classes rather than universal detection.

Core SERS Enhancement Mechanism Analysis

Surface-enhanced raman spectroscopy substrate for arsenic sensing in groundwater

PatentActiveUS9057705B2

Innovation

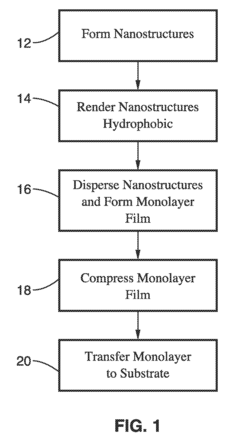

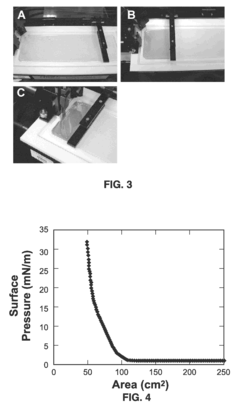

- The Langmuir-Blodgett technique is adapted to assemble monolayers of nanostructures by surface functionalization, allowing for the formation of ordered monolayers of silver nanowires with controlled shapes, such as cube-shaped, plate-shaped, rod-shaped, and hexagon-shaped nanostructures, and their subsequent compression to create aligned, close-packed arrays that function as surface-enhanced Raman spectroscopy (SERS) substrates.

A multi-layered substrate for spectroscopy and manufacturing process thereof

PatentInactiveEP3073251A1

Innovation

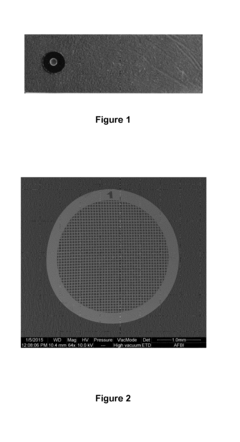

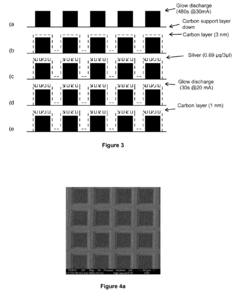

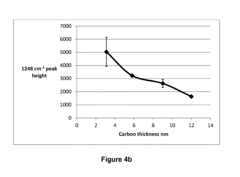

- A multi-layered substrate comprising a carbon base layer, a conductive metal support layer with a pattern, a thin carbon layer, and aligned silver or gold nanostructures, optionally coated with an ultrathin carbon or graphene layer, which enhances SERS activity and stability.

Nanofabrication Techniques for Advanced SERS Substrates

The evolution of nanofabrication techniques has revolutionized the development of Surface-Enhanced Raman Spectroscopy (SERS) substrates, enabling unprecedented sensitivity in chemical detection applications. Traditional fabrication methods have given way to sophisticated approaches that precisely control nanoscale features critical for SERS enhancement.

Electron-beam lithography (EBL) represents one of the most precise techniques for creating highly ordered SERS substrates with controlled geometries. This method achieves feature sizes below 10 nm, allowing for the creation of optimized hot spots that significantly amplify Raman signals. While EBL offers exceptional resolution, its throughput limitations and high equipment costs have restricted widespread industrial adoption.

Nanoimprint lithography has emerged as a cost-effective alternative that maintains nanoscale precision while enabling larger-scale production. This technique utilizes pre-fabricated templates to transfer patterns onto substrate surfaces, achieving feature sizes of approximately 20-50 nm with relatively high throughput. Recent advances in roll-to-roll nanoimprint processes have further enhanced manufacturing scalability.

Colloidal self-assembly represents another significant fabrication approach, leveraging the natural tendency of nanoparticles to organize into ordered structures. This bottom-up method produces large-area SERS substrates with reproducible enhancement factors at reduced costs. Innovations in directed self-assembly have improved the uniformity of hot spot distribution, addressing previous limitations in consistency.

Template-assisted fabrication techniques, including anodic aluminum oxide templates and nanosphere lithography, have gained prominence for creating highly uniform nanostructure arrays. These methods produce vertically aligned nanopillars, nanoholes, and other complex geometries that optimize electromagnetic field enhancement while maintaining manufacturing feasibility.

Recent advances in additive manufacturing at the nanoscale, particularly two-photon polymerization and direct laser writing, have enabled the creation of three-dimensional SERS substrates with precisely engineered hot spot configurations. These 3D architectures demonstrate superior analyte capture efficiency and enhanced signal amplification compared to traditional planar substrates.

Atomic layer deposition (ALD) has become instrumental in fine-tuning the surface properties of SERS substrates, allowing for angstrom-level control over metal coating thickness and composition. This precision enables optimization of plasmonic properties while maintaining the underlying nanostructure geometry, resulting in enhancement factors exceeding 10^9 for certain configurations.

Electron-beam lithography (EBL) represents one of the most precise techniques for creating highly ordered SERS substrates with controlled geometries. This method achieves feature sizes below 10 nm, allowing for the creation of optimized hot spots that significantly amplify Raman signals. While EBL offers exceptional resolution, its throughput limitations and high equipment costs have restricted widespread industrial adoption.

Nanoimprint lithography has emerged as a cost-effective alternative that maintains nanoscale precision while enabling larger-scale production. This technique utilizes pre-fabricated templates to transfer patterns onto substrate surfaces, achieving feature sizes of approximately 20-50 nm with relatively high throughput. Recent advances in roll-to-roll nanoimprint processes have further enhanced manufacturing scalability.

Colloidal self-assembly represents another significant fabrication approach, leveraging the natural tendency of nanoparticles to organize into ordered structures. This bottom-up method produces large-area SERS substrates with reproducible enhancement factors at reduced costs. Innovations in directed self-assembly have improved the uniformity of hot spot distribution, addressing previous limitations in consistency.

Template-assisted fabrication techniques, including anodic aluminum oxide templates and nanosphere lithography, have gained prominence for creating highly uniform nanostructure arrays. These methods produce vertically aligned nanopillars, nanoholes, and other complex geometries that optimize electromagnetic field enhancement while maintaining manufacturing feasibility.

Recent advances in additive manufacturing at the nanoscale, particularly two-photon polymerization and direct laser writing, have enabled the creation of three-dimensional SERS substrates with precisely engineered hot spot configurations. These 3D architectures demonstrate superior analyte capture efficiency and enhanced signal amplification compared to traditional planar substrates.

Atomic layer deposition (ALD) has become instrumental in fine-tuning the surface properties of SERS substrates, allowing for angstrom-level control over metal coating thickness and composition. This precision enables optimization of plasmonic properties while maintaining the underlying nanostructure geometry, resulting in enhancement factors exceeding 10^9 for certain configurations.

Environmental and Safety Considerations in SERS Applications

The integration of SERS technology into environmental monitoring and chemical detection systems necessitates careful consideration of environmental impacts and safety protocols. SERS substrates, while powerful analytical tools, often incorporate nanomaterials such as gold, silver, and copper nanoparticles that may pose ecological and health risks if improperly handled or disposed of. Recent studies have demonstrated that nanoparticle leaching from SERS substrates can potentially contaminate aquatic ecosystems, with silver nanoparticles particularly noted for their antimicrobial properties that may disrupt microbial communities in natural environments.

Regulatory frameworks governing nanomaterial usage in analytical applications vary significantly across regions, creating compliance challenges for global implementation of SERS-based detection systems. The European Union's REACH regulation and the US EPA's nanomaterial reporting rules represent divergent approaches to nanomaterial governance that researchers and manufacturers must navigate. These regulatory considerations directly impact substrate design choices and deployment strategies for field-based SERS applications.

Worker safety during SERS substrate manufacturing presents another critical consideration. Production processes often involve chemical reducing agents, strong acids for surface etching, and potentially harmful solvents. Comprehensive safety protocols, including proper ventilation systems, personal protective equipment, and specialized handling procedures, are essential to minimize exposure risks. The potential for nanoparticle aerosolization during substrate preparation requires particular attention to respiratory protection measures.

Sustainable design approaches are emerging as a response to these environmental and safety challenges. Green synthesis methods utilizing plant extracts or environmentally benign reducing agents offer promising alternatives to traditional chemical reduction processes for nanoparticle production. Additionally, recyclable SERS substrate designs that maintain sensitivity through multiple use cycles can significantly reduce waste generation and resource consumption, aligning with circular economy principles.

End-of-life management strategies for SERS substrates represent an underdeveloped area requiring further research. Current disposal practices often fail to address the potential for nanomaterial release into waste streams. Developing specialized recovery processes for precious metals from used substrates could simultaneously address environmental concerns and improve the economic viability of high-performance SERS platforms through material reclamation.

Future SERS substrate development should incorporate life cycle assessment methodologies to comprehensively evaluate environmental impacts from raw material extraction through disposal. This holistic approach would enable identification of environmental hotspots in the substrate life cycle and inform design modifications to minimize ecological footprints while maintaining analytical performance.

Regulatory frameworks governing nanomaterial usage in analytical applications vary significantly across regions, creating compliance challenges for global implementation of SERS-based detection systems. The European Union's REACH regulation and the US EPA's nanomaterial reporting rules represent divergent approaches to nanomaterial governance that researchers and manufacturers must navigate. These regulatory considerations directly impact substrate design choices and deployment strategies for field-based SERS applications.

Worker safety during SERS substrate manufacturing presents another critical consideration. Production processes often involve chemical reducing agents, strong acids for surface etching, and potentially harmful solvents. Comprehensive safety protocols, including proper ventilation systems, personal protective equipment, and specialized handling procedures, are essential to minimize exposure risks. The potential for nanoparticle aerosolization during substrate preparation requires particular attention to respiratory protection measures.

Sustainable design approaches are emerging as a response to these environmental and safety challenges. Green synthesis methods utilizing plant extracts or environmentally benign reducing agents offer promising alternatives to traditional chemical reduction processes for nanoparticle production. Additionally, recyclable SERS substrate designs that maintain sensitivity through multiple use cycles can significantly reduce waste generation and resource consumption, aligning with circular economy principles.

End-of-life management strategies for SERS substrates represent an underdeveloped area requiring further research. Current disposal practices often fail to address the potential for nanomaterial release into waste streams. Developing specialized recovery processes for precious metals from used substrates could simultaneously address environmental concerns and improve the economic viability of high-performance SERS platforms through material reclamation.

Future SERS substrate development should incorporate life cycle assessment methodologies to comprehensively evaluate environmental impacts from raw material extraction through disposal. This holistic approach would enable identification of environmental hotspots in the substrate life cycle and inform design modifications to minimize ecological footprints while maintaining analytical performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!